Assess Flexible Electronics Charge Capacity in Energy Harvesting

SEP 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Flexible Electronics Energy Harvesting Background & Objectives

Flexible electronics has emerged as a transformative technology over the past two decades, evolving from laboratory curiosities to commercially viable products. This technological domain represents the convergence of traditional electronics with flexible substrates, enabling electronic devices that can bend, stretch, and conform to non-planar surfaces. The evolution of flexible electronics has been driven by advancements in materials science, particularly the development of organic semiconductors, conductive polymers, and nanomaterials that maintain functionality under mechanical deformation.

Energy harvesting capabilities within flexible electronics have become increasingly significant as the Internet of Things (IoT) ecosystem expands, demanding self-powered devices that can operate autonomously in diverse environments. The trajectory of this technology shows a clear progression from rigid silicon-based energy harvesters to fully flexible systems capable of capturing energy from multiple ambient sources including mechanical vibration, thermal gradients, and light.

The primary objective of assessing charge capacity in flexible electronic energy harvesting systems is to determine the maximum electrical energy that can be reliably stored and delivered under various operational conditions. This assessment is crucial for designing self-sufficient electronic systems that can function without external power sources or battery replacements, particularly in remote or inaccessible locations.

Technical goals include quantifying the energy conversion efficiency across different harvesting mechanisms, evaluating the stability of charge storage under mechanical deformation, and determining the scalability of these systems for various application requirements. Additionally, there is a need to establish standardized testing protocols that account for the unique characteristics of flexible energy harvesters, such as performance changes during bending cycles and long-term reliability under environmental stressors.

The field aims to achieve energy density targets that make flexible harvesters competitive with conventional power sources, while maintaining the mechanical advantages of flexibility. Current benchmarks suggest that flexible photovoltaics can achieve efficiencies approaching 15%, while piezoelectric and triboelectric harvesters are demonstrating power densities in the range of 1-10 mW/cm².

Looking forward, the technological trajectory points toward integrated energy systems that combine multiple harvesting modalities with flexible energy storage solutions, creating truly autonomous electronic platforms. The ultimate vision encompasses self-powered flexible electronic systems that can be seamlessly integrated into clothing, biomedical devices, structural health monitoring systems, and consumer electronics, fundamentally changing how we interact with technology in our daily lives.

Energy harvesting capabilities within flexible electronics have become increasingly significant as the Internet of Things (IoT) ecosystem expands, demanding self-powered devices that can operate autonomously in diverse environments. The trajectory of this technology shows a clear progression from rigid silicon-based energy harvesters to fully flexible systems capable of capturing energy from multiple ambient sources including mechanical vibration, thermal gradients, and light.

The primary objective of assessing charge capacity in flexible electronic energy harvesting systems is to determine the maximum electrical energy that can be reliably stored and delivered under various operational conditions. This assessment is crucial for designing self-sufficient electronic systems that can function without external power sources or battery replacements, particularly in remote or inaccessible locations.

Technical goals include quantifying the energy conversion efficiency across different harvesting mechanisms, evaluating the stability of charge storage under mechanical deformation, and determining the scalability of these systems for various application requirements. Additionally, there is a need to establish standardized testing protocols that account for the unique characteristics of flexible energy harvesters, such as performance changes during bending cycles and long-term reliability under environmental stressors.

The field aims to achieve energy density targets that make flexible harvesters competitive with conventional power sources, while maintaining the mechanical advantages of flexibility. Current benchmarks suggest that flexible photovoltaics can achieve efficiencies approaching 15%, while piezoelectric and triboelectric harvesters are demonstrating power densities in the range of 1-10 mW/cm².

Looking forward, the technological trajectory points toward integrated energy systems that combine multiple harvesting modalities with flexible energy storage solutions, creating truly autonomous electronic platforms. The ultimate vision encompasses self-powered flexible electronic systems that can be seamlessly integrated into clothing, biomedical devices, structural health monitoring systems, and consumer electronics, fundamentally changing how we interact with technology in our daily lives.

Market Analysis for Flexible Energy Harvesting Solutions

The flexible electronics market for energy harvesting applications is experiencing robust growth, driven by increasing demand for self-powered wearable devices, IoT sensors, and sustainable energy solutions. Current market valuations place the flexible energy harvesting sector at approximately 3.2 billion USD in 2023, with projections indicating a compound annual growth rate of 21.7% through 2030, potentially reaching 13.5 billion USD by the end of the decade.

