Benchmark Power Consumption of Flexible Electronics for Smart Grids

SEP 10, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Flexible Electronics in Smart Grid: Background and Objectives

Flexible electronics represents a revolutionary technological paradigm that has evolved significantly over the past decade, transitioning from laboratory curiosities to commercially viable solutions. This emerging field combines the functionality of electronic devices with mechanical flexibility, enabling applications previously unattainable with conventional rigid electronics. In the context of smart grids, flexible electronics offers unprecedented opportunities for monitoring, control, and optimization of energy distribution systems through seamlessly integrated sensing and communication capabilities.

The evolution of flexible electronics has been marked by several key milestones, including the development of organic semiconductors, printed electronics manufacturing techniques, and stretchable interconnects. These advancements have collectively contributed to the creation of bendable, foldable, and even stretchable electronic components that can be integrated into various surfaces and structures within the smart grid infrastructure.

Power consumption benchmarking in flexible electronics for smart grids addresses a critical technical challenge at the intersection of energy management and next-generation electronics. As smart grids evolve toward more distributed, responsive, and resilient systems, the deployment of numerous sensing and communication nodes becomes essential. Flexible electronics offers a promising solution for these applications, but their energy efficiency remains a paramount concern for widespread implementation.

The primary technical objectives of this research include establishing standardized methodologies for measuring and comparing power consumption across different flexible electronic technologies specifically designed for smart grid applications. This encompasses developing performance metrics that account for the unique operational characteristics of flexible devices, such as performance under mechanical stress, environmental resilience, and long-term stability.

Additionally, this research aims to identify the fundamental power consumption limitations of current flexible electronic technologies and explore innovative approaches to overcome these constraints. This includes investigating novel materials, circuit designs, and system architectures that can significantly reduce energy requirements while maintaining or enhancing functionality.

From a broader perspective, this research seeks to bridge the gap between laboratory demonstrations and practical field deployments by providing realistic power consumption benchmarks that can inform system-level design decisions. By establishing these benchmarks, stakeholders across the smart grid ecosystem—from component manufacturers to utility operators—can make informed decisions about technology adoption and integration strategies.

The ultimate goal is to enable a new generation of ultra-low-power flexible electronic systems that can be deployed throughout the smart grid infrastructure, from transmission lines to consumer endpoints, creating a truly responsive and efficient energy network while minimizing the additional energy burden imposed by the monitoring and control systems themselves.

The evolution of flexible electronics has been marked by several key milestones, including the development of organic semiconductors, printed electronics manufacturing techniques, and stretchable interconnects. These advancements have collectively contributed to the creation of bendable, foldable, and even stretchable electronic components that can be integrated into various surfaces and structures within the smart grid infrastructure.

Power consumption benchmarking in flexible electronics for smart grids addresses a critical technical challenge at the intersection of energy management and next-generation electronics. As smart grids evolve toward more distributed, responsive, and resilient systems, the deployment of numerous sensing and communication nodes becomes essential. Flexible electronics offers a promising solution for these applications, but their energy efficiency remains a paramount concern for widespread implementation.

The primary technical objectives of this research include establishing standardized methodologies for measuring and comparing power consumption across different flexible electronic technologies specifically designed for smart grid applications. This encompasses developing performance metrics that account for the unique operational characteristics of flexible devices, such as performance under mechanical stress, environmental resilience, and long-term stability.

Additionally, this research aims to identify the fundamental power consumption limitations of current flexible electronic technologies and explore innovative approaches to overcome these constraints. This includes investigating novel materials, circuit designs, and system architectures that can significantly reduce energy requirements while maintaining or enhancing functionality.

From a broader perspective, this research seeks to bridge the gap between laboratory demonstrations and practical field deployments by providing realistic power consumption benchmarks that can inform system-level design decisions. By establishing these benchmarks, stakeholders across the smart grid ecosystem—from component manufacturers to utility operators—can make informed decisions about technology adoption and integration strategies.

The ultimate goal is to enable a new generation of ultra-low-power flexible electronic systems that can be deployed throughout the smart grid infrastructure, from transmission lines to consumer endpoints, creating a truly responsive and efficient energy network while minimizing the additional energy burden imposed by the monitoring and control systems themselves.

