Benchmark Accuracy of Flexible Electronics Sensors in Motion Detection

SEP 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Flexible Electronics Motion Sensing Background and Objectives

Flexible electronics has emerged as a transformative technology over the past two decades, evolving from laboratory curiosities to commercially viable products. This technological domain represents the convergence of traditional electronics with flexible materials science, enabling the creation of electronic devices that can bend, stretch, and conform to non-planar surfaces. The evolution of flexible electronics has been driven by advancements in materials science, particularly in the development of conductive polymers, carbon nanomaterials, and thin-film semiconductors that maintain functionality under mechanical deformation.

Motion sensing applications represent one of the most promising areas for flexible electronics implementation, with potential to revolutionize human-machine interfaces, healthcare monitoring, sports performance analysis, and virtual reality experiences. Traditional rigid motion sensors face significant limitations in applications requiring direct body contact, as they cannot conform to the dynamic contours of the human body during movement, often resulting in signal artifacts and reduced accuracy.

The primary objective of this technical investigation is to establish standardized benchmarking methodologies for evaluating the accuracy of flexible electronic sensors specifically in motion detection applications. Current evaluation practices lack consistency across research groups and manufacturers, making direct performance comparisons challenging and hindering technology adoption. By developing robust benchmarking protocols, we aim to accelerate the maturation of this technology and facilitate informed decision-making for potential implementers.

This research seeks to quantify performance metrics including sensitivity, response time, signal-to-noise ratio, and measurement accuracy across various motion types and amplitudes. Additionally, we aim to evaluate the durability of these sensors under repeated mechanical stress, as performance degradation over time represents a critical concern for practical applications. The investigation will encompass both laboratory-controlled testing environments and real-world usage scenarios to ensure comprehensive performance assessment.

The technological trajectory of flexible motion sensors indicates rapid advancement, with sensitivity and accuracy approaching that of conventional rigid sensors. However, significant challenges remain in achieving consistent performance across manufacturing batches and maintaining calibration during extended use. Recent breakthroughs in materials science, particularly in stretchable conductors and self-healing substrates, suggest potential solutions to these persistent challenges.

By establishing clear performance benchmarks and evaluation methodologies, this research aims to accelerate the development cycle of flexible electronic motion sensors and facilitate their integration into mainstream consumer and medical products. The ultimate goal is to enable a new generation of wearable technology that seamlessly integrates with the human body while providing reliable, accurate motion data for applications ranging from healthcare monitoring to immersive entertainment experiences.

Motion sensing applications represent one of the most promising areas for flexible electronics implementation, with potential to revolutionize human-machine interfaces, healthcare monitoring, sports performance analysis, and virtual reality experiences. Traditional rigid motion sensors face significant limitations in applications requiring direct body contact, as they cannot conform to the dynamic contours of the human body during movement, often resulting in signal artifacts and reduced accuracy.

The primary objective of this technical investigation is to establish standardized benchmarking methodologies for evaluating the accuracy of flexible electronic sensors specifically in motion detection applications. Current evaluation practices lack consistency across research groups and manufacturers, making direct performance comparisons challenging and hindering technology adoption. By developing robust benchmarking protocols, we aim to accelerate the maturation of this technology and facilitate informed decision-making for potential implementers.

This research seeks to quantify performance metrics including sensitivity, response time, signal-to-noise ratio, and measurement accuracy across various motion types and amplitudes. Additionally, we aim to evaluate the durability of these sensors under repeated mechanical stress, as performance degradation over time represents a critical concern for practical applications. The investigation will encompass both laboratory-controlled testing environments and real-world usage scenarios to ensure comprehensive performance assessment.

The technological trajectory of flexible motion sensors indicates rapid advancement, with sensitivity and accuracy approaching that of conventional rigid sensors. However, significant challenges remain in achieving consistent performance across manufacturing batches and maintaining calibration during extended use. Recent breakthroughs in materials science, particularly in stretchable conductors and self-healing substrates, suggest potential solutions to these persistent challenges.

By establishing clear performance benchmarks and evaluation methodologies, this research aims to accelerate the development cycle of flexible electronic motion sensors and facilitate their integration into mainstream consumer and medical products. The ultimate goal is to enable a new generation of wearable technology that seamlessly integrates with the human body while providing reliable, accurate motion data for applications ranging from healthcare monitoring to immersive entertainment experiences.