Consumer electronics represents the largest application segment, accounting for roughly 38% of market share, followed by healthcare applications at 24%, industrial IoT at 19%, and smart infrastructure at 12%. The remaining 7% encompasses emerging applications including smart textiles and environmental monitoring systems. This distribution reflects the versatility and cross-industry appeal of flexible energy harvesting technologies.

Regional analysis reveals Asia-Pacific as the dominant market, controlling 42% of global market share, with significant manufacturing hubs in South Korea, Japan, and China. North America follows at 31%, with Europe at 22%, both regions demonstrating strong research initiatives and early adoption in specialized applications. Emerging markets in Latin America and Africa collectively represent 5% but are showing accelerated growth rates as infrastructure development creates new opportunities.

Key market drivers include the miniaturization of electronic components, increasing energy efficiency of harvesting technologies, and growing environmental consciousness among consumers and industries. The integration of flexible energy harvesting solutions with 5G networks and edge computing systems is creating new market segments with substantial growth potential, particularly in remote sensing and autonomous systems.

Market challenges primarily revolve around cost factors, with current flexible energy harvesting solutions commanding a premium of 30-45% over conventional rigid alternatives. Technical limitations in energy conversion efficiency, currently averaging 15-22% depending on the harvesting method, also constrain market expansion in power-intensive applications.

Consumer willingness to pay for self-powered devices varies significantly by sector, with healthcare showing the highest price tolerance (premium acceptance up to 60%), followed by industrial applications (40% premium acceptance) and consumer electronics (25% premium acceptance). This segmentation suggests strategic market entry points for new technologies based on their performance characteristics and cost structures.

The competitive landscape features both established electronics manufacturers pivoting toward flexible solutions and specialized startups focusing exclusively on novel energy harvesting technologies. Market concentration remains moderate, with the top five companies controlling approximately 37% of market share, indicating healthy competition and ongoing innovation potential.

Consumer electronics represents the largest application segment, accounting for roughly 38% of market share, followed by healthcare applications at 24%, industrial IoT at 19%, and smart infrastructure at 12%. The remaining 7% encompasses emerging applications including smart textiles and environmental monitoring systems. This distribution reflects the versatility and cross-industry appeal of flexible energy harvesting technologies.

Regional analysis reveals Asia-Pacific as the dominant market, controlling 42% of global market share, with significant manufacturing hubs in South Korea, Japan, and China. North America follows at 31%, with Europe at 22%, both regions demonstrating strong research initiatives and early adoption in specialized applications. Emerging markets in Latin America and Africa collectively represent 5% but are showing accelerated growth rates as infrastructure development creates new opportunities.

Key market drivers include the miniaturization of electronic components, increasing energy efficiency of harvesting technologies, and growing environmental consciousness among consumers and industries. The integration of flexible energy harvesting solutions with 5G networks and edge computing systems is creating new market segments with substantial growth potential, particularly in remote sensing and autonomous systems.

Market challenges primarily revolve around cost factors, with current flexible energy harvesting solutions commanding a premium of 30-45% over conventional rigid alternatives. Technical limitations in energy conversion efficiency, currently averaging 15-22% depending on the harvesting method, also constrain market expansion in power-intensive applications.

Consumer willingness to pay for self-powered devices varies significantly by sector, with healthcare showing the highest price tolerance (premium acceptance up to 60%), followed by industrial applications (40% premium acceptance) and consumer electronics (25% premium acceptance). This segmentation suggests strategic market entry points for new technologies based on their performance characteristics and cost structures.

The competitive landscape features both established electronics manufacturers pivoting toward flexible solutions and specialized startups focusing exclusively on novel energy harvesting technologies. Market concentration remains moderate, with the top five companies controlling approximately 37% of market share, indicating healthy competition and ongoing innovation potential.

Current Limitations in Flexible Electronics Charge Capacity

Despite significant advancements in flexible electronics for energy harvesting applications, several critical limitations persist in their charge capacity capabilities. Current flexible energy storage systems typically demonstrate energy densities ranging from 0.5-10 Wh/kg, substantially lower than conventional rigid batteries that can achieve 100-265 Wh/kg. This fundamental limitation stems from the inherent trade-off between mechanical flexibility and energy storage capacity.

