Benchmark Signal Gain in Flexible Electronics: Frequency Test Data

SEP 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Flexible Electronics Signal Gain Background and Objectives

Flexible electronics represents a revolutionary departure from conventional rigid electronic systems, enabling the development of bendable, stretchable, and conformable electronic devices. The evolution of this technology can be traced back to the early 2000s when researchers began exploring organic semiconductors and thin-film technologies. Over the past two decades, significant advancements have been made in materials science, fabrication techniques, and circuit design methodologies specifically tailored for flexible substrates.

Signal gain in flexible electronics presents unique challenges compared to traditional silicon-based electronics. The performance metrics of flexible electronic circuits, particularly signal amplification capabilities, have historically lagged behind their rigid counterparts due to material limitations and manufacturing constraints. The signal gain benchmark serves as a critical parameter for evaluating the performance and reliability of flexible electronic systems across various applications including wearable health monitors, foldable displays, and soft robotics.

The technical objective of benchmarking signal gain in flexible electronics through frequency test data is multifaceted. First, it aims to establish standardized testing protocols that can accurately measure and compare signal amplification performance across different flexible electronic platforms. Second, it seeks to identify the frequency-dependent behavior of flexible circuits under various mechanical deformations, which is essential for predicting real-world performance. Third, it endeavors to correlate material properties and fabrication techniques with signal gain characteristics to guide future development efforts.

Current technical goals in this domain include achieving signal gain stability under repeated mechanical stress, minimizing performance degradation at high frequencies, and reducing noise interference in flexible circuit environments. Researchers are particularly focused on maintaining consistent gain values across the frequency spectrum from DC to several megahertz, which represents the operating range for most consumer and medical applications of flexible electronics.

The evolution trend points toward hybrid systems that combine the flexibility of organic materials with the high performance of inorganic semiconductors. Recent breakthroughs in nanomaterials such as graphene and carbon nanotubes have shown promising results in maintaining signal integrity under deformation. Additionally, advances in stretchable interconnects and novel encapsulation techniques are addressing reliability concerns that have historically limited the commercial viability of flexible electronic systems.

This technical investigation aims to comprehensively analyze frequency-dependent signal gain characteristics across various flexible electronic platforms, establishing benchmarks that can guide future innovation and standardization efforts in this rapidly evolving field.

Signal gain in flexible electronics presents unique challenges compared to traditional silicon-based electronics. The performance metrics of flexible electronic circuits, particularly signal amplification capabilities, have historically lagged behind their rigid counterparts due to material limitations and manufacturing constraints. The signal gain benchmark serves as a critical parameter for evaluating the performance and reliability of flexible electronic systems across various applications including wearable health monitors, foldable displays, and soft robotics.

The technical objective of benchmarking signal gain in flexible electronics through frequency test data is multifaceted. First, it aims to establish standardized testing protocols that can accurately measure and compare signal amplification performance across different flexible electronic platforms. Second, it seeks to identify the frequency-dependent behavior of flexible circuits under various mechanical deformations, which is essential for predicting real-world performance. Third, it endeavors to correlate material properties and fabrication techniques with signal gain characteristics to guide future development efforts.

Current technical goals in this domain include achieving signal gain stability under repeated mechanical stress, minimizing performance degradation at high frequencies, and reducing noise interference in flexible circuit environments. Researchers are particularly focused on maintaining consistent gain values across the frequency spectrum from DC to several megahertz, which represents the operating range for most consumer and medical applications of flexible electronics.

The evolution trend points toward hybrid systems that combine the flexibility of organic materials with the high performance of inorganic semiconductors. Recent breakthroughs in nanomaterials such as graphene and carbon nanotubes have shown promising results in maintaining signal integrity under deformation. Additionally, advances in stretchable interconnects and novel encapsulation techniques are addressing reliability concerns that have historically limited the commercial viability of flexible electronic systems.

This technical investigation aims to comprehensively analyze frequency-dependent signal gain characteristics across various flexible electronic platforms, establishing benchmarks that can guide future innovation and standardization efforts in this rapidly evolving field.

