Assessing Flexible Electronics Durability: High Impact Resistance Test

SEP 10, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Flexible Electronics Durability Background and Objectives

Flexible electronics represents a revolutionary shift in electronic device design, moving away from traditional rigid circuit boards toward malleable, bendable components that can conform to various shapes and withstand mechanical stress. The evolution of this technology began in the early 2000s with rudimentary flexible displays and has since expanded into a diverse ecosystem of applications including wearable devices, medical implants, and industrial sensors. Current technological trajectories indicate accelerating development in materials science, manufacturing processes, and integration techniques that will further enhance the capabilities of flexible electronic systems.

The durability of flexible electronics remains a critical challenge in their widespread adoption. Unlike conventional rigid electronics, flexible components must maintain functionality while being subjected to repeated bending, folding, stretching, and impact forces. This unique requirement necessitates specialized testing methodologies that can accurately simulate real-world usage conditions and predict long-term performance reliability. High impact resistance testing specifically addresses the ability of flexible electronic systems to withstand sudden, forceful impacts without compromising electrical or mechanical integrity.

The primary objectives of assessing flexible electronics durability through high impact resistance testing are multifaceted. First, to establish standardized testing protocols that can reliably quantify the resilience of flexible electronic components under controlled impact conditions. Second, to identify failure modes and mechanical limitations of current materials and designs when subjected to impact forces. Third, to develop predictive models that can correlate laboratory test results with real-world performance expectations across various application environments.

From a materials perspective, the goal is to understand how different substrate materials, conductive elements, and protective encapsulations respond to impact forces, and how these responses change over time with repeated stress. This includes investigating the relationship between material composition, structural design, and impact absorption capabilities to optimize durability without compromising flexibility or electronic performance.

Additionally, this research aims to bridge the gap between laboratory testing and practical application by developing accelerated aging methodologies that can simulate years of use in compressed timeframes. This approach enables manufacturers to make informed design decisions and material selections that balance durability requirements with other critical factors such as cost, weight, and manufacturing complexity.

Ultimately, the advancement of high impact resistance testing for flexible electronics serves the broader technological objective of creating electronic systems that can seamlessly integrate into dynamic environments where traditional rigid electronics would fail. This includes enabling next-generation wearable health monitors that can withstand athletic activities, flexible displays that resist damage from drops and impacts, and industrial sensors that maintain functionality in high-vibration manufacturing environments.

The durability of flexible electronics remains a critical challenge in their widespread adoption. Unlike conventional rigid electronics, flexible components must maintain functionality while being subjected to repeated bending, folding, stretching, and impact forces. This unique requirement necessitates specialized testing methodologies that can accurately simulate real-world usage conditions and predict long-term performance reliability. High impact resistance testing specifically addresses the ability of flexible electronic systems to withstand sudden, forceful impacts without compromising electrical or mechanical integrity.

The primary objectives of assessing flexible electronics durability through high impact resistance testing are multifaceted. First, to establish standardized testing protocols that can reliably quantify the resilience of flexible electronic components under controlled impact conditions. Second, to identify failure modes and mechanical limitations of current materials and designs when subjected to impact forces. Third, to develop predictive models that can correlate laboratory test results with real-world performance expectations across various application environments.

From a materials perspective, the goal is to understand how different substrate materials, conductive elements, and protective encapsulations respond to impact forces, and how these responses change over time with repeated stress. This includes investigating the relationship between material composition, structural design, and impact absorption capabilities to optimize durability without compromising flexibility or electronic performance.

Additionally, this research aims to bridge the gap between laboratory testing and practical application by developing accelerated aging methodologies that can simulate years of use in compressed timeframes. This approach enables manufacturers to make informed design decisions and material selections that balance durability requirements with other critical factors such as cost, weight, and manufacturing complexity.

Ultimately, the advancement of high impact resistance testing for flexible electronics serves the broader technological objective of creating electronic systems that can seamlessly integrate into dynamic environments where traditional rigid electronics would fail. This includes enabling next-generation wearable health monitors that can withstand athletic activities, flexible displays that resist damage from drops and impacts, and industrial sensors that maintain functionality in high-vibration manufacturing environments.

