Assessing Corrosion Resistance of Flexible Electronics

SEP 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Flexible Electronics Corrosion Background and Objectives

Flexible electronics represent a revolutionary advancement in the field of electronic devices, characterized by their ability to bend, fold, and conform to non-planar surfaces. The evolution of this technology began in the early 2000s with the development of organic semiconductors and has since expanded to include a diverse range of materials and applications. The trajectory of flexible electronics has been marked by continuous improvements in durability, functionality, and manufacturing processes, with significant breakthroughs occurring in the past decade.

Corrosion resistance has emerged as a critical challenge in the advancement of flexible electronics. Unlike traditional rigid electronics that can be hermetically sealed, flexible devices are often exposed to environmental factors such as moisture, oxygen, and various chemicals that can accelerate degradation processes. The inherent flexibility requirements often preclude the use of conventional protective encapsulation methods, necessitating innovative approaches to ensure longevity.

The primary objective of assessing corrosion resistance in flexible electronics is to develop comprehensive understanding of degradation mechanisms under various environmental conditions. This includes identifying the specific chemical and electrochemical processes that lead to material deterioration, particularly at interfaces between different components where stress concentrations can exacerbate corrosion effects.

Another crucial goal is to establish standardized testing protocols that accurately predict the operational lifetime of flexible electronic devices in real-world applications. Current testing methodologies often fail to account for the unique stresses experienced by flexible components, leading to discrepancies between laboratory results and field performance. Developing accelerated aging tests that correlate with actual usage conditions represents a significant technical challenge.

The development of novel protective strategies constitutes a third major objective. This encompasses the creation of barrier materials that maintain flexibility while providing effective protection against moisture and oxygen permeation, as well as the formulation of self-healing materials capable of autonomously repairing damage to maintain device integrity over extended periods.

Industry stakeholders are increasingly recognizing the importance of designing corrosion resistance as an intrinsic property rather than an afterthought. This paradigm shift requires fundamental research into material science, interface engineering, and encapsulation technologies. The ultimate aim is to enable flexible electronic devices that maintain performance and reliability throughout their intended service life, even when subjected to challenging environmental conditions.

Corrosion resistance has emerged as a critical challenge in the advancement of flexible electronics. Unlike traditional rigid electronics that can be hermetically sealed, flexible devices are often exposed to environmental factors such as moisture, oxygen, and various chemicals that can accelerate degradation processes. The inherent flexibility requirements often preclude the use of conventional protective encapsulation methods, necessitating innovative approaches to ensure longevity.

The primary objective of assessing corrosion resistance in flexible electronics is to develop comprehensive understanding of degradation mechanisms under various environmental conditions. This includes identifying the specific chemical and electrochemical processes that lead to material deterioration, particularly at interfaces between different components where stress concentrations can exacerbate corrosion effects.

Another crucial goal is to establish standardized testing protocols that accurately predict the operational lifetime of flexible electronic devices in real-world applications. Current testing methodologies often fail to account for the unique stresses experienced by flexible components, leading to discrepancies between laboratory results and field performance. Developing accelerated aging tests that correlate with actual usage conditions represents a significant technical challenge.

The development of novel protective strategies constitutes a third major objective. This encompasses the creation of barrier materials that maintain flexibility while providing effective protection against moisture and oxygen permeation, as well as the formulation of self-healing materials capable of autonomously repairing damage to maintain device integrity over extended periods.

Industry stakeholders are increasingly recognizing the importance of designing corrosion resistance as an intrinsic property rather than an afterthought. This paradigm shift requires fundamental research into material science, interface engineering, and encapsulation technologies. The ultimate aim is to enable flexible electronic devices that maintain performance and reliability throughout their intended service life, even when subjected to challenging environmental conditions.

Market Analysis for Corrosion-Resistant Flexible Electronics

The flexible electronics market is experiencing significant growth, with a projected market value reaching $48.5 billion by 2028, growing at a CAGR of 17.4% from 2023. Within this expanding sector, corrosion-resistant flexible electronics represent a crucial segment addressing durability concerns across multiple industries. The demand for these specialized components is primarily driven by harsh-environment applications in healthcare, automotive, aerospace, and consumer electronics sectors.

Healthcare applications constitute approximately 24% of the corrosion-resistant flexible electronics market, with wearable medical devices requiring protection against bodily fluids and disinfectants. The automotive industry follows closely at 22%, where flexible electronics must withstand exposure to various chemicals, temperature fluctuations, and environmental factors. Consumer electronics represents 19% of market demand, while aerospace and defense applications account for 15%.

