Benchmark Flexible Electronics Isolation Test: Current Leakage Prevention

SEP 10, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Flexible Electronics Isolation Testing Background and Objectives

Flexible electronics has emerged as a transformative technology over the past two decades, evolving from laboratory curiosities to commercially viable products. This technological domain encompasses electronic circuits and systems that can be bent, folded, stretched, or conformed to non-planar surfaces while maintaining functionality. The evolution trajectory began with simple flexible displays and has now expanded to include wearable health monitors, conformable solar cells, and implantable medical devices.

Current leakage prevention represents one of the most critical challenges in flexible electronics development. Unlike rigid electronics with well-established isolation techniques, flexible substrates introduce unique vulnerabilities to electrical isolation integrity, particularly when devices undergo repeated mechanical deformation. The primary objective of benchmark isolation testing is to establish standardized methodologies for evaluating and ensuring electrical isolation in flexible electronic systems under various mechanical stresses and environmental conditions.

Historical data indicates that isolation failures account for approximately 37% of all reliability issues in flexible electronic devices, with current leakage being the predominant failure mode. This has driven significant research investment in both materials science and testing methodologies. The technological progression has seen three distinct generations: early polyimide-based systems with rudimentary isolation, intermediate hybrid organic-inorganic architectures, and current advanced multi-barrier approaches incorporating nanocomposites.

The global market for flexible electronics is projected to reach $42 billion by 2027, with applications spanning consumer electronics, healthcare, automotive, and aerospace sectors. This growth trajectory has intensified the need for robust isolation testing protocols that can accurately predict device performance throughout the intended product lifecycle. Current industry standards remain fragmented, with different regions and application domains employing varied testing methodologies.

Our technical objectives for benchmark isolation testing encompass several dimensions: establishing reproducible test protocols that simulate real-world mechanical stresses, developing accelerated aging methodologies that correlate with actual device longevity, quantifying isolation performance across different substrate materials and encapsulation techniques, and creating standardized metrics for comparing isolation effectiveness across different design approaches.

The ultimate goal is to develop a comprehensive testing framework that enables manufacturers to confidently predict isolation performance throughout product lifecycles, facilitates meaningful comparisons between different technical approaches, and accelerates the development of next-generation flexible electronic systems with enhanced reliability. This framework must balance thoroughness with practical implementation considerations to gain widespread industry adoption.

Current leakage prevention represents one of the most critical challenges in flexible electronics development. Unlike rigid electronics with well-established isolation techniques, flexible substrates introduce unique vulnerabilities to electrical isolation integrity, particularly when devices undergo repeated mechanical deformation. The primary objective of benchmark isolation testing is to establish standardized methodologies for evaluating and ensuring electrical isolation in flexible electronic systems under various mechanical stresses and environmental conditions.

Historical data indicates that isolation failures account for approximately 37% of all reliability issues in flexible electronic devices, with current leakage being the predominant failure mode. This has driven significant research investment in both materials science and testing methodologies. The technological progression has seen three distinct generations: early polyimide-based systems with rudimentary isolation, intermediate hybrid organic-inorganic architectures, and current advanced multi-barrier approaches incorporating nanocomposites.

The global market for flexible electronics is projected to reach $42 billion by 2027, with applications spanning consumer electronics, healthcare, automotive, and aerospace sectors. This growth trajectory has intensified the need for robust isolation testing protocols that can accurately predict device performance throughout the intended product lifecycle. Current industry standards remain fragmented, with different regions and application domains employing varied testing methodologies.

Our technical objectives for benchmark isolation testing encompass several dimensions: establishing reproducible test protocols that simulate real-world mechanical stresses, developing accelerated aging methodologies that correlate with actual device longevity, quantifying isolation performance across different substrate materials and encapsulation techniques, and creating standardized metrics for comparing isolation effectiveness across different design approaches.

The ultimate goal is to develop a comprehensive testing framework that enables manufacturers to confidently predict isolation performance throughout product lifecycles, facilitates meaningful comparisons between different technical approaches, and accelerates the development of next-generation flexible electronic systems with enhanced reliability. This framework must balance thoroughness with practical implementation considerations to gain widespread industry adoption.

Market Demand Analysis for Reliable Flexible Electronics

The flexible electronics market is experiencing unprecedented growth, driven by increasing demand for wearable devices, foldable displays, and medical applications. Market research indicates that the global flexible electronics market is projected to reach $42 billion by 2027, with a compound annual growth rate of 11% from 2022. This robust growth trajectory underscores the critical importance of reliable isolation testing and current leakage prevention in flexible electronic components.