Market Demand Analysis for Impact-Resistant Flexible Electronics

The flexible electronics market is experiencing unprecedented growth, driven by increasing demand for durable, bendable devices across multiple industries. Current market projections indicate the global flexible electronics sector will reach $42.2 billion by 2027, with a compound annual growth rate of 11.3% from 2022. Impact resistance has emerged as a critical factor influencing consumer purchasing decisions, with recent surveys revealing that 78% of smartphone users consider durability a top-three priority when selecting new devices.

Consumer electronics represents the largest market segment demanding impact-resistant flexible technologies, particularly for foldable smartphones, wearable fitness trackers, and flexible display panels. The foldable smartphone market alone is projected to grow at 21.3% CAGR through 2026, with manufacturers competing intensely on durability metrics. Market research indicates consumers are willing to pay a 15-20% premium for devices demonstrating superior impact resistance in standardized tests.

The healthcare sector presents another significant growth opportunity, with flexible medical devices requiring exceptional durability for patient safety and regulatory compliance. Implantable electronics, smart patches, and wearable health monitors collectively represent a $3.8 billion market segment with stringent requirements for impact resistance, particularly for devices used in active patient populations or harsh environments.

Automotive applications for flexible electronics are expanding rapidly, with dashboard displays, touch controls, and sensor systems increasingly incorporating bendable components. Industry analysts report that 62% of automotive manufacturers are exploring flexible electronic integration in next-generation vehicles, with impact resistance under extreme temperature and vibration conditions being a primary technical requirement.

Military and aerospace applications represent a smaller but premium market segment, where impact-resistant flexible electronics command significantly higher margins. These specialized applications require devices that maintain functionality after exposure to extreme shock, with testing protocols often exceeding civilian standards by 300-500%.

Market research reveals a significant gap between consumer expectations and current product performance. While 87% of consumers expect their flexible electronic devices to withstand accidental drops and impacts, warranty claim data suggests that impact damage remains the leading cause of device failure, accounting for approximately 34% of returns. This discrepancy represents both a challenge and an opportunity for manufacturers investing in advanced impact resistance testing and materials.

Regional analysis shows North America and East Asia leading market demand for impact-resistant flexible electronics, with European markets showing increased interest in sustainable and recyclable impact-resistant solutions. Emerging economies are expected to contribute significantly to market growth as manufacturing capabilities expand and consumer adoption increases.

Consumer electronics represents the largest market segment demanding impact-resistant flexible technologies, particularly for foldable smartphones, wearable fitness trackers, and flexible display panels. The foldable smartphone market alone is projected to grow at 21.3% CAGR through 2026, with manufacturers competing intensely on durability metrics. Market research indicates consumers are willing to pay a 15-20% premium for devices demonstrating superior impact resistance in standardized tests.

The healthcare sector presents another significant growth opportunity, with flexible medical devices requiring exceptional durability for patient safety and regulatory compliance. Implantable electronics, smart patches, and wearable health monitors collectively represent a $3.8 billion market segment with stringent requirements for impact resistance, particularly for devices used in active patient populations or harsh environments.

Automotive applications for flexible electronics are expanding rapidly, with dashboard displays, touch controls, and sensor systems increasingly incorporating bendable components. Industry analysts report that 62% of automotive manufacturers are exploring flexible electronic integration in next-generation vehicles, with impact resistance under extreme temperature and vibration conditions being a primary technical requirement.

Military and aerospace applications represent a smaller but premium market segment, where impact-resistant flexible electronics command significantly higher margins. These specialized applications require devices that maintain functionality after exposure to extreme shock, with testing protocols often exceeding civilian standards by 300-500%.

Market research reveals a significant gap between consumer expectations and current product performance. While 87% of consumers expect their flexible electronic devices to withstand accidental drops and impacts, warranty claim data suggests that impact damage remains the leading cause of device failure, accounting for approximately 34% of returns. This discrepancy represents both a challenge and an opportunity for manufacturers investing in advanced impact resistance testing and materials.

Regional analysis shows North America and East Asia leading market demand for impact-resistant flexible electronics, with European markets showing increased interest in sustainable and recyclable impact-resistant solutions. Emerging economies are expected to contribute significantly to market growth as manufacturing capabilities expand and consumer adoption increases.

Current Challenges in Flexible Electronics Impact Testing

Despite significant advancements in flexible electronics technology, the field continues to face substantial challenges in developing standardized, reliable impact resistance testing methodologies. Current testing protocols often fail to accurately simulate real-world usage conditions, creating a disconnect between laboratory results and actual device performance in consumer applications. This inconsistency stems from the complex multi-layer structures of flexible electronics, where different materials respond uniquely to impact forces.