Geographically, North America currently leads the market with 35% share, followed by Asia-Pacific at 32%, Europe at 25%, and rest of the world at 8%. However, the Asia-Pacific region is expected to demonstrate the fastest growth rate of 19.2% annually through 2028, driven by expanding manufacturing capabilities and increasing adoption of flexible electronic devices in countries like China, South Korea, and Japan.

Market research indicates that consumers and industrial clients are willing to pay a premium of 15-20% for enhanced corrosion resistance in flexible electronics, recognizing the long-term cost benefits through extended product lifecycles and reduced maintenance requirements. This premium pricing potential has attracted significant investment in corrosion-resistant technologies.

Key market drivers include the growing demand for wearable technology, increasing deployment of flexible electronics in harsh environments, and rising consumer expectations for product durability. The healthcare sector specifically shows strong growth potential, with corrosion-resistant flexible biosensors and implantable devices projected to grow at 22% annually.

Market challenges include the higher initial production costs of corrosion-resistant materials, technical difficulties in maintaining flexibility while enhancing corrosion protection, and the need for standardized testing protocols. Additionally, environmental regulations increasingly impact material selection and manufacturing processes for corrosion-resistant coatings and substrates.

Industry surveys reveal that 78% of electronics manufacturers consider corrosion resistance a critical factor in their product development roadmaps, with 63% actively investing in related R&D activities. This indicates strong market recognition of corrosion resistance as a value-adding feature rather than merely a technical specification.

Healthcare applications constitute approximately 24% of the corrosion-resistant flexible electronics market, with wearable medical devices requiring protection against bodily fluids and disinfectants. The automotive industry follows closely at 22%, where flexible electronics must withstand exposure to various chemicals, temperature fluctuations, and environmental factors. Consumer electronics represents 19% of market demand, while aerospace and defense applications account for 15%.

Geographically, North America currently leads the market with 35% share, followed by Asia-Pacific at 32%, Europe at 25%, and rest of the world at 8%. However, the Asia-Pacific region is expected to demonstrate the fastest growth rate of 19.2% annually through 2028, driven by expanding manufacturing capabilities and increasing adoption of flexible electronic devices in countries like China, South Korea, and Japan.

Market research indicates that consumers and industrial clients are willing to pay a premium of 15-20% for enhanced corrosion resistance in flexible electronics, recognizing the long-term cost benefits through extended product lifecycles and reduced maintenance requirements. This premium pricing potential has attracted significant investment in corrosion-resistant technologies.

Key market drivers include the growing demand for wearable technology, increasing deployment of flexible electronics in harsh environments, and rising consumer expectations for product durability. The healthcare sector specifically shows strong growth potential, with corrosion-resistant flexible biosensors and implantable devices projected to grow at 22% annually.

Market challenges include the higher initial production costs of corrosion-resistant materials, technical difficulties in maintaining flexibility while enhancing corrosion protection, and the need for standardized testing protocols. Additionally, environmental regulations increasingly impact material selection and manufacturing processes for corrosion-resistant coatings and substrates.

Industry surveys reveal that 78% of electronics manufacturers consider corrosion resistance a critical factor in their product development roadmaps, with 63% actively investing in related R&D activities. This indicates strong market recognition of corrosion resistance as a value-adding feature rather than merely a technical specification.

Current Challenges in Flexible Electronics Corrosion Protection

Flexible electronics represent a revolutionary advancement in technology, enabling devices that can bend, stretch, and conform to various surfaces. However, these unique properties also introduce significant challenges in terms of corrosion protection. Unlike traditional rigid electronics that can be fully encapsulated in protective materials, flexible devices must maintain their mechanical properties while simultaneously resisting environmental degradation.

The primary challenge in protecting flexible electronics from corrosion stems from the dynamic mechanical stresses they experience. When these devices bend or stretch, microcracks can form in protective coatings, creating pathways for moisture, oxygen, and corrosive agents to penetrate and attack sensitive electronic components. This mechanical-environmental interaction creates a complex failure mechanism that traditional corrosion protection strategies cannot adequately address.

Material compatibility presents another significant hurdle. Conventional corrosion-resistant materials like thick metal oxides or glass encapsulations are too rigid for flexible applications. Meanwhile, polymeric materials that offer suitable flexibility often exhibit poor barrier properties against water vapor and oxygen transmission, which are primary corrosion accelerants for electronic components.