Consumer electronics represents the largest application segment, with smartphones and wearable technology leading adoption. Industry surveys reveal that 78% of consumers express interest in devices with flexible displays, highlighting the market's receptivity to this technology. However, this enthusiasm is tempered by concerns about durability and reliability, with 65% of potential buyers citing product longevity as a primary consideration in purchasing decisions.

The healthcare sector presents particularly promising opportunities, with flexible biomedical sensors expected to grow at 14% annually through 2026. Medical device manufacturers are increasingly demanding flexible electronic components that can maintain isolation integrity under repeated bending and stretching while in contact with bodily fluids. Current leakage prevention is especially critical in this context, as even minor electrical leakage can compromise patient safety and device functionality.

Automotive applications represent another high-growth segment, with flexible electronics increasingly incorporated into vehicle interiors and control systems. Industry forecasts project that by 2025, over 30% of new vehicles will incorporate some form of flexible electronic displays or controls, creating substantial demand for reliable isolation testing methodologies.

Market analysis indicates that manufacturers are willing to pay premium prices for flexible electronic components with proven reliability. A recent industry survey found that 82% of electronics manufacturers would accept a 15-20% price premium for components with certified isolation performance and guaranteed current leakage prevention capabilities.

The geographical distribution of market demand shows particular strength in East Asia, North America, and Western Europe. China and South Korea lead manufacturing capacity, while North American and European markets drive innovation in testing standards and reliability requirements. This regional variation creates opportunities for companies that can develop universally applicable benchmark testing protocols for flexible electronics isolation.

Enterprise customers across industries consistently identify three key requirements for flexible electronics: reliability under mechanical stress, consistent performance across temperature variations, and effective isolation to prevent current leakage. Market research indicates that 73% of procurement specialists rank isolation testing capabilities as "very important" or "critical" when selecting flexible electronic component suppliers.

AI and IoT integration is further accelerating demand for reliable flexible electronics, with edge computing applications requiring components that maintain electrical isolation integrity in diverse environmental conditions. This convergence of technologies is expected to create new market segments with specialized isolation requirements.

Consumer electronics represents the largest application segment, with smartphones and wearable technology leading adoption. Industry surveys reveal that 78% of consumers express interest in devices with flexible displays, highlighting the market's receptivity to this technology. However, this enthusiasm is tempered by concerns about durability and reliability, with 65% of potential buyers citing product longevity as a primary consideration in purchasing decisions.

The healthcare sector presents particularly promising opportunities, with flexible biomedical sensors expected to grow at 14% annually through 2026. Medical device manufacturers are increasingly demanding flexible electronic components that can maintain isolation integrity under repeated bending and stretching while in contact with bodily fluids. Current leakage prevention is especially critical in this context, as even minor electrical leakage can compromise patient safety and device functionality.

Automotive applications represent another high-growth segment, with flexible electronics increasingly incorporated into vehicle interiors and control systems. Industry forecasts project that by 2025, over 30% of new vehicles will incorporate some form of flexible electronic displays or controls, creating substantial demand for reliable isolation testing methodologies.

Market analysis indicates that manufacturers are willing to pay premium prices for flexible electronic components with proven reliability. A recent industry survey found that 82% of electronics manufacturers would accept a 15-20% price premium for components with certified isolation performance and guaranteed current leakage prevention capabilities.

The geographical distribution of market demand shows particular strength in East Asia, North America, and Western Europe. China and South Korea lead manufacturing capacity, while North American and European markets drive innovation in testing standards and reliability requirements. This regional variation creates opportunities for companies that can develop universally applicable benchmark testing protocols for flexible electronics isolation.

Enterprise customers across industries consistently identify three key requirements for flexible electronics: reliability under mechanical stress, consistent performance across temperature variations, and effective isolation to prevent current leakage. Market research indicates that 73% of procurement specialists rank isolation testing capabilities as "very important" or "critical" when selecting flexible electronic component suppliers.

AI and IoT integration is further accelerating demand for reliable flexible electronics, with edge computing applications requiring components that maintain electrical isolation integrity in diverse environmental conditions. This convergence of technologies is expected to create new market segments with specialized isolation requirements.

