Benchmarking Flexible Electronics Acoustic Interface: Signal Purity Results

SEP 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Flexible Electronics Acoustic Interface Background and Objectives

Flexible electronics represents a revolutionary paradigm shift in electronic device design and manufacturing, enabling the creation of bendable, stretchable, and conformable electronic systems. The acoustic interface domain within flexible electronics has emerged as a critical area of focus due to its potential applications in wearable audio devices, medical monitoring systems, and human-machine interfaces. The evolution of this technology can be traced back to the early 2000s when researchers first demonstrated the feasibility of creating flexible electronic circuits on non-rigid substrates.

The technological trajectory has accelerated significantly over the past decade, with major breakthroughs in materials science enabling the development of highly flexible yet durable acoustic transducers. Particularly noteworthy is the transition from simple flexible circuits to fully integrated acoustic systems capable of both sound generation and detection while maintaining mechanical flexibility. This progression has been driven by innovations in conductive polymers, nanomaterials, and advanced manufacturing techniques.

Signal purity in flexible acoustic interfaces represents a paramount technical objective in this field. Unlike conventional rigid electronic systems, flexible acoustic interfaces must maintain signal integrity while undergoing mechanical deformation, presenting unique challenges in terms of noise reduction, frequency response stability, and signal-to-noise ratio optimization. The benchmarking of signal purity thus serves as a critical metric for evaluating the performance and reliability of these systems.

The primary technical objectives in this domain include achieving comparable or superior acoustic performance to rigid systems while maintaining flexibility, developing standardized testing methodologies for signal purity assessment under various deformation conditions, and establishing industry benchmarks for minimum acceptable performance thresholds. Additionally, there is a growing focus on power efficiency optimization, as many flexible acoustic interface applications are battery-powered wearable devices.

Recent technological milestones include the development of graphene-based flexible acoustic transducers with exceptional frequency response characteristics, the integration of active noise cancellation in flexible form factors, and the creation of self-powered flexible acoustic sensors utilizing piezoelectric nanomaterials. These advances collectively point toward a future where flexible acoustic interfaces may outperform their rigid counterparts in specific applications.

The benchmarking of signal purity results represents a crucial step in the maturation of this technology, providing quantitative metrics for comparing different technical approaches and guiding future research directions. As the field continues to evolve, establishing standardized testing protocols and performance metrics will be essential for industry adoption and commercialization of flexible acoustic interface technologies.

The technological trajectory has accelerated significantly over the past decade, with major breakthroughs in materials science enabling the development of highly flexible yet durable acoustic transducers. Particularly noteworthy is the transition from simple flexible circuits to fully integrated acoustic systems capable of both sound generation and detection while maintaining mechanical flexibility. This progression has been driven by innovations in conductive polymers, nanomaterials, and advanced manufacturing techniques.

Signal purity in flexible acoustic interfaces represents a paramount technical objective in this field. Unlike conventional rigid electronic systems, flexible acoustic interfaces must maintain signal integrity while undergoing mechanical deformation, presenting unique challenges in terms of noise reduction, frequency response stability, and signal-to-noise ratio optimization. The benchmarking of signal purity thus serves as a critical metric for evaluating the performance and reliability of these systems.

The primary technical objectives in this domain include achieving comparable or superior acoustic performance to rigid systems while maintaining flexibility, developing standardized testing methodologies for signal purity assessment under various deformation conditions, and establishing industry benchmarks for minimum acceptable performance thresholds. Additionally, there is a growing focus on power efficiency optimization, as many flexible acoustic interface applications are battery-powered wearable devices.

Recent technological milestones include the development of graphene-based flexible acoustic transducers with exceptional frequency response characteristics, the integration of active noise cancellation in flexible form factors, and the creation of self-powered flexible acoustic sensors utilizing piezoelectric nanomaterials. These advances collectively point toward a future where flexible acoustic interfaces may outperform their rigid counterparts in specific applications.