Market Analysis for Flexible Electronics Applications

The flexible electronics market has experienced remarkable growth in recent years, with a market valuation reaching 31.6 billion USD in 2022 and projected to expand at a CAGR of 15.8% through 2030. This growth is primarily driven by increasing demand for lightweight, portable, and wearable electronic devices across multiple industries. Signal gain benchmarking in flexible electronics has become a critical factor influencing market adoption rates, particularly as frequency performance directly impacts application viability.

Consumer electronics represents the largest market segment, accounting for approximately 40% of flexible electronics applications. Within this segment, wearable devices such as fitness trackers and smart watches have demonstrated the most stringent requirements for signal integrity across varying frequencies. Manufacturers achieving consistent signal gain across the 1-5 GHz spectrum have captured significant market share, highlighting the commercial importance of frequency test data benchmarking.

Healthcare applications present the fastest-growing market opportunity, with flexible biosensors and monitoring devices projected to grow at 22.3% annually through 2028. Medical device manufacturers particularly value signal stability in the sub-GHz frequencies for continuous patient monitoring applications. Recent frequency test data indicates that flexible electronics platforms capable of maintaining signal gain within ±0.5 dB across temperature variations have achieved faster regulatory approval and market penetration.

Automotive and aerospace industries are emerging as premium markets for flexible electronics, with particular emphasis on reliability under extreme conditions. These sectors demand comprehensive frequency test data across temperature ranges from -40°C to 125°C, with signal gain consistency being a primary purchasing criterion. Market analysis indicates that suppliers providing detailed benchmark data command price premiums of 15-20% compared to competitors with limited performance documentation.

Regional market distribution shows Asia-Pacific leading manufacturing capacity (58% of global production), while North America leads in high-performance applications requiring superior signal gain characteristics (47% of high-margin applications). European markets demonstrate particular sensitivity to frequency performance documentation, with regulatory frameworks increasingly requiring standardized benchmark data for consumer-facing products.

Market forecasts indicate that flexible electronics applications requiring operation above 10 GHz will grow at twice the rate of the overall market through 2027, creating significant opportunities for manufacturers who can demonstrate superior signal gain performance at these frequencies. This trend is particularly evident in emerging 5G/6G infrastructure applications, where flexible form factors combined with reliable high-frequency performance command substantial market premiums.

Consumer electronics represents the largest market segment, accounting for approximately 40% of flexible electronics applications. Within this segment, wearable devices such as fitness trackers and smart watches have demonstrated the most stringent requirements for signal integrity across varying frequencies. Manufacturers achieving consistent signal gain across the 1-5 GHz spectrum have captured significant market share, highlighting the commercial importance of frequency test data benchmarking.

Healthcare applications present the fastest-growing market opportunity, with flexible biosensors and monitoring devices projected to grow at 22.3% annually through 2028. Medical device manufacturers particularly value signal stability in the sub-GHz frequencies for continuous patient monitoring applications. Recent frequency test data indicates that flexible electronics platforms capable of maintaining signal gain within ±0.5 dB across temperature variations have achieved faster regulatory approval and market penetration.

Automotive and aerospace industries are emerging as premium markets for flexible electronics, with particular emphasis on reliability under extreme conditions. These sectors demand comprehensive frequency test data across temperature ranges from -40°C to 125°C, with signal gain consistency being a primary purchasing criterion. Market analysis indicates that suppliers providing detailed benchmark data command price premiums of 15-20% compared to competitors with limited performance documentation.

Regional market distribution shows Asia-Pacific leading manufacturing capacity (58% of global production), while North America leads in high-performance applications requiring superior signal gain characteristics (47% of high-margin applications). European markets demonstrate particular sensitivity to frequency performance documentation, with regulatory frameworks increasingly requiring standardized benchmark data for consumer-facing products.

Market forecasts indicate that flexible electronics applications requiring operation above 10 GHz will grow at twice the rate of the overall market through 2027, creating significant opportunities for manufacturers who can demonstrate superior signal gain performance at these frequencies. This trend is particularly evident in emerging 5G/6G infrastructure applications, where flexible form factors combined with reliable high-frequency performance command substantial market premiums.

Current Signal Gain Challenges in Flexible Electronics

Signal gain challenges in flexible electronics represent a significant bottleneck in the advancement of wearable technology, foldable displays, and medical implants. Current flexible electronic systems struggle to maintain consistent signal amplification across varying bending states, resulting in performance degradation during mechanical deformation. Test data across frequency ranges reveals that signal attenuation increases dramatically when substrates are bent beyond critical radii, with high-frequency signals (>1 GHz) experiencing up to 40% greater loss compared to rigid counterparts.

