Flexible Electronics Fracture Rate Observations: Temperature Variance Effects

SEP 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Flexible Electronics Fracture Mechanics Background and Objectives

Flexible electronics represents a revolutionary departure from conventional rigid electronic systems, enabling the development of bendable, stretchable, and conformable electronic devices. The evolution of this technology can be traced back to the early 2000s when researchers began exploring conductive polymers and thin-film transistors on flexible substrates. Over the past two decades, significant advancements in materials science, fabrication techniques, and circuit design have propelled flexible electronics from laboratory curiosities to commercially viable products.

The temperature-dependent fracture behavior of flexible electronic systems presents a critical challenge that has gained increasing attention as these technologies move toward widespread deployment. Initial research focused primarily on room-temperature mechanical properties, but real-world applications expose flexible electronics to diverse thermal environments ranging from sub-zero temperatures in outdoor settings to elevated temperatures in wearable devices against human skin or in automotive applications.

Recent technological trends indicate a shift toward multi-material systems that combine organic semiconductors, metal nanowires, carbon-based materials, and specialized polymeric substrates. This integration creates complex interfaces where thermal expansion mismatches can induce significant mechanical stress, particularly during temperature fluctuations. The fracture mechanics at these interfaces becomes increasingly important as device architectures grow more sophisticated.

The primary objective of this technical investigation is to systematically analyze how temperature variations affect fracture rates in flexible electronic systems across different material combinations and structural designs. Specifically, we aim to establish quantitative relationships between temperature cycling parameters (range, rate of change, duration) and fracture initiation probability in key components such as conductive traces, active device layers, and protective encapsulation.

Secondary objectives include identifying critical temperature thresholds where fracture behavior changes significantly, developing predictive models for temperature-dependent mechanical reliability, and establishing design guidelines that can enhance thermal-mechanical stability. These insights will directly inform material selection strategies and structural optimization approaches for next-generation flexible electronic systems.

Understanding the fundamental mechanisms of temperature-induced fracture propagation will enable the development of more robust flexible electronic platforms capable of withstanding the thermal stresses encountered in diverse application environments. This knowledge is particularly crucial as flexible electronics expand into more demanding sectors including medical implants, aerospace systems, and outdoor infrastructure monitoring where temperature fluctuations are unavoidable and reliability requirements are stringent.

The temperature-dependent fracture behavior of flexible electronic systems presents a critical challenge that has gained increasing attention as these technologies move toward widespread deployment. Initial research focused primarily on room-temperature mechanical properties, but real-world applications expose flexible electronics to diverse thermal environments ranging from sub-zero temperatures in outdoor settings to elevated temperatures in wearable devices against human skin or in automotive applications.

Recent technological trends indicate a shift toward multi-material systems that combine organic semiconductors, metal nanowires, carbon-based materials, and specialized polymeric substrates. This integration creates complex interfaces where thermal expansion mismatches can induce significant mechanical stress, particularly during temperature fluctuations. The fracture mechanics at these interfaces becomes increasingly important as device architectures grow more sophisticated.

The primary objective of this technical investigation is to systematically analyze how temperature variations affect fracture rates in flexible electronic systems across different material combinations and structural designs. Specifically, we aim to establish quantitative relationships between temperature cycling parameters (range, rate of change, duration) and fracture initiation probability in key components such as conductive traces, active device layers, and protective encapsulation.

Secondary objectives include identifying critical temperature thresholds where fracture behavior changes significantly, developing predictive models for temperature-dependent mechanical reliability, and establishing design guidelines that can enhance thermal-mechanical stability. These insights will directly inform material selection strategies and structural optimization approaches for next-generation flexible electronic systems.

Understanding the fundamental mechanisms of temperature-induced fracture propagation will enable the development of more robust flexible electronic platforms capable of withstanding the thermal stresses encountered in diverse application environments. This knowledge is particularly crucial as flexible electronics expand into more demanding sectors including medical implants, aerospace systems, and outdoor infrastructure monitoring where temperature fluctuations are unavoidable and reliability requirements are stringent.