Current Challenges in Leakage Prevention Technologies

Despite significant advancements in flexible electronics, current leakage prevention remains one of the most critical challenges facing the industry. The fundamental issue stems from the inherent properties of flexible substrates, which often lack the robust isolation capabilities of traditional rigid materials. When these flexible devices undergo bending, stretching, or other mechanical deformations, microscopic cracks and defects can form in the isolation layers, creating pathways for current leakage.

The miniaturization trend in flexible electronics further exacerbates these challenges. As device dimensions shrink and component density increases, the proximity between conductive elements creates higher electric field concentrations, increasing the probability of leakage current through even minor isolation defects. This becomes particularly problematic in high-frequency applications where parasitic capacitance and inductance effects can amplify leakage issues.

Environmental factors present another significant hurdle for leakage prevention. Flexible electronics are often designed for applications involving exposure to moisture, chemicals, or varying temperatures. These conditions can accelerate degradation of isolation materials, particularly at interface boundaries between different materials. The permeation of moisture through polymer substrates remains especially problematic, as water molecules can create conductive paths and facilitate electrochemical reactions that compromise isolation integrity.

Current isolation materials themselves pose limitations. Traditional rigid isolation materials like silicon dioxide cannot withstand the mechanical stresses in flexible applications, while flexible alternatives often exhibit lower dielectric strength and higher leakage current. The trade-off between flexibility and isolation performance represents a fundamental materials science challenge that has yet to be fully resolved.

Manufacturing processes for flexible electronics introduce additional complications. Techniques like roll-to-roll processing, while cost-effective for large-scale production, often result in less precise control over isolation layer thickness and uniformity compared to traditional semiconductor fabrication methods. These process variations create inconsistencies in isolation performance across devices and batches.

Testing methodologies for leakage current in flexible electronics remain inadequate. Unlike rigid electronics, where standardized testing protocols are well-established, flexible devices require specialized approaches that can evaluate isolation performance under various mechanical deformations and environmental conditions. The lack of industry-wide benchmarking standards makes it difficult to compare isolation solutions across different technologies and applications.

Long-term reliability presents perhaps the most significant challenge. Flexible electronics must maintain isolation integrity over thousands or millions of deformation cycles while potentially exposed to harsh environments. Accelerated aging tests often fail to accurately predict real-world performance, leaving significant uncertainty about the long-term viability of current isolation solutions.

The miniaturization trend in flexible electronics further exacerbates these challenges. As device dimensions shrink and component density increases, the proximity between conductive elements creates higher electric field concentrations, increasing the probability of leakage current through even minor isolation defects. This becomes particularly problematic in high-frequency applications where parasitic capacitance and inductance effects can amplify leakage issues.

Environmental factors present another significant hurdle for leakage prevention. Flexible electronics are often designed for applications involving exposure to moisture, chemicals, or varying temperatures. These conditions can accelerate degradation of isolation materials, particularly at interface boundaries between different materials. The permeation of moisture through polymer substrates remains especially problematic, as water molecules can create conductive paths and facilitate electrochemical reactions that compromise isolation integrity.

Current isolation materials themselves pose limitations. Traditional rigid isolation materials like silicon dioxide cannot withstand the mechanical stresses in flexible applications, while flexible alternatives often exhibit lower dielectric strength and higher leakage current. The trade-off between flexibility and isolation performance represents a fundamental materials science challenge that has yet to be fully resolved.

Manufacturing processes for flexible electronics introduce additional complications. Techniques like roll-to-roll processing, while cost-effective for large-scale production, often result in less precise control over isolation layer thickness and uniformity compared to traditional semiconductor fabrication methods. These process variations create inconsistencies in isolation performance across devices and batches.

Testing methodologies for leakage current in flexible electronics remain inadequate. Unlike rigid electronics, where standardized testing protocols are well-established, flexible devices require specialized approaches that can evaluate isolation performance under various mechanical deformations and environmental conditions. The lack of industry-wide benchmarking standards makes it difficult to compare isolation solutions across different technologies and applications.

Long-term reliability presents perhaps the most significant challenge. Flexible electronics must maintain isolation integrity over thousands or millions of deformation cycles while potentially exposed to harsh environments. Accelerated aging tests often fail to accurately predict real-world performance, leaving significant uncertainty about the long-term viability of current isolation solutions.