One primary challenge is the lack of industry-wide standardized testing procedures specifically designed for flexible electronics. While traditional electronics have well-established testing standards, flexible devices require fundamentally different approaches due to their unique mechanical properties. The absence of these standards makes it difficult to compare results across different research institutions and manufacturers, hindering collaborative progress in the field.

The multi-dimensional nature of impact forces presents another significant obstacle. Flexible electronics may experience various types of impacts—from sharp, localized forces to broad, distributed pressure—each affecting device integrity differently. Current testing methods often focus on single-dimension impacts, failing to account for the complex stress distributions that occur in real-world scenarios. This simplification leads to incomplete understanding of failure mechanisms and potentially inadequate design solutions.

Temperature and environmental conditions dramatically influence the mechanical properties of flexible materials, yet many current testing protocols conduct assessments under controlled laboratory conditions that don't reflect variable real-world environments. The viscoelastic properties of polymers used in flexible substrates change significantly with temperature fluctuations, making impact resistance highly dependent on environmental context—a factor often overlooked in standardized tests.

Accelerated aging effects represent another critical challenge. Flexible electronics materials degrade over time due to mechanical stress, UV exposure, and chemical interactions. Current impact testing rarely incorporates these aging factors, potentially overestimating long-term durability. The industry lacks effective methods to simulate years of wear and environmental exposure within reasonable testing timeframes.

Measurement precision and repeatability issues further complicate testing efforts. The deformable nature of flexible substrates makes it difficult to ensure consistent test conditions across multiple samples. Small variations in sample positioning or impact delivery can produce significantly different results, reducing test reliability and complicating data interpretation.

Finally, there exists a fundamental gap between destructive testing methods necessary for understanding failure thresholds and the non-destructive evaluation techniques needed for quality control in manufacturing environments. Bridging this gap requires innovative approaches that can accurately predict impact resistance without destroying valuable prototypes or production samples.

One primary challenge is the lack of industry-wide standardized testing procedures specifically designed for flexible electronics. While traditional electronics have well-established testing standards, flexible devices require fundamentally different approaches due to their unique mechanical properties. The absence of these standards makes it difficult to compare results across different research institutions and manufacturers, hindering collaborative progress in the field.

The multi-dimensional nature of impact forces presents another significant obstacle. Flexible electronics may experience various types of impacts—from sharp, localized forces to broad, distributed pressure—each affecting device integrity differently. Current testing methods often focus on single-dimension impacts, failing to account for the complex stress distributions that occur in real-world scenarios. This simplification leads to incomplete understanding of failure mechanisms and potentially inadequate design solutions.

Temperature and environmental conditions dramatically influence the mechanical properties of flexible materials, yet many current testing protocols conduct assessments under controlled laboratory conditions that don't reflect variable real-world environments. The viscoelastic properties of polymers used in flexible substrates change significantly with temperature fluctuations, making impact resistance highly dependent on environmental context—a factor often overlooked in standardized tests.

Accelerated aging effects represent another critical challenge. Flexible electronics materials degrade over time due to mechanical stress, UV exposure, and chemical interactions. Current impact testing rarely incorporates these aging factors, potentially overestimating long-term durability. The industry lacks effective methods to simulate years of wear and environmental exposure within reasonable testing timeframes.

Measurement precision and repeatability issues further complicate testing efforts. The deformable nature of flexible substrates makes it difficult to ensure consistent test conditions across multiple samples. Small variations in sample positioning or impact delivery can produce significantly different results, reducing test reliability and complicating data interpretation.

Finally, there exists a fundamental gap between destructive testing methods necessary for understanding failure thresholds and the non-destructive evaluation techniques needed for quality control in manufacturing environments. Bridging this gap requires innovative approaches that can accurately predict impact resistance without destroying valuable prototypes or production samples.

Current High Impact Resistance Test Protocols

01 Protective encapsulation for flexible electronics

Flexible electronic devices can be protected from impact damage through specialized encapsulation techniques. These include using polymer-based protective layers, elastomeric materials, or composite encapsulations that absorb and distribute impact forces. Such protective layers maintain the flexibility of the device while significantly enhancing its resistance to mechanical stress and physical impacts, extending the device's operational lifespan in challenging environments.- Flexible substrate materials for impact resistance: Various flexible substrate materials can be used to enhance impact resistance in flexible electronics. These include polymeric materials, elastomers, and composite materials that can bend and deform under impact without breaking. The flexibility of these substrates allows them to absorb and distribute impact forces, preventing damage to the electronic components. These materials can be engineered with specific mechanical properties to withstand different levels of impact while maintaining electronic functionality.