Interface stability between different materials in flexible electronics poses additional challenges. The repeated mechanical deformation can cause delamination at material interfaces, creating voids where corrosive agents can accumulate. This is particularly problematic at connections between rigid components (like chips) and flexible substrates, which experience high stress concentrations during bending.

Environmental factors further complicate corrosion protection efforts. Flexible electronics are increasingly deployed in harsh environments including wearable applications exposed to sweat, implantable devices in contact with bodily fluids, and outdoor installations subjected to varying weather conditions. Each environment presents unique corrosive challenges that require specialized protection strategies.

Manufacturing scalability remains a significant obstacle. While laboratory-scale corrosion protection solutions have shown promise, translating these approaches to high-volume, cost-effective manufacturing processes has proven difficult. Techniques like atomic layer deposition offer excellent barrier properties but face throughput limitations in industrial settings.

Long-term reliability assessment presents methodological challenges. Accelerated testing protocols developed for rigid electronics often fail to accurately predict the corrosion behavior of flexible systems, as they cannot properly simulate the combined effects of mechanical stress and environmental exposure over extended periods. This creates uncertainty in lifetime predictions and reliability assessments.

The primary challenge in protecting flexible electronics from corrosion stems from the dynamic mechanical stresses they experience. When these devices bend or stretch, microcracks can form in protective coatings, creating pathways for moisture, oxygen, and corrosive agents to penetrate and attack sensitive electronic components. This mechanical-environmental interaction creates a complex failure mechanism that traditional corrosion protection strategies cannot adequately address.

Material compatibility presents another significant hurdle. Conventional corrosion-resistant materials like thick metal oxides or glass encapsulations are too rigid for flexible applications. Meanwhile, polymeric materials that offer suitable flexibility often exhibit poor barrier properties against water vapor and oxygen transmission, which are primary corrosion accelerants for electronic components.

Interface stability between different materials in flexible electronics poses additional challenges. The repeated mechanical deformation can cause delamination at material interfaces, creating voids where corrosive agents can accumulate. This is particularly problematic at connections between rigid components (like chips) and flexible substrates, which experience high stress concentrations during bending.

Environmental factors further complicate corrosion protection efforts. Flexible electronics are increasingly deployed in harsh environments including wearable applications exposed to sweat, implantable devices in contact with bodily fluids, and outdoor installations subjected to varying weather conditions. Each environment presents unique corrosive challenges that require specialized protection strategies.

Manufacturing scalability remains a significant obstacle. While laboratory-scale corrosion protection solutions have shown promise, translating these approaches to high-volume, cost-effective manufacturing processes has proven difficult. Techniques like atomic layer deposition offer excellent barrier properties but face throughput limitations in industrial settings.

Long-term reliability assessment presents methodological challenges. Accelerated testing protocols developed for rigid electronics often fail to accurately predict the corrosion behavior of flexible systems, as they cannot properly simulate the combined effects of mechanical stress and environmental exposure over extended periods. This creates uncertainty in lifetime predictions and reliability assessments.

Current Corrosion Assessment Methodologies and Solutions

01 Protective coatings for flexible electronics

Various protective coatings can be applied to flexible electronic components to enhance their corrosion resistance. These coatings create a barrier between the electronic components and corrosive environmental factors such as moisture, oxygen, and chemicals. Materials used for these protective coatings include polymers, metal oxides, and composite materials that maintain flexibility while providing effective protection against corrosion.- Protective coatings for flexible electronics: Various protective coatings can be applied to flexible electronic components to enhance their corrosion resistance. These coatings create a barrier between the electronic components and corrosive environmental factors such as moisture, oxygen, and chemicals. Materials used for these protective coatings include polymers, metal oxides, and composite materials that maintain flexibility while providing effective protection against corrosion.

- Flexible substrate materials with inherent corrosion resistance: The development of substrate materials that are both flexible and inherently corrosion-resistant is crucial for flexible electronics. These materials serve as the foundation for flexible electronic devices and must maintain their integrity under various environmental conditions. Advanced polymers, treated metals, and composite materials are being engineered to provide the necessary flexibility while resisting degradation from corrosive elements.

- Encapsulation techniques for moisture protection: Encapsulation methods are employed to protect flexible electronic components from moisture, which is a primary cause of corrosion. These techniques involve sealing the electronic components within water-resistant materials that maintain flexibility. Advanced encapsulation approaches include multi-layer barriers, edge sealing technologies, and breathable membranes that prevent water ingress while allowing for the release of trapped gases.

