Benchmark Flexible Electronics Reliability: Thermal Cycling Analysis

SEP 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Flexible Electronics Reliability Background and Objectives

Flexible electronics represents a revolutionary departure from conventional rigid electronic systems, enabling the development of bendable, stretchable, and conformable electronic devices. The evolution of this technology can be traced back to the early 2000s when researchers began exploring conductive polymers and thin-film transistors on flexible substrates. Over the past two decades, significant advancements in materials science, fabrication techniques, and circuit design have propelled flexible electronics from laboratory curiosities to commercially viable products.

The technological trajectory of flexible electronics has been characterized by continuous improvements in substrate materials, from early polyimide films to more recent developments in ultra-thin glass and biodegradable polymers. Concurrently, advances in conductive materials, including silver nanowires, carbon nanotubes, and graphene, have enhanced electrical performance while maintaining mechanical flexibility.

Thermal cycling reliability represents a critical aspect of flexible electronics development. As these devices undergo repeated temperature fluctuations during both manufacturing processes and real-world applications, they face unique challenges not encountered in conventional rigid electronics. The differential thermal expansion coefficients between various materials in flexible systems can lead to mechanical stress, delamination, and ultimately, electrical failure.

The primary objective of benchmarking flexible electronics reliability through thermal cycling analysis is to establish standardized testing protocols and performance metrics that accurately predict device longevity under real-world conditions. This involves developing accelerated testing methodologies that can compress years of thermal cycling into manageable laboratory timeframes while maintaining relevance to actual use cases.

Additionally, this benchmarking aims to identify critical failure mechanisms specific to flexible electronic systems, including crack propagation in conductive traces, interface delamination, and changes in electrical characteristics due to repeated mechanical deformation under thermal stress. Understanding these failure modes is essential for designing more robust flexible electronic systems.

From an industry perspective, establishing reliable benchmarking standards for thermal cycling will facilitate meaningful comparisons between different technological approaches and material systems. This standardization is crucial for the maturation of the flexible electronics industry, as it provides manufacturers, designers, and end-users with confidence in product reliability predictions.

The ultimate goal of this technical research is to develop a comprehensive framework for evaluating and improving the thermal cycling reliability of flexible electronic systems, thereby accelerating their adoption across diverse applications including wearable health monitors, flexible displays, soft robotics, and implantable medical devices.

The technological trajectory of flexible electronics has been characterized by continuous improvements in substrate materials, from early polyimide films to more recent developments in ultra-thin glass and biodegradable polymers. Concurrently, advances in conductive materials, including silver nanowires, carbon nanotubes, and graphene, have enhanced electrical performance while maintaining mechanical flexibility.

Thermal cycling reliability represents a critical aspect of flexible electronics development. As these devices undergo repeated temperature fluctuations during both manufacturing processes and real-world applications, they face unique challenges not encountered in conventional rigid electronics. The differential thermal expansion coefficients between various materials in flexible systems can lead to mechanical stress, delamination, and ultimately, electrical failure.

The primary objective of benchmarking flexible electronics reliability through thermal cycling analysis is to establish standardized testing protocols and performance metrics that accurately predict device longevity under real-world conditions. This involves developing accelerated testing methodologies that can compress years of thermal cycling into manageable laboratory timeframes while maintaining relevance to actual use cases.

Additionally, this benchmarking aims to identify critical failure mechanisms specific to flexible electronic systems, including crack propagation in conductive traces, interface delamination, and changes in electrical characteristics due to repeated mechanical deformation under thermal stress. Understanding these failure modes is essential for designing more robust flexible electronic systems.

From an industry perspective, establishing reliable benchmarking standards for thermal cycling will facilitate meaningful comparisons between different technological approaches and material systems. This standardization is crucial for the maturation of the flexible electronics industry, as it provides manufacturers, designers, and end-users with confidence in product reliability predictions.

The ultimate goal of this technical research is to develop a comprehensive framework for evaluating and improving the thermal cycling reliability of flexible electronic systems, thereby accelerating their adoption across diverse applications including wearable health monitors, flexible displays, soft robotics, and implantable medical devices.

Market Demand Analysis for Reliable Flexible Electronics

The flexible electronics market is experiencing unprecedented growth, driven by increasing demand for wearable devices, foldable displays, and electronic skin applications. Market research indicates that the global flexible electronics market is projected to reach $42 billion by 2027, with a compound annual growth rate of 11% from 2022 to 2027. This robust growth trajectory underscores the critical importance of reliability in flexible electronic systems, particularly their ability to withstand thermal cycling conditions.