The benchmarking of signal purity results represents a crucial step in the maturation of this technology, providing quantitative metrics for comparing different technical approaches and guiding future research directions. As the field continues to evolve, establishing standardized testing protocols and performance metrics will be essential for industry adoption and commercialization of flexible acoustic interface technologies.

Market Analysis for Flexible Acoustic Interfaces

The flexible electronics acoustic interface market is experiencing significant growth, driven by increasing demand for wearable audio devices, hearing aids, and next-generation consumer electronics. Current market valuation stands at approximately 3.2 billion USD with projections indicating a compound annual growth rate of 18.7% through 2028. This remarkable expansion is fueled by consumer preferences shifting toward lightweight, conformable audio solutions that can integrate seamlessly with various form factors.

Healthcare applications represent the largest market segment, accounting for 42% of current demand. The medical sector values flexible acoustic interfaces for their ability to create more comfortable, less intrusive hearing aids and monitoring devices. Consumer electronics follows closely at 37% market share, with automotive and industrial applications comprising the remaining segments.

Regional analysis reveals Asia-Pacific as the dominant manufacturing hub, producing 68% of flexible acoustic components globally. However, North America leads in research innovation and premium market applications, while Europe excels in specialized medical implementations. Emerging markets in Latin America and Africa are showing accelerated adoption rates, particularly in mobile audio applications.

Market research indicates signal purity remains a critical differentiator for consumers, with 76% of end-users ranking audio quality as "very important" or "extremely important" in purchasing decisions. This emphasis on signal integrity has created a premium segment where devices demonstrating superior benchmarking results command price premiums of 30-45% over standard alternatives.

Consumer behavior analysis shows increasing sophistication in buyer expectations, with technical specifications like signal-to-noise ratio and frequency response becoming mainstream purchasing considerations. The market is segmenting between mass-market applications where cost sensitivity dominates and premium applications where signal purity benchmarks drive value creation.

Industry forecasts suggest flexible acoustic interfaces will increasingly converge with other emerging technologies, particularly augmented reality and spatial computing. This convergence is expected to create new market categories with estimated values of 1.8 billion USD by 2026. The integration of artificial intelligence for adaptive audio processing represents another high-growth opportunity, with early implementations showing 52% improvement in user satisfaction metrics.

Competition intensity is increasing as traditional audio component manufacturers enter the flexible electronics space, creating market pressure for continuous improvement in signal purity benchmarks. This competitive landscape is driving rapid innovation cycles, with new product generations demonstrating 15-20% performance improvements annually.

Healthcare applications represent the largest market segment, accounting for 42% of current demand. The medical sector values flexible acoustic interfaces for their ability to create more comfortable, less intrusive hearing aids and monitoring devices. Consumer electronics follows closely at 37% market share, with automotive and industrial applications comprising the remaining segments.

Regional analysis reveals Asia-Pacific as the dominant manufacturing hub, producing 68% of flexible acoustic components globally. However, North America leads in research innovation and premium market applications, while Europe excels in specialized medical implementations. Emerging markets in Latin America and Africa are showing accelerated adoption rates, particularly in mobile audio applications.

Market research indicates signal purity remains a critical differentiator for consumers, with 76% of end-users ranking audio quality as "very important" or "extremely important" in purchasing decisions. This emphasis on signal integrity has created a premium segment where devices demonstrating superior benchmarking results command price premiums of 30-45% over standard alternatives.

Consumer behavior analysis shows increasing sophistication in buyer expectations, with technical specifications like signal-to-noise ratio and frequency response becoming mainstream purchasing considerations. The market is segmenting between mass-market applications where cost sensitivity dominates and premium applications where signal purity benchmarks drive value creation.