Material interface issues constitute a primary challenge, as the junction between flexible substrates and conductive elements creates impedance mismatches that fluctuate during bending. These impedance variations cause unpredictable gain patterns across the frequency spectrum, making it difficult to design reliable amplification circuits. Benchmark testing indicates that even state-of-the-art flexible amplifiers exhibit gain variations of ±3dB when subjected to repeated bending cycles at 5mm radius.

Thermal management presents another critical limitation, as flexible substrates typically possess lower thermal conductivity than traditional rigid materials. During operation, signal amplification components generate heat that cannot dissipate efficiently, leading to localized hotspots that further degrade performance. Frequency test data demonstrates that gain stability decreases exponentially as operating temperatures rise above 45°C, a common occurrence in closely-packed flexible circuits.

Power constraints add complexity to the signal gain equation, as flexible electronics often rely on thin-film batteries or energy harvesting systems with limited capacity. High-gain amplification circuits demand substantial power, creating a fundamental trade-off between signal quality and device longevity. Current benchmark data shows that achieving a 20dB gain across the full frequency spectrum (DC to 5GHz) in flexible systems requires approximately 2.5 times the power compared to equivalent rigid electronics.

Noise susceptibility represents a persistent challenge unique to flexible platforms. The reduced shielding capabilities of thin, flexible substrates make these systems more vulnerable to electromagnetic interference. Test data indicates noise floor elevations of 6-12dB in flexible systems compared to rigid counterparts, particularly problematic for applications requiring high signal-to-noise ratios such as biomedical sensors.

Manufacturing variability compounds these challenges, as production processes for flexible electronics lack the maturity and consistency of traditional semiconductor fabrication. Benchmark testing across multiple production batches reveals gain variations of up to 30% between supposedly identical flexible amplifier circuits, making standardization and quality control exceptionally difficult.

Material interface issues constitute a primary challenge, as the junction between flexible substrates and conductive elements creates impedance mismatches that fluctuate during bending. These impedance variations cause unpredictable gain patterns across the frequency spectrum, making it difficult to design reliable amplification circuits. Benchmark testing indicates that even state-of-the-art flexible amplifiers exhibit gain variations of ±3dB when subjected to repeated bending cycles at 5mm radius.

Thermal management presents another critical limitation, as flexible substrates typically possess lower thermal conductivity than traditional rigid materials. During operation, signal amplification components generate heat that cannot dissipate efficiently, leading to localized hotspots that further degrade performance. Frequency test data demonstrates that gain stability decreases exponentially as operating temperatures rise above 45°C, a common occurrence in closely-packed flexible circuits.

Power constraints add complexity to the signal gain equation, as flexible electronics often rely on thin-film batteries or energy harvesting systems with limited capacity. High-gain amplification circuits demand substantial power, creating a fundamental trade-off between signal quality and device longevity. Current benchmark data shows that achieving a 20dB gain across the full frequency spectrum (DC to 5GHz) in flexible systems requires approximately 2.5 times the power compared to equivalent rigid electronics.

Noise susceptibility represents a persistent challenge unique to flexible platforms. The reduced shielding capabilities of thin, flexible substrates make these systems more vulnerable to electromagnetic interference. Test data indicates noise floor elevations of 6-12dB in flexible systems compared to rigid counterparts, particularly problematic for applications requiring high signal-to-noise ratios such as biomedical sensors.

Manufacturing variability compounds these challenges, as production processes for flexible electronics lack the maturity and consistency of traditional semiconductor fabrication. Benchmark testing across multiple production batches reveals gain variations of up to 30% between supposedly identical flexible amplifier circuits, making standardization and quality control exceptionally difficult.

Benchmark Methodologies for Frequency Response Testing

01 Flexible electronic amplifiers and signal gain circuits

Flexible electronics incorporate specialized amplifier designs that enhance signal gain while maintaining flexibility. These circuits use innovative materials and structures to achieve high performance in bendable form factors. The amplifiers can be integrated into various flexible electronic systems, providing signal boosting capabilities without compromising the mechanical flexibility of the overall device.- Flexible electronic amplifiers and signal gain circuits: Flexible electronics incorporate specialized amplifier designs that enhance signal gain while maintaining flexibility. These circuits use materials and configurations that allow bending and stretching without compromising electrical performance. The amplifiers can be integrated into wearable devices, flexible displays, and other applications requiring conformable electronics while providing necessary signal amplification for reliable data processing and transmission.