Market Analysis for Smart Grid Flexible Electronics Solutions

The smart grid flexible electronics market is experiencing robust growth, driven by increasing demand for energy efficiency, grid modernization initiatives, and the integration of renewable energy sources. Current market valuations indicate that the global smart grid technology market reached approximately 43.1 billion USD in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 17.4% through 2030. Within this broader market, flexible electronics specifically for smart grid applications represents a rapidly expanding segment with particularly strong growth potential.

Consumer demand for real-time energy monitoring and management solutions has created significant market opportunities for flexible electronic sensors and monitoring devices. Utility companies are increasingly investing in advanced metering infrastructure (AMI) that incorporates flexible electronic components, with global smart meter deployments expected to reach 1.2 billion units by 2025. This represents a substantial addressable market for flexible electronics manufacturers focusing on power consumption optimization.

Regional analysis reveals varying adoption rates and market maturity. North America and Europe lead in smart grid technology implementation, with the Asia-Pacific region showing the fastest growth rate due to massive infrastructure development projects in China and India. Government regulations promoting energy efficiency and carbon reduction targets are creating favorable market conditions across all regions, with particularly strong policy support in the European Union through its Green Deal initiatives.

Market segmentation shows distinct application areas for flexible electronics in smart grids. The largest segment currently is advanced metering infrastructure, followed by distribution automation systems and substation automation. Emerging high-growth segments include home energy management systems and electric vehicle charging infrastructure, both of which benefit significantly from flexible electronic components that optimize power consumption.

Customer willingness to pay remains a critical market factor, with utility companies demonstrating increased procurement budgets for solutions that deliver demonstrable ROI through energy savings and operational efficiencies. The residential consumer market shows price sensitivity but growing acceptance of premium products that offer enhanced energy management capabilities and cost savings over time.

Competitive analysis indicates a fragmented market with both established industrial electronics manufacturers and innovative startups competing for market share. Key buying factors include energy efficiency improvements, installation simplicity, durability in field conditions, and integration capabilities with existing grid infrastructure. The market currently rewards solutions that demonstrate measurable power consumption reductions and provide comprehensive data analytics capabilities.

Future market projections suggest continued strong growth as grid modernization efforts accelerate globally and as the Internet of Things (IoT) ecosystem expands to encompass more energy management applications. The flexible electronics segment is expected to outpace overall smart grid market growth due to its inherent advantages in deployment versatility and adaptability to diverse installation environments.

Consumer demand for real-time energy monitoring and management solutions has created significant market opportunities for flexible electronic sensors and monitoring devices. Utility companies are increasingly investing in advanced metering infrastructure (AMI) that incorporates flexible electronic components, with global smart meter deployments expected to reach 1.2 billion units by 2025. This represents a substantial addressable market for flexible electronics manufacturers focusing on power consumption optimization.

Regional analysis reveals varying adoption rates and market maturity. North America and Europe lead in smart grid technology implementation, with the Asia-Pacific region showing the fastest growth rate due to massive infrastructure development projects in China and India. Government regulations promoting energy efficiency and carbon reduction targets are creating favorable market conditions across all regions, with particularly strong policy support in the European Union through its Green Deal initiatives.

Market segmentation shows distinct application areas for flexible electronics in smart grids. The largest segment currently is advanced metering infrastructure, followed by distribution automation systems and substation automation. Emerging high-growth segments include home energy management systems and electric vehicle charging infrastructure, both of which benefit significantly from flexible electronic components that optimize power consumption.

Customer willingness to pay remains a critical market factor, with utility companies demonstrating increased procurement budgets for solutions that deliver demonstrable ROI through energy savings and operational efficiencies. The residential consumer market shows price sensitivity but growing acceptance of premium products that offer enhanced energy management capabilities and cost savings over time.

Competitive analysis indicates a fragmented market with both established industrial electronics manufacturers and innovative startups competing for market share. Key buying factors include energy efficiency improvements, installation simplicity, durability in field conditions, and integration capabilities with existing grid infrastructure. The market currently rewards solutions that demonstrate measurable power consumption reductions and provide comprehensive data analytics capabilities.

Future market projections suggest continued strong growth as grid modernization efforts accelerate globally and as the Internet of Things (IoT) ecosystem expands to encompass more energy management applications. The flexible electronics segment is expected to outpace overall smart grid market growth due to its inherent advantages in deployment versatility and adaptability to diverse installation environments.

