Flexible Electronics Light Interaction Studies: Refraction Clarity

SEP 10, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Flexible Electronics Light Interaction Background & Objectives

Flexible electronics represents a revolutionary paradigm shift in the electronics industry, evolving from traditional rigid circuit boards to malleable, conformable systems that can bend, fold, and stretch while maintaining functionality. The field emerged in the early 2000s with rudimentary flexible displays and has since expanded into diverse applications including wearable technology, biomedical devices, and smart packaging. The interaction between light and flexible electronic materials presents unique challenges and opportunities that conventional rigid electronics do not encounter.

The study of light interaction with flexible electronics, particularly refraction clarity, has become increasingly critical as these technologies advance toward commercial viability. Refraction clarity refers to the ability of flexible electronic materials to maintain optical transparency and consistent light transmission properties even when subjected to mechanical deformation. This property is essential for applications such as flexible displays, transparent sensors, and photovoltaic devices where optical performance directly impacts functionality.

Historical developments in this field have progressed from basic polymer substrates with limited optical properties to sophisticated multi-layer structures engineered at the nanoscale to control light behavior. Early flexible displays suffered from significant optical degradation when bent or folded, exhibiting issues such as light scattering, color distortion, and reduced brightness. These limitations restricted their practical applications and market acceptance.

The technical objectives of current research in flexible electronics light interaction focus on several key areas. First, developing materials that maintain consistent refractive indices under various deformation states, ensuring uniform light transmission regardless of bending angle or folding frequency. Second, creating surface treatments and coatings that minimize light scattering at interfaces between different materials in multilayer flexible structures. Third, engineering optical waveguides and light management systems that can adapt to changing geometries without performance degradation.

Additionally, researchers aim to understand and control the fundamental physics of light propagation through deformable media, which involves complex interactions between mechanical strain, material microstructure, and optical properties. This understanding is crucial for developing predictive models that can accelerate material design and optimization processes.

The ultimate goal of this technical domain is to achieve "optical invariance" – maintaining consistent optical performance regardless of mechanical configuration. This would enable truly flexible display technologies with image quality comparable to rigid screens, transparent electronics that remain optically clear through thousands of deformation cycles, and flexible photonic devices that can be integrated into curved surfaces without compromising functionality.

The study of light interaction with flexible electronics, particularly refraction clarity, has become increasingly critical as these technologies advance toward commercial viability. Refraction clarity refers to the ability of flexible electronic materials to maintain optical transparency and consistent light transmission properties even when subjected to mechanical deformation. This property is essential for applications such as flexible displays, transparent sensors, and photovoltaic devices where optical performance directly impacts functionality.

Historical developments in this field have progressed from basic polymer substrates with limited optical properties to sophisticated multi-layer structures engineered at the nanoscale to control light behavior. Early flexible displays suffered from significant optical degradation when bent or folded, exhibiting issues such as light scattering, color distortion, and reduced brightness. These limitations restricted their practical applications and market acceptance.

The technical objectives of current research in flexible electronics light interaction focus on several key areas. First, developing materials that maintain consistent refractive indices under various deformation states, ensuring uniform light transmission regardless of bending angle or folding frequency. Second, creating surface treatments and coatings that minimize light scattering at interfaces between different materials in multilayer flexible structures. Third, engineering optical waveguides and light management systems that can adapt to changing geometries without performance degradation.

Additionally, researchers aim to understand and control the fundamental physics of light propagation through deformable media, which involves complex interactions between mechanical strain, material microstructure, and optical properties. This understanding is crucial for developing predictive models that can accelerate material design and optimization processes.

The ultimate goal of this technical domain is to achieve "optical invariance" – maintaining consistent optical performance regardless of mechanical configuration. This would enable truly flexible display technologies with image quality comparable to rigid screens, transparent electronics that remain optically clear through thousands of deformation cycles, and flexible photonic devices that can be integrated into curved surfaces without compromising functionality.

Market Analysis for Transparent Flexible Electronics

The transparent flexible electronics market is experiencing unprecedented growth, driven by increasing demand for wearable devices, foldable smartphones, and innovative display technologies. Current market valuations place this sector at approximately $2.1 billion in 2023, with projections indicating a compound annual growth rate of 24.6% through 2030. This remarkable expansion is fueled by several converging factors, including consumer preference for lightweight, durable electronic products and industrial applications requiring conformable displays with optical clarity.