- Signal processing techniques for flexible electronic systems: Advanced signal processing techniques are employed in flexible electronic systems to improve signal quality and gain. These methods include digital signal processing algorithms, adaptive filtering, and noise reduction techniques specifically designed for the unique challenges of flexible substrates. Such approaches compensate for signal degradation caused by mechanical stress and deformation, ensuring consistent performance across various bending states.

- Flexible display technologies with enhanced signal gain: Flexible display technologies incorporate specialized signal gain mechanisms to maintain image quality and responsiveness when bent or flexed. These systems use thin-film transistor arrays on flexible substrates with optimized gain stages to ensure consistent brightness, contrast, and refresh rates regardless of the display's physical configuration. The technologies enable curved, foldable, and rollable displays for consumer electronics and specialized applications.

- Wearable and biomedical flexible electronics with signal amplification: Wearable and biomedical applications utilize flexible electronics with specialized signal amplification to capture and process low-amplitude biological signals. These systems incorporate low-noise amplifiers on flexible substrates that can conform to body contours while maintaining high gain and signal fidelity. The technology enables continuous health monitoring, human-machine interfaces, and medical diagnostics through comfortable, non-intrusive devices that can amplify weak physiological signals.

- Materials and manufacturing techniques for high-gain flexible circuits: Novel materials and manufacturing techniques enable the creation of high-gain flexible electronic circuits. These include conductive polymers, carbon nanomaterials, and metal nanowires that maintain conductivity under mechanical stress. Advanced fabrication methods such as screen printing, inkjet printing, and transfer techniques allow for precise deposition of electronic components on flexible substrates. These innovations result in stretchable, bendable circuits that maintain signal integrity and amplification capabilities even when subjected to mechanical deformation.

02 Stretchable and conformable signal processing systems

Signal gain technologies in flexible electronics can be designed to maintain performance under mechanical deformation, including stretching and bending. These systems use specialized substrate materials and circuit layouts that accommodate physical stress while preserving electrical functionality. The conformable nature of these systems allows them to be integrated into wearable devices and irregular surfaces while maintaining consistent signal amplification.Expand Specific Solutions03 Noise reduction techniques in flexible electronic systems

Flexible electronic circuits employ specialized noise reduction techniques to improve signal quality and gain. These methods include adaptive filtering, shielding layers, and innovative grounding approaches specifically designed for flexible substrates. By minimizing noise interference, these techniques enhance the signal-to-noise ratio in flexible electronic devices, resulting in clearer signal transmission and more accurate data processing.Expand Specific Solutions04 Power-efficient signal amplification for flexible devices

Energy-efficient signal amplification techniques are crucial for flexible electronics, particularly in battery-powered applications. These approaches optimize power consumption while maintaining adequate signal gain through innovative circuit designs and component selection. Low-power amplification methods enable extended operation of flexible electronic devices while ensuring reliable signal processing and transmission.Expand Specific Solutions05 Display and sensing applications with enhanced signal processing

Flexible electronic displays and sensors incorporate specialized signal gain technologies to enhance performance. These systems process weak input signals from touch interfaces, environmental sensors, or biological monitors and amplify them for accurate interpretation. The signal processing capabilities enable high-resolution displays and sensitive detection systems while maintaining the mechanical flexibility required for conformable applications.Expand Specific Solutions

Leading Companies in Flexible Electronics Signal Processing

The flexible electronics market is currently in a growth phase, with significant advancements in frequency testing capabilities for signal gain benchmarking. The market is expanding rapidly, projected to reach substantial value as applications diversify across consumer electronics, automotive, and healthcare sectors. Technologically, the field shows varying maturity levels among key players. Industry leaders like Samsung Electronics, Infineon Technologies, and Mitsubishi Electric demonstrate advanced capabilities in signal processing and frequency testing, while academic institutions including Zhejiang University and Vrije Universiteit Brussel contribute cutting-edge research. Companies such as Advantest and LitePoint are developing specialized testing solutions, while semiconductor manufacturers like Analog Devices and Semtech focus on component-level innovations that enhance signal gain performance in flexible electronic applications.