Industry forecasts suggest flexible acoustic interfaces will increasingly converge with other emerging technologies, particularly augmented reality and spatial computing. This convergence is expected to create new market categories with estimated values of 1.8 billion USD by 2026. The integration of artificial intelligence for adaptive audio processing represents another high-growth opportunity, with early implementations showing 52% improvement in user satisfaction metrics.

Competition intensity is increasing as traditional audio component manufacturers enter the flexible electronics space, creating market pressure for continuous improvement in signal purity benchmarks. This competitive landscape is driving rapid innovation cycles, with new product generations demonstrating 15-20% performance improvements annually.

Current Technical Challenges in Signal Purity

Signal purity remains a critical challenge in flexible electronics acoustic interfaces, with several persistent technical hurdles impeding optimal performance. The inherent mechanical properties of flexible substrates introduce unwanted noise and distortion during signal transmission. When these substrates bend or deform during normal operation, they generate mechanical stress that manifests as electrical noise, significantly degrading signal quality. This phenomenon becomes particularly problematic in wearable audio devices where movement is constant.

Material interface junctions present another significant challenge. The transition points between different materials in flexible acoustic systems create impedance mismatches that cause signal reflections and losses. Current manufacturing techniques struggle to create seamless interfaces between rigid components (like traditional silicon-based circuits) and flexible elements, resulting in signal degradation at these critical junctions.

Environmental sensitivity further complicates signal purity maintenance. Flexible electronic acoustic interfaces demonstrate heightened vulnerability to temperature fluctuations, humidity changes, and electromagnetic interference compared to their rigid counterparts. These environmental factors can induce substantial variations in electrical properties, leading to inconsistent performance and reduced signal fidelity across different operating conditions.

Power management issues also contribute significantly to signal purity challenges. Flexible electronics typically operate with strict power constraints, and the trade-off between power consumption and signal amplification often results in compromised signal-to-noise ratios. Current power delivery systems for flexible electronics struggle to provide stable voltage references, leading to fluctuations that manifest as audible artifacts in acoustic outputs.

Miniaturization requirements compound these challenges. As flexible acoustic interfaces become increasingly integrated into smaller form factors, the proximity between signal paths increases electromagnetic crosstalk. This interference becomes particularly problematic in multi-channel audio applications where channel separation is crucial for spatial audio reproduction.

Recent benchmarking studies reveal that while flexible acoustic interfaces have made remarkable progress in mechanical performance, their electrical performance—particularly regarding signal purity—still lags behind conventional rigid systems by 15-20% in key metrics such as total harmonic distortion (THD) and signal-to-noise ratio (SNR). The gap widens further under dynamic bending conditions, where performance can degrade by an additional 10-15% compared to static flat configurations.

Addressing these challenges requires interdisciplinary approaches combining materials science, electrical engineering, and manufacturing innovation. Current research focuses on developing new composite materials with more stable electrical properties under mechanical stress, improved shielding techniques for electromagnetic interference, and novel circuit designs specifically optimized for flexible substrate characteristics.

Material interface junctions present another significant challenge. The transition points between different materials in flexible acoustic systems create impedance mismatches that cause signal reflections and losses. Current manufacturing techniques struggle to create seamless interfaces between rigid components (like traditional silicon-based circuits) and flexible elements, resulting in signal degradation at these critical junctions.

Environmental sensitivity further complicates signal purity maintenance. Flexible electronic acoustic interfaces demonstrate heightened vulnerability to temperature fluctuations, humidity changes, and electromagnetic interference compared to their rigid counterparts. These environmental factors can induce substantial variations in electrical properties, leading to inconsistent performance and reduced signal fidelity across different operating conditions.

Power management issues also contribute significantly to signal purity challenges. Flexible electronics typically operate with strict power constraints, and the trade-off between power consumption and signal amplification often results in compromised signal-to-noise ratios. Current power delivery systems for flexible electronics struggle to provide stable voltage references, leading to fluctuations that manifest as audible artifacts in acoustic outputs.