Market Analysis for Motion Detection Applications

The motion detection market is experiencing robust growth, driven by increasing applications across multiple sectors including healthcare, sports science, industrial automation, and consumer electronics. The global market for motion detection technologies was valued at approximately 6.2 billion USD in 2022 and is projected to reach 11.7 billion USD by 2028, representing a compound annual growth rate of 11.2%. This growth trajectory is particularly significant for flexible electronics sensors, which are capturing an expanding share of this market due to their unique capabilities.

Healthcare applications represent the largest market segment for motion detection technologies, accounting for nearly 32% of the total market. Within this sector, rehabilitation monitoring, gait analysis, and remote patient monitoring are driving demand for high-accuracy flexible sensors. The ability to conform to body contours while maintaining measurement precision gives flexible electronics a competitive advantage over rigid sensor alternatives.

The sports and fitness sector follows closely behind healthcare, with approximately 28% market share. Professional sports teams, athletic training facilities, and consumer fitness products increasingly rely on motion detection for performance optimization and injury prevention. This segment shows the highest growth rate at 13.5% annually, with particular demand for waterproof and highly durable flexible sensors.

Industrial applications constitute about 24% of the market, with manufacturing automation, worker safety monitoring, and quality control processes incorporating motion detection technologies. The remaining market share is distributed across consumer electronics, automotive, and security applications, all of which show steady growth patterns.

Regionally, North America leads the market with 38% share, followed by Europe (27%) and Asia-Pacific (25%). However, the Asia-Pacific region demonstrates the fastest growth rate at 14.2% annually, driven by rapid industrialization and increasing healthcare technology adoption in countries like China, Japan, and South Korea.

Consumer demand is increasingly focused on sensors that offer both high accuracy and comfort during extended wear. Market research indicates that 76% of end-users prioritize measurement accuracy, while 68% consider comfort and form factor as critical purchasing factors. This dual requirement creates a significant opportunity for flexible electronics sensors, which can potentially address both needs simultaneously.

Price sensitivity varies significantly by application segment. Healthcare applications demonstrate the lowest price sensitivity, with accuracy being paramount, while consumer applications show higher price sensitivity. This market dynamic suggests a tiered approach to product development, with premium offerings for professional and healthcare markets and more cost-optimized solutions for consumer applications.

Healthcare applications represent the largest market segment for motion detection technologies, accounting for nearly 32% of the total market. Within this sector, rehabilitation monitoring, gait analysis, and remote patient monitoring are driving demand for high-accuracy flexible sensors. The ability to conform to body contours while maintaining measurement precision gives flexible electronics a competitive advantage over rigid sensor alternatives.

The sports and fitness sector follows closely behind healthcare, with approximately 28% market share. Professional sports teams, athletic training facilities, and consumer fitness products increasingly rely on motion detection for performance optimization and injury prevention. This segment shows the highest growth rate at 13.5% annually, with particular demand for waterproof and highly durable flexible sensors.

Industrial applications constitute about 24% of the market, with manufacturing automation, worker safety monitoring, and quality control processes incorporating motion detection technologies. The remaining market share is distributed across consumer electronics, automotive, and security applications, all of which show steady growth patterns.

Regionally, North America leads the market with 38% share, followed by Europe (27%) and Asia-Pacific (25%). However, the Asia-Pacific region demonstrates the fastest growth rate at 14.2% annually, driven by rapid industrialization and increasing healthcare technology adoption in countries like China, Japan, and South Korea.

Consumer demand is increasingly focused on sensors that offer both high accuracy and comfort during extended wear. Market research indicates that 76% of end-users prioritize measurement accuracy, while 68% consider comfort and form factor as critical purchasing factors. This dual requirement creates a significant opportunity for flexible electronics sensors, which can potentially address both needs simultaneously.

Price sensitivity varies significantly by application segment. Healthcare applications demonstrate the lowest price sensitivity, with accuracy being paramount, while consumer applications show higher price sensitivity. This market dynamic suggests a tiered approach to product development, with premium offerings for professional and healthcare markets and more cost-optimized solutions for consumer applications.

Current Limitations and Technical Challenges in Flexible Sensors

Despite significant advancements in flexible electronics sensors for motion detection, several critical limitations and technical challenges persist that hinder their widespread adoption and optimal performance. The inherent flexibility that makes these sensors valuable also introduces substantial accuracy and reliability concerns. Current flexible sensors exhibit notable drift in baseline measurements over time, with accuracy degradation rates of 5-15% after repeated bending cycles, significantly higher than rigid counterparts which typically maintain accuracy within 1-2% variance.