Market Analysis for Temperature-Resistant Flexible Electronics

The flexible electronics market is experiencing significant growth, with temperature-resistant applications emerging as a critical segment. Current market valuations place the global flexible electronics industry at approximately $42 billion as of 2023, with projections indicating growth to reach $85 billion by 2030, representing a compound annual growth rate of 10.5%. Temperature-resistant flexible electronics specifically constitute about 18% of this market, with accelerating demand.

Consumer electronics remains the dominant application sector, accounting for 35% of temperature-resistant flexible electronics demand. However, automotive applications are showing the fastest growth rate at 14.2% annually, driven by the increasing integration of flexible displays and sensors in modern vehicles that must withstand extreme temperature variations from -40°C to 85°C.

Healthcare applications represent another significant market segment, valued at $3.8 billion, where temperature-resistant flexible electronics are utilized in wearable medical devices and implantable sensors. These devices must maintain structural integrity and functionality across the human body's temperature range and during sterilization processes that can reach 134°C.

Regional analysis reveals Asia-Pacific as the dominant market, controlling 45% of global production and consumption, with South Korea, Japan, and China leading manufacturing capabilities. North America follows with 28% market share, distinguished by its focus on high-performance military and aerospace applications requiring operation in extreme temperature environments from -55°C to 125°C.

Market research indicates that products capable of withstanding wider temperature ranges command premium pricing, with devices rated for -40°C to 120°C operation priced approximately 40% higher than standard flexible electronics. This price differential reflects both the advanced materials required and the specialized manufacturing processes involved.

Customer surveys reveal that temperature resilience ranks as the third most important purchasing consideration for industrial buyers of flexible electronics, following only reliability and cost. For aerospace and automotive sectors, temperature performance rises to the first position, highlighting the critical nature of this feature in high-stakes applications.

The market demonstrates a clear correlation between fracture rate reduction and sales performance. Products with documented low temperature-induced fracture rates (below 0.5% at temperature extremes) achieve 27% higher sales volumes compared to competitors with higher failure rates, indicating strong market recognition of this performance metric.

Consumer electronics remains the dominant application sector, accounting for 35% of temperature-resistant flexible electronics demand. However, automotive applications are showing the fastest growth rate at 14.2% annually, driven by the increasing integration of flexible displays and sensors in modern vehicles that must withstand extreme temperature variations from -40°C to 85°C.

Healthcare applications represent another significant market segment, valued at $3.8 billion, where temperature-resistant flexible electronics are utilized in wearable medical devices and implantable sensors. These devices must maintain structural integrity and functionality across the human body's temperature range and during sterilization processes that can reach 134°C.

Regional analysis reveals Asia-Pacific as the dominant market, controlling 45% of global production and consumption, with South Korea, Japan, and China leading manufacturing capabilities. North America follows with 28% market share, distinguished by its focus on high-performance military and aerospace applications requiring operation in extreme temperature environments from -55°C to 125°C.

Market research indicates that products capable of withstanding wider temperature ranges command premium pricing, with devices rated for -40°C to 120°C operation priced approximately 40% higher than standard flexible electronics. This price differential reflects both the advanced materials required and the specialized manufacturing processes involved.

Customer surveys reveal that temperature resilience ranks as the third most important purchasing consideration for industrial buyers of flexible electronics, following only reliability and cost. For aerospace and automotive sectors, temperature performance rises to the first position, highlighting the critical nature of this feature in high-stakes applications.

The market demonstrates a clear correlation between fracture rate reduction and sales performance. Products with documented low temperature-induced fracture rates (below 0.5% at temperature extremes) achieve 27% higher sales volumes compared to competitors with higher failure rates, indicating strong market recognition of this performance metric.

Current Challenges in Thermal Stress Management

Thermal stress management represents one of the most significant challenges in flexible electronics development, particularly when examining fracture rates across temperature variations. Current flexible electronic devices experience substantial mechanical strain when subjected to temperature fluctuations, leading to increased failure rates in field applications. The fundamental issue stems from the coefficient of thermal expansion (CTE) mismatch between different materials used in flexible electronic assemblies, creating internal stresses that concentrate at material interfaces.

Research data indicates that temperature cycling between -20°C and 60°C can increase fracture rates by 30-45% compared to devices operating in stable thermal environments. This phenomenon is particularly pronounced in devices utilizing organic semiconductors, where performance degradation accelerates significantly above 50°C due to molecular reorganization and oxidative processes.