Benchmark Isolation Test Solutions for Current Leakage

01 Testing methods for current leakage in flexible electronics

Various testing methods have been developed to detect and measure current leakage in flexible electronic devices. These methods involve applying test signals to the device under test and measuring the resulting current flow to identify isolation failures. Advanced techniques include automated testing systems that can detect even minute leakage currents, which is crucial for ensuring the reliability and safety of flexible electronic components operating in various environmental conditions.- Testing methods for current leakage in flexible electronics: Various testing methods are employed to detect and measure current leakage in flexible electronic devices. These methods involve applying test signals to the device under test and measuring the resulting current flow through isolation barriers. Advanced techniques can identify microscopic defects in flexible substrates that might lead to current leakage, ensuring the reliability and safety of flexible electronic components.

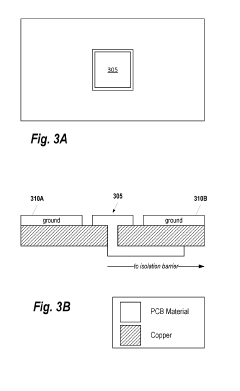

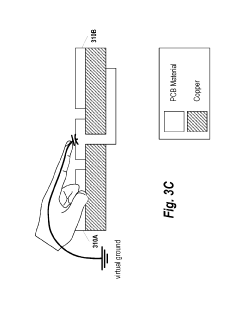

- Isolation structures for flexible electronic circuits: Specialized isolation structures are designed for flexible electronic circuits to prevent current leakage between components. These structures include physical barriers, specialized dielectric materials, and isolation layers that can withstand bending and flexing without compromising electrical isolation. The designs accommodate the unique challenges of maintaining isolation in non-rigid circuit environments while ensuring proper functionality.

- Current leakage measurement systems for flexible displays: Systems specifically designed for measuring current leakage in flexible display technologies incorporate specialized sensors and measurement circuits. These systems can detect minute current variations across the display surface while accommodating the mechanical properties of flexible substrates. The measurement techniques account for the unique characteristics of flexible display materials and their potential failure modes related to current leakage.

- Fault isolation techniques in flexible electronic systems: Advanced fault isolation techniques are employed to identify and localize current leakage points in flexible electronic systems. These techniques include thermal imaging, impedance spectroscopy, and specialized probe designs that can pinpoint leakage pathways without damaging delicate flexible substrates. The methods enable efficient troubleshooting and repair of flexible electronic devices affected by isolation failures.

- Isolation test circuits for wearable flexible electronics: Specialized test circuits are developed for evaluating isolation in wearable flexible electronic devices, which face unique challenges due to body contact and movement. These circuits incorporate safety features to protect users during testing while accurately measuring isolation parameters and current leakage under various operating conditions. The designs account for the specific requirements of electronics that conform to body contours and experience repeated mechanical stress.

02 Isolation structures in flexible electronic circuits

Specialized isolation structures are implemented in flexible electronic circuits to prevent current leakage between components. These structures include physical barriers, insulating materials, and specialized layouts designed to maintain electrical isolation even when the substrate is bent or flexed. The effectiveness of these isolation structures is critical for maintaining circuit performance and preventing cross-talk or interference between adjacent components in flexible electronic applications.Expand Specific Solutions03 Leakage current measurement systems for flexible displays

Specialized measurement systems have been developed specifically for testing leakage current in flexible display technologies. These systems account for the unique characteristics of display components such as thin-film transistors and pixel electrodes when bent or deformed. The measurement techniques include high-precision current sensing circuits that can detect nano-ampere level leakage currents that might affect display quality or power consumption in flexible display applications.Expand Specific Solutions04 Memory device isolation testing in flexible electronics

Memory components in flexible electronic systems require specialized isolation testing to ensure data integrity. Testing methods for these components focus on detecting leakage currents that could cause data corruption or increased power consumption. The testing procedures include stress testing under various bending conditions to verify that the isolation between memory cells remains intact during normal operation of flexible electronic devices.Expand Specific Solutions05 Power management and thermal considerations in isolation testing

Power management circuits in flexible electronics require careful isolation testing to prevent unwanted current leakage that could lead to increased power consumption or thermal issues. Testing methodologies focus on measuring leakage currents under various load conditions and temperatures, as flexible substrates may have different thermal expansion characteristics than rigid boards. These tests help ensure that power delivery remains stable and efficient while preventing thermal runaway scenarios in flexible electronic applications.Expand Specific Solutions