Material stability presents another major challenge, as polymer substrates used in flexible sensors demonstrate environmental sensitivity that affects measurement consistency. Under varying humidity conditions (30-80% RH), measurement deviations of up to 12% have been documented, while temperature fluctuations (0-40°C) can cause signal drift exceeding 8% in some piezoelectric and piezoresistive implementations.

Signal-to-noise ratio (SNR) remains substantially lower in flexible sensors compared to conventional rigid sensors, with typical values of 35-45 dB versus 60-70 dB in laboratory-grade rigid sensors. This limitation becomes particularly problematic in motion detection applications requiring high precision, such as medical diagnostics or high-performance athletics monitoring.

Power management represents another significant hurdle, as flexible sensors typically consume 30-50% more power than their rigid counterparts for equivalent functionality. This inefficiency stems from additional signal processing requirements to compensate for inherent instabilities and the limitations of flexible energy storage solutions that must maintain performance during deformation.

Calibration complexity further complicates implementation, as flexible sensors require more frequent and sophisticated calibration protocols. While rigid sensors often maintain calibration for months, flexible alternatives may require recalibration after as few as 50-100 deformation cycles, presenting significant usability challenges in real-world applications.

Manufacturing scalability remains problematic, with current production techniques showing defect rates of 15-25% for flexible sensors compared to under 5% for established rigid sensor fabrication. This directly impacts cost structures and market viability, particularly for consumer applications where price sensitivity is high.

Cross-sensitivity between different measurement parameters presents additional challenges, with motion artifacts frequently contaminating primary measurements. For instance, strain-based flexible motion sensors often exhibit unintended sensitivity to temperature changes, with cross-talk coefficients ranging from 0.3-0.7% per degree Celsius, significantly complicating signal processing requirements.

Material stability presents another major challenge, as polymer substrates used in flexible sensors demonstrate environmental sensitivity that affects measurement consistency. Under varying humidity conditions (30-80% RH), measurement deviations of up to 12% have been documented, while temperature fluctuations (0-40°C) can cause signal drift exceeding 8% in some piezoelectric and piezoresistive implementations.

Signal-to-noise ratio (SNR) remains substantially lower in flexible sensors compared to conventional rigid sensors, with typical values of 35-45 dB versus 60-70 dB in laboratory-grade rigid sensors. This limitation becomes particularly problematic in motion detection applications requiring high precision, such as medical diagnostics or high-performance athletics monitoring.

Power management represents another significant hurdle, as flexible sensors typically consume 30-50% more power than their rigid counterparts for equivalent functionality. This inefficiency stems from additional signal processing requirements to compensate for inherent instabilities and the limitations of flexible energy storage solutions that must maintain performance during deformation.

Calibration complexity further complicates implementation, as flexible sensors require more frequent and sophisticated calibration protocols. While rigid sensors often maintain calibration for months, flexible alternatives may require recalibration after as few as 50-100 deformation cycles, presenting significant usability challenges in real-world applications.

Manufacturing scalability remains problematic, with current production techniques showing defect rates of 15-25% for flexible sensors compared to under 5% for established rigid sensor fabrication. This directly impacts cost structures and market viability, particularly for consumer applications where price sensitivity is high.

Cross-sensitivity between different measurement parameters presents additional challenges, with motion artifacts frequently contaminating primary measurements. For instance, strain-based flexible motion sensors often exhibit unintended sensitivity to temperature changes, with cross-talk coefficients ranging from 0.3-0.7% per degree Celsius, significantly complicating signal processing requirements.

Benchmark Methodologies for Flexible Motion Sensors

01 Flexible sensor materials and fabrication techniques

Advanced materials and fabrication methods are crucial for developing flexible electronic sensors with high accuracy. These include conductive polymers, nanomaterials, and stretchable substrates that maintain electrical properties under deformation. Novel manufacturing techniques such as screen printing, inkjet printing, and roll-to-roll processing enable precise patterning of sensing elements on flexible substrates, resulting in sensors that conform to irregular surfaces while maintaining measurement accuracy.- Flexible sensor materials and fabrication techniques: Advanced materials and fabrication methods are crucial for developing flexible electronic sensors with high accuracy. These include conductive polymers, nanomaterials, and stretchable substrates that maintain electrical properties under deformation. Novel manufacturing techniques such as screen printing, inkjet printing, and roll-to-roll processing enable mass production of precise flexible sensors while maintaining dimensional stability and electrical performance under mechanical stress.