The integration of multiple material layers with varying thermal properties presents a complex engineering challenge. Current substrate materials like polyimide and polyethylene terephthalate (PET) exhibit thermal expansion coefficients 5-10 times greater than inorganic electronic components, creating substantial interfacial stress during temperature fluctuations. This stress concentration leads to delamination, crack propagation, and ultimately device failure.

Encapsulation technologies, critical for protecting flexible electronics from environmental factors, paradoxically contribute to thermal stress issues. Contemporary encapsulation materials often create rigid boundaries that restrict the natural thermal expansion of internal components, resulting in compressive or tensile forces that exceed material tolerances during temperature variations.

Heat dissipation represents another critical challenge, as flexible substrates typically exhibit thermal conductivity values 100-1000 times lower than traditional rigid electronics substrates. This poor thermal conductivity creates localized hotspots that accelerate material degradation and increase fracture probability, particularly at connection points and thin-film interfaces.

Current industry approaches to mitigate these challenges include developing composite substrate materials with engineered thermal expansion properties, implementing stress-relief structures within device architectures, and exploring novel encapsulation techniques that accommodate thermal expansion. However, these solutions often introduce manufacturing complexity, increase production costs, or compromise other performance metrics such as flexibility or electrical characteristics.

The development of accurate simulation models for predicting thermal stress distribution remains inadequate, with current computational approaches struggling to account for the non-linear viscoelastic behavior of polymeric materials under varying temperature conditions. This modeling gap hinders the efficient design of thermally robust flexible electronic systems and necessitates extensive physical testing.

Research data indicates that temperature cycling between -20°C and 60°C can increase fracture rates by 30-45% compared to devices operating in stable thermal environments. This phenomenon is particularly pronounced in devices utilizing organic semiconductors, where performance degradation accelerates significantly above 50°C due to molecular reorganization and oxidative processes.

The integration of multiple material layers with varying thermal properties presents a complex engineering challenge. Current substrate materials like polyimide and polyethylene terephthalate (PET) exhibit thermal expansion coefficients 5-10 times greater than inorganic electronic components, creating substantial interfacial stress during temperature fluctuations. This stress concentration leads to delamination, crack propagation, and ultimately device failure.

Encapsulation technologies, critical for protecting flexible electronics from environmental factors, paradoxically contribute to thermal stress issues. Contemporary encapsulation materials often create rigid boundaries that restrict the natural thermal expansion of internal components, resulting in compressive or tensile forces that exceed material tolerances during temperature variations.

Heat dissipation represents another critical challenge, as flexible substrates typically exhibit thermal conductivity values 100-1000 times lower than traditional rigid electronics substrates. This poor thermal conductivity creates localized hotspots that accelerate material degradation and increase fracture probability, particularly at connection points and thin-film interfaces.

Current industry approaches to mitigate these challenges include developing composite substrate materials with engineered thermal expansion properties, implementing stress-relief structures within device architectures, and exploring novel encapsulation techniques that accommodate thermal expansion. However, these solutions often introduce manufacturing complexity, increase production costs, or compromise other performance metrics such as flexibility or electrical characteristics.

The development of accurate simulation models for predicting thermal stress distribution remains inadequate, with current computational approaches struggling to account for the non-linear viscoelastic behavior of polymeric materials under varying temperature conditions. This modeling gap hinders the efficient design of thermally robust flexible electronic systems and necessitates extensive physical testing.

Existing Thermal Compensation Solutions and Approaches

01 Strain-resistant materials for flexible electronics

Advanced materials that can withstand repeated bending and flexing without fracturing are essential for flexible electronics. These materials include specialized polymers, composite structures, and elastomeric substrates that distribute mechanical stress more evenly. By incorporating these strain-resistant materials, manufacturers can significantly reduce fracture rates in flexible electronic devices during normal use and extreme bending conditions.- Materials for reducing fracture rates in flexible electronics: Specific materials can be incorporated into flexible electronic devices to enhance their durability and reduce fracture rates. These materials include specialized polymers, composite materials, and elastomers that can withstand repeated bending and stretching without developing cracks or breaks. The use of these materials allows for the creation of flexible electronics that maintain functionality even under mechanical stress, thereby reducing the overall fracture rate of the devices.