- Corrosion-resistant conductive materials for flexible circuits: The development of conductive materials that maintain electrical performance while resisting corrosion is essential for flexible electronics. These materials include modified metals, conductive polymers, and composite materials that can withstand bending and stretching without degradation. Surface treatments and alloying techniques are employed to enhance the corrosion resistance of traditional conductive materials while preserving their electrical properties and flexibility.

- Self-healing mechanisms for corrosion protection: Self-healing technologies are being incorporated into flexible electronic systems to automatically repair damage and prevent corrosion progression. These mechanisms include microcapsules containing healing agents that release when damage occurs, reversible polymer networks that can reform bonds after being broken, and dynamic chemistry that responds to environmental triggers. Such self-healing capabilities extend the lifespan of flexible electronics by addressing corrosion issues as they emerge.

02 Corrosion-resistant metal alloys for flexible circuits

Specialized metal alloys have been developed for use in flexible electronics that offer inherent corrosion resistance while maintaining the necessary flexibility. These alloys typically contain elements such as chromium, nickel, or titanium that form passive oxide layers, protecting the underlying metal from corrosive attack. The composition and processing of these alloys are optimized to achieve both mechanical flexibility and electrochemical stability in various operating environments.Expand Specific Solutions03 Encapsulation techniques for moisture protection

Encapsulation methods are employed to protect flexible electronic components from moisture, which is a primary cause of corrosion. These techniques involve sealing the electronic components with water-resistant materials such as specialized polymers, resins, or thin-film barriers. Multi-layer encapsulation approaches can provide enhanced protection while maintaining the flexibility of the electronic device, effectively preventing water ingress and subsequent corrosion damage.Expand Specific Solutions04 Surface treatment methods for improved corrosion resistance

Various surface treatment methods can be applied to the conductive elements of flexible electronics to enhance their corrosion resistance. These treatments include passivation, anodization, chemical conversion coatings, and plasma treatments. Such processes modify the surface properties of the materials, creating protective layers that inhibit corrosion reactions while preserving electrical conductivity and mechanical flexibility of the underlying substrate.Expand Specific Solutions05 Flexible substrate materials with inherent corrosion resistance

The development of substrate materials with inherent corrosion resistance is crucial for flexible electronics. These substrates include modified polyimides, fluoropolymers, and specialized composite materials that resist degradation in corrosive environments. The chemical stability of these materials prevents the initiation and propagation of corrosion processes, while their mechanical properties allow for the flexibility required in wearable and bendable electronic applications.Expand Specific Solutions

Key Industry Players in Corrosion-Resistant Flexible Electronics

The flexible electronics corrosion resistance market is currently in a growth phase, with increasing adoption across consumer electronics, automotive, and medical sectors. The global market size is projected to expand significantly as demand for durable, bendable electronic components rises. Technologically, the field shows moderate maturity with ongoing innovation. Leading players include Samsung Electronics and Samsung Display, who dominate with advanced display technologies; Corning and Infineon Technologies, focusing on protective materials and semiconductor solutions; while Huawei and 3M contribute significant R&D. Japanese firms like Nippon Steel Chemical, Hitachi, and Toshiba offer specialized corrosion-resistant materials. Academic institutions such as Northwestern University and Huazhong University collaborate with industry to advance fundamental research in protective coatings and encapsulation technologies.

Corning, Inc.

Technical Solution: Corning has developed an innovative approach to corrosion protection for flexible electronics through their Flexible Glass Barrier technology. Unlike traditional plastic-based barriers, Corning's ultra-thin flexible glass provides exceptional barrier properties against moisture and oxygen while maintaining flexibility required for bendable devices. Their Willow® Glass can be produced in thicknesses below 100 micrometers while providing hermetic-level protection against environmental factors that cause corrosion[9]. The inherent properties of glass create an almost perfect barrier against gas permeation, with water vapor transmission rates below 10^-7 g/m²/day, significantly outperforming polymer alternatives[10]. Corning has also developed specialized edge sealing technologies and handling processes to address the traditional brittleness concerns with glass materials. Their research demonstrates that properly processed flexible glass can withstand bend radii of 25mm while maintaining barrier integrity. Additionally, Corning has created hybrid solutions that combine their flexible glass with polymer layers to enhance durability while preserving the exceptional barrier properties of glass.