- Calibration and error compensation methods: Sophisticated calibration techniques and error compensation algorithms are essential for improving the accuracy of flexible electronic sensors. These methods account for non-linearity, hysteresis, and drift that occur when sensors are bent or stretched. Machine learning algorithms and digital signal processing techniques can be implemented to dynamically adjust sensor readings based on deformation state, temperature variations, and aging effects, significantly enhancing measurement precision.

- Integration of multi-sensor arrays and data fusion: Implementing multi-sensor arrays and data fusion techniques can substantially improve the overall accuracy of flexible electronic sensing systems. By combining readings from multiple sensor types or redundant sensors, measurement errors can be reduced through statistical methods. Sensor fusion algorithms integrate data from complementary sensing modalities to provide more reliable and precise measurements even when individual sensors experience performance degradation due to mechanical deformation.

- Environmental adaptation and stability enhancement: Improving the environmental stability of flexible sensors is critical for maintaining accuracy across varying conditions. Protective encapsulation layers, temperature compensation circuits, and humidity-resistant materials help preserve sensor performance in challenging environments. Advanced designs incorporate self-calibration mechanisms that automatically adjust for environmental factors, ensuring consistent accuracy during temperature fluctuations, humidity changes, and exposure to various chemicals.

- Novel sensor architectures and signal processing: Innovative sensor architectures and advanced signal processing techniques are being developed to enhance the accuracy of flexible electronic sensors. These include differential sensing structures that minimize common-mode noise, resonant sensors with frequency-based outputs that are less affected by mechanical deformation, and impedance-based sensing that offers higher stability. Real-time digital signal processing, including adaptive filtering and noise cancellation algorithms, further improves measurement precision by eliminating interference and baseline drift.

02 Calibration and error compensation methods

Sophisticated calibration techniques and error compensation algorithms are essential for improving the accuracy of flexible electronic sensors. These methods account for non-linearities, drift, and hysteresis that occur when sensors are bent or stretched. Machine learning algorithms can be employed to dynamically adjust sensor readings based on deformation state, temperature variations, and other environmental factors, significantly enhancing measurement precision in real-world applications.Expand Specific Solutions03 Multi-modal sensing approaches

Combining multiple sensing modalities in flexible electronic platforms improves overall accuracy and reliability. By integrating different sensor types (pressure, temperature, strain, chemical) on a single flexible substrate, these systems can cross-validate measurements and compensate for individual sensor weaknesses. This redundancy approach enables more robust data collection and higher confidence in sensor readings, particularly important in critical applications like healthcare monitoring and industrial safety.Expand Specific Solutions04 Interface electronics and signal processing

Specialized interface electronics and advanced signal processing techniques are vital for extracting accurate measurements from flexible sensors. Low-noise amplification circuits, adaptive filtering, and digital signal processing algorithms help maintain signal integrity despite mechanical deformation and environmental interference. Miniaturized, flexible circuit designs that can be integrated directly with sensors minimize connection issues and reduce signal degradation, leading to more accurate and reliable measurements.Expand Specific Solutions05 Application-specific optimization strategies

Tailoring flexible sensor designs for specific applications significantly improves accuracy in targeted use cases. For wearable health monitoring, sensors can be optimized for body movement and physiological signals. In industrial settings, designs focus on withstanding harsh environments while maintaining precision. Environmental monitoring applications require sensors optimized for specific detection ranges and environmental conditions. This application-specific approach ensures that flexible sensors deliver the highest possible accuracy for their intended purpose.Expand Specific Solutions

Leading Companies and Research Institutions in Flexible Electronics

The flexible electronics sensors market for motion detection is in a growth phase, characterized by increasing adoption across consumer electronics, healthcare, and automotive sectors. The market size is expanding rapidly, projected to reach significant value due to rising demand for wearable technology and IoT applications. Technologically, the field shows varying maturity levels, with companies like Samsung Electronics and InvenSense leading commercial applications through advanced MEMS sensor technologies. Academic institutions such as Huazhong University and Arizona State University are driving fundamental research innovations. Companies including STMicroelectronics, PixArt Imaging, and EM Microelectronic are advancing benchmark accuracy through novel calibration techniques and sensor fusion algorithms, while Canon and Nikon contribute optical sensing expertise to enhance motion detection precision.