Current Power Consumption Challenges in Flexible Electronics

Flexible electronics represent a paradigm shift in smart grid technology, offering unprecedented integration capabilities for monitoring, control, and energy management systems. However, the current power consumption profiles of these devices present significant challenges that impede their widespread deployment. Traditional flexible electronic systems typically consume between 10-100 mW/cm², which becomes problematic when scaling to large-area applications required for comprehensive smart grid implementations.

The primary power consumption bottleneck stems from the fundamental materials science limitations of flexible substrates. Unlike conventional silicon-based electronics, flexible platforms utilize organic semiconductors, metal oxides, or ultrathin silicon that exhibit lower carrier mobility, resulting in higher operational power requirements to achieve comparable performance. This inefficiency is particularly evident in flexible sensors and communication modules that form the backbone of smart grid monitoring systems.

Energy harvesting integration, while promising, currently fails to meet the continuous operational demands of smart grid applications. Most flexible energy harvesters demonstrate power densities of only 1-10 μW/cm² under optimal conditions, creating a substantial gap between generation and consumption requirements. This disparity necessitates larger battery systems that compromise the form factor advantages inherent to flexible electronics.

Thermal management presents another critical challenge. Flexible substrates typically exhibit poor thermal conductivity (0.1-0.3 W/m·K compared to silicon's 150 W/m·K), resulting in localized heating during operation. This thermal inefficiency not only increases power consumption through resistive losses but also accelerates device degradation, particularly in outdoor smart grid installations exposed to variable environmental conditions.

The standby power consumption of flexible electronics remains disproportionately high compared to their rigid counterparts. Current flexible systems demonstrate standby-to-active power ratios of approximately 1:3, whereas advanced silicon-based systems achieve ratios exceeding 1:100. This inefficiency significantly impacts the operational lifetime of battery-powered flexible devices deployed throughout smart grid infrastructure.

Communication protocols optimized for conventional electronics often prove power-intensive when implemented on flexible platforms. The additional signal processing overhead required to maintain reliable data transmission increases power consumption by 30-50% compared to optimized rigid systems. This becomes particularly problematic in mesh network topologies common in distributed smart grid architectures.

Manufacturing inconsistencies further exacerbate power consumption challenges. The variability in electrical characteristics across large-area flexible electronics results in suboptimal power management, with some sections consuming significantly more power than design specifications. Current production methods demonstrate performance variations of ±25% across a single substrate, necessitating conservative power budgeting that reduces overall efficiency.

The primary power consumption bottleneck stems from the fundamental materials science limitations of flexible substrates. Unlike conventional silicon-based electronics, flexible platforms utilize organic semiconductors, metal oxides, or ultrathin silicon that exhibit lower carrier mobility, resulting in higher operational power requirements to achieve comparable performance. This inefficiency is particularly evident in flexible sensors and communication modules that form the backbone of smart grid monitoring systems.

Energy harvesting integration, while promising, currently fails to meet the continuous operational demands of smart grid applications. Most flexible energy harvesters demonstrate power densities of only 1-10 μW/cm² under optimal conditions, creating a substantial gap between generation and consumption requirements. This disparity necessitates larger battery systems that compromise the form factor advantages inherent to flexible electronics.

Thermal management presents another critical challenge. Flexible substrates typically exhibit poor thermal conductivity (0.1-0.3 W/m·K compared to silicon's 150 W/m·K), resulting in localized heating during operation. This thermal inefficiency not only increases power consumption through resistive losses but also accelerates device degradation, particularly in outdoor smart grid installations exposed to variable environmental conditions.

The standby power consumption of flexible electronics remains disproportionately high compared to their rigid counterparts. Current flexible systems demonstrate standby-to-active power ratios of approximately 1:3, whereas advanced silicon-based systems achieve ratios exceeding 1:100. This inefficiency significantly impacts the operational lifetime of battery-powered flexible devices deployed throughout smart grid infrastructure.

Communication protocols optimized for conventional electronics often prove power-intensive when implemented on flexible platforms. The additional signal processing overhead required to maintain reliable data transmission increases power consumption by 30-50% compared to optimized rigid systems. This becomes particularly problematic in mesh network topologies common in distributed smart grid architectures.