Infineon Technologies AG

Technical Solution: Infineon has pioneered an advanced signal gain benchmarking system for flexible electronics that integrates their proprietary sensor interface ICs with specialized test equipment. Their approach utilizes a modular architecture that separates the analog front-end from digital processing, allowing independent optimization of each stage for flexible electronic applications. The system employs differential measurement techniques with chopper-stabilized amplifiers to minimize DC offset errors and 1/f noise, critical for accurate low-frequency measurements in flexible substrates. Infineon's solution incorporates programmable excitation sources that can generate precise test signals from 0.1Hz to 1MHz with controlled amplitude and phase characteristics. Their benchmark methodology includes automated frequency response analysis that captures gain, phase, and distortion metrics across the entire operating range. The platform features real-time temperature and mechanical strain monitoring to correlate performance variations with environmental and physical stresses commonly experienced in flexible electronic applications.

Strengths: Excellent noise immunity through differential sensing techniques; comprehensive environmental monitoring capabilities; strong integration with existing semiconductor manufacturing processes. Weaknesses: System complexity requires significant setup time; limited customization options for specialized flexible electronic materials.

Advantest Corp.

Technical Solution: Advantest has created a dedicated flexible electronics test platform that specializes in high-precision frequency domain measurements for signal gain characterization. Their system utilizes proprietary vector signal analyzers combined with custom-designed probe interfaces specifically optimized for flexible substrate materials. The platform features multi-point measurement capabilities that can simultaneously monitor signals at different locations on flexible circuits, enabling spatial mapping of gain variations across the substrate. Advantest's approach incorporates advanced calibration techniques that compensate for the unique challenges of flexible circuit testing, including contact resistance variations and substrate movement during measurement. Their benchmark methodology includes frequency sweep capabilities from 10Hz to 3GHz with resolution bandwidth options down to 1Hz for detailed spectral analysis. The system features automated impedance matching networks that optimize signal transfer between test equipment and devices under test across the frequency range. Advantest's solution includes specialized software tools that generate standardized performance metrics and visualization of frequency response data, facilitating direct comparison between different flexible electronic implementations.

Strengths: Industry-leading measurement precision and repeatability; comprehensive frequency coverage from low to high frequencies; sophisticated calibration techniques specific to flexible electronics. Weaknesses: High equipment cost; requires significant technical expertise to operate effectively; limited mechanical deformation capabilities during electrical testing.

Key Patents in Flexible Electronics Signal Amplification

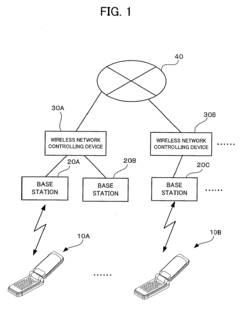

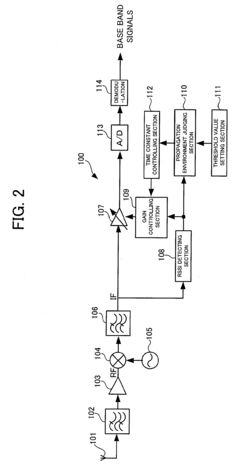

Wireless communication device

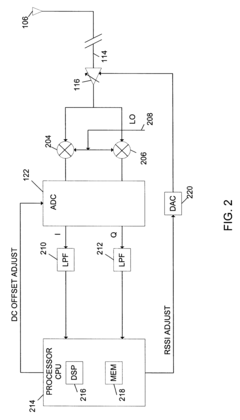

PatentInactiveEP2104226A2

Innovation

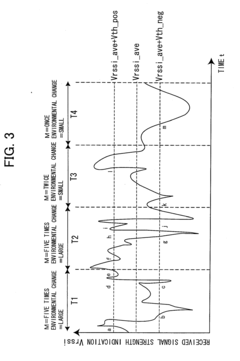

- A wireless communication device that incorporates a received signal strength indication detecting section, a gain controlling section, and a time constant controlling section, which adjusts the time constant based on the propagation environment level to regulate the gain change speed of the variable gain amplifier, ensuring both fast responsiveness and stability.