Consumer electronics represents the largest application segment, with smartphones and wearable technology leading adoption. Industry surveys reveal that 78% of consumers consider durability and reliability as primary purchasing factors for flexible electronic devices. The healthcare sector follows closely, with medical wearables and implantable devices requiring exceptional reliability standards due to their critical applications and proximity to the human body.

Thermal cycling reliability has emerged as a paramount concern for manufacturers and end-users alike. Data shows that approximately 40% of flexible electronic device failures are attributed to thermal stress-induced damage, highlighting the urgent market need for standardized thermal cycling analysis methodologies. This demand is particularly acute in automotive applications, where flexible electronics must withstand extreme temperature variations ranging from -40°C to 125°C.

Military and aerospace sectors represent premium market segments with stringent reliability requirements. These sectors demand flexible electronics that can maintain functionality through thousands of thermal cycles without performance degradation. The financial implications of reliability issues are substantial, with warranty claims and product recalls costing manufacturers an estimated $3.8 billion annually across all flexible electronics segments.

Regional market analysis indicates that Asia-Pacific dominates manufacturing capacity, while North America leads in research and development of reliability testing methodologies. European markets show the highest consumer sensitivity to reliability metrics, with 65% of surveyed European consumers willing to pay premium prices for devices with proven thermal cycling durability.

Industry stakeholders are increasingly recognizing the competitive advantage offered by superior reliability. Market differentiation through demonstrated thermal cycling performance is becoming a key strategy, with 82% of leading manufacturers investing in enhanced reliability testing infrastructure. This trend is reinforced by emerging regulatory frameworks in major markets that are beginning to mandate minimum reliability standards for flexible electronic products, particularly in medical and automotive applications.

Consumer electronics represents the largest application segment, with smartphones and wearable technology leading adoption. Industry surveys reveal that 78% of consumers consider durability and reliability as primary purchasing factors for flexible electronic devices. The healthcare sector follows closely, with medical wearables and implantable devices requiring exceptional reliability standards due to their critical applications and proximity to the human body.

Thermal cycling reliability has emerged as a paramount concern for manufacturers and end-users alike. Data shows that approximately 40% of flexible electronic device failures are attributed to thermal stress-induced damage, highlighting the urgent market need for standardized thermal cycling analysis methodologies. This demand is particularly acute in automotive applications, where flexible electronics must withstand extreme temperature variations ranging from -40°C to 125°C.

Military and aerospace sectors represent premium market segments with stringent reliability requirements. These sectors demand flexible electronics that can maintain functionality through thousands of thermal cycles without performance degradation. The financial implications of reliability issues are substantial, with warranty claims and product recalls costing manufacturers an estimated $3.8 billion annually across all flexible electronics segments.

Regional market analysis indicates that Asia-Pacific dominates manufacturing capacity, while North America leads in research and development of reliability testing methodologies. European markets show the highest consumer sensitivity to reliability metrics, with 65% of surveyed European consumers willing to pay premium prices for devices with proven thermal cycling durability.

Industry stakeholders are increasingly recognizing the competitive advantage offered by superior reliability. Market differentiation through demonstrated thermal cycling performance is becoming a key strategy, with 82% of leading manufacturers investing in enhanced reliability testing infrastructure. This trend is reinforced by emerging regulatory frameworks in major markets that are beginning to mandate minimum reliability standards for flexible electronic products, particularly in medical and automotive applications.

Current Challenges in Flexible Electronics Thermal Reliability

Despite significant advancements in flexible electronics, thermal reliability remains a critical challenge that impedes widespread commercial adoption. Current flexible electronic systems face substantial degradation when subjected to thermal cycling conditions, with failure rates increasing exponentially as temperature fluctuations become more extreme. The primary challenge stems from the inherent mismatch in coefficient of thermal expansion (CTE) between different materials used in flexible electronic assemblies, creating mechanical stress at interfaces during temperature variations.

Conventional rigid electronics typically utilize materials with relatively similar thermal expansion properties, whereas flexible systems incorporate diverse materials ranging from polymer substrates to metallic interconnects and semiconductor components. This heterogeneity results in differential expansion and contraction during thermal cycling, leading to delamination, cracking, and eventual electrical failure. For instance, polyimide substrates commonly used in flexible circuits exhibit a CTE approximately 10-20 times higher than silicon components.