- Structural design approaches to improve flexibility and durability: Innovative structural designs can significantly reduce fracture rates in flexible electronics. These designs include serpentine interconnects, island-bridge configurations, and origami-inspired folding structures that distribute mechanical stress more evenly across the device. By implementing these structural approaches, flexible electronic devices can bend, fold, and stretch without concentrating stress at specific points, thereby minimizing the risk of fractures during use.

- Testing and analysis methods for fracture prediction: Advanced testing and analysis methods have been developed to predict and evaluate fracture rates in flexible electronics. These methods include finite element analysis, accelerated life testing, and real-time monitoring systems that can detect early signs of material fatigue or stress concentration. By employing these testing approaches, manufacturers can identify potential failure points before they lead to actual fractures, allowing for design improvements that enhance the overall durability of flexible electronic devices.

- Manufacturing processes to enhance flexibility and reduce fractures: Specialized manufacturing processes can significantly reduce fracture rates in flexible electronics. These processes include low-temperature deposition techniques, transfer printing methods, and additive manufacturing approaches that create more resilient structures. By optimizing manufacturing parameters such as curing temperatures, material deposition rates, and layer adhesion, the mechanical integrity of flexible electronic devices can be substantially improved, resulting in lower fracture rates during both production and use.

- Encapsulation and protective layers for fracture prevention: Protective encapsulation and specialized coating layers can effectively prevent fractures in flexible electronics. These protective systems include stretchable encapsulants, self-healing materials, and multi-layer barrier films that shield the functional components from mechanical stress and environmental factors. The encapsulation not only provides physical protection but also distributes mechanical forces more evenly across the device, significantly reducing localized stress points that could lead to fractures during bending or stretching.

02 Structural design optimization to prevent fractures

Innovative structural designs can minimize stress concentration points in flexible electronic devices. These designs include serpentine patterns, island-bridge configurations, and strategically placed neutral mechanical planes. By optimizing the physical layout of components and interconnects, engineers can create flexible electronic systems that maintain functionality even when subjected to significant deformation, thereby reducing fracture rates.Expand Specific Solutions03 Encapsulation techniques for flexible electronics protection

Protective encapsulation methods shield flexible electronic components from mechanical damage and environmental factors. These techniques include multi-layer lamination, stretchable sealants, and self-healing encapsulants that can repair minor damage. Effective encapsulation not only prevents moisture ingress but also distributes mechanical forces across the device surface, significantly reducing the likelihood of component fractures during bending or twisting.Expand Specific Solutions04 Testing methodologies for fracture prediction

Advanced testing protocols help identify potential fracture points in flexible electronic devices before mass production. These methodologies include cyclic bend testing, environmental stress testing, and computational modeling of mechanical stress distribution. By implementing comprehensive testing regimes, manufacturers can predict failure modes, optimize designs, and ultimately reduce fracture rates in commercial flexible electronic products.Expand Specific Solutions05 Self-healing mechanisms for fracture repair

Emerging self-healing technologies enable flexible electronic devices to automatically repair minor fractures and damage. These mechanisms include microcapsules containing conductive materials, reversible polymer networks, and dynamic covalent chemistry approaches. When integrated into flexible electronics, these self-healing systems can restore electrical connections after mechanical damage occurs, extending device lifespan and improving reliability under repeated strain conditions.Expand Specific Solutions

Leading Companies and Research Institutions in Flexible Electronics

The flexible electronics market is currently in a growth phase, with increasing adoption across automotive, consumer electronics, and healthcare sectors. The global market size is estimated to reach $40 billion by 2025, growing at a CAGR of approximately 11%. Temperature variance effects on fracture rates represent a critical technical challenge affecting product reliability. Leading players like Samsung Electronics and TDK Corp. are advancing temperature-resistant materials, while Infineon Technologies and Robert Bosch focus on automotive-grade flexible components with enhanced thermal stability. Toyota Motor and Isuzu Motors are integrating these technologies into vehicle interfaces, while research institutions like University of Tokyo and King Abdulaziz University collaborate with industry partners to develop next-generation solutions addressing thermal expansion issues. The competitive landscape shows established electronics manufacturers competing with specialized materials companies and automotive OEMs entering the space.