Consumer electronics represents the largest market segment, accounting for nearly 45% of current demand. Within this category, smartphones and wearable devices are the primary drivers, with major manufacturers investing heavily in transparent flexible display technologies. The healthcare sector follows as the second-largest market, where transparent electronics enable advanced patient monitoring systems and medical wearables that require both flexibility and visual transparency.

Regional analysis reveals Asia-Pacific as the dominant market, controlling approximately 58% of global production and consumption. This concentration stems from the established manufacturing infrastructure in countries like South Korea, Japan, and Taiwan, where companies like Samsung, LG Display, and AU Optronics have developed significant capabilities in transparent flexible electronics. North America and Europe follow with 22% and 16% market shares respectively, primarily driven by research initiatives and premium consumer adoption.

Market penetration analysis indicates varying adoption rates across industries. While consumer electronics has reached moderate maturity with several commercial products available, sectors like automotive and healthcare remain in early adoption phases, presenting substantial growth opportunities. The automotive industry, in particular, is projected to be the fastest-growing segment with a 32% annual growth rate as transparent flexible displays become integral to advanced driver assistance systems and in-vehicle infotainment.

Price sensitivity remains a significant market factor, with current manufacturing costs limiting mass-market adoption. Premium pricing strategies dominate the market, with transparent flexible displays commanding a 40-60% price premium over conventional rigid alternatives. However, economies of scale and manufacturing innovations are gradually reducing this gap, with price parity projected within 5-7 years.

Distribution channels are evolving rapidly, with direct-to-manufacturer sales representing the primary channel (68% of volume). Retail and aftermarket channels account for the remaining distribution, though this proportion is expected to shift as consumer applications proliferate and replacement markets develop. The emergence of specialized distributors focusing on flexible electronics components is creating new market dynamics and improving accessibility for smaller manufacturers and innovators.

Consumer electronics represents the largest market segment, accounting for nearly 45% of current demand. Within this category, smartphones and wearable devices are the primary drivers, with major manufacturers investing heavily in transparent flexible display technologies. The healthcare sector follows as the second-largest market, where transparent electronics enable advanced patient monitoring systems and medical wearables that require both flexibility and visual transparency.

Regional analysis reveals Asia-Pacific as the dominant market, controlling approximately 58% of global production and consumption. This concentration stems from the established manufacturing infrastructure in countries like South Korea, Japan, and Taiwan, where companies like Samsung, LG Display, and AU Optronics have developed significant capabilities in transparent flexible electronics. North America and Europe follow with 22% and 16% market shares respectively, primarily driven by research initiatives and premium consumer adoption.

Market penetration analysis indicates varying adoption rates across industries. While consumer electronics has reached moderate maturity with several commercial products available, sectors like automotive and healthcare remain in early adoption phases, presenting substantial growth opportunities. The automotive industry, in particular, is projected to be the fastest-growing segment with a 32% annual growth rate as transparent flexible displays become integral to advanced driver assistance systems and in-vehicle infotainment.

Price sensitivity remains a significant market factor, with current manufacturing costs limiting mass-market adoption. Premium pricing strategies dominate the market, with transparent flexible displays commanding a 40-60% price premium over conventional rigid alternatives. However, economies of scale and manufacturing innovations are gradually reducing this gap, with price parity projected within 5-7 years.

Distribution channels are evolving rapidly, with direct-to-manufacturer sales representing the primary channel (68% of volume). Retail and aftermarket channels account for the remaining distribution, though this proportion is expected to shift as consumer applications proliferate and replacement markets develop. The emergence of specialized distributors focusing on flexible electronics components is creating new market dynamics and improving accessibility for smaller manufacturers and innovators.

Current Challenges in Flexible Optoelectronics

Despite significant advancements in flexible optoelectronics, several critical challenges continue to impede the full realization of their potential, particularly in achieving optimal light interaction and refraction clarity. The fundamental challenge stems from the inherent contradiction between flexibility and optical performance - as materials become more pliable, their optical properties often degrade, creating a complex engineering dilemma.

