Benchmark Flexible Electronics Signal Processing: Noise Reduction Validation

SEP 10, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Flexible Electronics Signal Processing Background and Objectives

Flexible electronics represents a revolutionary paradigm shift in electronic systems, characterized by devices that can bend, stretch, and conform to non-planar surfaces while maintaining functionality. The evolution of this technology has progressed significantly over the past two decades, transitioning from laboratory curiosities to commercially viable products. Initially focused on simple flexible displays and basic sensors, the field has expanded to encompass complex integrated systems including flexible processors, memory, and communication modules.

Signal processing in flexible electronics presents unique challenges compared to conventional rigid electronics. The inherent mechanical deformation these devices undergo introduces noise artifacts and signal degradation that traditional signal processing algorithms are not designed to address. The mechanical stress-induced variations in electrical properties create dynamic noise profiles that change with the physical configuration of the device, requiring adaptive processing techniques.

The primary objective of benchmarking noise reduction validation in flexible electronics signal processing is to establish standardized metrics and methodologies for evaluating the effectiveness of noise reduction algorithms specifically tailored for flexible electronic systems. This benchmarking aims to quantify performance across various deformation states, environmental conditions, and application scenarios to ensure consistent signal integrity regardless of mechanical configuration.

Current technical goals include developing robust algorithms capable of distinguishing between actual signals and noise artifacts introduced by mechanical deformation, creating adaptive filtering techniques that can respond in real-time to changing device configurations, and establishing industry-standard validation protocols that accurately reflect real-world usage conditions of flexible electronic devices.

The trajectory of flexible electronics signal processing is moving toward increased integration with machine learning approaches, where neural networks can be trained to recognize and compensate for deformation-specific noise patterns. Additionally, there is growing interest in developing specialized hardware accelerators that can efficiently implement these algorithms within the power and space constraints of flexible devices.

Noise reduction validation represents a critical bottleneck in the broader adoption of flexible electronics across industries. Without reliable signal processing, applications in healthcare monitoring, structural health monitoring, and human-machine interfaces cannot achieve the precision required for mission-critical applications. Establishing benchmark standards will accelerate development cycles and enable meaningful comparison between competing technical approaches.

The convergence of materials science advancements, novel semiconductor fabrication techniques, and sophisticated signal processing algorithms is expected to drive the next generation of flexible electronic systems with unprecedented signal fidelity even under extreme mechanical deformation conditions.

Signal processing in flexible electronics presents unique challenges compared to conventional rigid electronics. The inherent mechanical deformation these devices undergo introduces noise artifacts and signal degradation that traditional signal processing algorithms are not designed to address. The mechanical stress-induced variations in electrical properties create dynamic noise profiles that change with the physical configuration of the device, requiring adaptive processing techniques.

The primary objective of benchmarking noise reduction validation in flexible electronics signal processing is to establish standardized metrics and methodologies for evaluating the effectiveness of noise reduction algorithms specifically tailored for flexible electronic systems. This benchmarking aims to quantify performance across various deformation states, environmental conditions, and application scenarios to ensure consistent signal integrity regardless of mechanical configuration.

Current technical goals include developing robust algorithms capable of distinguishing between actual signals and noise artifacts introduced by mechanical deformation, creating adaptive filtering techniques that can respond in real-time to changing device configurations, and establishing industry-standard validation protocols that accurately reflect real-world usage conditions of flexible electronic devices.

The trajectory of flexible electronics signal processing is moving toward increased integration with machine learning approaches, where neural networks can be trained to recognize and compensate for deformation-specific noise patterns. Additionally, there is growing interest in developing specialized hardware accelerators that can efficiently implement these algorithms within the power and space constraints of flexible devices.

Noise reduction validation represents a critical bottleneck in the broader adoption of flexible electronics across industries. Without reliable signal processing, applications in healthcare monitoring, structural health monitoring, and human-machine interfaces cannot achieve the precision required for mission-critical applications. Establishing benchmark standards will accelerate development cycles and enable meaningful comparison between competing technical approaches.

The convergence of materials science advancements, novel semiconductor fabrication techniques, and sophisticated signal processing algorithms is expected to drive the next generation of flexible electronic systems with unprecedented signal fidelity even under extreme mechanical deformation conditions.