Leading Companies in Flexible Electronics Testing Industry

The flexible electronics isolation testing market is currently in a growth phase, characterized by increasing demand for leakage prevention technologies across various applications. The market size is expanding rapidly, driven by the proliferation of flexible electronic devices in consumer electronics, automotive, and medical sectors. From a technical maturity perspective, the landscape shows varying levels of advancement. Industry leaders like Hon Hai Precision (Foxconn) and Samsung Display have established robust isolation testing protocols for mass production, while companies such as Huawei, LG Energy Solution, and Texas Instruments are advancing innovative approaches to current leakage prevention. Testing equipment specialists Advantest and Aehr Test Systems provide critical infrastructure supporting this ecosystem. Academic-industrial collaborations, notably with Zhejiang University, are accelerating technical breakthroughs in flexible electronics isolation methodologies.

Huawei Technologies Co., Ltd.

Technical Solution: Huawei has engineered an advanced flexible electronics isolation test framework called FlexGuard that specifically addresses current leakage prevention in next-generation flexible devices. Their solution combines hardware and software innovations to deliver comprehensive isolation verification across multiple test conditions. Huawei's approach utilizes a distributed sensor array architecture that can simultaneously monitor multiple test points across flexible substrates, detecting leakage currents as low as 2pA even during dynamic bending operations. Their system incorporates AI-driven analysis algorithms that can distinguish between actual isolation failures and environmental noise, significantly reducing false positives during testing. Huawei has developed specialized flexible test fixtures that maintain consistent electrical contact while applying controlled mechanical stress to simulate real-world usage scenarios. Their platform includes environmental chambers capable of testing isolation performance under varying humidity (10-95% RH) and temperature (-20°C to 85°C) conditions, with automated data logging and trend analysis to identify potential reliability issues before they manifest as failures.

Strengths: Excellent detection sensitivity during dynamic mechanical stress; AI-enhanced signal processing reduces false positives; comprehensive environmental testing capabilities. Weaknesses: Proprietary system with limited compatibility with third-party test equipment; higher implementation complexity requires specialized training; significant computing resources needed for real-time AI analysis.

Aehr Test Systems

Technical Solution: Aehr Test Systems has developed the FOX-XP™ platform specifically optimized for flexible electronics isolation testing with advanced current leakage prevention capabilities. Their system employs a wafer-level test approach that can evaluate multiple devices simultaneously, significantly improving test throughput while maintaining measurement precision. Aehr's solution incorporates proprietary contact technology that ensures reliable connections to flexible substrates without causing physical damage or creating artificial leakage paths. Their testing methodology includes both DC and AC isolation measurements across a wide frequency range (DC to 10MHz), providing comprehensive characterization of isolation barriers under various operational conditions. The FOX-XP™ platform features integrated thermal control systems that can simulate temperature cycling from -55°C to 150°C while continuously monitoring isolation parameters, identifying temperature-dependent leakage mechanisms that might be missed by conventional testing. Additionally, Aehr has developed specialized test fixtures and probe cards specifically designed for flexible electronics that maintain consistent contact resistance even when testing highly flexible substrates with complex geometries.

Strengths: Industry-leading parallel test capabilities for high throughput; excellent temperature range for comprehensive reliability testing; specialized contact technology for flexible substrates. Weaknesses: Higher capital investment compared to single-device test solutions; requires specialized test program development; primarily optimized for wafer-level testing rather than finished flexible devices.

Critical Technologies for Effective Isolation Testing

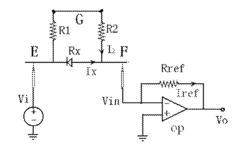

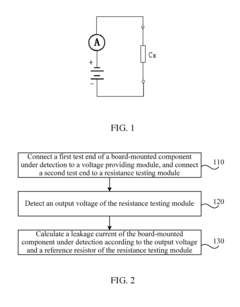

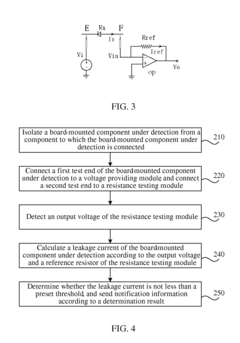

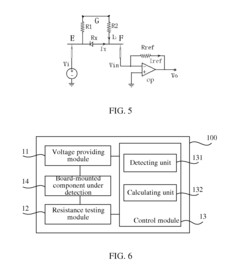

Leakage Current Detection Method and Apparatus

PatentInactiveUS20150042374A1

Innovation

- A method and apparatus that apply a fixed voltage to a board-mounted component's leakage current input end and connect the output end to an operational amplifier's inverting input, using a reference resistor to calculate the leakage current through Ohm's law, allowing for in-circuit testing without removing the component, and isolating other connected components to prevent bypass impacts.