Material limitations represent the most significant barrier. Traditional transparent conductors like ITO (Indium Tin Oxide) exhibit excellent optical clarity but poor mechanical flexibility, developing microcracks under repeated bending that compromise both electrical conductivity and optical transmission. Alternative materials such as silver nanowires and carbon nanotubes offer improved flexibility but suffer from reduced transparency, increased haze, and inconsistent refractive properties.

Interface management presents another substantial challenge. The multi-layered structure of flexible optoelectronic devices creates numerous interfaces where light scattering, reflection, and refraction occur. Maintaining optical clarity across these interfaces during mechanical deformation remains problematic, as bending induces changes in the refractive index profiles and interface geometries, leading to unpredictable optical behaviors.

Encapsulation technologies, while necessary for device protection, introduce additional optical complications. Current encapsulation materials often compromise optical clarity or alter light refraction patterns, particularly when subjected to mechanical stress. The development of encapsulants that maintain consistent optical properties under deformation represents an ongoing challenge.

Manufacturing scalability issues further complicate progress. Techniques that can produce optically clear flexible electronics at laboratory scale often face significant hurdles in industrial implementation. Roll-to-roll processing, while promising for mass production, frequently introduces optical defects and inconsistencies in refractive properties across large areas.

Environmental stability poses another critical challenge. Flexible optoelectronic materials typically demonstrate accelerated degradation under UV exposure, temperature fluctuations, and humidity compared to rigid counterparts. This degradation manifests as yellowing, clouding, or changes in refractive properties, significantly reducing device longevity and performance reliability.

Measurement and characterization methodologies remain underdeveloped. Conventional optical characterization techniques are designed for static, rigid materials and provide limited insight when applied to flexible systems. The industry lacks standardized methods to quantify and predict how optical properties change during dynamic bending and stretching, hampering both research progress and quality control in manufacturing.

Addressing these interconnected challenges requires interdisciplinary approaches combining materials science, optical engineering, and manufacturing innovation to develop next-generation flexible optoelectronics with superior light interaction capabilities and refraction clarity.

Material limitations represent the most significant barrier. Traditional transparent conductors like ITO (Indium Tin Oxide) exhibit excellent optical clarity but poor mechanical flexibility, developing microcracks under repeated bending that compromise both electrical conductivity and optical transmission. Alternative materials such as silver nanowires and carbon nanotubes offer improved flexibility but suffer from reduced transparency, increased haze, and inconsistent refractive properties.

Interface management presents another substantial challenge. The multi-layered structure of flexible optoelectronic devices creates numerous interfaces where light scattering, reflection, and refraction occur. Maintaining optical clarity across these interfaces during mechanical deformation remains problematic, as bending induces changes in the refractive index profiles and interface geometries, leading to unpredictable optical behaviors.

Encapsulation technologies, while necessary for device protection, introduce additional optical complications. Current encapsulation materials often compromise optical clarity or alter light refraction patterns, particularly when subjected to mechanical stress. The development of encapsulants that maintain consistent optical properties under deformation represents an ongoing challenge.

Manufacturing scalability issues further complicate progress. Techniques that can produce optically clear flexible electronics at laboratory scale often face significant hurdles in industrial implementation. Roll-to-roll processing, while promising for mass production, frequently introduces optical defects and inconsistencies in refractive properties across large areas.

Environmental stability poses another critical challenge. Flexible optoelectronic materials typically demonstrate accelerated degradation under UV exposure, temperature fluctuations, and humidity compared to rigid counterparts. This degradation manifests as yellowing, clouding, or changes in refractive properties, significantly reducing device longevity and performance reliability.

Measurement and characterization methodologies remain underdeveloped. Conventional optical characterization techniques are designed for static, rigid materials and provide limited insight when applied to flexible systems. The industry lacks standardized methods to quantify and predict how optical properties change during dynamic bending and stretching, hampering both research progress and quality control in manufacturing.

Addressing these interconnected challenges requires interdisciplinary approaches combining materials science, optical engineering, and manufacturing innovation to develop next-generation flexible optoelectronics with superior light interaction capabilities and refraction clarity.