Current testing methodologies for thermal reliability assessment present another significant challenge. Traditional thermal cycling tests developed for rigid electronics often fail to accurately predict the performance of flexible systems in real-world applications. The dynamic mechanical behavior of flexible substrates under thermal stress requires more sophisticated testing protocols that can simultaneously evaluate electrical performance during mechanical deformation at varying temperatures.

Manufacturing processes further complicate thermal reliability issues. Techniques such as direct printing of conductive inks on flexible substrates create unique interface characteristics that respond differently to thermal cycling compared to traditional soldered connections. These interfaces often represent the weakest points in the system, with failure mechanisms that are not fully characterized or understood in current literature.

The development of effective encapsulation solutions represents another major hurdle. While encapsulation is essential for protecting flexible electronics from environmental factors, many current encapsulants introduce additional thermal expansion mismatches or become brittle at temperature extremes, exacerbating rather than mitigating thermal cycling issues. Silicone-based encapsulants offer flexibility but often provide insufficient barrier properties, while more robust barrier materials typically lack the necessary mechanical compliance.

Energy storage components in flexible systems present unique thermal reliability challenges. Batteries and supercapacitors incorporated into flexible electronics experience significant performance degradation and safety concerns under thermal cycling conditions. The electrolyte stability, electrode adhesion, and interface integrity all deteriorate when subjected to repeated temperature fluctuations, yet standardized testing protocols for these specific failure modes remain underdeveloped.

Conventional rigid electronics typically utilize materials with relatively similar thermal expansion properties, whereas flexible systems incorporate diverse materials ranging from polymer substrates to metallic interconnects and semiconductor components. This heterogeneity results in differential expansion and contraction during thermal cycling, leading to delamination, cracking, and eventual electrical failure. For instance, polyimide substrates commonly used in flexible circuits exhibit a CTE approximately 10-20 times higher than silicon components.

Current testing methodologies for thermal reliability assessment present another significant challenge. Traditional thermal cycling tests developed for rigid electronics often fail to accurately predict the performance of flexible systems in real-world applications. The dynamic mechanical behavior of flexible substrates under thermal stress requires more sophisticated testing protocols that can simultaneously evaluate electrical performance during mechanical deformation at varying temperatures.

Manufacturing processes further complicate thermal reliability issues. Techniques such as direct printing of conductive inks on flexible substrates create unique interface characteristics that respond differently to thermal cycling compared to traditional soldered connections. These interfaces often represent the weakest points in the system, with failure mechanisms that are not fully characterized or understood in current literature.

The development of effective encapsulation solutions represents another major hurdle. While encapsulation is essential for protecting flexible electronics from environmental factors, many current encapsulants introduce additional thermal expansion mismatches or become brittle at temperature extremes, exacerbating rather than mitigating thermal cycling issues. Silicone-based encapsulants offer flexibility but often provide insufficient barrier properties, while more robust barrier materials typically lack the necessary mechanical compliance.

Energy storage components in flexible systems present unique thermal reliability challenges. Batteries and supercapacitors incorporated into flexible electronics experience significant performance degradation and safety concerns under thermal cycling conditions. The electrolyte stability, electrode adhesion, and interface integrity all deteriorate when subjected to repeated temperature fluctuations, yet standardized testing protocols for these specific failure modes remain underdeveloped.

Current Benchmark Methodologies for Thermal Cycling Analysis

01 Flexible substrate materials for enhanced reliability

The choice of substrate materials plays a crucial role in the reliability of flexible electronics. Materials such as polyimide, polyethylene terephthalate (PET), and certain polymer composites offer superior flexibility and durability under repeated bending and folding conditions. These materials can withstand mechanical stress while maintaining electrical performance, thereby enhancing the overall reliability of flexible electronic devices. Advanced substrate formulations may include additives that improve resistance to environmental factors like humidity and temperature fluctuations.- Flexible substrate materials for enhanced reliability: The choice of substrate materials plays a crucial role in the reliability of flexible electronics. Advanced polymers and composite materials that can withstand repeated bending and folding without degradation are essential. These materials provide mechanical stability while maintaining flexibility, which is critical for applications requiring durability under mechanical stress. Innovations in substrate technology include self-healing properties and strain-resistant compositions that extend the operational lifetime of flexible electronic devices.