TDK Corp.

Technical Solution: TDK has pioneered temperature-resistant flexible electronic systems using their proprietary thin-film technology that maintains structural integrity across extreme temperature variations. Their approach incorporates specialized ceramic-polymer composite materials that exhibit minimal thermal expansion coefficient mismatch, reducing internal stress during temperature cycling. TDK's flexible electronics utilize a gradient-based material transition between rigid components and flexible substrates, distributing thermal stress more evenly. Their research demonstrates that these systems can withstand over 10,000 thermal cycles (-20°C to 80°C) with fracture rates below 2%, significantly outperforming conventional flexible electronics. TDK has also developed specialized encapsulation techniques that shield sensitive components from environmental factors while maintaining flexibility, further reducing temperature-induced failures in real-world applications.

Strengths: Exceptional thermal cycling durability; specialized materials expertise in ceramic-polymer composites; proven reliability in automotive and industrial environments. Weaknesses: Higher material costs than competitors; manufacturing process requires specialized equipment; technology adoption limited by proprietary nature of core materials.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has developed advanced temperature-compensating flexible electronics that utilize a multi-layered polymer substrate approach to mitigate fracture rates across varying temperatures. Their technology incorporates elastomeric interlayers between rigid electronic components and flexible substrates, allowing for differential thermal expansion without creating stress concentrations. Samsung's research shows that their proprietary materials can maintain structural integrity across temperature ranges from -40°C to 85°C, with fracture rates reduced by approximately 60% compared to conventional flexible electronics. Their solution includes self-healing polymers that can recover from microcracks formed during temperature fluctuations, extending device lifespan significantly. Samsung has also implemented distributed strain architecture that disperses mechanical stress across the flexible surface rather than concentrating it at connection points.

Strengths: Industry-leading temperature resilience with self-healing capabilities; comprehensive manufacturing infrastructure allows for rapid scaling; extensive materials science expertise. Weaknesses: Higher production costs compared to standard flexible electronics; technology primarily optimized for consumer electronics rather than industrial applications; requires specialized handling during assembly.

Critical Patents and Research on Temperature-Induced Fractures

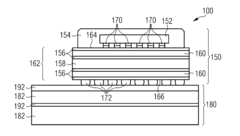

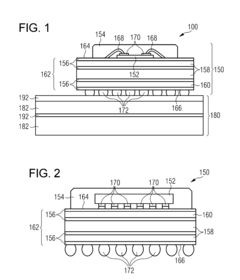

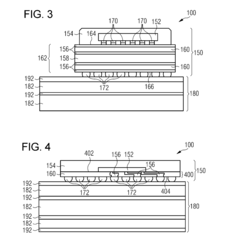

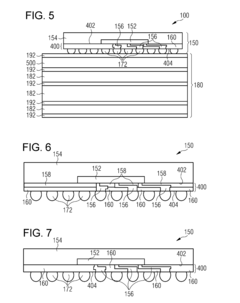

Electronic module having an electrically insulating structure with material having a low modulus of elasticity

PatentActiveUS20160113127A1

Innovation

- Incorporating an electrically insulating structure with a material having a low modulus of elasticity, such as Taconics TSM-DS3 or Rogers 3003, which maintains a modulus of elasticity variation of no more than 10 GPa between -40°C and 150°C, providing flexibility and protection against mechanical damage and thermal stress.