Strengths: Superior barrier performance against moisture and oxygen compared to polymer alternatives; excellent chemical resistance against a wide range of substances; maintains optical clarity and surface quality even after environmental exposure. Weaknesses: More limited flexibility compared to pure polymer solutions (minimum bend radius constraints); requires specialized handling during manufacturing; higher initial cost compared to conventional barrier films.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung Electronics has developed a comprehensive approach to enhancing corrosion resistance in flexible electronics through their Advanced Multi-Layer Protection (AMLP) system. This technology incorporates specialized barrier films with multiple protective layers that shield sensitive electronic components from moisture, oxygen, and corrosive agents. Their solution includes vapor-deposited inorganic layers (typically silicon nitride or aluminum oxide) alternating with organic polymer layers to create an effective barrier against environmental factors[1]. Samsung has also pioneered the use of graphene-enhanced protective coatings that provide exceptional corrosion resistance while maintaining flexibility. Their research shows these coatings can withstand over 200,000 bending cycles while maintaining barrier properties[3]. Additionally, Samsung has developed specialized edge-sealing technologies that address the vulnerable perimeter areas of flexible displays, which are particularly susceptible to corrosion from edge ingress of moisture.

Strengths: Superior multi-layer protection system that effectively blocks moisture and oxygen penetration while maintaining flexibility; industry-leading edge-sealing technology; extensive manufacturing capabilities for mass production. Weaknesses: Higher production costs compared to conventional protection methods; some solutions may add minimal but noticeable thickness to ultra-thin flexible devices; proprietary nature of technologies limits broader industry adoption.

Critical Patents and Research in Flexible Electronics Protection

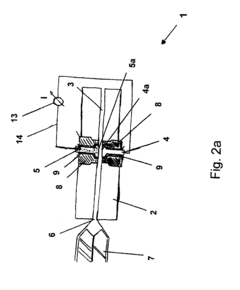

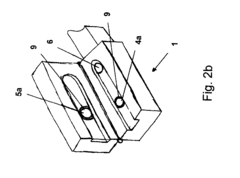

Device for determining the corrosivity of a plastic melt

PatentInactiveEP2775299A1

Innovation

- A device with a housing containing electrodes of differing materials, where the corrosion process between them is measured electrically, allowing for the determination of corrosiveness through electrical current or voltage, and optionally incorporating additional sensors for normalization, with features like interchangeable electrodes and easy cleaning access.