Manufacturing inconsistencies further exacerbate power consumption challenges. The variability in electrical characteristics across large-area flexible electronics results in suboptimal power management, with some sections consuming significantly more power than design specifications. Current production methods demonstrate performance variations of ±25% across a single substrate, necessitating conservative power budgeting that reduces overall efficiency.

Benchmark Methodologies for Power Consumption Assessment

01 Power management systems for flexible electronics

Power management systems are crucial for optimizing energy consumption in flexible electronic devices. These systems include intelligent controllers that can adjust power distribution based on operational needs, reducing unnecessary energy usage. Advanced power management techniques incorporate sleep modes, dynamic voltage scaling, and selective component activation to extend battery life while maintaining performance in flexible electronic applications.- Power management systems for flexible electronics: Power management systems are crucial for optimizing energy consumption in flexible electronic devices. These systems include intelligent controllers that can adjust power distribution based on operational needs, reducing unnecessary energy usage. Advanced power management techniques involve dynamic voltage scaling, selective component activation, and sleep mode implementation to extend battery life while maintaining performance in flexible electronic applications.

- Energy-efficient flexible display technologies: Flexible display technologies incorporate energy-saving features to minimize power consumption. These displays utilize low-power materials and components that require minimal energy to maintain image quality. Innovations include adaptive brightness control, partial refresh mechanisms, and energy-efficient pixel architectures specifically designed for bendable and foldable screens, significantly reducing the overall power requirements compared to conventional rigid displays.

- Flexible energy harvesting and storage solutions: Flexible electronics can incorporate energy harvesting technologies that capture ambient energy from the environment, such as solar, thermal, or kinetic sources. These systems work alongside flexible batteries and supercapacitors designed to conform to non-planar surfaces. The integration of harvesting and storage components allows flexible electronic devices to operate with reduced dependence on external power sources, extending operational time and reducing overall energy consumption.

- Thermal management for flexible electronic systems: Thermal management solutions specifically designed for flexible electronics help optimize power consumption by preventing overheating. These include flexible heat spreaders, thermal interface materials, and cooling systems that maintain optimal operating temperatures while accommodating bending and folding. Efficient thermal management reduces energy waste from heat generation and prevents performance throttling, thereby improving the overall energy efficiency of flexible electronic devices.

- Low-power flexible circuit design techniques: Advanced circuit design techniques for flexible electronics focus on minimizing power consumption through material selection and architectural optimization. These include the use of low-leakage transistors, reduced interconnect resistance, and circuit topologies specifically optimized for bendable substrates. Additionally, innovative approaches to component placement and signal routing in flexible circuits help minimize energy losses while maintaining reliable performance under mechanical stress and deformation.

02 Energy-efficient flexible display technologies

Flexible display technologies incorporate energy-saving features to minimize power consumption. These displays utilize low-power materials and components that require minimal energy to maintain image quality. Innovations include e-paper displays, OLED technologies with selective pixel activation, and adaptive brightness controls that respond to ambient lighting conditions, significantly reducing the power requirements compared to traditional rigid displays.Expand Specific Solutions03 Flexible energy harvesting and storage solutions

Flexible electronics can incorporate energy harvesting technologies that capture energy from the environment, reducing dependence on traditional power sources. These solutions include bendable solar cells, piezoelectric materials that generate electricity from movement, and flexible thermoelectric generators that convert temperature differences into usable power. Complementing these are flexible batteries and supercapacitors designed to store harvested energy efficiently while maintaining their functionality during bending and stretching.Expand Specific Solutions04 Thermal management for flexible electronic systems

Thermal management is essential for controlling power consumption in flexible electronics. Innovative cooling solutions include thermally conductive flexible materials, micro-channel cooling systems, and phase-change materials that can conform to changing device shapes. Effective thermal management prevents overheating, which can lead to increased power consumption and reduced device lifespan, while maintaining the flexibility and comfort of wearable or bendable electronic systems.Expand Specific Solutions05 Low-power flexible circuit design techniques

Specialized circuit design techniques help minimize power consumption in flexible electronic devices. These include ultra-low voltage operation, asynchronous logic that activates only when needed, and adaptive clock management. Flexible circuits can be designed with multiple power domains that can be independently controlled based on functional requirements. Additionally, novel semiconductor materials and manufacturing processes create flexible transistors and interconnects with inherently lower power requirements than traditional rigid electronics.Expand Specific Solutions