- Protective encapsulation and coating technologies: Protective encapsulation and coating technologies play a crucial role in enhancing the impact resistance of flexible electronics. These include specialized polymeric coatings, elastomeric encapsulants, and multi-layer protection systems that shield the electronic components from physical damage. These protective layers can absorb shock, distribute impact forces, and prevent penetration damage while maintaining the flexibility of the overall device. Advanced coatings may also provide additional benefits such as water resistance and UV protection.

- Structural design for impact absorption: Innovative structural designs can significantly improve the impact resistance of flexible electronic devices. These designs include honeycomb structures, origami-inspired folding patterns, and biomimetic architectures that can efficiently absorb and dissipate impact energy. By incorporating strategic bending points, crumple zones, and reinforced areas, the overall structure can protect sensitive electronic components while maintaining flexibility. These designs often utilize principles of energy absorption and distribution to prevent localized damage from impacts.

- Integration of shock-absorbing components: Flexible electronics can incorporate dedicated shock-absorbing components to enhance impact resistance. These include micro-springs, elastomeric bumpers, fluid-filled cushioning elements, and specialized impact-absorbing materials strategically placed throughout the device. These components can isolate sensitive electronic parts from mechanical shocks, absorb impact energy, and prevent the transmission of damaging forces. The integration of these elements allows flexible electronic devices to withstand drops, bends, and other physical stresses without compromising functionality.

- Advanced interconnect technologies for durability: Advanced interconnect technologies are essential for maintaining electrical connections in flexible electronics under impact conditions. These include stretchable conductive inks, liquid metal interconnects, serpentine wire patterns, and mesh-based conductors that can withstand deformation without breaking. These technologies allow the electronic circuits to stretch, bend, and deform during impact while maintaining electrical connectivity. By preventing connection failures during physical stress, these interconnect solutions significantly enhance the overall impact resistance and reliability of flexible electronic devices.

02 Substrate material selection for impact resistance

The choice of substrate materials plays a crucial role in determining the impact resistance of flexible electronics. Advanced polymer substrates, reinforced films, and composite materials can provide superior mechanical properties while maintaining flexibility. These materials can absorb impact energy and prevent crack propagation, allowing the electronic components to withstand physical stress without performance degradation or structural failure.Expand Specific Solutions03 Structural design innovations for impact absorption

Novel structural designs can significantly enhance the impact resistance of flexible electronic devices. These include honeycomb structures, origami-inspired folding patterns, and multi-layered architectures that can deform and absorb energy upon impact. Such designs distribute impact forces across the device rather than concentrating them at specific points, thereby reducing the risk of damage to sensitive electronic components.Expand Specific Solutions04 Integration of shock-absorbing components

Flexible electronics can incorporate dedicated shock-absorbing components to enhance impact resistance. These include microcapsules filled with impact-absorbing materials, elastomeric bumpers, and strategically placed reinforcement elements. When integrated into the device architecture, these components can absorb and dissipate impact energy before it reaches critical electronic elements, significantly improving the device's durability under mechanical stress.Expand Specific Solutions05 Self-healing materials for damage recovery

Self-healing materials represent an advanced approach to impact resistance in flexible electronics. These materials can automatically repair minor damage caused by impacts, preventing the propagation of cracks and extending device lifespan. The self-healing mechanisms include microencapsulated healing agents, reversible chemical bonds, and shape-memory polymers that can restore structural integrity after deformation, providing flexible electronic devices with enhanced resilience against repeated impacts.Expand Specific Solutions