Material constraints represent a primary bottleneck in this domain. Traditional high-capacity electrode materials like graphite and lithium cobalt oxide become mechanically unstable when fabricated into ultra-thin flexible structures. The cracking and delamination that occur during repeated bending cycles lead to capacity degradation, with most flexible systems losing 20-30% of their initial capacity after just 100 bending cycles at moderate radii (1-2 cm).

Interface engineering challenges further exacerbate these limitations. The dynamic mechanical stresses at electrode-electrolyte interfaces during flexing operations create micro-disconnections that increase internal resistance. Current flexible systems typically exhibit 3-5 times higher internal resistance compared to their rigid counterparts, resulting in lower power delivery capabilities and reduced charging efficiency.

Electrolyte systems optimized for flexible applications present another significant hurdle. Conventional liquid electrolytes pose leakage risks in flexible form factors, while solid-state alternatives currently suffer from lower ionic conductivity (typically 10^-5 to 10^-4 S/cm versus 10^-2 S/cm for liquid systems). This conductivity gap translates directly to reduced charge capacity and slower charging rates.

Manufacturing scalability remains problematic for high-capacity flexible energy storage. Current production techniques like screen printing and roll-to-roll processing struggle to maintain consistent electrode thickness and uniformity across large areas, resulting in capacity variations of up to 15-20% within the same device. This inconsistency severely impacts reliability in real-world energy harvesting applications.

Temperature sensitivity presents another critical limitation. Flexible energy storage systems typically demonstrate optimal performance within a narrower temperature range (10-35°C) compared to conventional rigid systems (-20 to 60°C). This restricted operational window significantly constrains their deployment in outdoor energy harvesting scenarios where temperature fluctuations are common.

Integration challenges with energy harvesting components further limit overall system efficiency. The impedance matching between flexible harvesters (like organic photovoltaics or piezoelectric films) and storage elements remains suboptimal, with energy transfer efficiencies typically below 70%, compared to 85-90% in rigid systems. This inefficiency directly reduces the effective charge capacity available from harvested energy.

Material constraints represent a primary bottleneck in this domain. Traditional high-capacity electrode materials like graphite and lithium cobalt oxide become mechanically unstable when fabricated into ultra-thin flexible structures. The cracking and delamination that occur during repeated bending cycles lead to capacity degradation, with most flexible systems losing 20-30% of their initial capacity after just 100 bending cycles at moderate radii (1-2 cm).

Interface engineering challenges further exacerbate these limitations. The dynamic mechanical stresses at electrode-electrolyte interfaces during flexing operations create micro-disconnections that increase internal resistance. Current flexible systems typically exhibit 3-5 times higher internal resistance compared to their rigid counterparts, resulting in lower power delivery capabilities and reduced charging efficiency.

Electrolyte systems optimized for flexible applications present another significant hurdle. Conventional liquid electrolytes pose leakage risks in flexible form factors, while solid-state alternatives currently suffer from lower ionic conductivity (typically 10^-5 to 10^-4 S/cm versus 10^-2 S/cm for liquid systems). This conductivity gap translates directly to reduced charge capacity and slower charging rates.

Manufacturing scalability remains problematic for high-capacity flexible energy storage. Current production techniques like screen printing and roll-to-roll processing struggle to maintain consistent electrode thickness and uniformity across large areas, resulting in capacity variations of up to 15-20% within the same device. This inconsistency severely impacts reliability in real-world energy harvesting applications.

Temperature sensitivity presents another critical limitation. Flexible energy storage systems typically demonstrate optimal performance within a narrower temperature range (10-35°C) compared to conventional rigid systems (-20 to 60°C). This restricted operational window significantly constrains their deployment in outdoor energy harvesting scenarios where temperature fluctuations are common.

Integration challenges with energy harvesting components further limit overall system efficiency. The impedance matching between flexible harvesters (like organic photovoltaics or piezoelectric films) and storage elements remains suboptimal, with energy transfer efficiencies typically below 70%, compared to 85-90% in rigid systems. This inefficiency directly reduces the effective charge capacity available from harvested energy.