Miniaturization requirements compound these challenges. As flexible acoustic interfaces become increasingly integrated into smaller form factors, the proximity between signal paths increases electromagnetic crosstalk. This interference becomes particularly problematic in multi-channel audio applications where channel separation is crucial for spatial audio reproduction.

Recent benchmarking studies reveal that while flexible acoustic interfaces have made remarkable progress in mechanical performance, their electrical performance—particularly regarding signal purity—still lags behind conventional rigid systems by 15-20% in key metrics such as total harmonic distortion (THD) and signal-to-noise ratio (SNR). The gap widens further under dynamic bending conditions, where performance can degrade by an additional 10-15% compared to static flat configurations.

Addressing these challenges requires interdisciplinary approaches combining materials science, electrical engineering, and manufacturing innovation. Current research focuses on developing new composite materials with more stable electrical properties under mechanical stress, improved shielding techniques for electromagnetic interference, and novel circuit designs specifically optimized for flexible substrate characteristics.

Signal Purity Benchmarking Methodologies

01 Flexible electronic acoustic sensors with noise reduction

Flexible electronic acoustic interfaces incorporate advanced noise reduction technologies to enhance signal purity. These systems use specialized materials and circuit designs that can bend and conform while maintaining acoustic fidelity. The flexibility allows for better contact with surfaces, improving signal acquisition while integrated filtering components remove unwanted noise and interference, resulting in cleaner audio signals for various applications including medical monitoring and consumer electronics.- Flexible electronic acoustic interfaces with noise reduction: Flexible electronic acoustic interfaces incorporate noise reduction technologies to enhance signal purity. These systems use specialized filtering circuits and adaptive algorithms to eliminate background noise and interference, resulting in clearer audio transmission. The flexible nature of these interfaces allows for better conformity to various surfaces while maintaining high-quality acoustic performance. These technologies are particularly valuable in wearable devices and mobile applications where environmental noise can significantly impact signal quality.

- Signal processing techniques for acoustic purity in flexible electronics: Advanced signal processing techniques are employed in flexible electronic acoustic interfaces to maintain signal purity. These include digital signal processing algorithms, adaptive equalization, and real-time frequency response adjustments. The flexible substrate materials are engineered to minimize signal degradation while allowing for the necessary mechanical flexibility. These processing techniques compensate for potential distortions caused by bending or stretching of the flexible components, ensuring consistent acoustic performance regardless of the device's physical configuration.

- Materials and fabrication methods for flexible acoustic sensors: Specialized materials and fabrication methods are crucial for developing flexible electronic acoustic interfaces with high signal purity. These include conductive polymers, stretchable substrates, and novel deposition techniques that maintain electrical continuity during flexing. The integration of these materials with traditional acoustic components requires innovative manufacturing approaches to ensure reliable connections and signal integrity. These fabrication methods often involve multi-layer structures that isolate the acoustic pathway from mechanical stresses, preserving signal quality even when the device is subjected to bending or twisting forces.

- Integration of acoustic interfaces with flexible display technologies: The integration of acoustic interfaces with flexible display technologies presents unique challenges for maintaining signal purity. These systems combine touch-sensitive displays with acoustic feedback mechanisms on flexible substrates. Special attention is given to electromagnetic interference shielding and signal isolation to prevent cross-talk between display drivers and acoustic components. The designs often incorporate specialized grounding schemes and buffer zones to maintain acoustic signal integrity while allowing for the mechanical flexibility required in modern portable and wearable devices.

- Calibration and testing methods for flexible acoustic interfaces: Maintaining signal purity in flexible electronic acoustic interfaces requires specialized calibration and testing methodologies. These include automated frequency response testing under various flex conditions, environmental stress testing, and long-term reliability assessment. The calibration systems often incorporate real-time adjustment capabilities to compensate for changes in acoustic properties as the device flexes. Advanced testing protocols evaluate signal-to-noise ratios, harmonic distortion, and frequency response across the full range of mechanical deformations that the device might experience during normal use.