- Encapsulation techniques for environmental protection: Protective encapsulation methods are vital for shielding flexible electronic components from environmental factors such as moisture, oxygen, and mechanical damage. Advanced encapsulation techniques include multi-layer barrier films, hermetic sealing technologies, and conformal coatings that maintain flexibility while providing robust protection. These approaches significantly improve the reliability of flexible electronics by preventing degradation from environmental exposure, thereby extending device lifespan and maintaining consistent performance under various operating conditions.

- Interconnect designs for mechanical durability: Innovative interconnect designs are essential for maintaining electrical connectivity in flexible electronics during bending, stretching, and folding operations. Serpentine, wavy, and mesh-like interconnect structures distribute mechanical stress more effectively than traditional linear connections. These designs accommodate deformation without breaking electrical pathways, significantly improving device reliability under mechanical strain. Advanced interconnect materials, including liquid metal alloys and stretchable conductive composites, further enhance the durability of connections in flexible electronic systems.

- Thermal management solutions for flexible devices: Effective thermal management is critical for the reliability of flexible electronics, as heat accumulation can accelerate material degradation and component failure. Innovative cooling solutions adapted for flexible form factors include thermally conductive adhesives, flexible heat spreaders, and phase-change materials that maintain performance during bending. These thermal management approaches prevent hotspots and ensure more uniform temperature distribution, significantly extending the operational lifetime and reliability of flexible electronic devices under various usage conditions.

- Testing and reliability assessment methodologies: Specialized testing protocols and reliability assessment methodologies have been developed specifically for flexible electronics. These include accelerated aging tests under combined mechanical and environmental stresses, cyclic bending tests, and in-situ monitoring of electrical performance during deformation. Advanced analytical techniques such as infrared thermography and acoustic microscopy help identify failure modes unique to flexible devices. These comprehensive testing approaches enable more accurate prediction of device lifespan and reliability in real-world applications, facilitating improvements in design and manufacturing processes.

02 Encapsulation techniques for environmental protection

Encapsulation methods are essential for protecting flexible electronic components from environmental factors that can compromise reliability. Techniques include thin-film encapsulation, lamination with barrier materials, and conformal coatings that shield sensitive components from moisture, oxygen, and mechanical damage. Advanced encapsulation approaches maintain flexibility while providing effective barriers against environmental degradation, extending the operational lifetime of flexible electronic devices even under challenging conditions.Expand Specific Solutions03 Strain-resistant interconnect designs

Innovative interconnect designs are critical for maintaining electrical connectivity in flexible electronics during bending and stretching. Serpentine, wavy, or mesh-like interconnect structures can accommodate mechanical deformation without fracturing. These designs distribute strain more evenly across the structure, preventing localized stress concentration that leads to failure. Materials such as liquid metal alloys and conductive polymers further enhance the reliability of interconnects by providing inherent flexibility and self-healing capabilities after mechanical stress.Expand Specific Solutions04 Thermal management solutions for flexible devices

Effective thermal management is crucial for the reliability of flexible electronics, as heat accumulation can lead to performance degradation and premature failure. Solutions include thermally conductive yet flexible materials, innovative heat spreading designs, and active cooling mechanisms adapted for bendable form factors. These approaches help maintain optimal operating temperatures even when devices are subjected to bending or folding, preventing thermal-induced stress and extending component lifespan.Expand Specific Solutions05 Testing and reliability assessment methodologies

Specialized testing methodologies have been developed to assess and predict the reliability of flexible electronic systems. These include accelerated aging tests, cyclic bending tests, environmental stress testing, and combined mechanical-electrical characterization techniques. Advanced reliability models incorporate factors such as mechanical fatigue, environmental exposure, and electrical stress to predict device lifetime under real-world usage conditions. These assessment approaches enable manufacturers to identify potential failure modes and implement design improvements before product deployment.Expand Specific Solutions

Key Industry Players in Flexible Electronics Reliability Testing

The flexible electronics reliability market is currently in a growth phase, with thermal cycling analysis emerging as a critical benchmark for product durability. The global market size is expanding rapidly, driven by applications in consumer electronics, automotive, and medical devices. Technical maturity varies significantly across players, with established semiconductor companies like GlobalFoundries and Marvell Asia leading in manufacturing reliability, while materials specialists such as ROHM and Resonac provide advanced substrate solutions. Research institutions including Xi'an Jiaotong University and Beihang University are contributing fundamental thermal cycling methodologies. Industrial giants ABB, Mitsubishi Electric, and Siemens Gamesa are integrating flexible electronics into their systems with rigorous reliability standards, creating a competitive landscape balanced between specialized technology providers and large-scale implementers.