Market Demand Analysis for Noise-Reduced Flexible Electronics

The flexible electronics market is experiencing unprecedented growth, with a significant demand for improved signal processing capabilities, particularly in noise reduction. This demand is driven by the expanding applications of flexible electronic devices across multiple industries including healthcare, consumer electronics, automotive, and industrial monitoring systems.

Healthcare applications represent one of the most promising market segments for noise-reduced flexible electronics. Wearable health monitoring devices require clean signals for accurate diagnosis and continuous patient monitoring. The global medical wearables market is rapidly expanding, with healthcare providers increasingly adopting these technologies for remote patient monitoring and preventive care.

Consumer electronics constitutes another major market driver. As flexible displays, bendable smartphones, and wearable technology gain popularity, consumers expect devices that maintain signal integrity regardless of physical manipulation. The demand for improved user experience through clearer audio, more responsive touch interfaces, and reliable sensor readings is pushing manufacturers to prioritize noise reduction technologies.

The automotive industry presents substantial growth opportunities for flexible electronics with enhanced signal processing. Advanced driver-assistance systems (ADAS) and autonomous vehicles rely on numerous sensors that must function reliably under varying conditions. Flexible electronics that can conform to vehicle contours while maintaining signal fidelity are increasingly sought after by automotive manufacturers.

Industrial IoT applications represent another significant market segment. Flexible sensors deployed in manufacturing environments must operate reliably despite electromagnetic interference, mechanical vibrations, and other noise sources. The ability to process clean signals from these sensors directly impacts operational efficiency and predictive maintenance capabilities.

Market research indicates that companies are willing to pay premium prices for flexible electronic components with superior noise reduction capabilities. This price elasticity reflects the critical nature of signal integrity in many applications where false readings or missed signals could have significant consequences.

Regional analysis shows particularly strong demand growth in North America and Asia-Pacific markets. North American demand is primarily driven by healthcare and defense applications, while Asia-Pacific growth stems from consumer electronics manufacturing and industrial automation sectors.

The market is also seeing increased demand for integrated solutions that combine hardware noise reduction techniques with advanced signal processing algorithms. This trend toward comprehensive noise management solutions indicates a maturing market where customers seek end-to-end performance rather than component-level specifications.

Environmental considerations are also shaping market demand, with growing interest in energy-efficient signal processing solutions that extend battery life in portable and wearable flexible electronic devices.

Healthcare applications represent one of the most promising market segments for noise-reduced flexible electronics. Wearable health monitoring devices require clean signals for accurate diagnosis and continuous patient monitoring. The global medical wearables market is rapidly expanding, with healthcare providers increasingly adopting these technologies for remote patient monitoring and preventive care.

Consumer electronics constitutes another major market driver. As flexible displays, bendable smartphones, and wearable technology gain popularity, consumers expect devices that maintain signal integrity regardless of physical manipulation. The demand for improved user experience through clearer audio, more responsive touch interfaces, and reliable sensor readings is pushing manufacturers to prioritize noise reduction technologies.

The automotive industry presents substantial growth opportunities for flexible electronics with enhanced signal processing. Advanced driver-assistance systems (ADAS) and autonomous vehicles rely on numerous sensors that must function reliably under varying conditions. Flexible electronics that can conform to vehicle contours while maintaining signal fidelity are increasingly sought after by automotive manufacturers.

Industrial IoT applications represent another significant market segment. Flexible sensors deployed in manufacturing environments must operate reliably despite electromagnetic interference, mechanical vibrations, and other noise sources. The ability to process clean signals from these sensors directly impacts operational efficiency and predictive maintenance capabilities.

Market research indicates that companies are willing to pay premium prices for flexible electronic components with superior noise reduction capabilities. This price elasticity reflects the critical nature of signal integrity in many applications where false readings or missed signals could have significant consequences.

Regional analysis shows particularly strong demand growth in North America and Asia-Pacific markets. North American demand is primarily driven by healthcare and defense applications, while Asia-Pacific growth stems from consumer electronics manufacturing and industrial automation sectors.

The market is also seeing increased demand for integrated solutions that combine hardware noise reduction techniques with advanced signal processing algorithms. This trend toward comprehensive noise management solutions indicates a maturing market where customers seek end-to-end performance rather than component-level specifications.

Environmental considerations are also shaping market demand, with growing interest in energy-efficient signal processing solutions that extend battery life in portable and wearable flexible electronic devices.