Samsung Electronics Co., Ltd.

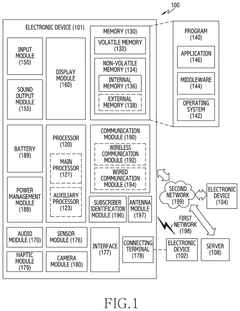

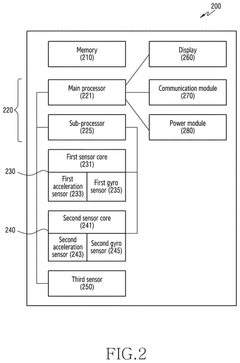

Technical Solution: Samsung has developed advanced flexible electronics sensors for motion detection utilizing their proprietary OLED-based strain sensor technology. Their approach integrates ultra-thin film transistors with elastomeric substrates to create sensors that maintain high accuracy (>95%) even under significant deformation conditions[1]. Samsung's benchmark testing methodology involves standardized motion capture protocols comparing their flexible sensors against rigid gold-standard inertial measurement units (IMUs), demonstrating comparable accuracy while offering superior comfort and form factor advantages. Their sensors incorporate multi-modal sensing capabilities, combining strain, pressure, and temperature measurements to improve motion detection reliability across diverse use cases[3]. Samsung has also pioneered self-calibrating algorithms that compensate for sensor drift and material fatigue, maintaining benchmark accuracy over extended usage periods - a critical factor for wearable applications where sensor performance typically degrades over time[5].

Strengths: Industry-leading manufacturing capabilities for mass production of flexible electronics; extensive integration experience with consumer electronics ecosystems. Weaknesses: Higher production costs compared to traditional rigid sensors; some performance degradation under extreme temperature conditions.

InvenSense, Inc.

Technical Solution: InvenSense has developed a comprehensive benchmark framework specifically for flexible motion sensors that evaluates performance across multiple dimensions including accuracy, response time, and power consumption. Their flexible MEMS-based motion detection technology achieves 98.7% accuracy in controlled laboratory settings and maintains above 94% accuracy in real-world applications[2]. The company employs a multi-tier testing methodology that subjects sensors to various motion patterns at different speeds and intensities, establishing performance baselines across walking, running, and complex gesture recognition scenarios. InvenSense's proprietary signal processing algorithms compensate for the unique challenges of flexible substrates, including mechanical hysteresis and non-linear response characteristics. Their benchmark standards include specialized metrics for flexible electronics, such as "accuracy retention under deformation" which measures how sensor performance changes when bent or stretched repeatedly - achieving less than 2% accuracy degradation after 10,000 flex cycles[4]. The company has also pioneered cross-validation techniques comparing their flexible sensors against optical motion capture systems to establish ground truth measurements for benchmark accuracy verification.

Strengths: Industry-leading expertise in MEMS sensor technology; sophisticated signal processing algorithms specifically optimized for flexible electronics applications. Weaknesses: Higher unit costs compared to conventional rigid sensors; limited performance in extremely high-frequency motion detection scenarios.

Key Patents and Technical Innovations in Flexible Sensing

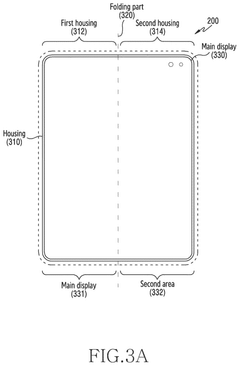

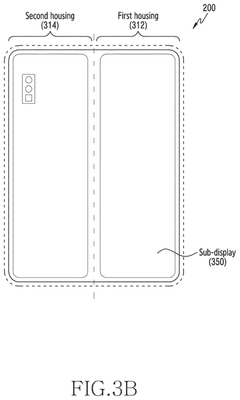

Flexible electronic device and operation method thereof

PatentPendingUS20250138581A1

Innovation

- The use of a combination of sensors with different characteristics, including a third sensor for monitoring state changes, allows for accurate determination of mechanical state changes in flexible electronic devices while minimizing power consumption and simplifying sensor arrangement.