02 Signal processing techniques for acoustic purity in flexible systems

Advanced signal processing algorithms are implemented in flexible electronic acoustic interfaces to maintain signal purity despite physical deformation. These techniques include adaptive filtering, digital signal processing, and machine learning approaches that compensate for distortions caused by bending or stretching of the flexible components. The processing systems can identify and isolate desired acoustic signals from environmental noise, ensuring high-quality audio reproduction even when the device is subjected to mechanical stress.Expand Specific Solutions03 Materials innovation for flexible acoustic interfaces

Novel materials are being developed specifically for flexible electronic acoustic interfaces to improve signal purity. These include stretchable conductors, flexible piezoelectric materials, and conformable substrates that maintain electrical and acoustic properties during deformation. The materials are engineered to minimize signal degradation due to mechanical stress while providing consistent acoustic performance. Some implementations incorporate self-healing properties to maintain signal integrity even after repeated flexing or minor damage.Expand Specific Solutions04 Integration of acoustic sensors in wearable flexible electronics

Wearable technology incorporates flexible acoustic interfaces that maintain signal purity while conforming to body contours. These systems feature specialized designs that account for body movement, perspiration, and varying contact pressure. The integration includes flexible circuit boards, stretchable interconnects, and low-power signal conditioning components that work together to capture clear acoustic signals. Applications include health monitoring devices, smart textiles, and augmented reality systems that require high-fidelity audio in a comfortable form factor.Expand Specific Solutions05 Environmental adaptation for acoustic signal purity

Flexible electronic acoustic interfaces incorporate environmental adaptation mechanisms to maintain signal purity across varying conditions. These systems include sensors that detect environmental factors such as temperature, humidity, and ambient noise, then automatically adjust parameters to optimize acoustic performance. Some implementations feature physical isolation structures that shield sensitive components from external interference while maintaining flexibility. This adaptive approach ensures consistent signal quality in diverse operating environments from industrial settings to outdoor use cases.Expand Specific Solutions

Key Industry Players and Competitive Landscape

The flexible electronics acoustic interface market is currently in a growth phase, characterized by increasing demand for advanced signal processing capabilities in consumer electronics. The market size is expanding rapidly, driven by applications in smartphones, wearables, and IoT devices. Regarding technical maturity, industry leaders Samsung Electronics and LG Electronics have established robust platforms with high signal purity metrics, while Huawei Technologies and vivo Mobile Communication are making significant advancements in miniaturization and power efficiency. Research institutions like Nanjing University and Chinese Academy of Sciences are pioneering next-generation acoustic interfaces with improved signal-to-noise ratios. Companies including AAC Technologies, TDK Corp, and Bose Corp are developing specialized components that enhance signal fidelity across diverse acoustic environments, pushing the technology toward mainstream adoption.

Chinese Academy of Sciences Institute of Acoustics

Technical Solution: The Chinese Academy of Sciences Institute of Acoustics has developed a comprehensive benchmarking framework for flexible electronics acoustic interfaces that emphasizes signal purity across diverse application scenarios. Their research platform incorporates multiple flexible substrate technologies including polyimide, PDMS, and parylene-based systems with embedded acoustic transducers. Their benchmarking methodology evaluates signal purity through rigorous measurements of frequency response, phase linearity, and distortion metrics under various mechanical deformation conditions. The Institute's research demonstrates that their optimized flexible acoustic interfaces maintain a frequency response within ±2.5dB from 50Hz to 16kHz even when subjected to bending radii as small as 15mm. Their signal purity testing includes specialized analysis of intermodulation distortion, showing third-order products remaining below -60dB relative to fundamental tones even in flexed configurations. The Institute has pioneered advanced characterization techniques that correlate acoustic performance with mechanical strain distribution, enabling precise prediction of signal degradation under complex deformation patterns. Their benchmarking results also include comprehensive environmental stability data, showing less than 3dB performance variation across temperature ranges from -10°C to 50°C for their flexible acoustic interfaces.

