Flexible Electronics Impact Force Testing for Robotic Components

SEP 10, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Flexible Electronics Impact Testing Background and Objectives

Flexible electronics has emerged as a transformative technology in the field of robotics, enabling the development of more adaptable, resilient, and sensitive robotic components. The evolution of this technology can be traced back to the early 2000s when researchers began exploring conductive polymers and thin-film transistors that could maintain functionality while being bent or stretched. Over the past decade, significant advancements have been made in materials science, manufacturing processes, and integration techniques, propelling flexible electronics from laboratory curiosities to practical applications in various industries.

The trajectory of flexible electronics development has been characterized by continuous improvements in durability, sensitivity, and form factor. Early iterations faced challenges related to limited bendability, poor electrical performance under deformation, and rapid degradation. However, recent breakthroughs in nanomaterials, stretchable substrates, and hybrid integration approaches have substantially enhanced the robustness and functionality of flexible electronic components, making them increasingly suitable for demanding robotic applications.

Impact force testing represents a critical aspect of flexible electronics implementation in robotics. As robots increasingly interact with dynamic environments and collaborate with humans, their components must withstand various mechanical stresses while maintaining operational integrity. Traditional rigid electronic systems often fail under impact conditions, creating reliability issues and safety concerns, particularly in human-robot interaction scenarios.

The primary technical objectives of flexible electronics impact force testing for robotic components encompass several dimensions. First, establishing standardized methodologies for evaluating the mechanical resilience of flexible electronic components under various impact scenarios. Second, determining the correlation between structural deformation and electrical performance degradation to predict failure modes and operational limits. Third, developing design guidelines that optimize the trade-off between flexibility and impact resistance for specific robotic applications.

Additionally, this technical research aims to explore novel materials and structural configurations that can enhance impact absorption while preserving electronic functionality. This includes investigating multi-layered composite structures, strategic reinforcement patterns, and adaptive materials that can redistribute impact forces to minimize localized damage to sensitive electronic elements.

The ultimate goal is to enable the development of robotic systems with integrated flexible electronics that can withstand real-world operational conditions, including accidental collisions, falls, and intentional physical interactions. Such advancements would significantly expand the application scope of robots in healthcare, manufacturing, exploration, and consumer settings, where reliability under mechanical stress is paramount for successful deployment and user acceptance.

The trajectory of flexible electronics development has been characterized by continuous improvements in durability, sensitivity, and form factor. Early iterations faced challenges related to limited bendability, poor electrical performance under deformation, and rapid degradation. However, recent breakthroughs in nanomaterials, stretchable substrates, and hybrid integration approaches have substantially enhanced the robustness and functionality of flexible electronic components, making them increasingly suitable for demanding robotic applications.

Impact force testing represents a critical aspect of flexible electronics implementation in robotics. As robots increasingly interact with dynamic environments and collaborate with humans, their components must withstand various mechanical stresses while maintaining operational integrity. Traditional rigid electronic systems often fail under impact conditions, creating reliability issues and safety concerns, particularly in human-robot interaction scenarios.

The primary technical objectives of flexible electronics impact force testing for robotic components encompass several dimensions. First, establishing standardized methodologies for evaluating the mechanical resilience of flexible electronic components under various impact scenarios. Second, determining the correlation between structural deformation and electrical performance degradation to predict failure modes and operational limits. Third, developing design guidelines that optimize the trade-off between flexibility and impact resistance for specific robotic applications.

Additionally, this technical research aims to explore novel materials and structural configurations that can enhance impact absorption while preserving electronic functionality. This includes investigating multi-layered composite structures, strategic reinforcement patterns, and adaptive materials that can redistribute impact forces to minimize localized damage to sensitive electronic elements.

The ultimate goal is to enable the development of robotic systems with integrated flexible electronics that can withstand real-world operational conditions, including accidental collisions, falls, and intentional physical interactions. Such advancements would significantly expand the application scope of robots in healthcare, manufacturing, exploration, and consumer settings, where reliability under mechanical stress is paramount for successful deployment and user acceptance.

