Flexible Electronics Bend Resistance Performance in Mobile Technology

SEP 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Flexible Electronics Evolution and Performance Objectives

Flexible electronics technology has evolved significantly over the past two decades, transitioning from laboratory curiosities to commercially viable products. The journey began with rudimentary flexible displays in the early 2000s, characterized by limited durability and performance degradation after minimal bending cycles. By 2010, significant breakthroughs in materials science enabled the development of more robust flexible components, particularly in conductive polymers and thin-film transistors that could withstand moderate mechanical stress.

The evolution accelerated around 2015 with the introduction of graphene and carbon nanotube-based flexible conductors, which demonstrated exceptional electrical properties while maintaining structural integrity under deformation. This period marked a critical transition from proof-of-concept prototypes to practical applications in consumer electronics, particularly in mobile devices where form factor innovation became a key differentiator in the market.

Current flexible electronics technology aims to achieve several critical performance objectives that balance technical capabilities with practical implementation requirements. Primary among these is bend resistance performance, with industry standards now targeting components that can withstand 200,000+ bend cycles at radii of less than 5mm without significant performance degradation. This represents a substantial improvement from early iterations that failed after merely hundreds of cycles.

Electrical performance stability under mechanical stress remains a fundamental challenge, with objectives focused on maintaining consistent conductivity and signal integrity during and after repeated deformation. Modern specifications typically require less than 5% resistance variation across the operational bending range, a target that necessitates sophisticated material engineering and structural design approaches.

Durability objectives extend beyond mere bend resistance to encompass environmental resilience, including temperature fluctuations (-20°C to 60°C), humidity variations, and exposure to common chemicals found in everyday use environments. The industry is working toward flexible components with operational lifespans comparable to rigid electronics, targeting 3-5 years of regular use in mobile devices.

Manufacturing scalability represents another critical objective, with efforts focused on transitioning from laboratory-scale production to mass manufacturing techniques that maintain performance consistency while reducing unit costs. Current goals include developing roll-to-roll processing methods capable of producing flexible electronic components with defect rates below 100 parts per million.

Integration compatibility with existing mobile technology ecosystems constitutes the final major objective, requiring flexible components that can interface seamlessly with conventional rigid electronics while accommodating the space and power constraints inherent in portable devices. This includes developing standardized connection interfaces and addressing thermal management challenges unique to flexible form factors.

The evolution accelerated around 2015 with the introduction of graphene and carbon nanotube-based flexible conductors, which demonstrated exceptional electrical properties while maintaining structural integrity under deformation. This period marked a critical transition from proof-of-concept prototypes to practical applications in consumer electronics, particularly in mobile devices where form factor innovation became a key differentiator in the market.

Current flexible electronics technology aims to achieve several critical performance objectives that balance technical capabilities with practical implementation requirements. Primary among these is bend resistance performance, with industry standards now targeting components that can withstand 200,000+ bend cycles at radii of less than 5mm without significant performance degradation. This represents a substantial improvement from early iterations that failed after merely hundreds of cycles.

Electrical performance stability under mechanical stress remains a fundamental challenge, with objectives focused on maintaining consistent conductivity and signal integrity during and after repeated deformation. Modern specifications typically require less than 5% resistance variation across the operational bending range, a target that necessitates sophisticated material engineering and structural design approaches.

Durability objectives extend beyond mere bend resistance to encompass environmental resilience, including temperature fluctuations (-20°C to 60°C), humidity variations, and exposure to common chemicals found in everyday use environments. The industry is working toward flexible components with operational lifespans comparable to rigid electronics, targeting 3-5 years of regular use in mobile devices.

Manufacturing scalability represents another critical objective, with efforts focused on transitioning from laboratory-scale production to mass manufacturing techniques that maintain performance consistency while reducing unit costs. Current goals include developing roll-to-roll processing methods capable of producing flexible electronic components with defect rates below 100 parts per million.

Integration compatibility with existing mobile technology ecosystems constitutes the final major objective, requiring flexible components that can interface seamlessly with conventional rigid electronics while accommodating the space and power constraints inherent in portable devices. This includes developing standardized connection interfaces and addressing thermal management challenges unique to flexible form factors.