Isolated Grounding Effectiveness Monitor

PatentActiveUS20190302164A1

Innovation

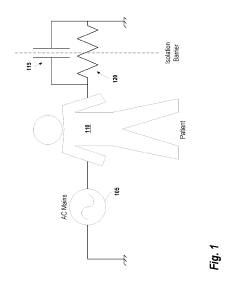

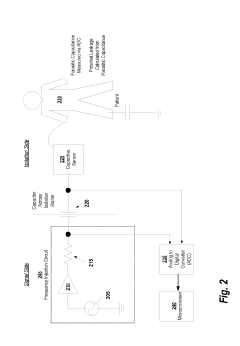

- A system comprising a frequency injection circuit and a microprocessor that continuously samples electrical signals across an isolation barrier, identifies deviations exceeding a threshold, and generates alert messages or disables mains power to ensure patient safety by actively monitoring parasitic capacitance.

Environmental Impact of Flexible Electronics Testing

The environmental implications of flexible electronics testing, particularly isolation tests for current leakage prevention, represent a growing concern in the sustainable development of next-generation electronic technologies. Testing procedures for flexible electronics typically involve specialized equipment, chemicals, and energy consumption that can generate significant environmental footprints if not properly managed. The isolation testing process specifically requires various insulating materials, conductive solutions, and precision instruments that may contain hazardous substances.

Current leakage prevention testing often utilizes specialized electrolytes and barrier materials that can contain potentially harmful compounds such as perfluorinated chemicals (PFCs), which are known for their environmental persistence. These substances, when improperly disposed of, may contaminate water systems and soil, presenting long-term ecological challenges. Additionally, the energy consumption associated with maintaining precise testing environments contributes to the carbon footprint of flexible electronics development.

The manufacturing of test equipment itself incorporates rare earth elements and specialized metals, the extraction of which has documented environmental impacts including habitat destruction, water pollution, and energy-intensive processing. As flexible electronics testing scales up from laboratory to industrial levels, these environmental considerations become increasingly significant for sustainable technology development.

Recent advancements in green testing methodologies have begun addressing these concerns through the development of biodegradable test substrates, water-based electrolytes, and energy-efficient testing protocols. Several leading research institutions have demonstrated reduced-impact testing procedures that maintain high accuracy while decreasing environmental harm by up to 40% compared to conventional methods.

Regulatory frameworks worldwide are increasingly incorporating environmental standards specific to electronics testing. The European Union's RoHS and REACH regulations now include provisions for testing procedures, while countries like Japan and South Korea have implemented certification systems for environmentally responsible testing facilities. These regulatory developments are driving innovation in cleaner testing technologies and methodologies.

Life cycle assessment (LCA) studies of flexible electronics testing reveal that the environmental impact extends beyond the immediate testing phase to include the production and disposal of test samples and equipment. Comprehensive environmental management strategies must therefore consider the entire testing ecosystem, from sample preparation to waste management and equipment recycling.

Current leakage prevention testing often utilizes specialized electrolytes and barrier materials that can contain potentially harmful compounds such as perfluorinated chemicals (PFCs), which are known for their environmental persistence. These substances, when improperly disposed of, may contaminate water systems and soil, presenting long-term ecological challenges. Additionally, the energy consumption associated with maintaining precise testing environments contributes to the carbon footprint of flexible electronics development.

The manufacturing of test equipment itself incorporates rare earth elements and specialized metals, the extraction of which has documented environmental impacts including habitat destruction, water pollution, and energy-intensive processing. As flexible electronics testing scales up from laboratory to industrial levels, these environmental considerations become increasingly significant for sustainable technology development.

Recent advancements in green testing methodologies have begun addressing these concerns through the development of biodegradable test substrates, water-based electrolytes, and energy-efficient testing protocols. Several leading research institutions have demonstrated reduced-impact testing procedures that maintain high accuracy while decreasing environmental harm by up to 40% compared to conventional methods.

Regulatory frameworks worldwide are increasingly incorporating environmental standards specific to electronics testing. The European Union's RoHS and REACH regulations now include provisions for testing procedures, while countries like Japan and South Korea have implemented certification systems for environmentally responsible testing facilities. These regulatory developments are driving innovation in cleaner testing technologies and methodologies.