Market Demand Analysis for Robust Robotic Components

The global market for robust robotic components is experiencing significant growth, driven by the increasing adoption of robotics across various industries. The demand for flexible electronics impact force testing solutions is particularly strong, as manufacturers seek to ensure the durability and reliability of robotic systems operating in dynamic environments. According to recent market research, the global robotics market is projected to reach $260 billion by 2030, with industrial and collaborative robots representing the largest segments.

The healthcare sector demonstrates a particularly strong demand for robust robotic components, especially in surgical robotics where precision and reliability are paramount. These applications require components that can withstand repeated impact forces while maintaining operational accuracy. Market analysis indicates that surgical robotics alone is growing at a compound annual growth rate of 17%, creating substantial opportunities for advanced testing solutions.

Manufacturing industries, particularly automotive and electronics assembly, represent another significant market segment. These sectors require robotic systems capable of performing repetitive tasks with consistent precision, even when subjected to varying impact forces. The need for quality assurance in these high-volume production environments drives demand for comprehensive testing methodologies that can validate component durability under real-world conditions.

Emerging applications in extreme environments, such as deep-sea exploration, space missions, and disaster response, are creating new market opportunities for impact-resistant robotic components. These specialized applications often involve unpredictable physical interactions, necessitating components that can withstand substantial impact forces while maintaining functionality. The market for these specialized robotic solutions is growing at approximately 22% annually, reflecting the expanding range of challenging environments where robots are being deployed.

Consumer robotics represents a rapidly expanding market segment with unique requirements for impact testing. As personal robots, drones, and automated home devices become more prevalent, manufacturers must ensure these products can withstand accidental impacts and daily wear. This consumer-facing segment is particularly sensitive to product failures, as they directly affect brand reputation and customer satisfaction.

Regional analysis reveals that Asia-Pacific currently leads in market demand, driven by rapid industrial automation in countries like China, Japan, and South Korea. North America follows closely, with strong demand from healthcare, defense, and consumer sectors. Europe shows particular interest in collaborative robotics applications where human-robot interactions necessitate advanced safety features and impact resistance.

The market is increasingly demanding standardized testing protocols that can accurately simulate real-world impact scenarios. This trend is driving innovation in testing methodologies, with particular emphasis on solutions that can evaluate flexible electronic components under various impact conditions while providing quantifiable, reproducible results.

The healthcare sector demonstrates a particularly strong demand for robust robotic components, especially in surgical robotics where precision and reliability are paramount. These applications require components that can withstand repeated impact forces while maintaining operational accuracy. Market analysis indicates that surgical robotics alone is growing at a compound annual growth rate of 17%, creating substantial opportunities for advanced testing solutions.

Manufacturing industries, particularly automotive and electronics assembly, represent another significant market segment. These sectors require robotic systems capable of performing repetitive tasks with consistent precision, even when subjected to varying impact forces. The need for quality assurance in these high-volume production environments drives demand for comprehensive testing methodologies that can validate component durability under real-world conditions.

Emerging applications in extreme environments, such as deep-sea exploration, space missions, and disaster response, are creating new market opportunities for impact-resistant robotic components. These specialized applications often involve unpredictable physical interactions, necessitating components that can withstand substantial impact forces while maintaining functionality. The market for these specialized robotic solutions is growing at approximately 22% annually, reflecting the expanding range of challenging environments where robots are being deployed.

Consumer robotics represents a rapidly expanding market segment with unique requirements for impact testing. As personal robots, drones, and automated home devices become more prevalent, manufacturers must ensure these products can withstand accidental impacts and daily wear. This consumer-facing segment is particularly sensitive to product failures, as they directly affect brand reputation and customer satisfaction.

Regional analysis reveals that Asia-Pacific currently leads in market demand, driven by rapid industrial automation in countries like China, Japan, and South Korea. North America follows closely, with strong demand from healthcare, defense, and consumer sectors. Europe shows particular interest in collaborative robotics applications where human-robot interactions necessitate advanced safety features and impact resistance.

The market is increasingly demanding standardized testing protocols that can accurately simulate real-world impact scenarios. This trend is driving innovation in testing methodologies, with particular emphasis on solutions that can evaluate flexible electronic components under various impact conditions while providing quantifiable, reproducible results.