Market Demand Analysis for Bendable Mobile Devices

The global market for bendable mobile devices has witnessed significant growth in recent years, driven by consumer demand for more durable, versatile, and innovative products. Market research indicates that the flexible electronics sector, particularly in mobile technology, is projected to reach $42 billion by 2026, with a compound annual growth rate of 23% from 2021. This remarkable growth trajectory underscores the increasing consumer appetite for devices that can withstand physical stress while maintaining functionality.

Consumer preference studies reveal that durability ranks among the top three purchasing considerations for smartphone buyers, with 67% of consumers expressing concern about screen damage from drops or bending. This concern has created a substantial market opportunity for manufacturers who can deliver robust flexible display technologies that maintain performance integrity even after thousands of bend cycles.

The enterprise sector represents another significant market segment, with businesses increasingly adopting foldable devices for their employees. Corporate procurement data shows a 34% increase in enterprise spending on flexible display devices between 2020 and 2022, primarily driven by the enhanced productivity offered by larger screen real estate in a compact form factor.

Regional market analysis indicates varying adoption rates across different geographical areas. Asia-Pacific leads the market with 43% share, followed by North America (28%) and Europe (22%). Emerging markets in South America and Africa are showing accelerated growth rates, albeit from a smaller base, suggesting untapped potential for future expansion.

Consumer willingness-to-pay metrics demonstrate that users are prepared to pay a premium of 15-20% for devices with proven bend resistance capabilities compared to conventional rigid alternatives. This price elasticity provides manufacturers with margin potential to invest in advanced flexible electronics research and development.

Market segmentation analysis reveals distinct consumer groups with different needs regarding flexibility. The "tech enthusiast" segment prioritizes innovation and novel form factors, while the "durability-focused" segment values longevity and resistance to daily wear and tear. Meanwhile, the "productivity-oriented" segment seeks devices that can transform between different usage modes.

Industry forecasts predict that as manufacturing processes mature and economies of scale take effect, the cost differential between flexible and rigid devices will narrow to under 10% by 2025. This price convergence is expected to accelerate mainstream adoption, potentially expanding the addressable market by an additional 30% over the next five years.

Consumer preference studies reveal that durability ranks among the top three purchasing considerations for smartphone buyers, with 67% of consumers expressing concern about screen damage from drops or bending. This concern has created a substantial market opportunity for manufacturers who can deliver robust flexible display technologies that maintain performance integrity even after thousands of bend cycles.

The enterprise sector represents another significant market segment, with businesses increasingly adopting foldable devices for their employees. Corporate procurement data shows a 34% increase in enterprise spending on flexible display devices between 2020 and 2022, primarily driven by the enhanced productivity offered by larger screen real estate in a compact form factor.

Regional market analysis indicates varying adoption rates across different geographical areas. Asia-Pacific leads the market with 43% share, followed by North America (28%) and Europe (22%). Emerging markets in South America and Africa are showing accelerated growth rates, albeit from a smaller base, suggesting untapped potential for future expansion.

Consumer willingness-to-pay metrics demonstrate that users are prepared to pay a premium of 15-20% for devices with proven bend resistance capabilities compared to conventional rigid alternatives. This price elasticity provides manufacturers with margin potential to invest in advanced flexible electronics research and development.

Market segmentation analysis reveals distinct consumer groups with different needs regarding flexibility. The "tech enthusiast" segment prioritizes innovation and novel form factors, while the "durability-focused" segment values longevity and resistance to daily wear and tear. Meanwhile, the "productivity-oriented" segment seeks devices that can transform between different usage modes.

Industry forecasts predict that as manufacturing processes mature and economies of scale take effect, the cost differential between flexible and rigid devices will narrow to under 10% by 2025. This price convergence is expected to accelerate mainstream adoption, potentially expanding the addressable market by an additional 30% over the next five years.

Current Challenges in Flexible Electronics Durability

Despite significant advancements in flexible electronics, durability remains a critical challenge, particularly in mobile technology applications where devices undergo frequent bending and folding. The primary issue lies in the mechanical stress that occurs during repeated flexing, which can lead to material fatigue and eventual failure. Current flexible displays typically withstand between 100,000 to 200,000 bend cycles before showing signs of degradation, which is insufficient for long-term consumer use in foldable smartphones and wearable devices.