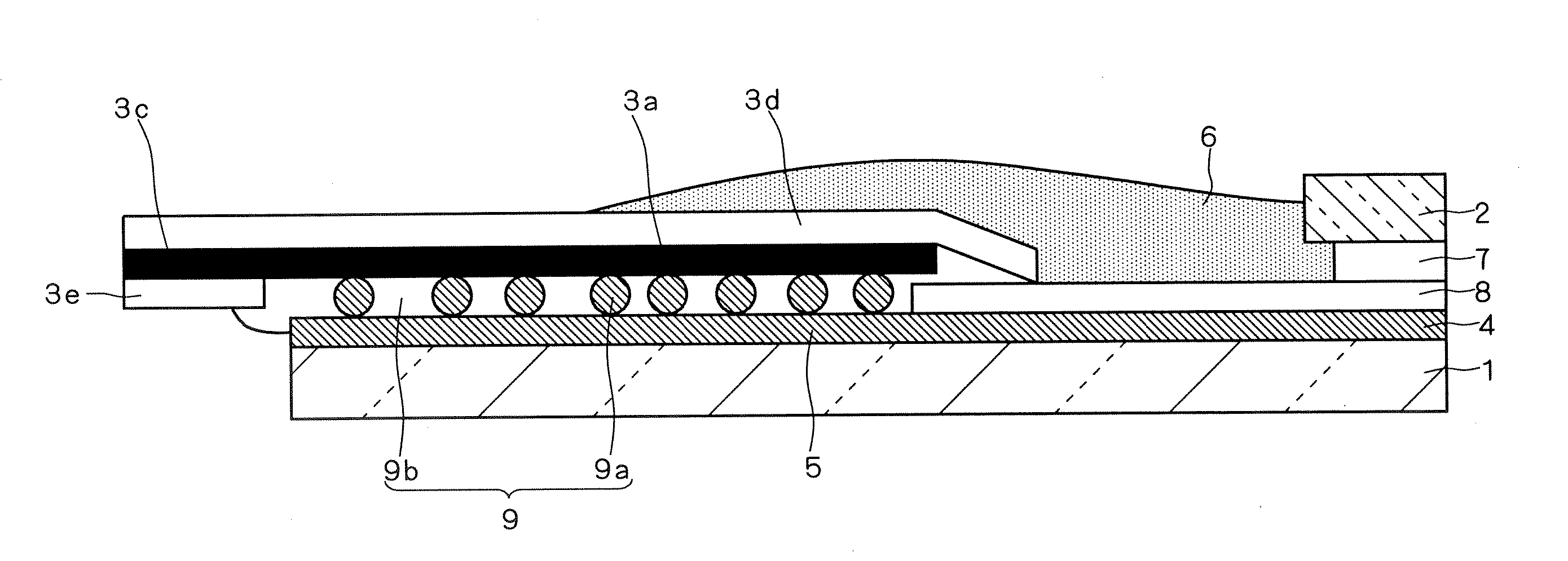

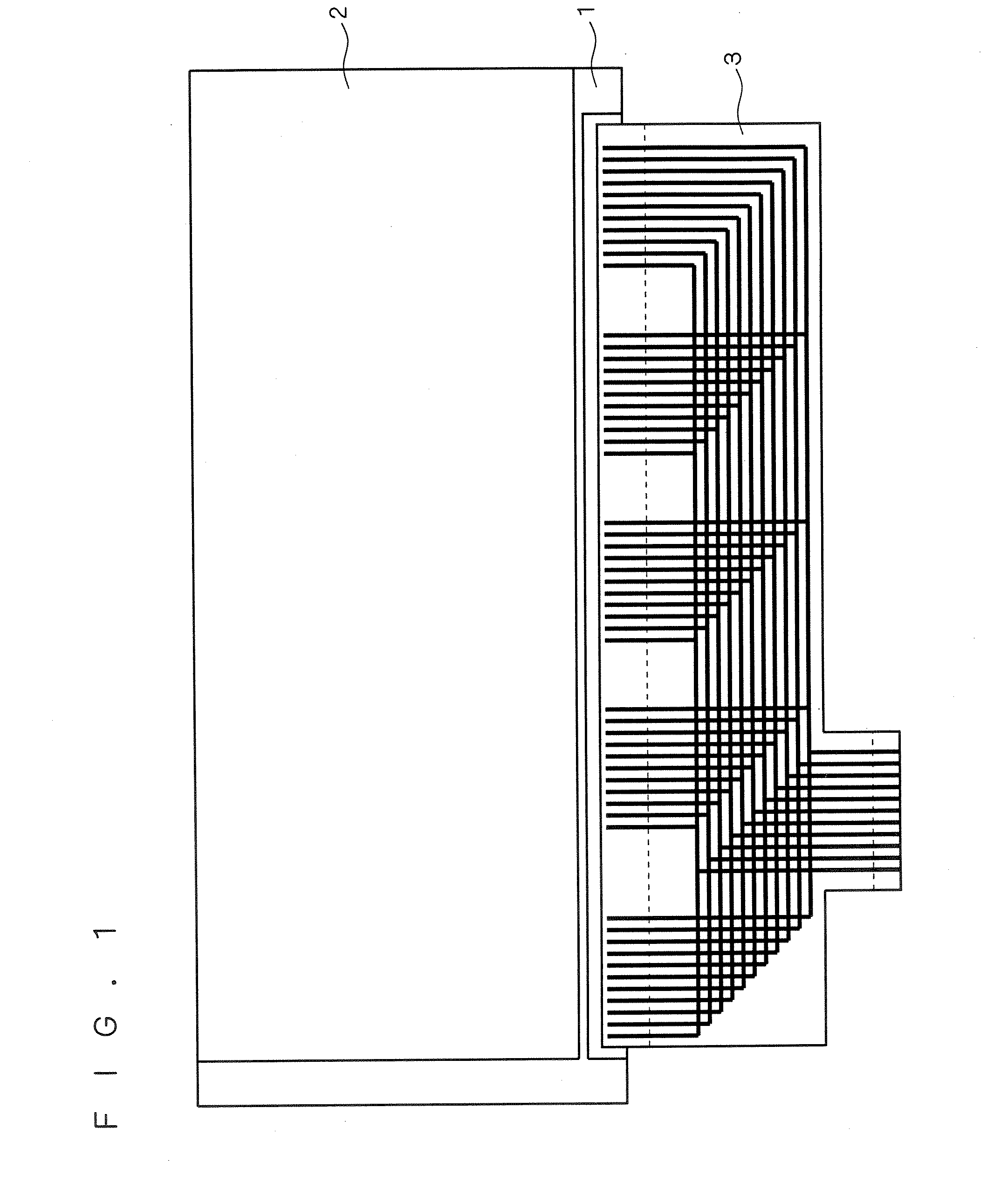

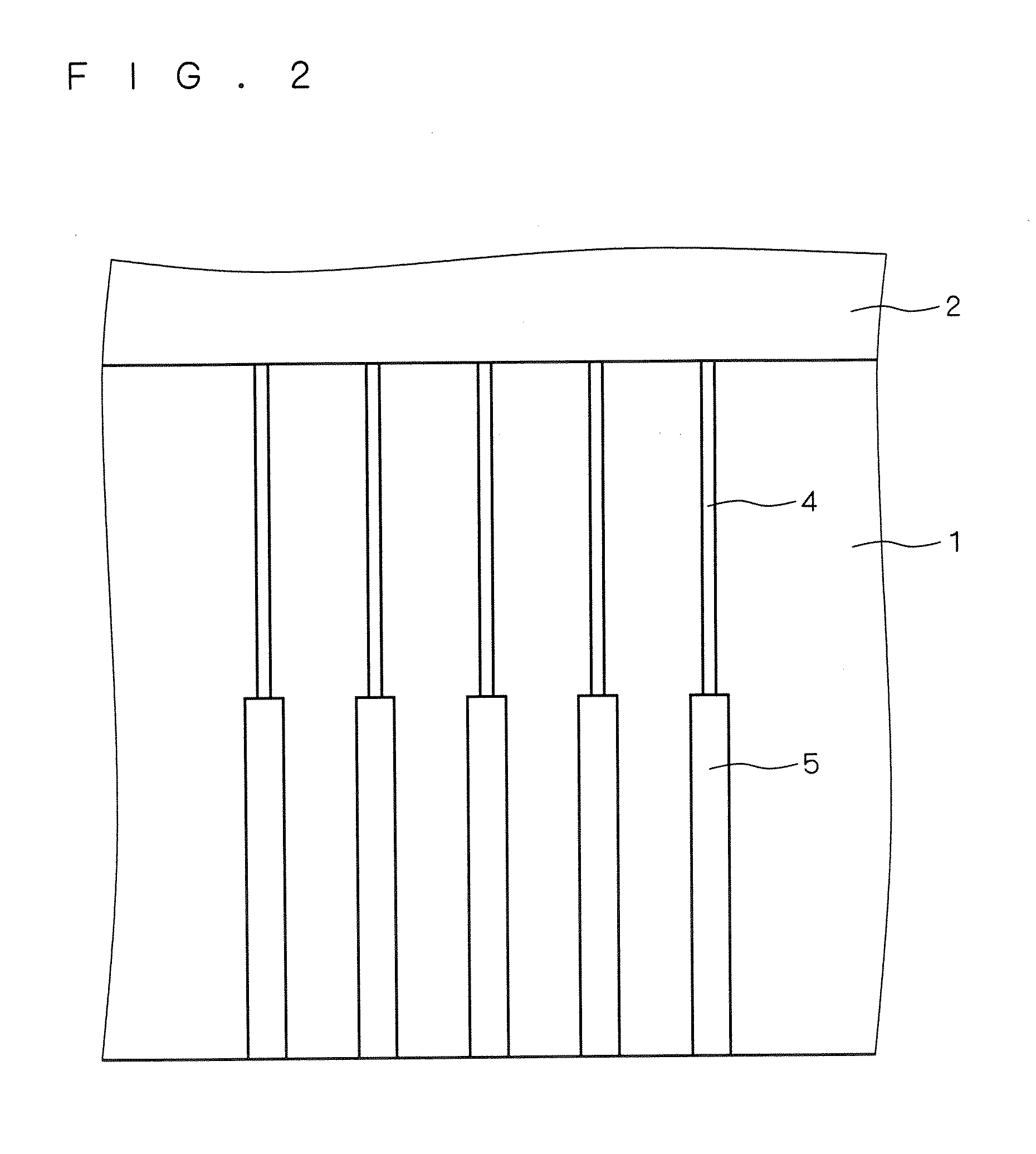

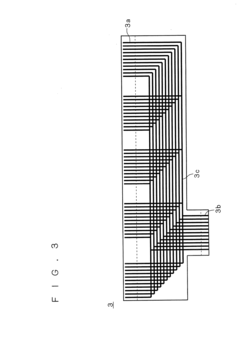

Flexible printed circuit and display device using the same

PatentActiveUS20070013856A1

Innovation

- A flexible printed circuit design where at least one terminal's end is located inside the insulative film, ensuring the connections are covered and protected from corrosion, using a flexible insulative film with interconnections and a resist layer, and employing thermo-compression bonding with an anisotropic conductive film to maintain electrical connectivity while preventing adjacent terminal short-circuiting.