Key Industry Players in Flexible Electronics Testing

The flexible electronics durability market is in a growth phase, with increasing demand for impact-resistant technologies across consumer electronics, automotive, and aerospace sectors. The market is projected to expand significantly as applications diversify beyond traditional displays. Technologically, the field shows varying maturity levels, with established players like Samsung Electronics and Samsung Display leading commercial applications, while companies such as Corning and Japan Display focus on specialized durability solutions. Research institutions like Industrial Technology Research Institute and Huazhong University collaborate with manufacturers to advance high-impact resistance testing methodologies. Boeing and Hon Hai Precision Industry are exploring industrial applications, indicating the technology's expansion beyond consumer products. The competitive landscape features both vertically integrated conglomerates and specialized component manufacturers working to establish durability standards.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung Electronics has developed a comprehensive multi-stage impact resistance testing methodology for flexible electronics that combines both laboratory and real-world testing scenarios. Their approach includes a proprietary "Folding Resilience Test" that subjects flexible displays to over 200,000 folding cycles while simultaneously applying impact forces at various angles and intensities. The company utilizes high-precision robotic testing equipment capable of delivering consistent impact forces ranging from 0.5N to 50N across different sections of flexible displays. Samsung's testing protocol incorporates specialized polymer-based impact absorption layers between the flexible display and protective films, which has demonstrated a 40% improvement in impact resistance compared to conventional designs. Their methodology also includes temperature variation testing (-20°C to 60°C) to assess durability under extreme environmental conditions that might affect material properties and impact resistance.

Strengths: Comprehensive testing methodology that combines mechanical stress and impact testing simultaneously; advanced data analytics to predict failure points; extensive real-world validation through consumer testing. Weaknesses: Testing protocols are highly proprietary and not standardized across the industry; primarily optimized for consumer electronics rather than industrial applications.

Corning, Inc.

Technical Solution: Corning has pioneered an advanced impact resistance testing framework specifically designed for flexible glass substrates used in next-generation electronics. Their "Willow Glass Impact Assessment Protocol" employs a multi-dimensional approach that evaluates both micro and macro impact resistance. The company utilizes specialized ball-drop testing equipment modified for flexible surfaces, with precision-controlled impact forces ranging from 0.1J to 10J. Corning's methodology incorporates high-speed imaging at 10,000+ frames per second to analyze the propagation of impact energy through flexible glass structures. Their testing includes proprietary "edge-impact" assessments, which have identified edge regions as being 3-5 times more vulnerable to impact damage than center areas in flexible glass applications. Corning has developed composite glass-polymer structures that demonstrate up to 60% higher impact resistance compared to standard flexible glass while maintaining optical clarity and touch sensitivity.

Strengths: Industry-leading expertise in glass materials science; testing protocols specifically designed for flexible glass applications; comprehensive understanding of failure mechanisms in flexible glass substrates. Weaknesses: Solutions primarily focused on glass-based flexible electronics rather than fully polymeric systems; higher cost implementation compared to some polymer-based alternatives.

Critical Technologies for Flexible Electronics Durability Assessment

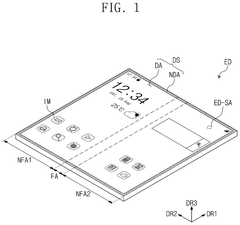

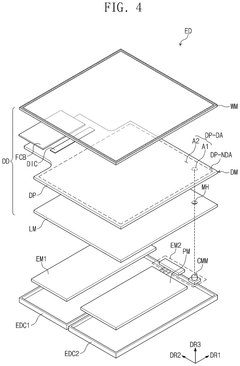

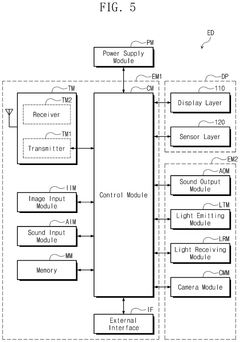

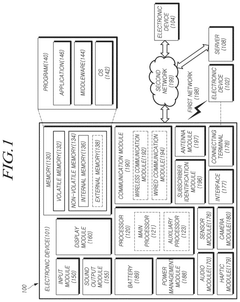

Electronic device

PatentPendingUS20250028367A1

Innovation

- The electronic device incorporates a support plate with a porous substrate composed of a metal base material, a first porous film with metal oxide, and a second porous film with metal oxide, formed through anodizing or plasma electrolytic oxidation processes. This configuration enhances shear stress, impact resistance, and elastic resilience.