Material limitations constitute a fundamental obstacle. Traditional conductive materials like indium tin oxide (ITO) are inherently brittle and develop microcracks when subjected to bending stress. While alternative materials such as silver nanowires, carbon nanotubes, and graphene demonstrate improved flexibility, they still face challenges in maintaining consistent electrical conductivity after repeated bending cycles, especially at bend radii below 3mm.

Interface delamination presents another significant durability concern. Flexible electronic devices consist of multiple layers with different mechanical properties, creating stress concentrations at interfaces during bending. These stress differentials often lead to delamination between layers, compromising both structural integrity and electrical performance. Current adhesion technologies struggle to maintain robust bonds under dynamic bending conditions, particularly in environments with fluctuating temperature and humidity.

Environmental factors further exacerbate durability challenges. Moisture ingress through microscopic cracks that develop during bending can accelerate corrosion of conductive elements. Additionally, temperature variations cause differential thermal expansion between materials, intensifying mechanical stress during bending cycles. Most current flexible electronics demonstrate significant performance degradation when subjected to combined environmental stressors and mechanical bending.

Testing methodologies for bend resistance also present limitations. Standard testing protocols often fail to accurately simulate real-world usage patterns, leading to discrepancies between laboratory performance and actual field durability. The industry lacks standardized testing methods that comprehensively evaluate bend resistance across different environmental conditions and usage scenarios, making it difficult to compare solutions or establish reliable benchmarks.

Manufacturing scalability compounds these challenges. While laboratory-scale prototypes may demonstrate promising bend resistance, translating these results to mass production remains problematic. Current manufacturing processes introduce variability that affects bend performance consistency, with yield rates for high-durability flexible components typically below 70%, significantly higher than the industry standard of 90% for rigid electronics.

Addressing these challenges requires interdisciplinary approaches combining materials science, mechanical engineering, and manufacturing innovation to develop next-generation flexible electronics with substantially improved bend resistance performance for mobile technology applications.

Material limitations constitute a fundamental obstacle. Traditional conductive materials like indium tin oxide (ITO) are inherently brittle and develop microcracks when subjected to bending stress. While alternative materials such as silver nanowires, carbon nanotubes, and graphene demonstrate improved flexibility, they still face challenges in maintaining consistent electrical conductivity after repeated bending cycles, especially at bend radii below 3mm.

Interface delamination presents another significant durability concern. Flexible electronic devices consist of multiple layers with different mechanical properties, creating stress concentrations at interfaces during bending. These stress differentials often lead to delamination between layers, compromising both structural integrity and electrical performance. Current adhesion technologies struggle to maintain robust bonds under dynamic bending conditions, particularly in environments with fluctuating temperature and humidity.

Environmental factors further exacerbate durability challenges. Moisture ingress through microscopic cracks that develop during bending can accelerate corrosion of conductive elements. Additionally, temperature variations cause differential thermal expansion between materials, intensifying mechanical stress during bending cycles. Most current flexible electronics demonstrate significant performance degradation when subjected to combined environmental stressors and mechanical bending.

Testing methodologies for bend resistance also present limitations. Standard testing protocols often fail to accurately simulate real-world usage patterns, leading to discrepancies between laboratory performance and actual field durability. The industry lacks standardized testing methods that comprehensively evaluate bend resistance across different environmental conditions and usage scenarios, making it difficult to compare solutions or establish reliable benchmarks.

Manufacturing scalability compounds these challenges. While laboratory-scale prototypes may demonstrate promising bend resistance, translating these results to mass production remains problematic. Current manufacturing processes introduce variability that affects bend performance consistency, with yield rates for high-durability flexible components typically below 70%, significantly higher than the industry standard of 90% for rigid electronics.

Addressing these challenges requires interdisciplinary approaches combining materials science, mechanical engineering, and manufacturing innovation to develop next-generation flexible electronics with substantially improved bend resistance performance for mobile technology applications.