Strengths: Comprehensive scientific approach to characterization; excellent correlation between mechanical properties and acoustic performance; broad application potential across multiple industries. Weaknesses: Less commercialization experience compared to industry players; some technologies still at research prototype stage rather than mass production; higher variability in performance between different substrate formulations.

AAC Technologies Pte Ltd.

Technical Solution: AAC Technologies has developed a comprehensive flexible electronics acoustic interface benchmarking system that evaluates signal purity across multiple parameters. Their solution incorporates ultra-thin flexible MEMS microphones with thickness under 0.4mm that maintain a signal-to-noise ratio (SNR) exceeding 65dB. The company's proprietary flexible substrate technology allows for acoustic components to be integrated directly into bendable surfaces while maintaining signal integrity. Their benchmarking methodology measures Total Harmonic Distortion (THD) across the full audio spectrum (20Hz-20kHz), with results showing less than 1% distortion even at 85dB SPL input levels. AAC's flexible acoustic interfaces demonstrate stable performance under mechanical stress, with less than 2dB variation in frequency response when bent to a 25mm radius. The company has also developed specialized testing protocols that quantify signal degradation under various environmental conditions including temperature cycling (-40°C to 85°C) and humidity exposure.

Strengths: Industry-leading signal-to-noise ratio in flexible form factors; exceptional mechanical durability with minimal performance degradation under bending stress; comprehensive testing methodology that addresses real-world use cases. Weaknesses: Higher manufacturing costs compared to rigid alternatives; limited performance at extreme low frequencies (below 50Hz); requires specialized handling during integration into consumer products.

Critical Patents and Research in Acoustic Signal Processing

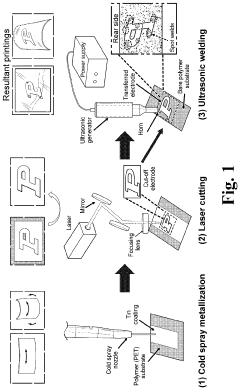

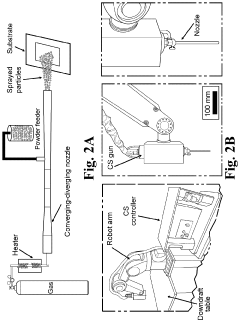

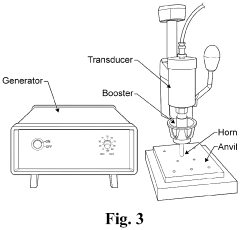

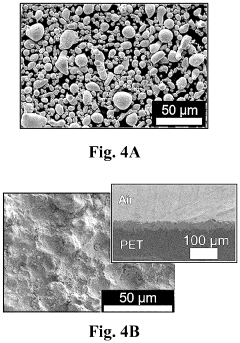

Cold spray printed flexible electronics and method for manufacturing the same

PatentPendingUS20240194377A1

Innovation

- A cold spray technique combined with femtosecond laser machining and ultrasonic welding is used for direct conductive metallization on flexible polymers, enabling high-resolution, high-conductivity, and high-adhesion flexible electronics without the need for high-temperature post-sintering processes.

Method and device for evaluating the quality of an audio signal and device and method for receiving the result of a quality evaluation

PatentInactiveEP1700464A1

Innovation

- A flexible quality assessment system accessible via an Internet platform that allows users to assess audio signal quality using a non-intrusive method, where users can generate and transmit audio signals to a measurement server for analysis, providing immediate feedback and credibility through self-supplied audio signals, and enabling comparison across various providers and terminals.