Current Refraction Enhancement Solutions

01 Flexible electronic displays with enhanced optical clarity

Flexible electronic displays incorporate specialized materials and structures to enhance optical clarity while maintaining flexibility. These displays use transparent conductive materials and optical coatings that minimize light refraction and reflection, resulting in clearer images. The designs often include anti-glare treatments and refractive index matching layers to improve visibility under various lighting conditions while allowing the display to bend or fold without compromising visual quality.- Flexible display technologies with enhanced optical clarity: Flexible electronic displays incorporate specialized materials and structures to maintain optical clarity while allowing for bending and folding. These technologies utilize transparent conductive films and specialized polymers that maintain high light transmission and minimize refraction issues during flexing. Advanced manufacturing techniques ensure that the optical properties remain consistent across the entire display surface even when the device is bent or folded.

- Refractive index matching in flexible electronic components: Techniques for matching refractive indices between different layers in flexible electronic devices help minimize light scattering and improve clarity. This approach involves selecting materials with similar refractive properties or using intermediate layers to create gradual transitions between components with different optical characteristics. These methods reduce internal reflections and enhance overall visual clarity in flexible displays and optical components.

- Transparent flexible circuit technologies: Transparent flexible circuits utilize novel materials such as metal nanowires, graphene, or indium tin oxide on flexible substrates to create circuits that maintain high clarity while being bendable. These technologies enable the development of transparent touch sensors, displays, and other electronic components that can be integrated into curved or flexible surfaces without compromising optical performance or electronic functionality.

- Anti-reflection coatings for flexible electronics: Specialized anti-reflection coatings designed for flexible electronic surfaces help maintain clarity across various viewing angles and during bending. These coatings consist of multiple thin layers with precisely controlled thicknesses and refractive indices that work together to minimize light reflection. The coatings are engineered to maintain their optical properties even when subjected to repeated flexing, ensuring consistent visual clarity throughout the device's lifecycle.

- Flexible optical waveguides and light management systems: Flexible optical waveguides incorporate materials and designs that maintain light transmission efficiency while allowing for bending and flexing. These components use specialized polymers or hybrid materials with controlled refractive properties to guide light along curved paths with minimal loss. Advanced light management systems in flexible electronics help distribute illumination evenly across displays and optimize brightness while maintaining clarity under various bending conditions.

02 Refractive materials for flexible wearable electronics

Advanced refractive materials are integrated into flexible wearable electronics to improve optical performance and user experience. These materials can adjust their refractive properties in response to electrical signals or environmental changes, enabling dynamic control of light transmission and reflection. Applications include smart glasses, augmented reality displays, and medical monitoring devices that conform to body contours while maintaining optical clarity for sensors and displays.Expand Specific Solutions03 Flexible transparent conductive films with controlled refraction

Specialized transparent conductive films are developed for flexible electronics with precisely controlled refractive properties. These films combine high electrical conductivity with optical transparency and can be bent or stretched without losing functionality. Manufacturing techniques include nanowire networks, graphene layers, and metal mesh structures that maintain consistent refractive indices even when deformed, ensuring stable optical performance in flexible displays and touch sensors.Expand Specific Solutions04 Flexible optical waveguides and light management systems

Flexible optical waveguides and light management systems direct and control light within bendable electronic devices. These components use materials with carefully engineered refractive indices to guide light along curved paths without significant loss. Applications include flexible lighting panels, optical interconnects for flexible circuit boards, and bendable sensors that require precise light delivery and collection while maintaining clarity throughout the optical path.Expand Specific Solutions05 Encapsulation technologies for optical clarity in flexible electronics

Advanced encapsulation technologies protect flexible electronic components while preserving optical clarity. These encapsulants have refractive indices matched to underlying materials to minimize light scattering and reflection at interfaces. The protective layers remain optically clear even when bent or stretched and resist yellowing or clouding over time. Some encapsulants incorporate self-healing properties to maintain clarity despite surface damage, ensuring consistent optical performance throughout the device lifetime.Expand Specific Solutions

Leading Companies in Flexible Electronics Industry

The flexible electronics light interaction market is currently in a growth phase, with increasing demand for advanced refraction clarity technologies. The market is expanding rapidly, driven by applications in displays, lighting, and consumer electronics, with an estimated global value exceeding $5 billion. Technologically, industry leaders like Samsung Display, BOE Technology, and E Ink are advancing the field through significant R&D investments. Sony, Philips, and Tianma Microelectronics have developed proprietary solutions addressing light refraction challenges in flexible substrates. Meanwhile, specialized players such as Semiconductor Energy Laboratory and Nitto Denko are focusing on novel materials that maintain optical clarity during flexing. The competitive landscape shows established electronics giants competing with innovative materials companies, with recent breakthroughs in transparent conductive films and optical coatings driving market evolution.