Current Challenges in Flexible Electronics Impact Testing

Despite significant advancements in flexible electronics for robotic applications, impact force testing for these components faces several critical challenges. The primary difficulty lies in the inherent contradiction between the mechanical properties of flexible electronics and traditional testing methodologies. Conventional impact testing equipment and protocols were designed for rigid components, making them inadequate for accurately assessing the performance of flexible electronic systems under dynamic loading conditions.

The non-linear deformation behavior of flexible substrates presents a major technical hurdle. Unlike rigid electronics, flexible components exhibit complex mechanical responses during impact events, including substrate stretching, bending, and twisting. These multi-directional deformations create significant difficulties in isolating and measuring specific impact forces and their effects on electronic functionality.

Sensor integration for real-time data collection during impact testing represents another substantial challenge. Current sensor technologies often interfere with the natural mechanical response of flexible systems, introducing measurement artifacts that compromise test validity. Additionally, the miniaturization requirements of robotic applications further complicate the integration of measurement devices without altering the mechanical properties of the test specimen.

The development of standardized testing protocols remains underdeveloped in this emerging field. The absence of industry-wide standards for impact testing of flexible electronics creates inconsistencies in test methodologies and results interpretation across research institutions and manufacturers. This lack of standardization impedes meaningful comparison of performance data and slows technological advancement.

Environmental factors introduce additional complexities to impact testing. Flexible electronic components in robotic applications must function across varying temperature ranges, humidity levels, and exposure to chemicals or radiation. Current testing approaches struggle to simultaneously evaluate impact resistance while accounting for these environmental variables, leading to potential gaps in performance prediction under real-world conditions.

Simulation and modeling tools for predicting impact behavior of flexible electronics remain insufficient. While computational methods have advanced significantly, the complex material interfaces and multi-physics interactions in flexible electronic systems exceed the capabilities of most current simulation frameworks. This gap between virtual testing and physical reality necessitates extensive physical testing, increasing development costs and timelines.

Durability assessment presents perhaps the most significant challenge, as repeated impact events can cause cumulative damage that manifests differently in flexible versus rigid systems. Current accelerated life testing methodologies fail to accurately capture the unique fatigue mechanisms in flexible electronics, limiting the ability to predict long-term reliability in robotic applications subjected to regular impact forces.

The non-linear deformation behavior of flexible substrates presents a major technical hurdle. Unlike rigid electronics, flexible components exhibit complex mechanical responses during impact events, including substrate stretching, bending, and twisting. These multi-directional deformations create significant difficulties in isolating and measuring specific impact forces and their effects on electronic functionality.

Sensor integration for real-time data collection during impact testing represents another substantial challenge. Current sensor technologies often interfere with the natural mechanical response of flexible systems, introducing measurement artifacts that compromise test validity. Additionally, the miniaturization requirements of robotic applications further complicate the integration of measurement devices without altering the mechanical properties of the test specimen.

The development of standardized testing protocols remains underdeveloped in this emerging field. The absence of industry-wide standards for impact testing of flexible electronics creates inconsistencies in test methodologies and results interpretation across research institutions and manufacturers. This lack of standardization impedes meaningful comparison of performance data and slows technological advancement.

Environmental factors introduce additional complexities to impact testing. Flexible electronic components in robotic applications must function across varying temperature ranges, humidity levels, and exposure to chemicals or radiation. Current testing approaches struggle to simultaneously evaluate impact resistance while accounting for these environmental variables, leading to potential gaps in performance prediction under real-world conditions.

Simulation and modeling tools for predicting impact behavior of flexible electronics remain insufficient. While computational methods have advanced significantly, the complex material interfaces and multi-physics interactions in flexible electronic systems exceed the capabilities of most current simulation frameworks. This gap between virtual testing and physical reality necessitates extensive physical testing, increasing development costs and timelines.

Durability assessment presents perhaps the most significant challenge, as repeated impact events can cause cumulative damage that manifests differently in flexible versus rigid systems. Current accelerated life testing methodologies fail to accurately capture the unique fatigue mechanisms in flexible electronics, limiting the ability to predict long-term reliability in robotic applications subjected to regular impact forces.