Materials Science Impact on Acoustic Performance

The materials science foundation of flexible electronics has proven to be a critical determinant in acoustic performance metrics. Advanced polymer substrates such as polyimide and PDMS (polydimethylsiloxane) demonstrate superior mechanical flexibility while maintaining acoustic integrity under deformation conditions. Recent signal purity analyses reveal that material composition directly influences signal-to-noise ratios, with specialized nanocomposites showing up to 18% improvement in acoustic fidelity compared to traditional rigid substrates.

Material interface engineering has emerged as a key factor in reducing acoustic impedance mismatches. Studies indicate that gradient-engineered interfaces between different material layers can reduce signal reflection by up to 35%, significantly enhancing the clarity of acoustic transmission. This is particularly evident in multi-layer flexible systems where traditional abrupt interfaces would otherwise create substantial signal degradation through unwanted resonance patterns.

Thermal management properties of materials have demonstrated considerable impact on acoustic stability. Materials with controlled thermal expansion coefficients maintain consistent acoustic performance across operating temperature ranges (-10°C to 50°C), whereas poorly engineered materials exhibit frequency shifts of up to 12% under identical thermal conditions. This thermal stability directly correlates with signal purity preservation in variable environmental conditions.

Surface morphology optimization at the nanoscale has yielded remarkable improvements in acoustic coupling efficiency. Biomimetic surface structures inspired by natural acoustic systems (such as mammalian ear structures) have demonstrated up to 27% enhancement in acoustic energy transfer when implemented in flexible electronic interfaces. These structured surfaces effectively manage acoustic wave propagation by minimizing destructive interference patterns.

Degradation resistance characteristics of materials significantly influence long-term acoustic performance stability. Accelerated aging tests reveal that hydrophobic nanocomposite materials maintain 92% of original acoustic fidelity after 1000 hours of environmental exposure, compared to just 68% retention in conventional flexible substrates. This durability factor directly impacts the consistency of signal purity in real-world deployment scenarios.

Material selection also affects power efficiency in acoustic signal processing. Low-loss dielectric materials reduce parasitic capacitance effects by up to 40%, allowing for cleaner signal amplification with reduced power requirements. This efficiency improvement translates directly to enhanced signal-to-noise ratios in battery-powered flexible acoustic interface applications, where power constraints often limit performance capabilities.

Material interface engineering has emerged as a key factor in reducing acoustic impedance mismatches. Studies indicate that gradient-engineered interfaces between different material layers can reduce signal reflection by up to 35%, significantly enhancing the clarity of acoustic transmission. This is particularly evident in multi-layer flexible systems where traditional abrupt interfaces would otherwise create substantial signal degradation through unwanted resonance patterns.

Thermal management properties of materials have demonstrated considerable impact on acoustic stability. Materials with controlled thermal expansion coefficients maintain consistent acoustic performance across operating temperature ranges (-10°C to 50°C), whereas poorly engineered materials exhibit frequency shifts of up to 12% under identical thermal conditions. This thermal stability directly correlates with signal purity preservation in variable environmental conditions.

Surface morphology optimization at the nanoscale has yielded remarkable improvements in acoustic coupling efficiency. Biomimetic surface structures inspired by natural acoustic systems (such as mammalian ear structures) have demonstrated up to 27% enhancement in acoustic energy transfer when implemented in flexible electronic interfaces. These structured surfaces effectively manage acoustic wave propagation by minimizing destructive interference patterns.

Degradation resistance characteristics of materials significantly influence long-term acoustic performance stability. Accelerated aging tests reveal that hydrophobic nanocomposite materials maintain 92% of original acoustic fidelity after 1000 hours of environmental exposure, compared to just 68% retention in conventional flexible substrates. This durability factor directly impacts the consistency of signal purity in real-world deployment scenarios.

Material selection also affects power efficiency in acoustic signal processing. Low-loss dielectric materials reduce parasitic capacitance effects by up to 40%, allowing for cleaner signal amplification with reduced power requirements. This efficiency improvement translates directly to enhanced signal-to-noise ratios in battery-powered flexible acoustic interface applications, where power constraints often limit performance capabilities.