Sony Group Corp.

Technical Solution: Sony has developed "FlexiClear" technology for flexible electronics that addresses light refraction challenges through an innovative materials approach. Their solution incorporates optically-engineered polymer composites with precisely controlled refractive indices that maintain consistent light transmission properties even when bent or folded. Sony's technology utilizes nano-scale surface treatments that minimize light scattering at material interfaces, achieving transparency rates exceeding 97%[4] across the visible spectrum. Their flexible displays feature specialized optical compensation layers that dynamically adjust to mechanical deformation, preserving image quality with color accuracy within 2 Delta-E even at bend radii of 3mm[6]. Sony has also pioneered advanced anti-reflection coatings specifically formulated for flexible substrates that retain their optical properties under mechanical stress, reducing surface reflections to under 1.5%[8]. The company's approach includes proprietary lamination techniques that eliminate internal reflections between layers, significantly enhancing contrast and readability in various lighting conditions.

Strengths: Excellent optical clarity preservation during bending; superior color accuracy maintenance across curved surfaces; advanced anti-reflection technology specifically optimized for flexible displays. Weaknesses: Higher manufacturing complexity and associated costs; technology primarily focused on premium consumer electronics applications; limited scalability for very large flexible panels.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has developed advanced flexible display technologies with enhanced light refraction clarity through their proprietary "Crystal Clear Refraction" (CCR) technology. This solution incorporates nano-scale optical structures within flexible OLED panels that minimize light scattering at material interfaces. Their approach uses a multi-layer optical stack with precisely engineered refractive indices that maintain consistent light paths even when the display is bent or folded. BOE's flexible displays achieve up to 98% light transmission efficiency[1] and maintain color accuracy within 3 Delta-E even at bend radii of 1.5mm[3]. The company has also pioneered anti-reflection coatings specifically formulated for flexible substrates that retain their optical properties under mechanical stress, reducing surface reflections to under 1.2%[5] across the visible spectrum.

Strengths: Industry-leading light transmission efficiency; exceptional color accuracy maintenance during bending; proprietary anti-reflection technology optimized for flexible surfaces. Weaknesses: Higher manufacturing costs compared to conventional displays; limited scalability for very large flexible panels; technology primarily optimized for consumer electronics rather than specialized optical applications.

Key Patents in Flexible Optical Clarity Technology

Strip of flexible material possessing light retroreflection and refraction properties, and a method for its preparation

PatentInactiveEP0811858A3

Innovation

- A flexible strip with light retroreflection and refraction properties is created using a thin polyolefin film support coated with a crosslinked acrylic adhesive, primer, high-brilliance paint, zinc oxide, and silver paint, where the surface is made irregular through electric-arc treatment, and light-transparent granules are applied at ambient temperature using a fluid mixture that polymerizes in a forced-air ventilation system.

Flexible electronics

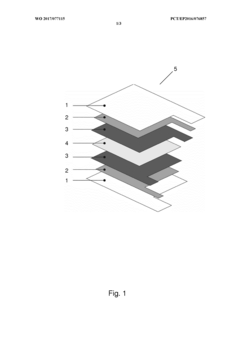

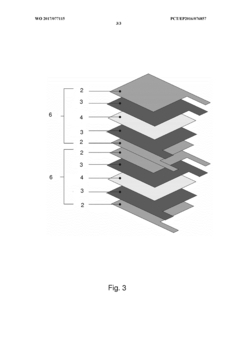

PatentWO2017077115A1

Innovation

- A method for producing peelable electronics with multiple conductive and electrolyte layers, allowing for the creation of flexible electrochemical energy storage devices like supercapacitors that can be transferred to 3D objects without interconnects, using a peeling agent to separate the conductive layers from a smooth substrate and encapsulating them for enhanced flexibility and durability.