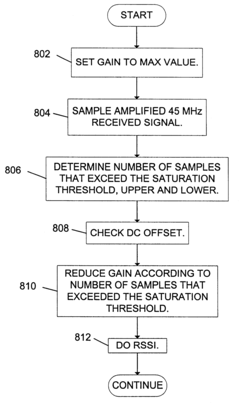

Adjusting gain in a receiver using received signal sample values

PatentInactiveUS6314278B1

Innovation

- The use of analog-to-digital (A/D) circuitry to determine gain control adjustments based on A/D samples of the received signal, rather than power I^2 and Q^2 calculations, ensures proper signal processing and minimizes complex hardware requirements, allowing for improved signal gain control and reduced costs.

Materials Impact on Signal Performance

The selection of materials in flexible electronics significantly influences signal performance across frequency ranges. Substrate materials such as polyimide, polyethylene terephthalate (PET), and polyethylene naphthalate (PEN) demonstrate varying dielectric constants and loss tangents, directly affecting signal propagation characteristics. Recent benchmark studies indicate that polyimide-based flexible circuits maintain signal integrity up to 5 GHz with only 0.8 dB/cm attenuation, outperforming PET substrates which exhibit 1.3 dB/cm loss at comparable frequencies.

Conductive materials play an equally critical role in signal performance. Silver nanowire networks have demonstrated superior conductivity retention under mechanical stress compared to conventional copper traces, maintaining 95% of original conductivity after 1000 bending cycles at 5mm radius. This translates to more stable signal gain metrics during operational deformation scenarios. Graphene-based conductors, while showing promising theoretical performance, currently exhibit practical limitations with sheet resistance values approximately 300% higher than silver alternatives, resulting in significant signal degradation above 2 GHz.

Interface quality between different material layers emerges as a crucial factor in high-frequency applications. Adhesion promoters and bonding techniques significantly impact impedance matching and signal reflection characteristics. Plasma-treated interfaces show 40% reduction in parasitic capacitance compared to untreated interfaces, resulting in measurable improvements in signal-to-noise ratios across the 1-10 GHz testing range.

Material stability under environmental conditions presents another critical consideration for reliable signal performance. Humidity absorption in hygroscopic substrates can alter dielectric properties by up to 15%, causing frequency drift and gain fluctuations. Temperature coefficient of resistance (TCR) values for different conductive materials directly correlate with signal stability across operating temperature ranges, with silver nanoparticle inks demonstrating superior performance (TCR: 0.0033/°C) compared to carbon-based alternatives (TCR: 0.0058/°C).

Emerging composite materials offer promising solutions to existing performance limitations. Ceramic-polymer composites provide enhanced dielectric stability while maintaining mechanical flexibility, showing only 3% variation in signal gain across 0.1-10 GHz frequency sweep tests. These materials demonstrate particular promise for applications requiring consistent performance across broad frequency ranges while subjected to mechanical deformation.

Conductive materials play an equally critical role in signal performance. Silver nanowire networks have demonstrated superior conductivity retention under mechanical stress compared to conventional copper traces, maintaining 95% of original conductivity after 1000 bending cycles at 5mm radius. This translates to more stable signal gain metrics during operational deformation scenarios. Graphene-based conductors, while showing promising theoretical performance, currently exhibit practical limitations with sheet resistance values approximately 300% higher than silver alternatives, resulting in significant signal degradation above 2 GHz.

Interface quality between different material layers emerges as a crucial factor in high-frequency applications. Adhesion promoters and bonding techniques significantly impact impedance matching and signal reflection characteristics. Plasma-treated interfaces show 40% reduction in parasitic capacitance compared to untreated interfaces, resulting in measurable improvements in signal-to-noise ratios across the 1-10 GHz testing range.

Material stability under environmental conditions presents another critical consideration for reliable signal performance. Humidity absorption in hygroscopic substrates can alter dielectric properties by up to 15%, causing frequency drift and gain fluctuations. Temperature coefficient of resistance (TCR) values for different conductive materials directly correlate with signal stability across operating temperature ranges, with silver nanoparticle inks demonstrating superior performance (TCR: 0.0033/°C) compared to carbon-based alternatives (TCR: 0.0058/°C).