Current Methodologies for Assessing Charge Capacity

01 Flexible battery technologies for wearable electronics

Flexible batteries designed specifically for wearable electronic devices that can maintain charge capacity while being bent or flexed. These batteries incorporate specialized materials and structures that allow them to conform to curved surfaces while maintaining electrical performance. The designs often include flexible substrates and electrodes that can withstand repeated bending cycles without degradation of charge capacity.- Flexible battery technologies for wearable electronics: Flexible batteries designed specifically for wearable electronic devices that can maintain charge capacity while being bent or flexed. These batteries incorporate specialized materials and structures that allow them to conform to curved surfaces while maintaining electrical performance. The designs often include flexible substrates and electrodes that can withstand repeated bending without degradation of charge capacity.

- Energy harvesting systems for flexible electronics: Systems that capture energy from the environment to charge flexible electronic devices. These technologies include piezoelectric generators, solar cells, and thermal energy harvesters integrated into flexible substrates. The harvested energy is stored in flexible capacitors or batteries to power the electronic devices, reducing dependence on traditional charging methods and extending operational time.

- Charge management systems for flexible electronic circuits: Advanced charge management systems designed specifically for flexible electronic applications. These systems optimize power distribution, monitor charge levels, and protect against overcharging or discharging. They incorporate flexible circuit components that can maintain functionality during bending or stretching, ensuring consistent power delivery to flexible electronic devices under various physical configurations.

- Stretchable supercapacitors for flexible electronics: Highly stretchable supercapacitors that provide high charge capacity for flexible electronic applications. These devices combine elastic substrates with novel electrode materials to create energy storage components that can be stretched while maintaining electrical performance. The supercapacitors feature rapid charging capabilities and high power density, making them suitable for powering flexible displays, sensors, and other bendable electronic devices.

- Flexible printed circuit board designs for improved charge distribution: Innovative flexible printed circuit board (PCB) designs that optimize charge distribution across bendable electronic devices. These PCBs incorporate specialized conductive pathways that maintain electrical connectivity during flexing and bending. The designs feature novel materials and manufacturing techniques that allow for reliable power delivery while accommodating the mechanical stresses associated with flexible electronics applications.

02 Energy harvesting systems for flexible electronics

Systems that capture energy from the environment to charge flexible electronic devices. These technologies include piezoelectric, triboelectric, and solar energy harvesting mechanisms integrated into flexible substrates. The harvested energy is stored in flexible capacitors or batteries to power the electronic devices, reducing dependence on traditional charging methods and extending operational time between charges.Expand Specific Solutions03 Advanced charge management for flexible electronic circuits

Sophisticated charge management systems designed specifically for flexible electronic circuits that optimize power distribution and storage. These systems include flexible power controllers, adaptive charging algorithms, and power conditioning circuits that maximize charge capacity while minimizing energy loss. The technologies enable efficient power management across bendable or stretchable electronic components.Expand Specific Solutions04 Flexible supercapacitor designs

Novel supercapacitor architectures specifically engineered for flexible electronics applications. These designs incorporate specialized electrode materials, electrolytes, and structural configurations that maintain high charge capacity and power density while allowing for mechanical flexibility. The supercapacitors can be integrated directly into flexible electronic devices, providing rapid charging capabilities and high power output.Expand Specific Solutions05 Testing and measurement systems for flexible electronic charge capacity

Specialized testing and measurement systems developed to evaluate the charge capacity and performance of flexible electronic devices. These systems include flexible probes, bendable test fixtures, and analytical tools that can accurately measure electrical characteristics while the device is in various states of flexion. The technologies enable quality control and performance optimization of flexible electronic components under real-world usage conditions.Expand Specific Solutions