GLOBALFOUNDRIES, Inc.

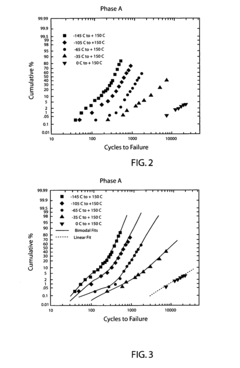

Technical Solution: GLOBALFOUNDRIES has developed a comprehensive thermal cycling analysis platform specifically for flexible electronics reliability benchmarking. Their approach combines physical testing with advanced simulation techniques to evaluate material fatigue and interconnect reliability under thermal stress conditions. The company utilizes specialized thermal chambers capable of rapid temperature cycling from -40°C to 125°C, with controlled ramp rates to simulate real-world environmental conditions. Their methodology incorporates in-situ electrical performance monitoring during thermal cycling to detect early failure indicators. GLOBALFOUNDRIES has pioneered a multi-physics simulation framework that predicts thermal-mechanical stress distribution across flexible substrates and interconnects, allowing for accelerated reliability testing and failure mode analysis. The company has established industry-standard test protocols for flexible electronics that account for unique deformation mechanisms not present in rigid electronics[1][3].

Strengths: Industry-leading simulation capabilities that accurately predict thermal cycling effects on flexible substrates; comprehensive test infrastructure specifically designed for flexible electronics. Weakness: Their solutions are primarily optimized for semiconductor-based flexible electronics rather than other emerging flexible technologies like printed electronics.

Mitsubishi Electric Corp.

Technical Solution: Mitsubishi Electric has developed an advanced thermal cycling reliability assessment system for flexible electronics that combines environmental stress testing with AI-powered predictive analytics. Their approach utilizes specialized thermal chambers with precise temperature control (±0.5°C accuracy) capable of cycling between -65°C to 150°C to evaluate material degradation and interconnect reliability. The company's proprietary "FlexReliability" platform incorporates real-time electrical parameter monitoring during thermal cycling, capturing subtle performance shifts that precede catastrophic failure. Mitsubishi's methodology includes specialized fixtures that maintain controlled mechanical strain states during thermal cycling, simulating real-world deployment conditions. Their system employs high-resolution infrared thermography to map temperature distribution across flexible circuits, identifying hotspots and thermal gradient-induced stress points. The company has developed accelerated test protocols that correlate with long-term field reliability data, enabling accurate lifetime predictions from shorter test durations[2][5].

Strengths: Comprehensive integration of electrical, thermal, and mechanical testing in a single platform; advanced AI algorithms for failure prediction based on extensive reliability databases. Weakness: Their system requires significant capital investment and specialized expertise, making it less accessible for smaller manufacturers and research institutions.

Critical Technologies in Flexible Electronics Thermal Testing

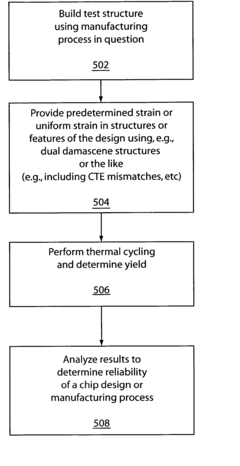

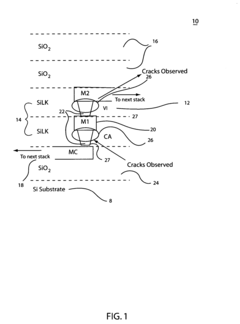

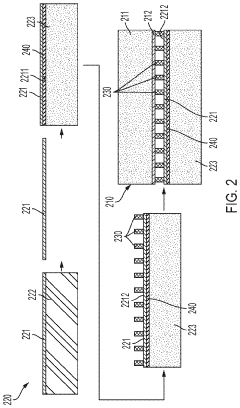

Method and structure for determining thermal cycle reliability

PatentInactiveUS20060273460A1

Innovation

- A method and system that utilize a test structure with uniform via strain and dummy vias to evaluate the thermal cycle performance of semiconductor chip structures, correlating yield with thermal cycle reliability, allowing for the prediction of thermal cycling failures and process control.