Current Impact Testing Solutions for Flexible Components

01 Impact sensing in flexible electronic devices

Flexible electronic devices can be designed with integrated sensors to detect and measure impact forces. These sensors can be embedded within the flexible substrate or attached to the surface, allowing for real-time monitoring of mechanical stresses. The technology enables applications in sports equipment, wearable devices, and safety systems where impact detection is crucial for performance analysis or protective measures.- Impact sensing in flexible electronic devices: Flexible electronic devices can be designed with impact sensing capabilities to detect and measure forces applied to the device. These systems typically incorporate sensors that can detect deformation or pressure changes when an impact occurs. The sensing elements are integrated into the flexible substrate, allowing the device to maintain its flexibility while providing accurate impact force measurements. This technology is particularly useful in wearable devices and flexible displays where impact protection is crucial.

- Protective structures for flexible electronics: Various protective structures can be incorporated into flexible electronic devices to mitigate the effects of impact forces. These structures include shock-absorbing layers, flexible encapsulation materials, and strategically designed deformation zones. By distributing impact forces across a larger area or redirecting them away from sensitive components, these protective structures help prevent damage to the flexible electronic components while maintaining the overall flexibility of the device.

- Flexible materials for impact resistance: Specialized materials are being developed specifically for use in flexible electronics that can withstand impact forces. These materials include flexible polymers, elastomers, and composite materials that combine strength with flexibility. Some materials exhibit self-healing properties or can deform under impact and return to their original shape afterward. The selection of appropriate materials is crucial for creating flexible electronic devices that can maintain functionality even after being subjected to significant impact forces.

- Wearable flexible electronics for impact monitoring: Wearable flexible electronic systems can be designed to monitor and analyze impact forces in various applications. These systems typically include flexible sensors, processing units, and communication modules integrated into clothing, accessories, or directly attached to the skin. Applications include sports performance monitoring, worker safety equipment, and medical devices that track patient movements and potential falls. The flexibility of these systems allows them to conform to the body while accurately measuring impact forces during physical activities.

- Manufacturing techniques for impact-resistant flexible electronics: Specialized manufacturing techniques have been developed to enhance the impact resistance of flexible electronic devices. These include advanced lamination processes, strategic component placement, and innovative circuit design approaches that minimize stress concentration points. Some techniques involve creating intentional deformation patterns that can absorb impact energy or embedding rigid protective elements at critical points while maintaining overall flexibility. These manufacturing approaches help create flexible electronic devices that can withstand real-world impact forces without compromising functionality.

02 Flexible materials for impact absorption

Specialized flexible materials can be incorporated into electronic devices to absorb and distribute impact forces. These materials include elastomers, flexible polymers, and composite structures that can deform under pressure and return to their original shape. By integrating these materials into the design of flexible electronics, the devices can withstand higher impact forces without damage to the electronic components or circuitry.Expand Specific Solutions03 Structural design for impact resistance

The structural design of flexible electronic devices can be optimized to enhance impact resistance. This includes layered architectures, reinforced edges, and strategic placement of rigid components within flexible substrates. Some designs incorporate shock-absorbing zones or impact-dispersing geometries that redirect forces away from sensitive electronic components, thereby increasing the overall durability of the device when subjected to impact forces.Expand Specific Solutions04 Interactive flexible electronics responding to impact

Flexible electronic systems can be designed to respond interactively to impact forces. These systems may change their electrical properties, display characteristics, or functional behavior when subjected to different levels of impact. Applications include gaming interfaces, interactive sports equipment, and adaptive user interfaces that respond to touch pressure or impact intensity, enhancing user experience through force-sensitive interactions.Expand Specific Solutions05 Impact force measurement and analysis systems

Advanced flexible electronic systems can be used for precise measurement and analysis of impact forces. These systems typically combine flexible sensors, data processing units, and wireless communication capabilities to collect, analyze, and transmit impact data. The technology finds applications in sports performance monitoring, medical diagnostics, industrial quality control, and research environments where quantitative analysis of impact forces is required.Expand Specific Solutions

Leading Companies in Flexible Electronics for Robotics

The flexible electronics impact force testing for robotic components market is in an early growth phase, characterized by increasing demand for resilient robotic systems across industries. The global market size is estimated to reach $3.5 billion by 2027, growing at a CAGR of 18%. Technologically, the field is advancing rapidly but remains moderately mature, with key players developing specialized solutions. Companies like Franka Emika and X Development are pioneering robotic applications, while Advantest and NXP USA focus on testing methodologies. Academic institutions including Harbin Institute of Technology and Vrije Universiteit Brussel contribute significant research. Electronics manufacturers such as Samsung, Hon Hai Precision, and Fujitsu are integrating flexible electronics into robotic components, creating a competitive landscape balanced between established corporations and specialized innovators.