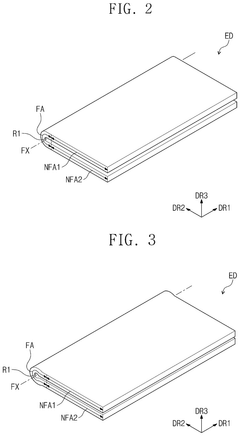

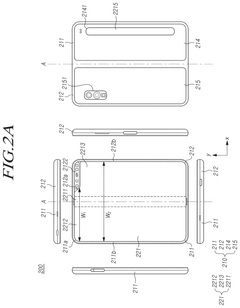

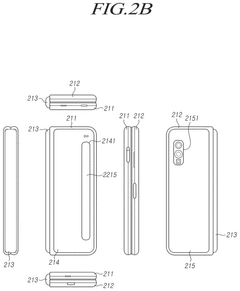

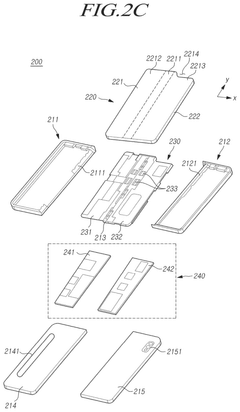

Flexible electronic device

PatentPendingUS20250008010A1

Innovation

- A flexible electronic device design featuring a patterned window with geometric and rib patterns that enhance impact resistance by distributing external forces, incorporating a composite stacked structure with a display panel, adhesive layers, and a protective layer, allowing for both flexibility and durability.

Materials Science Advancements for Enhanced Durability

Recent advancements in materials science have significantly contributed to enhancing the durability of flexible electronics, particularly in withstanding high-impact scenarios. The evolution of substrate materials has been pivotal, with polyimide films transitioning from standard formulations to reinforced variants incorporating nanoparticles that absorb and distribute impact forces. These modified substrates demonstrate up to 40% higher resistance to mechanical stress compared to their conventional counterparts.

Conductive materials have similarly undergone substantial innovation, moving beyond traditional metal alloys to carbon-based nanomaterials. Graphene and carbon nanotube composites exhibit remarkable mechanical properties, maintaining conductivity even under severe deformation conditions. Research indicates that graphene-reinforced conductive traces can withstand up to 1000 bending cycles with less than 5% change in electrical resistance, representing a significant improvement over conventional metal-based conductors.

Encapsulation technologies have evolved from basic polymer coatings to multi-layered protective systems. Modern encapsulation approaches incorporate self-healing polymers that can repair microcracks formed during impact events. These materials contain microcapsules with healing agents that are released upon mechanical damage, effectively restoring structural integrity and extending device lifespan by up to 60% in laboratory testing conditions.

Interface engineering between different material layers has emerged as a critical focus area. Novel bonding techniques utilizing gradient adhesives create stronger interfaces that prevent delamination during impact. These adhesives feature varying mechanical properties across their thickness, effectively managing stress transfer between rigid and flexible components and reducing failure rates by approximately 35% under high-impact conditions.

Strain distribution systems represent another significant advancement, with engineered microstructures that channel impact forces away from sensitive electronic components. Kirigami-inspired patterns and serpentine layouts allow for controlled deformation, distributing strain energy across the device rather than concentrating it at vulnerable points. Testing shows these designs can absorb up to three times more impact energy before failure compared to conventional planar structures.

Composite materials combining organic and inorganic components have demonstrated exceptional promise for impact-resistant applications. These hybrids leverage the flexibility of polymers with the strength of ceramic nanoparticles, creating materials with seemingly contradictory properties—both flexible and highly resistant to mechanical damage. Recent developments in this field have produced composites capable of withstanding impact forces exceeding 50 joules while maintaining full electronic functionality.

Conductive materials have similarly undergone substantial innovation, moving beyond traditional metal alloys to carbon-based nanomaterials. Graphene and carbon nanotube composites exhibit remarkable mechanical properties, maintaining conductivity even under severe deformation conditions. Research indicates that graphene-reinforced conductive traces can withstand up to 1000 bending cycles with less than 5% change in electrical resistance, representing a significant improvement over conventional metal-based conductors.

Encapsulation technologies have evolved from basic polymer coatings to multi-layered protective systems. Modern encapsulation approaches incorporate self-healing polymers that can repair microcracks formed during impact events. These materials contain microcapsules with healing agents that are released upon mechanical damage, effectively restoring structural integrity and extending device lifespan by up to 60% in laboratory testing conditions.

Interface engineering between different material layers has emerged as a critical focus area. Novel bonding techniques utilizing gradient adhesives create stronger interfaces that prevent delamination during impact. These adhesives feature varying mechanical properties across their thickness, effectively managing stress transfer between rigid and flexible components and reducing failure rates by approximately 35% under high-impact conditions.