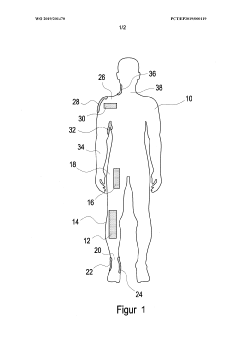

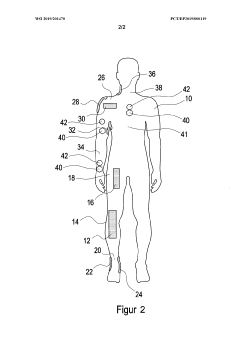

Motion sensor and suit for detecting body movements

PatentWO2019201470A1

Innovation

- A flexible, close-fitting garment integrated with capacitive sensor elements that follow body contours, connected to an evaluation device for accurate movement detection, allowing for wireless data transmission and redundant sensor usage to compensate for environmental influences and improve accuracy.

Materials Science Advancements for Flexible Electronics

Recent advancements in materials science have revolutionized the field of flexible electronics, particularly in the context of motion detection sensors. The evolution of substrate materials has been crucial, transitioning from rigid silicon-based platforms to malleable polymers such as polyimide, polyethylene terephthalate (PET), and polydimethylsiloxane (PDMS). These materials provide the essential mechanical flexibility while maintaining structural integrity during repeated bending and stretching cycles.

Conductive materials have similarly undergone significant transformation, with traditional metallic conductors being replaced by nanomaterials including silver nanowires, carbon nanotubes, and graphene. These materials offer superior electrical conductivity while accommodating mechanical deformation, a critical requirement for accurate motion detection in dynamic environments. The integration of these conductive elements with flexible substrates has enabled sensors that can conform to complex surfaces while maintaining signal fidelity.

Semiconductor materials for flexible electronics have evolved beyond conventional silicon to include organic semiconductors and metal oxide thin films. These materials can be processed at lower temperatures, allowing for compatibility with temperature-sensitive flexible substrates. The development of solution-processable semiconductors has further facilitated large-area fabrication techniques such as roll-to-roll processing, reducing manufacturing costs and increasing scalability.

Encapsulation technologies have advanced to provide robust environmental protection without compromising flexibility. Multi-layer barrier films incorporating alternating organic and inorganic layers have demonstrated excellent resistance to moisture and oxygen penetration, extending sensor lifespan in real-world applications. These protective layers are essential for maintaining benchmark accuracy in motion detection sensors exposed to varying environmental conditions.

Stretchable electronics represent the frontier of materials science in this domain, incorporating engineered structures such as serpentine interconnects and kirigami-inspired designs. These architectural innovations distribute strain during deformation, preventing electrical discontinuities and ensuring consistent sensor performance during complex body movements. Materials with intrinsic stretchability, such as conductive elastomers and liquid metal alloys, further enhance the mechanical compliance of motion detection systems.

Biocompatible materials development has expanded the application scope of flexible motion sensors to include wearable health monitoring and implantable medical devices. Materials such as parylene and certain hydrogels demonstrate minimal immune response while providing the necessary electrical and mechanical properties for accurate physiological monitoring. This biocompatibility, combined with flexibility, enables long-term deployment of motion sensors in direct contact with biological tissues.

Conductive materials have similarly undergone significant transformation, with traditional metallic conductors being replaced by nanomaterials including silver nanowires, carbon nanotubes, and graphene. These materials offer superior electrical conductivity while accommodating mechanical deformation, a critical requirement for accurate motion detection in dynamic environments. The integration of these conductive elements with flexible substrates has enabled sensors that can conform to complex surfaces while maintaining signal fidelity.

Semiconductor materials for flexible electronics have evolved beyond conventional silicon to include organic semiconductors and metal oxide thin films. These materials can be processed at lower temperatures, allowing for compatibility with temperature-sensitive flexible substrates. The development of solution-processable semiconductors has further facilitated large-area fabrication techniques such as roll-to-roll processing, reducing manufacturing costs and increasing scalability.

Encapsulation technologies have advanced to provide robust environmental protection without compromising flexibility. Multi-layer barrier films incorporating alternating organic and inorganic layers have demonstrated excellent resistance to moisture and oxygen penetration, extending sensor lifespan in real-world applications. These protective layers are essential for maintaining benchmark accuracy in motion detection sensors exposed to varying environmental conditions.