Current Bend Resistance Solutions and Materials

01 Materials for enhancing bend resistance in flexible electronics

Various materials can be incorporated into flexible electronic devices to enhance their bend resistance. These include specialized polymers, composite materials, and elastomeric substrates that can withstand repeated bending without degradation. The materials are designed to distribute stress evenly across the device, preventing localized strain that could lead to failure. These advanced materials maintain electrical conductivity and performance while allowing the device to flex and bend during normal operation.- Flexible substrate materials for bend resistance: Various substrate materials are used in flexible electronics to enhance bend resistance. These include polymer-based substrates, thin metal foils, and composite materials that can withstand repeated bending without damage. The materials are engineered to maintain electrical conductivity and structural integrity while being subjected to mechanical stress. These substrates serve as the foundation for mounting electronic components in applications requiring flexibility.

- Structural design for improved bend durability: Specific structural designs are implemented to improve the bend durability of flexible electronics. These include serpentine patterns, origami-inspired folding structures, and strategic placement of components to minimize stress concentration. The designs distribute mechanical stress during bending, preventing localized strain that could lead to failure. Such structural approaches allow for repeated bending cycles without compromising electronic functionality.

- Protective encapsulation techniques: Protective encapsulation methods are employed to shield flexible electronic components from mechanical stress during bending. These include specialized coating materials, lamination techniques, and multi-layer protection systems that maintain flexibility while providing mechanical support. The encapsulation layers act as stress buffers, preventing direct strain on sensitive electronic components and interconnects while allowing the overall device to bend.

- Interconnect technologies for flexible circuits: Advanced interconnect technologies are developed specifically for flexible electronic circuits to maintain electrical connectivity during bending. These include stretchable conductive inks, liquid metal conductors, and specialized bonding techniques that can accommodate mechanical deformation. The interconnects are designed to flex without breaking, maintaining reliable electrical connections even when the substrate is repeatedly bent or twisted.

- Testing and measurement methods for bend resistance: Specialized testing and measurement methods are developed to evaluate the bend resistance of flexible electronics. These include cyclic bend testing apparatus, strain measurement techniques, and accelerated aging tests that simulate real-world bending conditions. The methods provide quantitative data on the durability of flexible electronic devices, allowing for optimization of designs and materials to improve long-term reliability under mechanical stress.

02 Structural designs for improving bend durability

Specific structural designs can significantly improve the bend resistance of flexible electronics. These include layered architectures, serpentine patterns for conductive traces, and strategic placement of rigid components away from primary bend zones. Some designs incorporate neutral mechanical planes where strain is minimized during bending. Other approaches use segmented rigid islands connected by flexible bridges to allow overall device flexibility while protecting sensitive components.Expand Specific Solutions03 Protective encapsulation techniques

Encapsulation methods play a crucial role in protecting flexible electronic components from mechanical stress during bending. These techniques involve coating the electronics with specialized materials that can flex without cracking while providing environmental protection. Some approaches use multi-layer encapsulation with varying elastic properties to absorb and distribute mechanical stress. Advanced encapsulants can self-heal minor damage caused by repeated bending, extending the operational lifetime of flexible devices.Expand Specific Solutions04 Testing and measurement methods for bend resistance

Specialized testing methodologies have been developed to evaluate the bend resistance of flexible electronic devices. These include cyclic bend testing, fold endurance measurements, and real-time monitoring of electrical performance during mechanical deformation. Advanced imaging techniques can identify microscopic damage before device failure occurs. Some testing approaches simulate real-world usage scenarios to predict device longevity under typical bending conditions, while others focus on extreme bending to establish failure thresholds.Expand Specific Solutions05 Interconnect technologies for flexible circuits

Advanced interconnect technologies are essential for maintaining electrical connections in flexible electronics during bending. These include stretchable conductive inks, liquid metal alloys in microchannels, and specialized bonding techniques that accommodate movement. Some approaches use hierarchical structures with different levels of flexibility to prevent connection failures. Other methods incorporate redundant pathways to maintain functionality even if some connections are compromised during extreme bending, ensuring the overall reliability of the flexible electronic system.Expand Specific Solutions