Current Challenges in Flexible Electronics Signal Processing

Flexible electronics represents a revolutionary advancement in electronic systems, offering unprecedented mechanical compliance and adaptability. However, signal processing in these systems faces significant challenges that impede their widespread adoption and optimal performance. The inherent flexibility that makes these devices attractive also introduces complex noise patterns that conventional signal processing techniques struggle to address effectively.

The primary challenge in flexible electronics signal processing stems from motion artifacts. As these devices bend, stretch, and conform to various surfaces, they generate unpredictable noise signatures that contaminate the underlying signals. This is particularly problematic in wearable health monitoring applications where patient movement can severely compromise data integrity, leading to false readings and unreliable diagnostics.

Environmental interference presents another substantial hurdle. Flexible electronic systems typically operate in uncontrolled environments with varying electromagnetic fields, temperature fluctuations, and humidity levels. These environmental factors introduce additional noise components that are difficult to model and filter using traditional approaches. The thin-film transistors commonly used in flexible electronics also exhibit higher noise levels compared to their rigid counterparts, further complicating signal extraction.

Power constraints significantly limit the implementation of sophisticated signal processing algorithms in flexible electronics. The ultra-low power requirements of many flexible electronic applications restrict the computational resources available for noise reduction. This creates a fundamental tension between processing capability and energy efficiency that engineers must carefully balance.

Material degradation over time introduces progressive changes in signal characteristics. As flexible substrates and conductive materials undergo repeated mechanical stress, their electrical properties gradually alter, resulting in baseline drift and changing noise profiles. Current signal processing methods lack adaptive capabilities to compensate for these time-dependent variations, leading to diminishing performance as devices age.

Cross-talk between adjacent channels in densely packed flexible circuits represents another significant challenge. The close proximity of components in space-constrained flexible designs creates signal interference that conventional isolation techniques cannot adequately address. This is particularly problematic in high-density sensor arrays where spatial resolution is critical.

Benchmark standardization remains underdeveloped in the flexible electronics domain. Unlike traditional electronics, there are no widely accepted protocols for characterizing noise profiles or validating noise reduction techniques in flexible systems. This absence of standardized benchmarking methodologies makes it difficult to objectively compare different signal processing approaches or establish performance targets.

The integration of analog and digital domains presents unique challenges in flexible systems. The analog-to-digital conversion process is particularly susceptible to noise in flexible electronics due to variable reference voltages and ground planes. Developing robust mixed-signal architectures that maintain signal integrity across this boundary remains an ongoing challenge for researchers and engineers in the field.

The primary challenge in flexible electronics signal processing stems from motion artifacts. As these devices bend, stretch, and conform to various surfaces, they generate unpredictable noise signatures that contaminate the underlying signals. This is particularly problematic in wearable health monitoring applications where patient movement can severely compromise data integrity, leading to false readings and unreliable diagnostics.

Environmental interference presents another substantial hurdle. Flexible electronic systems typically operate in uncontrolled environments with varying electromagnetic fields, temperature fluctuations, and humidity levels. These environmental factors introduce additional noise components that are difficult to model and filter using traditional approaches. The thin-film transistors commonly used in flexible electronics also exhibit higher noise levels compared to their rigid counterparts, further complicating signal extraction.

Power constraints significantly limit the implementation of sophisticated signal processing algorithms in flexible electronics. The ultra-low power requirements of many flexible electronic applications restrict the computational resources available for noise reduction. This creates a fundamental tension between processing capability and energy efficiency that engineers must carefully balance.

Material degradation over time introduces progressive changes in signal characteristics. As flexible substrates and conductive materials undergo repeated mechanical stress, their electrical properties gradually alter, resulting in baseline drift and changing noise profiles. Current signal processing methods lack adaptive capabilities to compensate for these time-dependent variations, leading to diminishing performance as devices age.

Cross-talk between adjacent channels in densely packed flexible circuits represents another significant challenge. The close proximity of components in space-constrained flexible designs creates signal interference that conventional isolation techniques cannot adequately address. This is particularly problematic in high-density sensor arrays where spatial resolution is critical.

Benchmark standardization remains underdeveloped in the flexible electronics domain. Unlike traditional electronics, there are no widely accepted protocols for characterizing noise profiles or validating noise reduction techniques in flexible systems. This absence of standardized benchmarking methodologies makes it difficult to objectively compare different signal processing approaches or establish performance targets.

The integration of analog and digital domains presents unique challenges in flexible systems. The analog-to-digital conversion process is particularly susceptible to noise in flexible electronics due to variable reference voltages and ground planes. Developing robust mixed-signal architectures that maintain signal integrity across this boundary remains an ongoing challenge for researchers and engineers in the field.