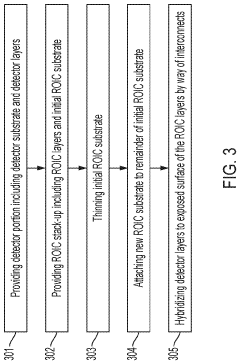

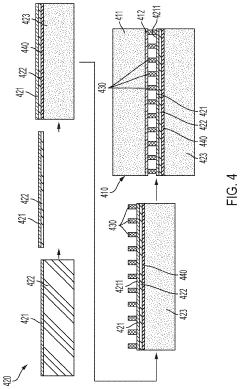

Eliminating interconnect strains in microcircuits

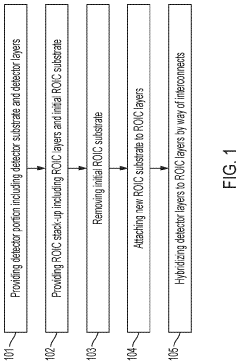

PatentPendingUS20230411427A1

Innovation

- The method involves replacing the initial ROIC substrate with a new one that matches the coefficient of thermal expansion (CTE) of the detector substrate, and hybridizing the detector layers to the ROIC layers using interconnects, which can be deposited before or after bonding, to eliminate interconnect strains caused by thermal cycling.

Standardization Efforts in Flexible Electronics Testing

The standardization landscape for flexible electronics testing is currently fragmented, with various organizations developing their own protocols for reliability assessment. Key international bodies such as the International Electrotechnical Commission (IEC) and the Institute of Electrical and Electronics Engineers (IEEE) have established working groups specifically focused on flexible electronics standards development. These efforts aim to create unified testing methodologies that can be universally applied across the industry.

The IEC Technical Committee 119 (Printed Electronics) has been particularly active in developing standards for flexible and printed electronic devices, including test methods for thermal cycling reliability. Their published standards provide guidelines for temperature ranges, cycle durations, and failure criteria specifically tailored to the unique properties of flexible substrates and interconnects.

ASTM International has contributed significantly through its Committee F42, which has released several standards addressing mechanical and environmental testing of flexible electronic systems. These standards incorporate thermal cycling protocols that consider the distinctive thermal expansion behaviors of polymer substrates and thin-film conductors.

Industry consortia like the Flexible Electronics and Display Center (FEDC) and NextFlex have developed collaborative testing frameworks that are gaining traction as de facto standards. These frameworks often include detailed thermal cycling methodologies designed to simulate real-world operational conditions for wearable electronics, flexible displays, and medical devices.

The Japanese Electronics and Information Technology Industries Association (JEITA) has established specialized testing protocols for flexible displays and sensors that include rigorous thermal cycling requirements. These standards have been widely adopted throughout Asia and are increasingly referenced globally.

Harmonization efforts between different standardization bodies remain a significant challenge. Current initiatives focus on creating cross-reference matrices between existing standards and developing unified terminology and testing parameters. The International Organization for Standardization (ISO) has recently launched a coordination committee to address these fragmentation issues.

Emerging standards are increasingly incorporating accelerated testing methodologies that can predict long-term reliability from shorter test durations. These approaches utilize mathematical models that correlate thermal cycling performance with expected field reliability, allowing manufacturers to reduce development cycles while maintaining confidence in product durability.

The IEC Technical Committee 119 (Printed Electronics) has been particularly active in developing standards for flexible and printed electronic devices, including test methods for thermal cycling reliability. Their published standards provide guidelines for temperature ranges, cycle durations, and failure criteria specifically tailored to the unique properties of flexible substrates and interconnects.

ASTM International has contributed significantly through its Committee F42, which has released several standards addressing mechanical and environmental testing of flexible electronic systems. These standards incorporate thermal cycling protocols that consider the distinctive thermal expansion behaviors of polymer substrates and thin-film conductors.

Industry consortia like the Flexible Electronics and Display Center (FEDC) and NextFlex have developed collaborative testing frameworks that are gaining traction as de facto standards. These frameworks often include detailed thermal cycling methodologies designed to simulate real-world operational conditions for wearable electronics, flexible displays, and medical devices.