Leading Companies in Flexible Electronics Industry

The flexible electronics bend resistance market in mobile technology is currently in a growth phase, with increasing demand for bendable displays and components. The market is expanding rapidly, driven by consumer preferences for durable, flexible devices. Technologically, major players like Samsung Electronics and LG Display lead with advanced OLED flexible display technologies, while companies such as Huawei, Apple, and ZTE are integrating these innovations into commercial products. Research institutions like Huazhong University and Industrial Technology Research Institute are advancing fundamental technologies. Japanese manufacturers including Sharp, Panasonic, and NEC contribute specialized components, creating a competitive landscape where Asian companies dominate but with significant global participation across the value chain.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has pioneered the Ultra-Thin Glass (UTG) technology for flexible displays, which offers superior bend resistance compared to polymer-based alternatives. Their proprietary UTG undergoes a specialized tempering process that enhances flexibility while maintaining structural integrity. Samsung's flexible electronics incorporate a multi-layer structure with a neutral plane design that positions sensitive electronic components at the zero-strain point during bending. Their displays can withstand over 200,000 folding cycles without significant performance degradation. Additionally, Samsung has developed specialized adhesives and encapsulation materials that maintain flexibility while protecting sensitive components from environmental factors. Their latest innovation includes a variable stiffness layer that can dynamically adjust rigidity across different sections of the display to optimize bend resistance at folding points.

Strengths: Industry-leading UTG technology provides superior scratch resistance while maintaining flexibility; extensive manufacturing infrastructure enables mass production of flexible displays. Weaknesses: Higher production costs compared to polymer alternatives; UTG still has limitations in achieving extremely tight folding radiuses without risking damage.

LG Electronics, Inc.

Technical Solution: LG has developed a proprietary Free-Form Battery technology that complements their flexible displays, allowing for truly bendable electronic devices. Their approach utilizes a specialized polymer substrate with embedded nano-reinforcement structures that enhance bend resistance while maintaining flexibility. LG's flexible displays incorporate a unique stress-relief layer that absorbs mechanical forces during bending, protecting the active display components. Their technology employs a variable thickness design that strategically reinforces high-stress areas while maintaining overall flexibility. LG has also pioneered advanced lamination techniques that prevent delamination during repeated bending cycles. Their latest innovation includes a self-compensating circuit design that maintains consistent electrical performance regardless of the display's physical configuration, ensuring reliable operation even after thousands of bending cycles.

Strengths: Extensive experience in OLED manufacturing provides technical advantages in flexible display production; innovative battery technologies complement flexible display development. Weaknesses: Somewhat fragmented approach to product development has resulted in less market penetration compared to competitors; some technologies still face challenges with long-term durability.

Key Patents and Research in Flexible Circuit Durability

Electric connecting part

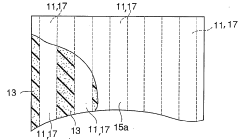

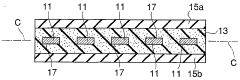

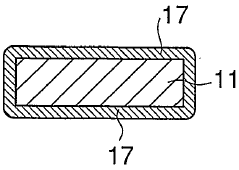

PatentWO2004089047A1

Innovation

- A flexible electrical connection component comprising a plate-like conductive pattern member embedded in a sheet-like gel member, sandwiched between flexible base sheets, which disperses bending stress through the gel member, using materials like nickel and gold for enhanced conductivity and durability.

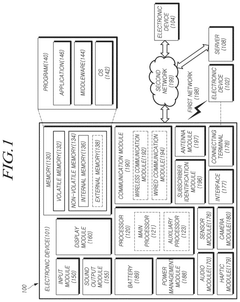

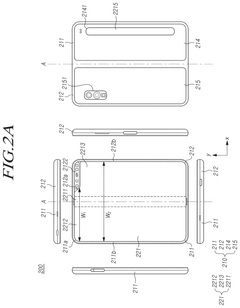

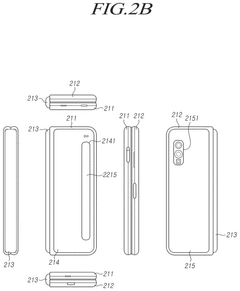

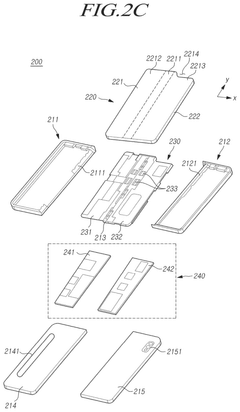

Flexible electronic device

PatentPendingUS20250008010A1

Innovation

- A flexible electronic device design featuring a patterned window with geometric and rib patterns that enhance impact resistance by distributing external forces, incorporating a composite stacked structure with a display panel, adhesive layers, and a protective layer, allowing for both flexibility and durability.