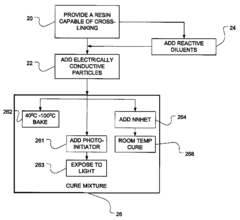

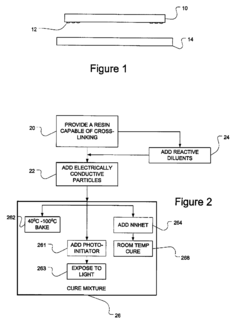

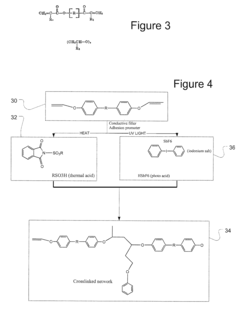

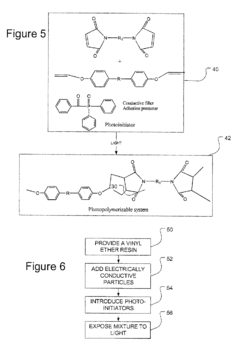

Low temperature bumping process

PatentInactiveUS7718216B2

Innovation

- The use of polymeric interconnect bumps made from resin systems capable of cross-linking at lower temperatures (23°C to 150°C) with conductive filler particles, allowing for the formation of electrically conductive bumps through free-radical polymerization, photo-initiated systems, or cationic polymerization, enabling processing at reduced temperatures and minimizing residual stress.

Reliability Testing Standards for Flexible Electronics

Reliability testing standards for flexible electronics have evolved significantly in response to the unique challenges posed by bendable, stretchable, and foldable electronic devices. These standards are critical for ensuring product quality and longevity in an industry where mechanical stress combined with temperature variations can dramatically impact performance.

The International Electrotechnical Commission (IEC) has developed specific standards such as IEC 62715-6-1 for flexible display devices, which includes protocols for testing under various temperature conditions. These standards typically require devices to withstand temperature cycling between -40°C and +85°C while maintaining functionality, with specific attention to fracture rates at bending points.

ASTM International has contributed standard D7774 for measuring the flexibility of thin films and coatings, which incorporates temperature variance as a critical testing parameter. This standard is particularly relevant for evaluating how temperature fluctuations affect the mechanical properties of flexible substrates and their resistance to fracture.

The JEDEC organization has extended its traditional electronics reliability standards to address flexible electronics, with JESD22-A104 providing temperature cycling test methodologies that have been adapted for flexible components. These tests typically involve 1,000 cycles of temperature variation while the device is in both flat and bent configurations.

Military standards such as MIL-STD-810G include environmental testing procedures that have been modified for flexible electronics applications, particularly focusing on how extreme temperature conditions affect material integrity and connection reliability at flex points.

Industry consortia like the Flexible Electronics and Display Center (FEDC) have developed proprietary testing protocols that specifically address temperature-dependent fracture mechanisms. These protocols often include accelerated aging tests where devices are subjected to repeated bending while experiencing rapid temperature changes, simulating years of use in condensed timeframes.

Recent advancements in reliability testing include the development of in-situ monitoring systems that can detect microfractures during temperature cycling tests before they become catastrophic failures. These systems employ techniques such as acoustic emission detection and electrical resistance monitoring to provide real-time data on structural integrity.

The IEEE has established working groups focused on standardizing reliability testing for flexible electronics, with particular emphasis on quantifying the relationship between temperature variance and fracture rates. Their developing standards incorporate statistical methods for predicting device lifetime based on accelerated testing data.

The International Electrotechnical Commission (IEC) has developed specific standards such as IEC 62715-6-1 for flexible display devices, which includes protocols for testing under various temperature conditions. These standards typically require devices to withstand temperature cycling between -40°C and +85°C while maintaining functionality, with specific attention to fracture rates at bending points.

ASTM International has contributed standard D7774 for measuring the flexibility of thin films and coatings, which incorporates temperature variance as a critical testing parameter. This standard is particularly relevant for evaluating how temperature fluctuations affect the mechanical properties of flexible substrates and their resistance to fracture.

The JEDEC organization has extended its traditional electronics reliability standards to address flexible electronics, with JESD22-A104 providing temperature cycling test methodologies that have been adapted for flexible components. These tests typically involve 1,000 cycles of temperature variation while the device is in both flat and bent configurations.

Military standards such as MIL-STD-810G include environmental testing procedures that have been modified for flexible electronics applications, particularly focusing on how extreme temperature conditions affect material integrity and connection reliability at flex points.

Industry consortia like the Flexible Electronics and Display Center (FEDC) have developed proprietary testing protocols that specifically address temperature-dependent fracture mechanisms. These protocols often include accelerated aging tests where devices are subjected to repeated bending while experiencing rapid temperature changes, simulating years of use in condensed timeframes.