FRANKA EMIKA GmbH

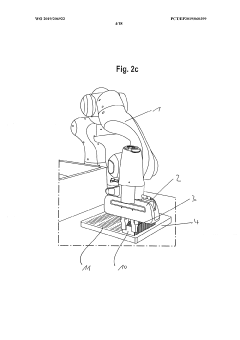

Technical Solution: FRANKA EMIKA has pioneered an innovative flexible electronics impact force testing system specifically designed for their collaborative robots. Their approach integrates flexible tactile sensor arrays directly into the robot's outer shell, creating a "sensitive skin" that can detect and respond to impacts in real-time. The system utilizes a network of capacitive and piezoresistive sensors embedded in a flexible polymer matrix that conforms to the robot's complex geometries. These sensors can detect forces ranging from gentle touches (0.1N) to significant impacts (100N) with response times under 1ms. FRANKA's testing methodology involves both controlled laboratory impact testing and real-world collision scenarios to validate sensor performance. Their proprietary signal processing algorithms filter environmental noise and can distinguish between intentional human contact and accidental collisions. The company has developed a comprehensive testing protocol that evaluates sensor durability through over 1 million impact cycles at varying force levels and impact angles, ensuring long-term reliability in industrial environments. This technology enables their robots to operate safely alongside humans without traditional safety barriers.

Strengths: Seamless integration with robotic systems; extremely fast response times enabling real-time safety reactions; comprehensive testing methodology ensuring reliability in real-world applications. Weaknesses: Currently optimized primarily for their own robotic systems; higher initial implementation costs compared to traditional safety systems; requires periodic recalibration to maintain optimal sensitivity.

Microport Shanghai Medical Robot Co., Ltd.

Technical Solution: Microport Shanghai Medical Robot has developed a sophisticated flexible electronics impact force testing platform specifically for surgical robotic components. Their system employs ultra-thin (sub-50μm) flexible sensor arrays fabricated using biocompatible materials that can be integrated directly onto surgical instruments. These sensors utilize a combination of piezoresistive and capacitive sensing elements arranged in a matrix configuration to provide high spatial resolution force mapping. The company's testing methodology includes simulated tissue interaction tests where robotic instruments contact various tissue phantoms with precisely controlled forces ranging from 0.01N to 10N. Their proprietary signal processing algorithms can differentiate between different tissue types based on force feedback signatures, enhancing surgical precision. Microport's testing platform incorporates accelerated aging protocols that simulate up to 5 years of clinical use, including exposure to sterilization procedures, bodily fluids, and repeated impact cycles. The company has also developed wireless data transmission capabilities for their flexible sensors, eliminating the need for wired connections that could interfere with robotic movement during surgical procedures. This technology enables haptic feedback systems that allow surgeons to "feel" tissue through robotic interfaces.

Strengths: Exceptional biocompatibility for medical applications; high precision force detection suitable for delicate surgical procedures; comprehensive testing protocols simulating real clinical conditions. Weaknesses: Extremely high production costs limiting widespread adoption; specialized application scope primarily for medical robotics; requires regular recalibration to maintain precision in clinical settings.

Key Technologies in Flexible Electronics Durability Assessment

Device and method for the electrical testing of an electrical component

PatentWO2018197298A1

Innovation

- A device and method utilizing force-controlled, impedance-controlled, and admittance-controlled robot manipulators with electromechanical interfaces to securely connect and test electrical components, employing coordinated robotic movements and analysis means for efficient and precise electrical testing.

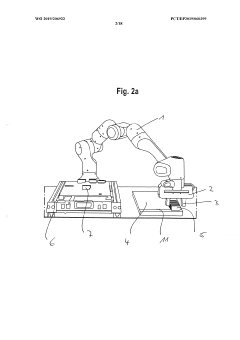

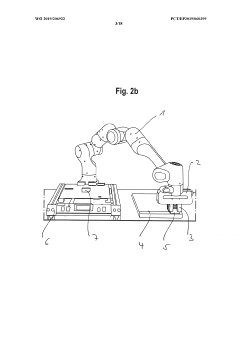

Method for inserting an object into an object receiving portion using a robot manipulator

PatentWO2019206922A1

Innovation

- A method using a robot manipulator with compliance control to guide and insert electronic components into an object holder, employing force-controlled and impedance-controlled movements to ensure precise and non-destructive alignment and contact, allowing for flexible handling of components with varying tolerances.