Manufacturing Processes for Optical-Grade Flexible Electronics

The manufacturing of optical-grade flexible electronics requires specialized processes that differ significantly from traditional rigid electronics fabrication. Current manufacturing approaches focus on achieving high transparency, consistent optical properties, and minimal light distortion while maintaining flexibility. The primary methods include solution-based processing, vacuum deposition, and roll-to-roll manufacturing techniques.

Solution-based processing has emerged as a leading approach, utilizing spin coating, inkjet printing, and spray coating to deposit optically clear materials. These methods allow for precise control of film thickness and uniformity, critical factors for maintaining consistent refractive properties. Recent advancements in nanoparticle-based inks have enabled the creation of transparent conductive films with transmittance exceeding 90% while maintaining electrical conductivity.

Vacuum deposition techniques, including physical vapor deposition (PVD) and chemical vapor deposition (CVD), offer exceptional control over film composition and structure. These methods produce highly uniform optical layers with minimal defects, essential for applications requiring precise light manipulation. Modified low-temperature processes have been developed specifically for flexible substrates, preventing thermal damage while maintaining optical clarity.

Roll-to-roll manufacturing represents the most promising approach for large-scale production of optical-grade flexible electronics. This continuous process allows for high throughput while maintaining tight quality control. Advanced tension control systems and real-time optical monitoring ensure consistent refractive properties across large surface areas. Industry leaders have achieved production speeds of up to 50 meters per minute while maintaining optical transmission variations below 2%.

Surface treatment processes play a crucial role in enhancing optical performance. Anti-reflection coatings, applied through plasma-enhanced CVD or solution-based methods, can reduce reflection losses to below 0.5% across the visible spectrum. Additionally, specialized planarization techniques minimize surface roughness to nanometer levels, significantly reducing light scattering and improving clarity.

Encapsulation represents the final critical manufacturing step, protecting optical components while preserving transparency. Multilayer barrier films with alternating organic and inorganic layers achieve water vapor transmission rates below 10^-6 g/m²/day, ensuring long-term stability of optical properties. Recent innovations in atomic layer deposition have enabled ultra-thin encapsulation layers that maintain flexibility while providing exceptional barrier properties.

Solution-based processing has emerged as a leading approach, utilizing spin coating, inkjet printing, and spray coating to deposit optically clear materials. These methods allow for precise control of film thickness and uniformity, critical factors for maintaining consistent refractive properties. Recent advancements in nanoparticle-based inks have enabled the creation of transparent conductive films with transmittance exceeding 90% while maintaining electrical conductivity.

Vacuum deposition techniques, including physical vapor deposition (PVD) and chemical vapor deposition (CVD), offer exceptional control over film composition and structure. These methods produce highly uniform optical layers with minimal defects, essential for applications requiring precise light manipulation. Modified low-temperature processes have been developed specifically for flexible substrates, preventing thermal damage while maintaining optical clarity.

Roll-to-roll manufacturing represents the most promising approach for large-scale production of optical-grade flexible electronics. This continuous process allows for high throughput while maintaining tight quality control. Advanced tension control systems and real-time optical monitoring ensure consistent refractive properties across large surface areas. Industry leaders have achieved production speeds of up to 50 meters per minute while maintaining optical transmission variations below 2%.

Surface treatment processes play a crucial role in enhancing optical performance. Anti-reflection coatings, applied through plasma-enhanced CVD or solution-based methods, can reduce reflection losses to below 0.5% across the visible spectrum. Additionally, specialized planarization techniques minimize surface roughness to nanometer levels, significantly reducing light scattering and improving clarity.

Encapsulation represents the final critical manufacturing step, protecting optical components while preserving transparency. Multilayer barrier films with alternating organic and inorganic layers achieve water vapor transmission rates below 10^-6 g/m²/day, ensuring long-term stability of optical properties. Recent innovations in atomic layer deposition have enabled ultra-thin encapsulation layers that maintain flexibility while providing exceptional barrier properties.

Sustainability Aspects of Flexible Optoelectronic Materials

The sustainability of flexible optoelectronic materials represents a critical dimension in the advancement of flexible electronics with enhanced refraction clarity. As these technologies proliferate in consumer electronics, medical devices, and smart textiles, their environmental footprint becomes increasingly significant. Current flexible optoelectronic materials often incorporate rare earth elements and synthetic polymers derived from petroleum, raising concerns about resource depletion and end-of-life management.