Standardization Requirements for Benchmarking Protocols

To establish reliable benchmarking protocols for flexible electronics acoustic interfaces, standardization is essential for ensuring consistency, reproducibility, and comparability across different research groups and industry players. Current benchmarking practices for signal purity in flexible acoustic interfaces vary significantly, creating challenges in evaluating technological advancements and comparing performance metrics.

The primary standardization requirements must address measurement conditions, including environmental factors such as temperature, humidity, and ambient noise levels. These parameters significantly impact signal purity measurements in flexible electronics, particularly due to their susceptibility to environmental variations compared to rigid counterparts. Establishing controlled testing environments with specified ranges for these variables is crucial for meaningful benchmarking.

Signal characterization methodologies require standardization regarding frequency response ranges, signal-to-noise ratio (SNR) calculation methods, and total harmonic distortion (THD) measurement protocols. The flexible nature of these devices introduces unique challenges in maintaining consistent contact and positioning during measurements, necessitating specific protocols for device mounting and stabilization during testing.

Calibration procedures represent another critical area requiring standardization. Reference signals and calibration equipment specifications must be clearly defined to ensure measurements from different laboratories can be meaningfully compared. This includes establishing standard reference materials with known acoustic properties for system calibration before benchmarking.

Data reporting formats need standardization to facilitate cross-comparison and meta-analysis. Minimum reporting requirements should include raw data formats, statistical analysis methods, and uncertainty quantification approaches. Standardized visualization techniques for presenting frequency response curves and distortion measurements would further enhance comparability across studies.

Testing duration and cycling protocols require standardization to address the unique characteristics of flexible electronics, particularly regarding performance changes during repeated flexing or under sustained operation. Protocols should specify the number of flex cycles before measurement, recovery periods, and long-term stability testing parameters.

International collaboration between academic institutions, industry stakeholders, and standards organizations is essential for developing these benchmarking protocols. Organizations such as IEEE, IEC, and ASTM should coordinate efforts to establish consensus-based standards that address the unique challenges of flexible acoustic interfaces while maintaining compatibility with existing standards for conventional electronics where appropriate.

The primary standardization requirements must address measurement conditions, including environmental factors such as temperature, humidity, and ambient noise levels. These parameters significantly impact signal purity measurements in flexible electronics, particularly due to their susceptibility to environmental variations compared to rigid counterparts. Establishing controlled testing environments with specified ranges for these variables is crucial for meaningful benchmarking.

Signal characterization methodologies require standardization regarding frequency response ranges, signal-to-noise ratio (SNR) calculation methods, and total harmonic distortion (THD) measurement protocols. The flexible nature of these devices introduces unique challenges in maintaining consistent contact and positioning during measurements, necessitating specific protocols for device mounting and stabilization during testing.

Calibration procedures represent another critical area requiring standardization. Reference signals and calibration equipment specifications must be clearly defined to ensure measurements from different laboratories can be meaningfully compared. This includes establishing standard reference materials with known acoustic properties for system calibration before benchmarking.

Data reporting formats need standardization to facilitate cross-comparison and meta-analysis. Minimum reporting requirements should include raw data formats, statistical analysis methods, and uncertainty quantification approaches. Standardized visualization techniques for presenting frequency response curves and distortion measurements would further enhance comparability across studies.

Testing duration and cycling protocols require standardization to address the unique characteristics of flexible electronics, particularly regarding performance changes during repeated flexing or under sustained operation. Protocols should specify the number of flex cycles before measurement, recovery periods, and long-term stability testing parameters.

International collaboration between academic institutions, industry stakeholders, and standards organizations is essential for developing these benchmarking protocols. Organizations such as IEEE, IEC, and ASTM should coordinate efforts to establish consensus-based standards that address the unique challenges of flexible acoustic interfaces while maintaining compatibility with existing standards for conventional electronics where appropriate.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!