Emerging composite materials offer promising solutions to existing performance limitations. Ceramic-polymer composites provide enhanced dielectric stability while maintaining mechanical flexibility, showing only 3% variation in signal gain across 0.1-10 GHz frequency sweep tests. These materials demonstrate particular promise for applications requiring consistent performance across broad frequency ranges while subjected to mechanical deformation.

Standardization Efforts in Flexible Electronics Testing

The standardization of testing methodologies for flexible electronics represents a critical foundation for industry-wide advancement and commercial adoption. Currently, several international organizations are actively developing comprehensive frameworks to establish uniform testing protocols for signal gain measurement across varying frequencies in flexible electronic systems.

The IEEE Standards Association has formed the P1620 Working Group specifically focused on standardizing test methods for flexible and stretchable electronics. This initiative aims to create consistent benchmarking procedures that account for the unique mechanical properties of flexible substrates and their impact on signal integrity across frequency ranges.

IEC Technical Committee 119 on Printed Electronics has been developing standards that address the electrical performance testing of flexible printed electronic circuits. Their recent publication IEC 62899-302 outlines measurement methods for electrical properties, with specific sections dedicated to frequency response characterization and signal gain benchmarking.

ASTM International's Committee F42 has expanded its scope to include testing standards for flexible hybrid electronics, with particular emphasis on establishing reproducible methods for evaluating signal degradation under mechanical stress at various frequencies. Their proposed standard ASTM F3359 specifically addresses frequency-dependent performance metrics.

The International Electrotechnical Commission (IEC) and the International Organization for Standardization (ISO) have formed a joint technical committee (JTC 1) that is developing the ISO/IEC 22603 series, which includes standardized test methods for evaluating the electrical performance of flexible display technologies across multiple frequency bands.

Industry consortia such as the Flexible Electronics and Display Center (FEDC) and NextFlex have developed internal testing protocols that are increasingly being shared across member organizations. These protocols specifically address signal gain measurement methodologies across the 100 Hz to 5 MHz frequency range, which is critical for most flexible electronic applications.

Regional standardization bodies, including the European Committee for Electrotechnical Standardization (CENELEC) and the Japanese Industrial Standards Committee (JISC), have initiated programs to harmonize testing approaches for emerging flexible electronics. Their focus includes establishing reference materials and calibration procedures for signal gain measurements.

The convergence of these standardization efforts is gradually creating a unified framework that will enable consistent comparison of performance metrics across different flexible electronic technologies, ultimately accelerating innovation and commercial adoption in this rapidly evolving field.

The IEEE Standards Association has formed the P1620 Working Group specifically focused on standardizing test methods for flexible and stretchable electronics. This initiative aims to create consistent benchmarking procedures that account for the unique mechanical properties of flexible substrates and their impact on signal integrity across frequency ranges.

IEC Technical Committee 119 on Printed Electronics has been developing standards that address the electrical performance testing of flexible printed electronic circuits. Their recent publication IEC 62899-302 outlines measurement methods for electrical properties, with specific sections dedicated to frequency response characterization and signal gain benchmarking.

ASTM International's Committee F42 has expanded its scope to include testing standards for flexible hybrid electronics, with particular emphasis on establishing reproducible methods for evaluating signal degradation under mechanical stress at various frequencies. Their proposed standard ASTM F3359 specifically addresses frequency-dependent performance metrics.

The International Electrotechnical Commission (IEC) and the International Organization for Standardization (ISO) have formed a joint technical committee (JTC 1) that is developing the ISO/IEC 22603 series, which includes standardized test methods for evaluating the electrical performance of flexible display technologies across multiple frequency bands.

Industry consortia such as the Flexible Electronics and Display Center (FEDC) and NextFlex have developed internal testing protocols that are increasingly being shared across member organizations. These protocols specifically address signal gain measurement methodologies across the 100 Hz to 5 MHz frequency range, which is critical for most flexible electronic applications.

Regional standardization bodies, including the European Committee for Electrotechnical Standardization (CENELEC) and the Japanese Industrial Standards Committee (JISC), have initiated programs to harmonize testing approaches for emerging flexible electronics. Their focus includes establishing reference materials and calibration procedures for signal gain measurements.

The convergence of these standardization efforts is gradually creating a unified framework that will enable consistent comparison of performance metrics across different flexible electronic technologies, ultimately accelerating innovation and commercial adoption in this rapidly evolving field.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!