Current Noise Reduction Methodologies for Flexible Electronics

01 Flexible electronic circuits for noise reduction

Flexible electronic circuits can be designed with specific components and layouts to minimize noise in signal processing applications. These circuits often incorporate specialized materials and configurations that maintain signal integrity while allowing for physical flexibility. The flexible nature of these circuits enables their integration into various form factors and applications where traditional rigid circuits would be impractical, while still maintaining effective noise reduction capabilities.- Flexible electronic circuits for noise reduction in signal processing: Flexible electronic circuits can be designed to reduce noise in signal processing applications. These circuits incorporate specialized components and layouts that minimize electromagnetic interference and signal distortion. The flexibility of these circuits allows them to be integrated into various form factors while maintaining signal integrity. Advanced materials and manufacturing techniques enable these circuits to bend and conform to different shapes without compromising their noise reduction capabilities.

- Adaptive filtering techniques for noise cancellation in flexible electronics: Adaptive filtering algorithms can be implemented in flexible electronic systems to dynamically reduce noise in signal processing. These techniques continuously adjust filter parameters based on the characteristics of the incoming signal and noise, providing optimal noise cancellation in changing environments. The implementation of these algorithms in flexible form factors allows for effective noise reduction in wearable devices and other applications where traditional rigid electronics would be impractical.

- Audio signal processing in flexible electronic devices: Flexible electronic devices can incorporate specialized audio signal processing techniques to reduce noise in audio applications. These techniques include advanced digital signal processing algorithms that filter out ambient noise, enhance desired audio signals, and improve overall sound quality. The flexibility of these devices allows for better positioning of microphones and speakers, further enhancing noise reduction capabilities in applications such as hearing aids, headphones, and communication devices.

- Image and video signal processing in flexible display technologies: Flexible display technologies incorporate specialized signal processing techniques to reduce noise in image and video applications. These techniques include advanced algorithms for pixel correction, motion compensation, and artifact reduction that maintain image quality despite the challenges posed by flexible substrates. The integration of these processing methods with flexible display hardware enables high-quality visual output in bendable screens, foldable devices, and curved displays while minimizing visual noise and distortion.

- Power management and interference reduction in flexible electronic systems: Power management techniques in flexible electronic systems can significantly reduce electrical noise that affects signal processing. These techniques include specialized power distribution networks, ground plane designs, and isolation methods that minimize interference between components. Advanced shielding materials compatible with flexible substrates can be incorporated to block external electromagnetic interference. The implementation of these approaches ensures clean power delivery and reduced noise in signal processing applications while maintaining the mechanical flexibility of the overall system.

02 Signal processing algorithms for noise cancellation in flexible electronics

Advanced signal processing algorithms specifically designed for flexible electronic systems can effectively reduce noise interference. These algorithms may include adaptive filtering, digital signal processing techniques, and machine learning approaches that can identify and filter out noise patterns in real-time. The implementation of these algorithms in flexible electronic devices helps maintain signal quality despite the unique challenges posed by bendable and stretchable form factors.Expand Specific Solutions03 Wearable audio devices with noise reduction technology

Flexible electronics enable the development of wearable audio devices with enhanced noise reduction capabilities. These devices incorporate flexible components that conform to body contours while maintaining acoustic performance. Signal processing techniques specifically optimized for wearable applications can filter environmental noise, improve voice clarity, and enhance the overall audio experience while maintaining user comfort through flexible form factors.Expand Specific Solutions04 Imaging and display systems with flexible noise reduction components

Flexible electronic components in imaging and display systems can incorporate specialized noise reduction technologies. These systems use signal processing techniques to enhance image quality by reducing visual noise and artifacts. The flexibility of these components allows for integration into curved displays, foldable screens, and other non-traditional form factors while maintaining high signal-to-noise ratios and image clarity.Expand Specific Solutions05 Power management for noise reduction in flexible electronic systems

Effective power management techniques can significantly reduce noise in flexible electronic systems. These approaches include specialized circuit designs that minimize electromagnetic interference, power conditioning components that filter noise from power supplies, and intelligent power distribution systems. By optimizing power delivery and consumption, these techniques help maintain signal integrity in flexible electronic devices while extending battery life and improving overall system performance.Expand Specific Solutions