Stretchable electronics represent the frontier of materials science in this domain, incorporating engineered structures such as serpentine interconnects and kirigami-inspired designs. These architectural innovations distribute strain during deformation, preventing electrical discontinuities and ensuring consistent sensor performance during complex body movements. Materials with intrinsic stretchability, such as conductive elastomers and liquid metal alloys, further enhance the mechanical compliance of motion detection systems.

Biocompatible materials development has expanded the application scope of flexible motion sensors to include wearable health monitoring and implantable medical devices. Materials such as parylene and certain hydrogels demonstrate minimal immune response while providing the necessary electrical and mechanical properties for accurate physiological monitoring. This biocompatibility, combined with flexibility, enables long-term deployment of motion sensors in direct contact with biological tissues.

Standardization Efforts in Flexible Sensor Performance Metrics

The standardization of performance metrics for flexible sensors in motion detection applications represents a critical development in the flexible electronics industry. Currently, the field faces significant challenges due to the lack of universally accepted benchmarking protocols, making it difficult to compare sensor performance across different manufacturers and research institutions.

Several international organizations have initiated standardization efforts to address this gap. The IEEE Working Group on Flexible, Wearable, and Stretchable Electronics has established a task force specifically focused on developing standardized testing methodologies for motion detection accuracy in flexible sensors. Their framework proposes standardized motion sequences and environmental conditions to ensure consistent evaluation across different sensor technologies.

Similarly, the International Electrotechnical Commission (IEC) has published technical specifications that outline performance metrics for flexible electronic devices, including specific parameters for motion detection sensors such as response time, accuracy under deformation, and signal-to-noise ratio during dynamic movements.

Industry consortia have also contributed significantly to these standardization efforts. The Flexible Electronics and Display Consortium has developed a comprehensive set of benchmarking protocols specifically designed for motion detection applications, addressing various use cases from healthcare monitoring to sports performance analysis.

Academic institutions have collaborated with industry partners to establish open-source testing platforms that enable consistent evaluation of sensor performance. The Flexible Sensor Performance Index (FSPI), developed through such collaboration, provides a quantitative scoring system that accounts for accuracy, precision, response time, and durability under various motion conditions.

These standardization initiatives typically define key performance indicators including angular resolution, minimum detectable motion, cross-axis sensitivity, and drift characteristics under repeated mechanical stress. They also specify environmental testing conditions such as temperature ranges, humidity levels, and mechanical strain parameters that sensors must withstand while maintaining specified accuracy levels.

The adoption of these standards has begun to facilitate more meaningful comparisons between different flexible sensor technologies and accelerate their integration into commercial applications. However, challenges remain in harmonizing competing standards and ensuring their relevance across the rapidly evolving landscape of flexible electronics applications in motion detection.

Several international organizations have initiated standardization efforts to address this gap. The IEEE Working Group on Flexible, Wearable, and Stretchable Electronics has established a task force specifically focused on developing standardized testing methodologies for motion detection accuracy in flexible sensors. Their framework proposes standardized motion sequences and environmental conditions to ensure consistent evaluation across different sensor technologies.

Similarly, the International Electrotechnical Commission (IEC) has published technical specifications that outline performance metrics for flexible electronic devices, including specific parameters for motion detection sensors such as response time, accuracy under deformation, and signal-to-noise ratio during dynamic movements.

Industry consortia have also contributed significantly to these standardization efforts. The Flexible Electronics and Display Consortium has developed a comprehensive set of benchmarking protocols specifically designed for motion detection applications, addressing various use cases from healthcare monitoring to sports performance analysis.

Academic institutions have collaborated with industry partners to establish open-source testing platforms that enable consistent evaluation of sensor performance. The Flexible Sensor Performance Index (FSPI), developed through such collaboration, provides a quantitative scoring system that accounts for accuracy, precision, response time, and durability under various motion conditions.

These standardization initiatives typically define key performance indicators including angular resolution, minimum detectable motion, cross-axis sensitivity, and drift characteristics under repeated mechanical stress. They also specify environmental testing conditions such as temperature ranges, humidity levels, and mechanical strain parameters that sensors must withstand while maintaining specified accuracy levels.

The adoption of these standards has begun to facilitate more meaningful comparisons between different flexible sensor technologies and accelerate their integration into commercial applications. However, challenges remain in harmonizing competing standards and ensuring their relevance across the rapidly evolving landscape of flexible electronics applications in motion detection.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!