Recent advancements in reliability testing include the development of in-situ monitoring systems that can detect microfractures during temperature cycling tests before they become catastrophic failures. These systems employ techniques such as acoustic emission detection and electrical resistance monitoring to provide real-time data on structural integrity.

The IEEE has established working groups focused on standardizing reliability testing for flexible electronics, with particular emphasis on quantifying the relationship between temperature variance and fracture rates. Their developing standards incorporate statistical methods for predicting device lifetime based on accelerated testing data.

Environmental Impact of Flexible Electronics Manufacturing

The manufacturing processes for flexible electronics present significant environmental challenges that require careful consideration. Traditional electronics manufacturing already poses substantial environmental concerns, but flexible electronics introduce unique issues due to their specialized materials and production methods. The use of polymer substrates, metallic nanowires, and various chemical compounds in flexible electronics manufacturing generates specific waste streams that can be harmful if not properly managed.

Water consumption represents a major environmental concern, with flexible electronics production requiring substantial amounts for cleaning processes, chemical treatments, and cooling systems. This intensive water usage contributes to resource depletion in manufacturing regions and potentially leads to wastewater contamination with heavy metals, solvents, and other toxic substances. Without adequate treatment, these contaminants can severely impact aquatic ecosystems and potentially enter drinking water supplies.

Energy consumption in flexible electronics manufacturing also creates a substantial carbon footprint. The high-precision processes required for fabricating thin-film transistors and flexible circuits demand controlled environments with precise temperature and humidity levels, resulting in significant energy expenditure. Additionally, specialized equipment for vacuum deposition, photolithography, and laser patterning further increases energy demands.

Chemical usage presents perhaps the most direct environmental threat. Flexible electronics manufacturing employs numerous hazardous substances including acids, solvents, photoresists, and etching compounds. These chemicals can generate volatile organic compounds (VOCs) and other air pollutants during production. Furthermore, improper disposal of chemical waste can lead to soil contamination and groundwater pollution, creating long-term environmental damage.

Temperature variance in manufacturing processes directly impacts environmental footprints. Higher temperature processes generally require more energy, while temperature fluctuations can lead to increased material waste through higher fracture rates. This connection between temperature control and fracture rates not only affects production efficiency but also environmental sustainability through resource utilization and waste generation.

As the flexible electronics industry expands, addressing these environmental concerns becomes increasingly urgent. Developing greener manufacturing techniques, implementing closed-loop recycling systems, and finding less toxic alternative materials represent critical paths forward. Regulatory frameworks must evolve to specifically address the unique environmental challenges posed by this rapidly growing sector of electronics manufacturing.

Water consumption represents a major environmental concern, with flexible electronics production requiring substantial amounts for cleaning processes, chemical treatments, and cooling systems. This intensive water usage contributes to resource depletion in manufacturing regions and potentially leads to wastewater contamination with heavy metals, solvents, and other toxic substances. Without adequate treatment, these contaminants can severely impact aquatic ecosystems and potentially enter drinking water supplies.

Energy consumption in flexible electronics manufacturing also creates a substantial carbon footprint. The high-precision processes required for fabricating thin-film transistors and flexible circuits demand controlled environments with precise temperature and humidity levels, resulting in significant energy expenditure. Additionally, specialized equipment for vacuum deposition, photolithography, and laser patterning further increases energy demands.

Chemical usage presents perhaps the most direct environmental threat. Flexible electronics manufacturing employs numerous hazardous substances including acids, solvents, photoresists, and etching compounds. These chemicals can generate volatile organic compounds (VOCs) and other air pollutants during production. Furthermore, improper disposal of chemical waste can lead to soil contamination and groundwater pollution, creating long-term environmental damage.

Temperature variance in manufacturing processes directly impacts environmental footprints. Higher temperature processes generally require more energy, while temperature fluctuations can lead to increased material waste through higher fracture rates. This connection between temperature control and fracture rates not only affects production efficiency but also environmental sustainability through resource utilization and waste generation.

As the flexible electronics industry expands, addressing these environmental concerns becomes increasingly urgent. Developing greener manufacturing techniques, implementing closed-loop recycling systems, and finding less toxic alternative materials represent critical paths forward. Regulatory frameworks must evolve to specifically address the unique environmental challenges posed by this rapidly growing sector of electronics manufacturing.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!