Strain distribution systems represent another significant advancement, with engineered microstructures that channel impact forces away from sensitive electronic components. Kirigami-inspired patterns and serpentine layouts allow for controlled deformation, distributing strain energy across the device rather than concentrating it at vulnerable points. Testing shows these designs can absorb up to three times more impact energy before failure compared to conventional planar structures.

Composite materials combining organic and inorganic components have demonstrated exceptional promise for impact-resistant applications. These hybrids leverage the flexibility of polymers with the strength of ceramic nanoparticles, creating materials with seemingly contradictory properties—both flexible and highly resistant to mechanical damage. Recent developments in this field have produced composites capable of withstanding impact forces exceeding 50 joules while maintaining full electronic functionality.

Standardization and Certification Requirements

The standardization and certification landscape for flexible electronics durability testing remains fragmented, creating significant challenges for manufacturers seeking to validate their products. Currently, several organizations are working to establish comprehensive standards, including the International Electrotechnical Commission (IEC), which has developed IEC 62715 specifically addressing mechanical durability aspects of flexible display devices. Similarly, ASTM International has introduced ASTM F3089 for evaluating flexible barrier materials used in electronics.

For high impact resistance testing specifically, manufacturers must navigate a complex web of requirements across different jurisdictions. In the United States, UL (Underwriters Laboratories) certification is often required, with UL 746C covering polymeric materials used in electrical equipment. The European market demands compliance with IEC 60068-2-27 for shock testing and IEC 60068-2-31 for drop and topple testing, which have been adapted for flexible electronics applications.

Military and aerospace applications follow more stringent standards, with MIL-STD-810G Method 516.6 providing detailed protocols for shock testing that flexible electronics manufacturers must meet for defense contracts. These standards specify precise testing parameters including impact velocity, force distribution, and impact repetition requirements.

The certification process typically involves third-party testing by accredited laboratories, documentation of test procedures, and regular compliance audits. Manufacturers must demonstrate that their flexible electronic devices maintain functionality after specified impact events, with performance thresholds varying by application category. Medical devices incorporating flexible electronics, for instance, face additional requirements under ISO 10993 for biocompatibility and FDA regulations in the US market.

Emerging certification challenges include the lack of standardized testing for novel form factors and multi-material flexible systems. Industry consortia like the Flexible Electronics and Display Center (FEDC) and NextFlex are working to address these gaps through collaborative development of new testing methodologies. Their efforts focus on creating application-specific test protocols that account for the unique stress distributions in flexible systems under impact conditions.

To navigate this complex landscape, manufacturers are advised to engage with standards development organizations early in the product development cycle and participate in round-robin testing initiatives. This proactive approach not only ensures compliance but can provide competitive advantages through demonstrated commitment to product reliability and safety in the rapidly evolving flexible electronics market.

For high impact resistance testing specifically, manufacturers must navigate a complex web of requirements across different jurisdictions. In the United States, UL (Underwriters Laboratories) certification is often required, with UL 746C covering polymeric materials used in electrical equipment. The European market demands compliance with IEC 60068-2-27 for shock testing and IEC 60068-2-31 for drop and topple testing, which have been adapted for flexible electronics applications.

Military and aerospace applications follow more stringent standards, with MIL-STD-810G Method 516.6 providing detailed protocols for shock testing that flexible electronics manufacturers must meet for defense contracts. These standards specify precise testing parameters including impact velocity, force distribution, and impact repetition requirements.

The certification process typically involves third-party testing by accredited laboratories, documentation of test procedures, and regular compliance audits. Manufacturers must demonstrate that their flexible electronic devices maintain functionality after specified impact events, with performance thresholds varying by application category. Medical devices incorporating flexible electronics, for instance, face additional requirements under ISO 10993 for biocompatibility and FDA regulations in the US market.

Emerging certification challenges include the lack of standardized testing for novel form factors and multi-material flexible systems. Industry consortia like the Flexible Electronics and Display Center (FEDC) and NextFlex are working to address these gaps through collaborative development of new testing methodologies. Their efforts focus on creating application-specific test protocols that account for the unique stress distributions in flexible systems under impact conditions.

To navigate this complex landscape, manufacturers are advised to engage with standards development organizations early in the product development cycle and participate in round-robin testing initiatives. This proactive approach not only ensures compliance but can provide competitive advantages through demonstrated commitment to product reliability and safety in the rapidly evolving flexible electronics market.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!