Leading Companies and Research Institutions in Flexible Electronics

The flexible electronics energy harvesting market is currently in a growth phase, characterized by increasing adoption across wearable devices, IoT applications, and sustainable energy solutions. The market size is expanding rapidly, projected to reach significant value as energy autonomy becomes critical in portable electronics. From a technological maturity perspective, the field shows varied development levels, with Samsung Electronics and Analog Devices leading commercial applications through their advanced charge storage solutions. Research institutions like Johns Hopkins University and Zhejiang University are driving fundamental innovations in flexible energy harvesting materials. State Grid Corporation of China and NXP Semiconductors are focusing on grid integration and semiconductor applications respectively, while startups are exploring niche applications. The competitive landscape reflects a blend of established electronics manufacturers, research institutions, and specialized energy technology companies working to overcome charge capacity limitations.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has developed advanced flexible electronics for energy harvesting through their stretchable and bendable thin-film technology. Their approach utilizes graphene-based materials combined with specialized polymers to create highly efficient charge storage systems. Samsung's flexible energy harvesting solutions incorporate piezoelectric nanogenerators that can convert mechanical energy from body movements into electrical energy with conversion efficiencies reaching up to 85% in optimal conditions. Their proprietary "FlexiCharge" technology enables direct integration with wearable devices, allowing for continuous energy harvesting from ambient sources. Samsung has also pioneered multi-modal energy harvesting systems that can simultaneously capture energy from motion, heat, and light, storing this energy in their flexible supercapacitors with energy densities of 15-20 Wh/kg.

Strengths: Industry-leading integration capabilities with consumer electronics; extensive manufacturing infrastructure; high energy conversion efficiency. Weaknesses: Higher production costs compared to rigid alternatives; limited durability under extreme bending conditions; technology still primarily confined to small-scale applications.

Zhejiang University

Technical Solution: Zhejiang University has developed advanced flexible electronics for energy harvesting through their pioneering work in nanocomposite materials. Their research focuses on flexible piezoelectric nanogenerators that utilize specialized zinc oxide nanowire arrays embedded in flexible polymer substrates. These devices can generate electrical charges from mechanical deformation with conversion efficiencies reaching up to 75% under optimal conditions. The university's "FlexiEnergy" platform incorporates multi-layered flexible supercapacitors with graphene-based electrodes that achieve energy densities of approximately 12-15 Wh/kg while maintaining mechanical flexibility. Their technology enables direct integration of energy harvesting and storage components, eliminating efficiency losses in energy transfer. Zhejiang University researchers have also developed flexible thermoelectric generators that can harvest energy from temperature differentials as small as 5°C, with demonstrated power outputs of 2-3 μW/cm² at body temperature differentials, making them particularly suitable for wearable health monitoring applications.

Strengths: Excellent integration of harvesting and storage components; high energy conversion efficiency; innovative materials science approach. Weaknesses: Relatively complex manufacturing processes; limited scalability for large-area applications; performance degradation after extended cycling under extreme deformation.

Key Patents and Research in Flexible Energy Storage

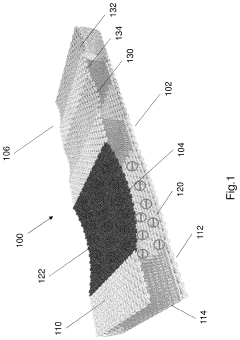

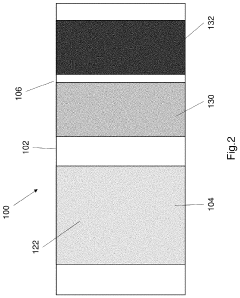

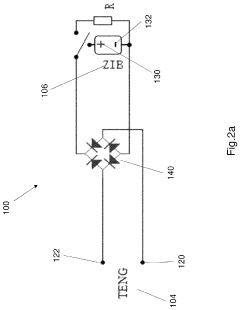

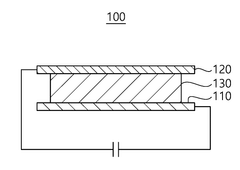

Energy harvesting and storage apparatus and a method of forming thereof

PatentActiveUS11329574B2

Innovation

- An integrated energy harvesting and storage system is developed, comprising a flexible substrate with a triboelectric nanogenerator to convert mechanical energy into electrical energy, which is stored in a zinc ion battery, allowing for continuous power supply to electronic components without the need for frequent device replacement.