Key Industry Players in Flexible Electronics Signal Processing

The flexible electronics signal processing market, particularly in noise reduction validation, is currently in a growth phase with an estimated market size of $3-5 billion and projected annual growth of 15-20%. The technology maturity varies across key players, with established electronics giants like Sony Group, Philips, and Apple leading innovation through extensive R&D investments. Semiconductor specialists including Intel, Micron, and Sony Semiconductor Solutions are advancing signal processing capabilities for flexible substrates. Meanwhile, companies like Huawei, NEC, and Fujitsu are focusing on integration with IoT and mobile applications. The competitive landscape shows a convergence of consumer electronics manufacturers and semiconductor firms developing specialized noise reduction algorithms and validation methodologies for flexible form factors.

Sony Group Corp.

Technical Solution: Sony has developed a sophisticated benchmark system for flexible electronics signal processing focused on noise reduction validation. Their approach leverages their extensive experience in consumer electronics and professional audio equipment to create a comprehensive testing framework. Sony's solution incorporates a multi-layered signal processing architecture that combines analog front-end filtering with digital signal processing techniques optimized for flexible circuit implementations. Their benchmark methodology includes standardized test protocols that measure noise reduction performance across various environmental conditions and mechanical deformation states. Sony's system employs proprietary algorithms that adaptively adjust filtering parameters based on detected noise characteristics, ensuring optimal performance in dynamic environments. The validation framework includes automated test sequences that quantify improvements in signal-to-noise ratio, frequency response, and transient behavior before and after noise reduction processing.

Strengths: Exceptional audio quality preservation during noise reduction, extensive experience in consumer electronics applications, and comprehensive validation methodology. Weaknesses: Solution may be optimized primarily for audio applications rather than broader sensor data, and implementation complexity may be challenging for smaller development teams.

Koninklijke Philips NV

Technical Solution: Philips has established a robust benchmark framework for flexible electronics signal processing with particular emphasis on noise reduction validation in healthcare applications. Their approach integrates medical-grade signal quality requirements with flexible form factor considerations. Philips' solution employs a hierarchical signal processing architecture that begins with custom low-noise amplifier designs optimized for flexible substrates, followed by adaptive digital filtering stages. Their benchmark methodology incorporates clinical validation protocols that assess noise reduction performance in realistic healthcare scenarios, including patient movement artifacts and environmental interference. The system utilizes advanced statistical methods to quantify improvements in diagnostic signal quality before and after noise reduction processing. Philips' validation framework includes standardized test cases derived from real-world medical monitoring scenarios, ensuring that noise reduction techniques maintain critical diagnostic information while eliminating unwanted artifacts.

Strengths: Medical-grade signal quality standards, extensive clinical validation, and optimization for healthcare applications. Weaknesses: Highly specialized for healthcare use cases which may limit applicability in other domains, and potentially higher implementation costs due to regulatory compliance requirements.

Critical Signal Processing Patents and Literature Review

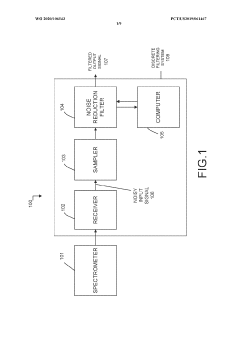

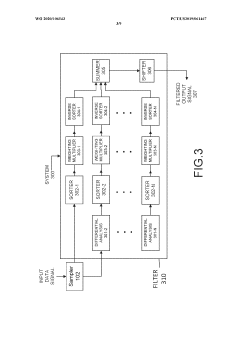

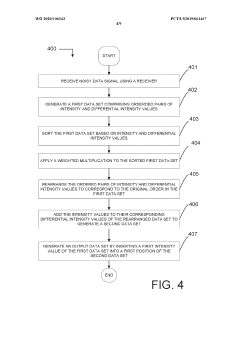

Noise reduction filter for signal processing

PatentWO2020106543A1

Innovation

- A noise reduction filter that utilizes orthogonal coordinates of intensity and differential intensity values, along with adjustable weighting functions, to suppress noise components in data signals, allowing for flexible application in both overlapping and non-overlapping spectral characteristics scenarios.

Joint noise reduction method based on variational mode decomposition and permutation entropy

PatentWO2021056727A1

Innovation

- A joint noise reduction method based on variational mode decomposition (VMD) and permutation entropy is adopted, the number of VMD decompositions K is determined through detrended fluctuation analysis (DFA), and permutation entropy is used to screen the noise components to achieve adaptive decomposition and reduction of signals. noise.