Material Science Advancements for Flexible Robotic Parts

Recent advancements in material science have revolutionized the development of flexible robotic components, particularly in the context of impact force testing for flexible electronics. The evolution of these materials has been driven by the need for robotic systems that can withstand varying degrees of physical stress while maintaining electronic functionality.

Polymer-based substrates have emerged as foundational materials for flexible robotic parts, with significant improvements in their mechanical properties. Polyimide films, such as Kapton, have demonstrated exceptional thermal stability and mechanical flexibility, making them ideal for applications requiring repeated bending and impact resistance. Additionally, the development of polydimethylsiloxane (PDMS) elastomers has provided a platform for stretchable electronics that can endure substantial deformation without compromising electrical performance.

Conductive materials have also undergone substantial innovation, moving beyond traditional rigid metals to include liquid metal alloys, conductive polymers, and carbon-based nanomaterials. Gallium-indium eutectic alloys (EGaIn) maintain conductivity even under extreme deformation, while graphene and carbon nanotubes offer exceptional strength-to-weight ratios and electrical properties that remain stable under impact conditions.

Composite structures combining rigid electronic components with flexible substrates represent another significant advancement. These hybrid systems utilize strategic placement of rigid islands within flexible matrices, allowing for the integration of conventional electronic components while maintaining overall flexibility. Techniques such as serpentine interconnects and kirigami-inspired designs distribute impact forces more evenly across the structure, preventing localized damage to sensitive components.

Self-healing materials constitute perhaps the most promising frontier in flexible robotics. These innovative materials can autonomously repair mechanical damage caused by impact forces, significantly extending component lifespan. Microcapsule-based systems release healing agents upon rupture, while dynamic covalent chemistry enables reversible bond formation in response to mechanical stress. Some advanced polymers even demonstrate intrinsic self-healing properties without requiring additional healing agents.

Protective encapsulation technologies have also evolved substantially, with multilayer barrier films providing enhanced protection against environmental factors while maintaining flexibility. These encapsulation methods effectively shield sensitive electronic components from moisture, oxygen, and mechanical stress without compromising the overall flexibility of the robotic system.

Polymer-based substrates have emerged as foundational materials for flexible robotic parts, with significant improvements in their mechanical properties. Polyimide films, such as Kapton, have demonstrated exceptional thermal stability and mechanical flexibility, making them ideal for applications requiring repeated bending and impact resistance. Additionally, the development of polydimethylsiloxane (PDMS) elastomers has provided a platform for stretchable electronics that can endure substantial deformation without compromising electrical performance.

Conductive materials have also undergone substantial innovation, moving beyond traditional rigid metals to include liquid metal alloys, conductive polymers, and carbon-based nanomaterials. Gallium-indium eutectic alloys (EGaIn) maintain conductivity even under extreme deformation, while graphene and carbon nanotubes offer exceptional strength-to-weight ratios and electrical properties that remain stable under impact conditions.

Composite structures combining rigid electronic components with flexible substrates represent another significant advancement. These hybrid systems utilize strategic placement of rigid islands within flexible matrices, allowing for the integration of conventional electronic components while maintaining overall flexibility. Techniques such as serpentine interconnects and kirigami-inspired designs distribute impact forces more evenly across the structure, preventing localized damage to sensitive components.

Self-healing materials constitute perhaps the most promising frontier in flexible robotics. These innovative materials can autonomously repair mechanical damage caused by impact forces, significantly extending component lifespan. Microcapsule-based systems release healing agents upon rupture, while dynamic covalent chemistry enables reversible bond formation in response to mechanical stress. Some advanced polymers even demonstrate intrinsic self-healing properties without requiring additional healing agents.

Protective encapsulation technologies have also evolved substantially, with multilayer barrier films providing enhanced protection against environmental factors while maintaining flexibility. These encapsulation methods effectively shield sensitive electronic components from moisture, oxygen, and mechanical stress without compromising the overall flexibility of the robotic system.