The Japanese Electronics and Information Technology Industries Association (JEITA) has established specialized testing protocols for flexible displays and sensors that include rigorous thermal cycling requirements. These standards have been widely adopted throughout Asia and are increasingly referenced globally.

Harmonization efforts between different standardization bodies remain a significant challenge. Current initiatives focus on creating cross-reference matrices between existing standards and developing unified terminology and testing parameters. The International Organization for Standardization (ISO) has recently launched a coordination committee to address these fragmentation issues.

Emerging standards are increasingly incorporating accelerated testing methodologies that can predict long-term reliability from shorter test durations. These approaches utilize mathematical models that correlate thermal cycling performance with expected field reliability, allowing manufacturers to reduce development cycles while maintaining confidence in product durability.

Environmental Impact of Flexible Electronics Lifecycle

The environmental footprint of flexible electronics spans their entire lifecycle, presenting both challenges and opportunities compared to conventional rigid electronics. The manufacturing processes for flexible electronics often involve specialized materials and techniques that can be resource-intensive. Production typically requires rare earth elements, specialized polymers, and thin-film deposition processes that may generate hazardous waste streams if not properly managed. However, the reduced material usage in flexible electronics—often being thinner and lighter than traditional counterparts—can potentially lower the overall resource consumption.

During the use phase, flexible electronics demonstrate significant environmental advantages. Their inherent energy efficiency, primarily due to lower operating temperatures and reduced power requirements, contributes to decreased energy consumption over product lifetimes. Thermal cycling analysis reveals that flexible electronics generally maintain functionality across wider temperature ranges with less energy expenditure for thermal management. This efficiency translates directly to reduced carbon emissions during operation, particularly important for battery-powered devices where energy conservation extends battery life and reduces replacement frequency.

End-of-life considerations present complex environmental trade-offs. The composite nature of flexible electronic materials—often involving intimately bonded polymers, metals, and semiconductors—creates recycling challenges that conventional e-waste infrastructure struggles to address. Current thermal cycling reliability tests indicate that while flexible electronics may withstand mechanical stresses better than rigid alternatives, their degradation patterns differ significantly, necessitating specialized recycling approaches.

Recent lifecycle assessments comparing flexible and conventional electronics reveal a nuanced environmental profile. While flexible electronics typically show reduced environmental impact during manufacturing and use phases, their end-of-life management remains problematic. The biodegradability of certain flexible electronic components offers promising pathways for reducing e-waste, though complete biodegradable systems remain in early development stages.

Thermal cycling analysis plays a crucial role in understanding the environmental durability of flexible electronics. Tests simulating real-world temperature fluctuations demonstrate that properly designed flexible systems can maintain functionality through thousands of thermal cycles, potentially extending product lifespans beyond conventional electronics. This longevity factor significantly reduces the environmental impact per functional unit of service delivered, though it requires careful design considerations to achieve in practice.

During the use phase, flexible electronics demonstrate significant environmental advantages. Their inherent energy efficiency, primarily due to lower operating temperatures and reduced power requirements, contributes to decreased energy consumption over product lifetimes. Thermal cycling analysis reveals that flexible electronics generally maintain functionality across wider temperature ranges with less energy expenditure for thermal management. This efficiency translates directly to reduced carbon emissions during operation, particularly important for battery-powered devices where energy conservation extends battery life and reduces replacement frequency.

End-of-life considerations present complex environmental trade-offs. The composite nature of flexible electronic materials—often involving intimately bonded polymers, metals, and semiconductors—creates recycling challenges that conventional e-waste infrastructure struggles to address. Current thermal cycling reliability tests indicate that while flexible electronics may withstand mechanical stresses better than rigid alternatives, their degradation patterns differ significantly, necessitating specialized recycling approaches.

Recent lifecycle assessments comparing flexible and conventional electronics reveal a nuanced environmental profile. While flexible electronics typically show reduced environmental impact during manufacturing and use phases, their end-of-life management remains problematic. The biodegradability of certain flexible electronic components offers promising pathways for reducing e-waste, though complete biodegradable systems remain in early development stages.

Thermal cycling analysis plays a crucial role in understanding the environmental durability of flexible electronics. Tests simulating real-world temperature fluctuations demonstrate that properly designed flexible systems can maintain functionality through thousands of thermal cycles, potentially extending product lifespans beyond conventional electronics. This longevity factor significantly reduces the environmental impact per functional unit of service delivered, though it requires careful design considerations to achieve in practice.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!