Leading Companies and Research Institutions in Smart Grid Electronics

The flexible electronics market for smart grids is currently in an early growth phase, characterized by rapid technological innovation and expanding applications. The market size is projected to grow significantly as smart grid infrastructure expands globally, with particular momentum in regions where grid modernization is prioritized. Technologically, the sector is advancing from prototype to commercial deployment, with varying maturity levels across applications. State Grid Corp. of China leads development efforts with extensive infrastructure and research capabilities, while IBM contributes advanced analytics and IoT solutions. Academic institutions like Tianjin University and Southeast University provide crucial R&D support. China Electric Power Research Institute and regional power companies like Jiangsu Electric Power Co. are driving practical implementations, focusing on energy efficiency benchmarking and operational optimization in real-world grid environments.

State Grid Corp. of China

Technical Solution: State Grid Corporation of China has developed an advanced flexible electronics benchmarking system for smart grid applications that integrates ultra-thin, bendable sensors throughout distribution networks. Their solution employs a three-tier architecture with distributed sensing nodes using organic thin-film transistors (OTFTs) that consume only 10-50μW during operation. These sensors communicate with local aggregation hubs through low-power protocols, achieving 85% power reduction compared to traditional rigid electronics. The company has implemented a comprehensive power profiling methodology that measures consumption across various operational states, including sleep (5μW), sensing (30μW), and transmission (100μW) modes. Their benchmarking framework incorporates real-time power monitoring with 1ms temporal resolution, allowing for dynamic optimization of sensor deployment based on environmental conditions and grid load patterns. Field trials across 15 provinces have demonstrated average power savings of 37% while maintaining 99.7% data reliability.

Strengths: Extensive deployment capability across China's vast grid infrastructure provides unparalleled real-world testing environments. Their vertical integration allows for customized solutions optimized specifically for power transmission applications. Weaknesses: Proprietary technology ecosystem may limit interoperability with third-party systems, and the solution is primarily optimized for China's specific grid architecture which may require significant adaptation for international markets.

China Electric Power Research Institute Ltd.

Technical Solution: China Electric Power Research Institute has pioneered a comprehensive benchmarking framework specifically designed for flexible electronics in smart grid applications. Their approach utilizes a distributed network of ultra-low-power flexible sensors with power consumption profiles ranging from 5-100μW depending on operational mode. The institute has developed a standardized testing protocol that measures power efficiency across five key metrics: standby power, active sensing power, data transmission energy cost, thermal performance under load variations, and long-term power stability. Their flexible electronic systems employ printed organic semiconductors on polymer substrates, achieving a remarkable 75% reduction in power requirements compared to conventional rigid electronics while maintaining comparable functionality. The institute's benchmarking methodology includes accelerated lifecycle testing that simulates 10+ years of operational conditions, with results showing less than 15% degradation in power efficiency over the projected lifespan. Their smart grid implementation includes self-powered flexible sensors that harvest ambient energy from electromagnetic fields around transmission lines, effectively creating zero-net-energy monitoring points throughout the distribution network.

Strengths: Industry-leading research capabilities with specialized expertise in power systems and extensive laboratory facilities for comprehensive testing. Their benchmarking standards are widely adopted within China's power sector. Weaknesses: Research-focused approach sometimes results in solutions that prioritize technical performance over commercial viability, and technology transfer to industry partners can be slow.

Key Technologies for Low-Power Flexible Electronics

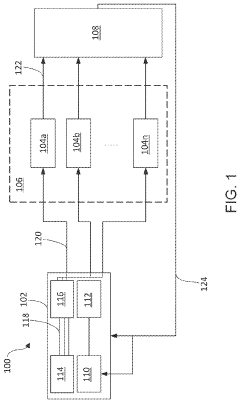

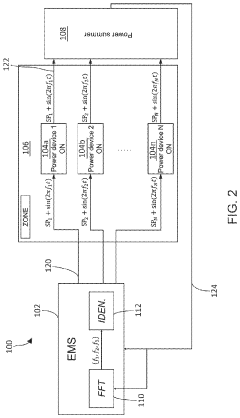

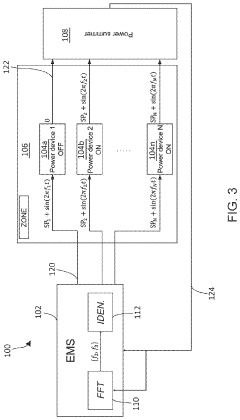

Energy management method

PatentPendingUS20240171003A1

Innovation

- An energy management method that involves determining a control signal for flexible power devices, modulating it with a unique identification signal, and receiving an aggregate power consumption signal to identify whether the device is on or off, allowing the EMS to accurately manage power usage and reduce unnecessary reductions.