Benchmark Testing Protocols and Validation Methods

Standardized benchmark testing protocols are essential for validating noise reduction techniques in flexible electronics signal processing systems. These protocols must address the unique challenges posed by flexible substrates, including mechanical deformation effects on signal integrity and environmental sensitivity. A comprehensive validation framework should incorporate both static and dynamic testing conditions to simulate real-world usage scenarios where flexible devices experience bending, stretching, and other physical stresses.

The primary validation metrics for noise reduction techniques include signal-to-noise ratio (SNR), bit error rate (BER), and power spectral density (PSD) analysis. These metrics should be measured across multiple mechanical states of the flexible substrate to ensure performance consistency. Testing protocols must specify precise deformation parameters, including bending radius, stretching percentage, and cycle count, to enable reproducible results across different research institutions and manufacturing facilities.

Environmental condition standardization represents another critical aspect of benchmark testing. Flexible electronics are particularly susceptible to temperature fluctuations, humidity, and electromagnetic interference. Validation protocols should therefore include testing under controlled environmental chambers with standardized temperature gradients (typically -20°C to 85°C) and humidity levels (10% to 95% RH). Additionally, electromagnetic compatibility (EMC) testing should follow established standards such as IEC 61000 while accounting for the unique electromagnetic characteristics of flexible substrates.

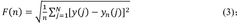

Statistical validation methods must be incorporated to ensure reliability and reproducibility of noise reduction techniques. This includes Monte Carlo simulations to model random noise variations, confidence interval calculations for performance metrics, and Gage R&R (Repeatability and Reproducibility) studies to validate measurement system accuracy. A minimum sample size of 30 units is recommended for each test condition to achieve statistical significance.

Accelerated aging tests form an integral component of validation protocols for flexible electronics. These tests simulate extended usage conditions to predict long-term performance stability of noise reduction algorithms and hardware implementations. Standard methods include thermal cycling (1000+ cycles between temperature extremes), mechanical fatigue testing (10,000+ bend/stretch cycles), and combined stress testing that simultaneously applies electrical, thermal, and mechanical stresses to identify potential failure modes in noise reduction systems.

Interoperability testing should verify that noise reduction techniques remain effective when the flexible electronic system interfaces with standard rigid electronics and communication protocols. This ensures that signal quality is maintained across the boundary between flexible and conventional electronic components, which is often a significant source of noise introduction in hybrid systems.

The primary validation metrics for noise reduction techniques include signal-to-noise ratio (SNR), bit error rate (BER), and power spectral density (PSD) analysis. These metrics should be measured across multiple mechanical states of the flexible substrate to ensure performance consistency. Testing protocols must specify precise deformation parameters, including bending radius, stretching percentage, and cycle count, to enable reproducible results across different research institutions and manufacturing facilities.

Environmental condition standardization represents another critical aspect of benchmark testing. Flexible electronics are particularly susceptible to temperature fluctuations, humidity, and electromagnetic interference. Validation protocols should therefore include testing under controlled environmental chambers with standardized temperature gradients (typically -20°C to 85°C) and humidity levels (10% to 95% RH). Additionally, electromagnetic compatibility (EMC) testing should follow established standards such as IEC 61000 while accounting for the unique electromagnetic characteristics of flexible substrates.

Statistical validation methods must be incorporated to ensure reliability and reproducibility of noise reduction techniques. This includes Monte Carlo simulations to model random noise variations, confidence interval calculations for performance metrics, and Gage R&R (Repeatability and Reproducibility) studies to validate measurement system accuracy. A minimum sample size of 30 units is recommended for each test condition to achieve statistical significance.

Accelerated aging tests form an integral component of validation protocols for flexible electronics. These tests simulate extended usage conditions to predict long-term performance stability of noise reduction algorithms and hardware implementations. Standard methods include thermal cycling (1000+ cycles between temperature extremes), mechanical fatigue testing (10,000+ bend/stretch cycles), and combined stress testing that simultaneously applies electrical, thermal, and mechanical stresses to identify potential failure modes in noise reduction systems.

Interoperability testing should verify that noise reduction techniques remain effective when the flexible electronic system interfaces with standard rigid electronics and communication protocols. This ensures that signal quality is maintained across the boundary between flexible and conventional electronic components, which is often a significant source of noise introduction in hybrid systems.