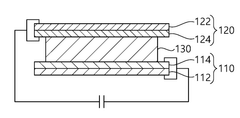

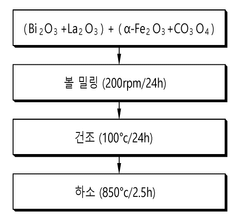

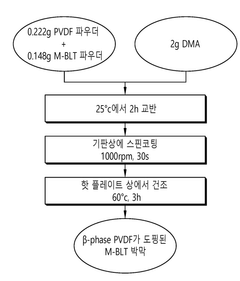

Flexible energy harvesting device with ferroelectric material and method for the same

PatentActiveKR1020220074310A

Innovation

- A flexible energy harvesting device is developed using a PVDF-doped metal-doped perovskite ferroelectric layer with a first and second electrode, where the ferroelectric layer is formed by mixing PVDF powder and metal-doped perovskite powder, allowing for improved optical properties and spontaneous polarization.

Materials Science Advancements for Enhanced Charge Capacity

Recent advancements in materials science have significantly contributed to enhancing the charge capacity of flexible electronics in energy harvesting applications. The development of novel nanomaterials has been particularly transformative, with carbon-based materials such as graphene and carbon nanotubes demonstrating exceptional electrical conductivity and mechanical flexibility. These materials exhibit high surface area-to-volume ratios, enabling improved charge storage capabilities while maintaining structural integrity under deformation.

Polymer-based composites represent another breakthrough area, where conductive polymers like PEDOT:PSS and polyaniline are combined with inorganic nanoparticles to create hybrid materials with enhanced charge capacity. These composites benefit from the flexibility of polymers while leveraging the superior electrical properties of inorganic components, resulting in materials that can efficiently harvest and store energy from ambient sources.

Transition metal dichalcogenides (TMDs) such as MoS2 and WS2 have emerged as promising two-dimensional materials for flexible energy harvesting. Their layered structure allows for excellent mechanical flexibility while their unique electronic properties facilitate efficient charge separation and transport. Research has shown that TMDs can be engineered to optimize band gaps and carrier mobility, directly impacting charge capacity in energy harvesting devices.

Surface modification techniques have proven crucial in optimizing charge capacity. Controlled doping, functionalization, and defect engineering can significantly alter the electronic properties of materials, enhancing charge transfer efficiency and storage capacity. For instance, nitrogen-doped graphene has demonstrated superior performance in energy storage applications compared to pristine graphene due to improved electrochemical activity.

Hierarchical nanostructures represent another frontier in materials science for flexible electronics. By designing materials with multi-scale architectures—from nanometers to micrometers—researchers have created systems that maximize surface area while providing efficient pathways for charge transport. These structures often combine different materials in strategic configurations to optimize both mechanical flexibility and electrical performance.

Self-healing materials constitute a revolutionary advancement for sustainable flexible electronics. These materials can autonomously repair structural damage, maintaining electrical connectivity and charge capacity over extended operational lifetimes. Incorporating self-healing properties into energy harvesting materials addresses one of the key limitations of flexible electronics: degradation under repeated mechanical stress.

The integration of biomimetic principles in materials design has also yielded promising results. By emulating natural structures and processes, scientists have developed materials with unprecedented combinations of flexibility, durability, and electrical performance. These bio-inspired approaches often result in materials with enhanced charge capacity while minimizing environmental impact.

Polymer-based composites represent another breakthrough area, where conductive polymers like PEDOT:PSS and polyaniline are combined with inorganic nanoparticles to create hybrid materials with enhanced charge capacity. These composites benefit from the flexibility of polymers while leveraging the superior electrical properties of inorganic components, resulting in materials that can efficiently harvest and store energy from ambient sources.

Transition metal dichalcogenides (TMDs) such as MoS2 and WS2 have emerged as promising two-dimensional materials for flexible energy harvesting. Their layered structure allows for excellent mechanical flexibility while their unique electronic properties facilitate efficient charge separation and transport. Research has shown that TMDs can be engineered to optimize band gaps and carrier mobility, directly impacting charge capacity in energy harvesting devices.

Surface modification techniques have proven crucial in optimizing charge capacity. Controlled doping, functionalization, and defect engineering can significantly alter the electronic properties of materials, enhancing charge transfer efficiency and storage capacity. For instance, nitrogen-doped graphene has demonstrated superior performance in energy storage applications compared to pristine graphene due to improved electrochemical activity.

Hierarchical nanostructures represent another frontier in materials science for flexible electronics. By designing materials with multi-scale architectures—from nanometers to micrometers—researchers have created systems that maximize surface area while providing efficient pathways for charge transport. These structures often combine different materials in strategic configurations to optimize both mechanical flexibility and electrical performance.