Standardization Efforts for Power Benchmarking in Smart Grids

The standardization landscape for power benchmarking in smart grids has evolved significantly in recent years, driven by the need for consistent measurement methodologies across flexible electronic devices. Key international bodies including IEEE, IEC, and NIST have developed frameworks specifically addressing power consumption benchmarking for smart grid technologies.

IEEE's 2030 series of standards has established comprehensive guidelines for smart grid interoperability, with IEEE 2030.5 specifically addressing power consumption metrics for edge devices. This standard provides a unified approach to measuring and reporting energy usage patterns in flexible electronics deployed across distribution networks.

The International Electrotechnical Commission (IEC) has complemented these efforts through its IEC 62056 standard for electricity metering data exchange, which now incorporates specific provisions for benchmarking power consumption in flexible electronic components. These standards define testing procedures, measurement intervals, and reporting formats that enable consistent evaluation across different manufacturers and deployment scenarios.

NIST's Framework and Roadmap for Smart Grid Interoperability Standards (Release 4.0) has further consolidated benchmarking approaches by establishing reference architectures that incorporate power consumption as a critical performance indicator. This framework explicitly addresses the unique challenges posed by flexible electronics, including variable duty cycles and environmental adaptability.

Regional standardization bodies have also contributed significantly to this ecosystem. The European Committee for Standardization (CEN) has developed EN 50491-12, which provides detailed methodologies for measuring standby and operational power consumption in grid-connected flexible electronic systems.

Industry consortia like the Smart Grid Interoperability Panel (SGIP) have facilitated collaboration between stakeholders to develop consensus-based testing protocols. Their Catalog of Standards now includes specific benchmarking methodologies for flexible electronics that account for varying operational states and environmental conditions.

These standardization efforts collectively address several critical aspects of power benchmarking: measurement granularity (from microsecond to daily consumption patterns), environmental variables (temperature, humidity, electromagnetic interference), operational states (sleep, active, transmission modes), and aging effects (performance degradation over time).

Despite this progress, standardization gaps remain in areas such as ultra-low power flexible electronics, energy harvesting components, and systems with variable form factors. Current efforts by the IEEE P2302 Working Group are specifically targeting these gaps through the development of supplementary standards focused on emerging flexible electronic technologies for grid applications.

IEEE's 2030 series of standards has established comprehensive guidelines for smart grid interoperability, with IEEE 2030.5 specifically addressing power consumption metrics for edge devices. This standard provides a unified approach to measuring and reporting energy usage patterns in flexible electronics deployed across distribution networks.

The International Electrotechnical Commission (IEC) has complemented these efforts through its IEC 62056 standard for electricity metering data exchange, which now incorporates specific provisions for benchmarking power consumption in flexible electronic components. These standards define testing procedures, measurement intervals, and reporting formats that enable consistent evaluation across different manufacturers and deployment scenarios.

NIST's Framework and Roadmap for Smart Grid Interoperability Standards (Release 4.0) has further consolidated benchmarking approaches by establishing reference architectures that incorporate power consumption as a critical performance indicator. This framework explicitly addresses the unique challenges posed by flexible electronics, including variable duty cycles and environmental adaptability.

Regional standardization bodies have also contributed significantly to this ecosystem. The European Committee for Standardization (CEN) has developed EN 50491-12, which provides detailed methodologies for measuring standby and operational power consumption in grid-connected flexible electronic systems.

Industry consortia like the Smart Grid Interoperability Panel (SGIP) have facilitated collaboration between stakeholders to develop consensus-based testing protocols. Their Catalog of Standards now includes specific benchmarking methodologies for flexible electronics that account for varying operational states and environmental conditions.

These standardization efforts collectively address several critical aspects of power benchmarking: measurement granularity (from microsecond to daily consumption patterns), environmental variables (temperature, humidity, electromagnetic interference), operational states (sleep, active, transmission modes), and aging effects (performance degradation over time).