Manufacturing Processes for Enhanced Bend Performance

The manufacturing processes for flexible electronics have evolved significantly to address the critical challenge of bend resistance in mobile technology applications. Traditional rigid circuit board fabrication techniques have given way to specialized methods that accommodate the unique requirements of flexible substrates. The primary manufacturing approaches now include roll-to-roll processing, which enables continuous production of flexible circuits on polymer substrates, significantly reducing production costs while maintaining consistent quality across large surface areas.

Direct printing technologies have emerged as another cornerstone manufacturing method, with inkjet printing and screen printing allowing for precise deposition of conductive materials onto flexible substrates. These techniques eliminate the need for etching processes that can compromise substrate integrity, thereby enhancing the overall bend performance of the final product. The development of specialized conductive inks with high elasticity properties has been crucial in this advancement, allowing circuits to maintain conductivity even after thousands of bending cycles.

Lamination techniques have been refined to create multi-layer flexible circuits without compromising bend resistance. By utilizing low-temperature bonding processes and specialized adhesives that maintain flexibility after curing, manufacturers can create complex circuit architectures that withstand repeated bending stress. The integration of stress-relief structures during lamination has proven particularly effective in preventing delamination at bend points.

Laser processing has revolutionized the precision cutting and patterning of flexible substrates. Unlike mechanical cutting methods that can create microfractures at edges, laser techniques produce clean cuts with minimal heat-affected zones, significantly improving bend durability at the circuit boundaries. Advanced laser systems now incorporate real-time monitoring to ensure consistent processing parameters across variable substrate thicknesses.

Surface treatment processes have been developed specifically to enhance the adhesion between conductive materials and flexible substrates. Plasma treatment, corona discharge, and chemical functionalization methods create optimal surface conditions for material bonding without compromising the substrate's inherent flexibility. These treatments have been shown to increase bend cycle lifetimes by up to 300% in some applications.

Encapsulation technologies represent the final critical manufacturing step, with specialized polymers and thin-film barrier layers protecting sensitive electronic components while maintaining overall device flexibility. Recent innovations include self-healing encapsulants that can repair microcracks formed during bending, significantly extending the operational lifetime of flexible electronic devices in mobile applications.

Direct printing technologies have emerged as another cornerstone manufacturing method, with inkjet printing and screen printing allowing for precise deposition of conductive materials onto flexible substrates. These techniques eliminate the need for etching processes that can compromise substrate integrity, thereby enhancing the overall bend performance of the final product. The development of specialized conductive inks with high elasticity properties has been crucial in this advancement, allowing circuits to maintain conductivity even after thousands of bending cycles.

Lamination techniques have been refined to create multi-layer flexible circuits without compromising bend resistance. By utilizing low-temperature bonding processes and specialized adhesives that maintain flexibility after curing, manufacturers can create complex circuit architectures that withstand repeated bending stress. The integration of stress-relief structures during lamination has proven particularly effective in preventing delamination at bend points.

Laser processing has revolutionized the precision cutting and patterning of flexible substrates. Unlike mechanical cutting methods that can create microfractures at edges, laser techniques produce clean cuts with minimal heat-affected zones, significantly improving bend durability at the circuit boundaries. Advanced laser systems now incorporate real-time monitoring to ensure consistent processing parameters across variable substrate thicknesses.

Surface treatment processes have been developed specifically to enhance the adhesion between conductive materials and flexible substrates. Plasma treatment, corona discharge, and chemical functionalization methods create optimal surface conditions for material bonding without compromising the substrate's inherent flexibility. These treatments have been shown to increase bend cycle lifetimes by up to 300% in some applications.