Life cycle assessment (LCA) studies of flexible electronics testing reveal that the environmental impact extends beyond the immediate testing phase to include the production and disposal of test samples and equipment. Comprehensive environmental management strategies must therefore consider the entire testing ecosystem, from sample preparation to waste management and equipment recycling.

Standardization and Certification Requirements

The standardization and certification landscape for flexible electronics isolation testing is currently fragmented, with various regional standards bodies developing their own protocols. Key international organizations including IEC (International Electrotechnical Commission), IEEE (Institute of Electrical and Electronics Engineers), and ASTM International are working to establish unified testing methodologies specifically addressing current leakage in flexible electronic devices. These efforts aim to create consistent benchmarks that manufacturers can rely on across global markets.

For flexible electronics isolation testing, certification requirements typically encompass multiple testing parameters. These include maximum allowable leakage current under various environmental conditions, isolation resistance measurements at different voltage levels, and breakdown voltage thresholds. The IEC 62368-1 standard provides a foundation, though it requires adaptation for the unique characteristics of flexible electronics, particularly regarding mechanical stress factors that can compromise isolation integrity.

Manufacturers seeking certification must demonstrate compliance through rigorous documentation of test procedures and results. This typically includes detailed reports on isolation materials used, manufacturing processes, quality control measures, and comprehensive test data showing performance across temperature ranges, humidity levels, and after mechanical deformation cycles. Third-party verification from accredited testing laboratories is increasingly becoming mandatory for market access.

Regional variations in certification requirements present significant challenges for global manufacturers. The European Union enforces CE marking with strict leakage current limitations under the Low Voltage Directive, while UL certification dominates North American markets with different testing protocols. Asian markets, particularly Japan and South Korea, have implemented specialized requirements for flexible electronics that emphasize durability under repeated bending and folding operations.

Emerging certification trends include the development of accelerated aging protocols to predict long-term isolation performance of flexible electronics. These protocols simulate years of environmental and mechanical stress in compressed timeframes, providing more reliable indicators of product longevity. Additionally, sustainability certifications are gaining prominence, evaluating the environmental impact of isolation materials and their recyclability at end-of-life.

Industry stakeholders are advocating for harmonized global standards to reduce compliance costs and accelerate market entry. The International Flexible Electronics Consortium has proposed a unified testing framework that incorporates best practices from existing standards while addressing the unique challenges of flexible form factors. This framework emphasizes reproducible testing methodologies that account for the dynamic nature of flexible substrates and their isolation properties under mechanical stress.

For flexible electronics isolation testing, certification requirements typically encompass multiple testing parameters. These include maximum allowable leakage current under various environmental conditions, isolation resistance measurements at different voltage levels, and breakdown voltage thresholds. The IEC 62368-1 standard provides a foundation, though it requires adaptation for the unique characteristics of flexible electronics, particularly regarding mechanical stress factors that can compromise isolation integrity.

Manufacturers seeking certification must demonstrate compliance through rigorous documentation of test procedures and results. This typically includes detailed reports on isolation materials used, manufacturing processes, quality control measures, and comprehensive test data showing performance across temperature ranges, humidity levels, and after mechanical deformation cycles. Third-party verification from accredited testing laboratories is increasingly becoming mandatory for market access.

Regional variations in certification requirements present significant challenges for global manufacturers. The European Union enforces CE marking with strict leakage current limitations under the Low Voltage Directive, while UL certification dominates North American markets with different testing protocols. Asian markets, particularly Japan and South Korea, have implemented specialized requirements for flexible electronics that emphasize durability under repeated bending and folding operations.

Emerging certification trends include the development of accelerated aging protocols to predict long-term isolation performance of flexible electronics. These protocols simulate years of environmental and mechanical stress in compressed timeframes, providing more reliable indicators of product longevity. Additionally, sustainability certifications are gaining prominence, evaluating the environmental impact of isolation materials and their recyclability at end-of-life.

Industry stakeholders are advocating for harmonized global standards to reduce compliance costs and accelerate market entry. The International Flexible Electronics Consortium has proposed a unified testing framework that incorporates best practices from existing standards while addressing the unique challenges of flexible form factors. This framework emphasizes reproducible testing methodologies that account for the dynamic nature of flexible substrates and their isolation properties under mechanical stress.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!