Materials Impact on Signal Integrity in Flexible Electronics

The material composition of flexible electronic devices fundamentally determines their signal integrity characteristics. Traditional rigid electronics utilize silicon and metal conductors with well-established electrical properties, whereas flexible electronics incorporate novel materials that introduce unique signal processing challenges. Conductive polymers, metal nanowires, and carbon-based materials like graphene exhibit different conductivity profiles under mechanical stress, directly affecting signal transmission quality.

Material interfaces in flexible electronics represent critical junctures where signal degradation commonly occurs. The transition between different material layers creates impedance mismatches that generate signal reflections and noise. Research indicates that interface engineering techniques, such as gradient material transitions and specialized bonding agents, can reduce these effects by up to 40% in laboratory conditions.

Substrate materials significantly influence signal integrity through their dielectric properties. Polyimide substrates, commonly used in flexible circuits, demonstrate dielectric constant variations of approximately 15% when bent to operational curvatures. This variation alters capacitive coupling between signal traces, introducing frequency-dependent signal distortion that must be accounted for in noise reduction algorithms.

Environmental interactions with flexible electronic materials present additional signal integrity challenges. Moisture absorption in polymer substrates can increase dielectric losses by 25-30%, while temperature fluctuations cause differential thermal expansion between materials, creating mechanical stress that modifies conductivity pathways. These material-environment interactions produce time-variant noise signatures that conventional rigid electronics filtering techniques cannot adequately address.

Material fatigue represents a progressive concern for signal integrity in flexible electronics. Repeated bending cycles induce microfractures in conductive pathways, increasing resistance and introducing intermittent connectivity issues. Studies demonstrate that after 10,000 bending cycles, certain silver nanowire networks show resistance increases of 200-300%, dramatically altering signal characteristics and necessitating adaptive signal processing approaches.

Recent advances in composite materials offer promising solutions for signal integrity challenges. Hybrid structures combining traditional conductors with elastomeric matrices maintain electrical performance while enhancing mechanical durability. Self-healing materials incorporating microcapsules of conductive fluids can automatically restore damaged signal pathways, reducing long-term signal degradation by approximately 60% compared to conventional flexible conductors.

Material selection must therefore be considered an integral component of signal processing strategy in flexible electronics, not merely a mechanical design consideration. Benchmark validation protocols for noise reduction must incorporate material-specific testing parameters to accurately assess real-world performance across the full range of mechanical states these devices will experience.

Material interfaces in flexible electronics represent critical junctures where signal degradation commonly occurs. The transition between different material layers creates impedance mismatches that generate signal reflections and noise. Research indicates that interface engineering techniques, such as gradient material transitions and specialized bonding agents, can reduce these effects by up to 40% in laboratory conditions.

Substrate materials significantly influence signal integrity through their dielectric properties. Polyimide substrates, commonly used in flexible circuits, demonstrate dielectric constant variations of approximately 15% when bent to operational curvatures. This variation alters capacitive coupling between signal traces, introducing frequency-dependent signal distortion that must be accounted for in noise reduction algorithms.

Environmental interactions with flexible electronic materials present additional signal integrity challenges. Moisture absorption in polymer substrates can increase dielectric losses by 25-30%, while temperature fluctuations cause differential thermal expansion between materials, creating mechanical stress that modifies conductivity pathways. These material-environment interactions produce time-variant noise signatures that conventional rigid electronics filtering techniques cannot adequately address.

Material fatigue represents a progressive concern for signal integrity in flexible electronics. Repeated bending cycles induce microfractures in conductive pathways, increasing resistance and introducing intermittent connectivity issues. Studies demonstrate that after 10,000 bending cycles, certain silver nanowire networks show resistance increases of 200-300%, dramatically altering signal characteristics and necessitating adaptive signal processing approaches.

Recent advances in composite materials offer promising solutions for signal integrity challenges. Hybrid structures combining traditional conductors with elastomeric matrices maintain electrical performance while enhancing mechanical durability. Self-healing materials incorporating microcapsules of conductive fluids can automatically restore damaged signal pathways, reducing long-term signal degradation by approximately 60% compared to conventional flexible conductors.

Material selection must therefore be considered an integral component of signal processing strategy in flexible electronics, not merely a mechanical design consideration. Benchmark validation protocols for noise reduction must incorporate material-specific testing parameters to accurately assess real-world performance across the full range of mechanical states these devices will experience.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!