Encapsulation technologies represent the final critical manufacturing step, with specialized polymers and thin-film barrier layers protecting sensitive electronic components while maintaining overall device flexibility. Recent innovations include self-healing encapsulants that can repair microcracks formed during bending, significantly extending the operational lifetime of flexible electronic devices in mobile applications.

Environmental Impact of Flexible Electronics Materials

The environmental implications of flexible electronics materials represent a critical dimension in the sustainability assessment of emerging mobile technologies. Current flexible electronic devices predominantly utilize materials such as polyimide, polyethylene terephthalate (PET), and polyethylene naphthalate (PEN) as substrates, combined with conductive materials including silver nanowires, carbon nanotubes, and indium tin oxide (ITO). These material combinations enable the bend resistance performance essential for modern mobile applications, but simultaneously present significant environmental challenges.

Manufacturing processes for flexible electronics involve energy-intensive procedures and potentially hazardous chemicals. The production of flexible substrates requires substantial energy inputs, with polyimide manufacturing generating approximately 30% more greenhouse gas emissions compared to conventional rigid substrates. Additionally, the etching processes used in creating conductive patterns often employ acids and solvents that pose environmental risks if improperly managed.

The end-of-life management of flexible electronic components presents another environmental concern. Unlike traditional electronics with easily separable components, the integrated nature of flexible electronics—where conductive materials are intimately bonded with polymer substrates—complicates recycling efforts. Current estimates suggest less than 5% of flexible electronic materials are effectively recycled, with the remainder contributing to electronic waste streams.

Water consumption represents another significant environmental impact factor. The production of high-performance flexible electronic materials requires ultra-pure water for cleaning and processing, with manufacturing a single square meter of flexible display potentially consuming up to 1,500 liters of water. This intensive water usage occurs predominantly in regions already experiencing water stress.

Recent advancements in bio-based and biodegradable substrates offer promising alternatives to petroleum-derived polymers. Materials such as cellulose nanofibers and biodegradable polyesters demonstrate comparable bend resistance while reducing environmental footprint. Research indicates these bio-based alternatives can reduce carbon emissions by 35-60% compared to conventional flexible substrates, though commercial viability remains limited by higher production costs and technical performance gaps.

The environmental impact assessment must also consider the potential benefits of flexible electronics. Their lightweight nature reduces transportation-related emissions, while their durability and bend resistance can extend product lifespans, potentially offsetting initial manufacturing impacts. Life cycle assessments suggest that if a flexible device lasts 30% longer than its rigid counterpart, the overall environmental impact may be neutralized despite higher initial production impacts.

Manufacturing processes for flexible electronics involve energy-intensive procedures and potentially hazardous chemicals. The production of flexible substrates requires substantial energy inputs, with polyimide manufacturing generating approximately 30% more greenhouse gas emissions compared to conventional rigid substrates. Additionally, the etching processes used in creating conductive patterns often employ acids and solvents that pose environmental risks if improperly managed.

The end-of-life management of flexible electronic components presents another environmental concern. Unlike traditional electronics with easily separable components, the integrated nature of flexible electronics—where conductive materials are intimately bonded with polymer substrates—complicates recycling efforts. Current estimates suggest less than 5% of flexible electronic materials are effectively recycled, with the remainder contributing to electronic waste streams.

Water consumption represents another significant environmental impact factor. The production of high-performance flexible electronic materials requires ultra-pure water for cleaning and processing, with manufacturing a single square meter of flexible display potentially consuming up to 1,500 liters of water. This intensive water usage occurs predominantly in regions already experiencing water stress.

Recent advancements in bio-based and biodegradable substrates offer promising alternatives to petroleum-derived polymers. Materials such as cellulose nanofibers and biodegradable polyesters demonstrate comparable bend resistance while reducing environmental footprint. Research indicates these bio-based alternatives can reduce carbon emissions by 35-60% compared to conventional flexible substrates, though commercial viability remains limited by higher production costs and technical performance gaps.

The environmental impact assessment must also consider the potential benefits of flexible electronics. Their lightweight nature reduces transportation-related emissions, while their durability and bend resistance can extend product lifespans, potentially offsetting initial manufacturing impacts. Life cycle assessments suggest that if a flexible device lasts 30% longer than its rigid counterpart, the overall environmental impact may be neutralized despite higher initial production impacts.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!