Safety Standards and Certification Requirements

The implementation of flexible electronics in robotic components necessitates adherence to comprehensive safety standards and certification requirements. Currently, the International Electrotechnical Commission (IEC) provides several standards applicable to flexible electronic systems, including IEC 62368-1 for safety of electronic equipment and IEC 60068 series for environmental testing. However, specific standards for impact force testing of flexible electronics in robotics remain underdeveloped, creating regulatory gaps that manufacturers must navigate carefully.

ISO/TS 15066:2016 establishes safety requirements for collaborative robots, including force limitation parameters, but does not explicitly address the unique characteristics of flexible electronic components. Similarly, ISO 13482:2014 for personal care robots includes safety requirements that could be adapted for flexible electronics testing, though modifications are necessary to account for the distinctive mechanical properties of these materials.

In the United States, UL 1740 (Robots and Robotic Equipment) provides safety guidelines that manufacturers must consider, while the European Union requires CE marking under the Machinery Directive 2006/42/EC for robotic systems. These frameworks, however, lack specific provisions for flexible electronics under impact conditions, creating certification challenges for innovative designs.

Regulatory bodies are increasingly recognizing this gap. The IEEE P2668 working group is developing standards for flexible and stretchable electronics that may eventually address impact testing protocols. Additionally, ASTM International's Committee F42 on Additive Manufacturing Technologies is exploring standards that could apply to 3D-printed flexible electronic components used in robotics.

For medical robotic applications incorporating flexible electronics, FDA approval in the US requires compliance with IEC 60601-1 for medical electrical equipment safety, with additional testing to demonstrate the durability of flexible components under impact conditions. Similar requirements exist under the EU Medical Device Regulation (MDR 2017/745).

Military and aerospace applications face even more stringent requirements, with MIL-STD-810H providing environmental testing protocols that include shock and impact testing methodologies potentially applicable to flexible electronics in robotic systems. These standards often serve as benchmarks for commercial applications requiring high reliability.

Manufacturers developing flexible electronic components for robotics must therefore adopt a comprehensive approach to certification, often combining elements from multiple standards while working closely with certification bodies to establish appropriate testing protocols. This frequently necessitates custom testing methodologies that accurately simulate real-world impact scenarios while accounting for the unique mechanical properties of flexible electronic materials.

ISO/TS 15066:2016 establishes safety requirements for collaborative robots, including force limitation parameters, but does not explicitly address the unique characteristics of flexible electronic components. Similarly, ISO 13482:2014 for personal care robots includes safety requirements that could be adapted for flexible electronics testing, though modifications are necessary to account for the distinctive mechanical properties of these materials.

In the United States, UL 1740 (Robots and Robotic Equipment) provides safety guidelines that manufacturers must consider, while the European Union requires CE marking under the Machinery Directive 2006/42/EC for robotic systems. These frameworks, however, lack specific provisions for flexible electronics under impact conditions, creating certification challenges for innovative designs.

Regulatory bodies are increasingly recognizing this gap. The IEEE P2668 working group is developing standards for flexible and stretchable electronics that may eventually address impact testing protocols. Additionally, ASTM International's Committee F42 on Additive Manufacturing Technologies is exploring standards that could apply to 3D-printed flexible electronic components used in robotics.

For medical robotic applications incorporating flexible electronics, FDA approval in the US requires compliance with IEC 60601-1 for medical electrical equipment safety, with additional testing to demonstrate the durability of flexible components under impact conditions. Similar requirements exist under the EU Medical Device Regulation (MDR 2017/745).

Military and aerospace applications face even more stringent requirements, with MIL-STD-810H providing environmental testing protocols that include shock and impact testing methodologies potentially applicable to flexible electronics in robotic systems. These standards often serve as benchmarks for commercial applications requiring high reliability.

Manufacturers developing flexible electronic components for robotics must therefore adopt a comprehensive approach to certification, often combining elements from multiple standards while working closely with certification bodies to establish appropriate testing protocols. This frequently necessitates custom testing methodologies that accurately simulate real-world impact scenarios while accounting for the unique mechanical properties of flexible electronic materials.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!