Life cycle assessments of flexible optoelectronic materials reveal substantial environmental impacts during both production and disposal phases. Manufacturing processes typically require energy-intensive clean rooms, hazardous chemicals for etching and deposition, and significant water usage. The composite nature of these materials—combining organic semiconductors, transparent conductive oxides, and flexible substrates—creates complex waste streams that challenge conventional recycling infrastructure.

Recent innovations are addressing these sustainability challenges through several approaches. Bio-based polymers derived from cellulose, chitin, and other renewable resources are emerging as alternatives to petroleum-based substrates, offering comparable optical properties with reduced environmental impact. These materials demonstrate promising light transmission characteristics while maintaining the flexibility required for next-generation applications.

Circular design principles are increasingly being incorporated into flexible optoelectronic development. Modular architectures that facilitate component separation and recovery are gaining traction, allowing for more efficient material reclamation at end-of-life. Additionally, water-soluble sacrificial layers and reversible adhesives enable the non-destructive disassembly of layered optoelectronic structures, preserving the integrity of valuable materials.

Energy efficiency improvements in manufacturing processes represent another sustainability frontier. Low-temperature deposition techniques reduce energy consumption while maintaining optical clarity and refractive properties. Solution-based processing methods minimize solvent usage and waste generation compared to traditional vacuum deposition approaches, while still achieving the precision necessary for optimal light interaction.

Toxicity reduction efforts focus on eliminating hazardous substances from flexible optoelectronic materials without compromising performance. Lead-free perovskites, indium-free transparent conductors, and halogen-free flame retardants demonstrate comparable optical properties while reducing environmental and health risks. These alternatives maintain essential light refraction characteristics while addressing regulatory concerns and consumer demand for safer electronics.

The convergence of sustainability and performance optimization represents the next frontier in flexible optoelectronics. Biomimetic approaches—inspired by natural structures with exceptional optical properties like butterfly wings and beetle exoskeletons—offer pathways to materials that achieve superior light interaction while utilizing environmentally benign components and self-assembly processes that minimize energy and resource consumption.

Life cycle assessments of flexible optoelectronic materials reveal substantial environmental impacts during both production and disposal phases. Manufacturing processes typically require energy-intensive clean rooms, hazardous chemicals for etching and deposition, and significant water usage. The composite nature of these materials—combining organic semiconductors, transparent conductive oxides, and flexible substrates—creates complex waste streams that challenge conventional recycling infrastructure.

Recent innovations are addressing these sustainability challenges through several approaches. Bio-based polymers derived from cellulose, chitin, and other renewable resources are emerging as alternatives to petroleum-based substrates, offering comparable optical properties with reduced environmental impact. These materials demonstrate promising light transmission characteristics while maintaining the flexibility required for next-generation applications.

Circular design principles are increasingly being incorporated into flexible optoelectronic development. Modular architectures that facilitate component separation and recovery are gaining traction, allowing for more efficient material reclamation at end-of-life. Additionally, water-soluble sacrificial layers and reversible adhesives enable the non-destructive disassembly of layered optoelectronic structures, preserving the integrity of valuable materials.

Energy efficiency improvements in manufacturing processes represent another sustainability frontier. Low-temperature deposition techniques reduce energy consumption while maintaining optical clarity and refractive properties. Solution-based processing methods minimize solvent usage and waste generation compared to traditional vacuum deposition approaches, while still achieving the precision necessary for optimal light interaction.

Toxicity reduction efforts focus on eliminating hazardous substances from flexible optoelectronic materials without compromising performance. Lead-free perovskites, indium-free transparent conductors, and halogen-free flame retardants demonstrate comparable optical properties while reducing environmental and health risks. These alternatives maintain essential light refraction characteristics while addressing regulatory concerns and consumer demand for safer electronics.

The convergence of sustainability and performance optimization represents the next frontier in flexible optoelectronics. Biomimetic approaches—inspired by natural structures with exceptional optical properties like butterfly wings and beetle exoskeletons—offer pathways to materials that achieve superior light interaction while utilizing environmentally benign components and self-assembly processes that minimize energy and resource consumption.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!