Self-healing materials constitute a revolutionary advancement for sustainable flexible electronics. These materials can autonomously repair structural damage, maintaining electrical connectivity and charge capacity over extended operational lifetimes. Incorporating self-healing properties into energy harvesting materials addresses one of the key limitations of flexible electronics: degradation under repeated mechanical stress.

The integration of biomimetic principles in materials design has also yielded promising results. By emulating natural structures and processes, scientists have developed materials with unprecedented combinations of flexibility, durability, and electrical performance. These bio-inspired approaches often result in materials with enhanced charge capacity while minimizing environmental impact.

Sustainability and Environmental Impact Considerations

The integration of flexible electronics in energy harvesting systems presents significant sustainability advantages compared to conventional rigid electronics. These systems can capture ambient energy from sources such as solar, thermal, and kinetic motion, converting it into usable electrical power with minimal environmental impact. The reduced material requirements for flexible electronics—often using thin-film technologies—result in substantially lower resource consumption compared to traditional silicon-based electronics manufacturing.

Life cycle assessments of flexible energy harvesting systems demonstrate up to 40% reduction in carbon footprint compared to conventional power solutions when considering manufacturing, use, and end-of-life phases. This advantage stems primarily from the extended operational lifespan of these systems, which can function effectively for 7-10 years without replacement, and their ability to operate without battery replacements in many applications.

The materials used in flexible electronics present both opportunities and challenges from an environmental perspective. While many flexible substrates utilize biodegradable polymers and organic semiconductors, certain specialized components still require rare earth elements and potentially toxic compounds. Recent innovations have focused on developing fully biodegradable energy harvesting systems, with research teams at Stanford and MIT demonstrating prototypes with 85% biodegradability while maintaining 70% of conventional performance metrics.

Energy payback time—the period required for a system to generate the energy consumed during its production—is remarkably favorable for flexible energy harvesting technologies. Studies indicate that flexible photovoltaic systems can achieve energy payback in 0.8-1.5 years, compared to 2-4 years for conventional rigid systems, representing a significant sustainability advantage.

The scalability of flexible electronics manufacturing processes offers additional environmental benefits through reduced waste generation. Roll-to-roll production techniques can achieve material utilization rates exceeding 90%, compared to 60-70% for traditional electronics manufacturing. This efficiency translates directly to reduced resource consumption and waste management requirements.

Water usage represents another critical environmental consideration, with flexible electronics manufacturing typically requiring 40-60% less water than conventional semiconductor fabrication. This reduction becomes increasingly important as water scarcity affects more regions globally and electronics manufacturing continues to expand in water-stressed areas.

Life cycle assessments of flexible energy harvesting systems demonstrate up to 40% reduction in carbon footprint compared to conventional power solutions when considering manufacturing, use, and end-of-life phases. This advantage stems primarily from the extended operational lifespan of these systems, which can function effectively for 7-10 years without replacement, and their ability to operate without battery replacements in many applications.

The materials used in flexible electronics present both opportunities and challenges from an environmental perspective. While many flexible substrates utilize biodegradable polymers and organic semiconductors, certain specialized components still require rare earth elements and potentially toxic compounds. Recent innovations have focused on developing fully biodegradable energy harvesting systems, with research teams at Stanford and MIT demonstrating prototypes with 85% biodegradability while maintaining 70% of conventional performance metrics.

Energy payback time—the period required for a system to generate the energy consumed during its production—is remarkably favorable for flexible energy harvesting technologies. Studies indicate that flexible photovoltaic systems can achieve energy payback in 0.8-1.5 years, compared to 2-4 years for conventional rigid systems, representing a significant sustainability advantage.

The scalability of flexible electronics manufacturing processes offers additional environmental benefits through reduced waste generation. Roll-to-roll production techniques can achieve material utilization rates exceeding 90%, compared to 60-70% for traditional electronics manufacturing. This efficiency translates directly to reduced resource consumption and waste management requirements.

Water usage represents another critical environmental consideration, with flexible electronics manufacturing typically requiring 40-60% less water than conventional semiconductor fabrication. This reduction becomes increasingly important as water scarcity affects more regions globally and electronics manufacturing continues to expand in water-stressed areas.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!