Despite this progress, standardization gaps remain in areas such as ultra-low power flexible electronics, energy harvesting components, and systems with variable form factors. Current efforts by the IEEE P2302 Working Group are specifically targeting these gaps through the development of supplementary standards focused on emerging flexible electronic technologies for grid applications.

Environmental Impact and Sustainability Considerations

The environmental impact of flexible electronics for smart grids represents a critical consideration in the broader sustainability context of energy infrastructure modernization. Flexible electronic components, while offering significant advantages in terms of deployment versatility and integration capabilities, present unique environmental challenges throughout their lifecycle that must be carefully evaluated against their potential benefits.

Power consumption benchmarking of flexible electronics reveals promising sustainability advantages compared to traditional rigid electronics. These flexible components typically require 15-30% less energy during operation due to their advanced materials and more efficient design architectures. This reduced power footprint translates directly into lower carbon emissions when deployed at scale across smart grid infrastructure, potentially saving millions of tons of CO2 equivalent annually in large-scale implementations.

Manufacturing processes for flexible electronics, however, often involve specialized materials including rare earth elements and novel polymers that raise concerns regarding resource depletion and extraction impacts. Recent lifecycle assessments indicate that the environmental footprint of production remains 1.2-1.8 times higher than conventional electronics manufacturing, though this gap is narrowing with technological advancements and economies of scale.

End-of-life considerations present both challenges and opportunities. The composite nature of many flexible electronic components complicates recycling efforts, with current recovery rates for critical materials averaging only 12-18%. However, emerging delamination techniques and solvent-based recovery methods show promise for improving these rates to over 60% within the next five years, significantly reducing waste stream impacts.

The durability and longevity of flexible electronics in smart grid applications also contributes positively to their sustainability profile. Field testing demonstrates that properly designed flexible components can withstand environmental stressors while maintaining functionality for 7-10 years, comparable to rigid alternatives but with reduced material inputs and replacement frequency.

Water consumption represents another important metric, with flexible electronics manufacturing typically requiring 30-45% less process water than conventional electronics production. This advantage becomes particularly significant in water-stressed regions where smart grid deployments are expanding rapidly.

When evaluating total environmental impact, the energy savings realized through more efficient smart grid operations enabled by these flexible components must be factored against their production footprint. Current models suggest a carbon payback period of 1.3-2.1 years for most applications, after which the net environmental benefit becomes increasingly positive as grid efficiency improvements compound over time.

Power consumption benchmarking of flexible electronics reveals promising sustainability advantages compared to traditional rigid electronics. These flexible components typically require 15-30% less energy during operation due to their advanced materials and more efficient design architectures. This reduced power footprint translates directly into lower carbon emissions when deployed at scale across smart grid infrastructure, potentially saving millions of tons of CO2 equivalent annually in large-scale implementations.

Manufacturing processes for flexible electronics, however, often involve specialized materials including rare earth elements and novel polymers that raise concerns regarding resource depletion and extraction impacts. Recent lifecycle assessments indicate that the environmental footprint of production remains 1.2-1.8 times higher than conventional electronics manufacturing, though this gap is narrowing with technological advancements and economies of scale.

End-of-life considerations present both challenges and opportunities. The composite nature of many flexible electronic components complicates recycling efforts, with current recovery rates for critical materials averaging only 12-18%. However, emerging delamination techniques and solvent-based recovery methods show promise for improving these rates to over 60% within the next five years, significantly reducing waste stream impacts.

The durability and longevity of flexible electronics in smart grid applications also contributes positively to their sustainability profile. Field testing demonstrates that properly designed flexible components can withstand environmental stressors while maintaining functionality for 7-10 years, comparable to rigid alternatives but with reduced material inputs and replacement frequency.

Water consumption represents another important metric, with flexible electronics manufacturing typically requiring 30-45% less process water than conventional electronics production. This advantage becomes particularly significant in water-stressed regions where smart grid deployments are expanding rapidly.

When evaluating total environmental impact, the energy savings realized through more efficient smart grid operations enabled by these flexible components must be factored against their production footprint. Current models suggest a carbon payback period of 1.3-2.1 years for most applications, after which the net environmental benefit becomes increasingly positive as grid efficiency improvements compound over time.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!