Environmental Factors Affecting Flexible Electronics Durability

Flexible electronics face a multitude of environmental challenges that significantly impact their durability and functional lifespan. Temperature fluctuations represent one of the most critical factors, with extreme heat accelerating chemical degradation processes while cold temperatures can cause material embrittlement and cracking in polymer substrates. These thermal stresses are particularly problematic at connection points between rigid and flexible components, where differential expansion rates create mechanical strain.

Humidity and moisture exposure constitute another major threat to flexible electronic systems. Water molecules can penetrate protective layers and initiate electrochemical corrosion processes, particularly in the presence of ionic contaminants. This moisture intrusion often leads to delamination between layers, oxidation of conductive traces, and eventual circuit failure. Research indicates that relative humidity above 60% dramatically accelerates degradation rates in unprotected flexible circuits.

Ultraviolet radiation presents a persistent challenge, particularly for outdoor applications. UV exposure degrades polymer substrates through photochemical reactions, leading to yellowing, embrittlement, and reduced mechanical flexibility. This degradation compromises both the physical integrity of the substrate and the adhesion between electronic components and the flexible base material.

Chemical exposure represents another significant environmental factor. Acidic or alkaline substances, even in trace amounts from environmental pollution or human perspiration, can initiate localized corrosion processes. Industrial environments containing sulfur compounds or chlorides are particularly aggressive toward metallic components in flexible electronics, creating vulnerability points throughout the system.

Mechanical stresses from repeated bending, folding, or stretching compound these environmental challenges. The combination of mechanical strain with environmental factors creates synergistic degradation mechanisms that accelerate failure rates beyond what would be expected from either factor alone. For instance, microcracks formed during bending create entry points for moisture and contaminants, accelerating corrosion processes.

Atmospheric pollutants, particularly in urban or industrial settings, introduce additional corrosion mechanisms. Sulfur dioxide, nitrogen oxides, and particulate matter can deposit on flexible electronic surfaces and create localized corrosion cells. These pollutants often combine with moisture to form acidic compounds that aggressively attack metallic components and protective coatings.

The interaction between these environmental factors creates complex degradation pathways that must be understood and mitigated through appropriate material selection, protective strategies, and design approaches. Comprehensive testing protocols that simulate real-world environmental conditions, often in combination, are essential for accurately predicting the durability of flexible electronic systems in their intended application environments.

Humidity and moisture exposure constitute another major threat to flexible electronic systems. Water molecules can penetrate protective layers and initiate electrochemical corrosion processes, particularly in the presence of ionic contaminants. This moisture intrusion often leads to delamination between layers, oxidation of conductive traces, and eventual circuit failure. Research indicates that relative humidity above 60% dramatically accelerates degradation rates in unprotected flexible circuits.

Ultraviolet radiation presents a persistent challenge, particularly for outdoor applications. UV exposure degrades polymer substrates through photochemical reactions, leading to yellowing, embrittlement, and reduced mechanical flexibility. This degradation compromises both the physical integrity of the substrate and the adhesion between electronic components and the flexible base material.

Chemical exposure represents another significant environmental factor. Acidic or alkaline substances, even in trace amounts from environmental pollution or human perspiration, can initiate localized corrosion processes. Industrial environments containing sulfur compounds or chlorides are particularly aggressive toward metallic components in flexible electronics, creating vulnerability points throughout the system.

Mechanical stresses from repeated bending, folding, or stretching compound these environmental challenges. The combination of mechanical strain with environmental factors creates synergistic degradation mechanisms that accelerate failure rates beyond what would be expected from either factor alone. For instance, microcracks formed during bending create entry points for moisture and contaminants, accelerating corrosion processes.

Atmospheric pollutants, particularly in urban or industrial settings, introduce additional corrosion mechanisms. Sulfur dioxide, nitrogen oxides, and particulate matter can deposit on flexible electronic surfaces and create localized corrosion cells. These pollutants often combine with moisture to form acidic compounds that aggressively attack metallic components and protective coatings.

The interaction between these environmental factors creates complex degradation pathways that must be understood and mitigated through appropriate material selection, protective strategies, and design approaches. Comprehensive testing protocols that simulate real-world environmental conditions, often in combination, are essential for accurately predicting the durability of flexible electronic systems in their intended application environments.

Standardization and Testing Protocols for Corrosion Assessment

The standardization of testing protocols for corrosion assessment in flexible electronics represents a critical challenge in the industry. Currently, there exists a significant gap between traditional corrosion testing methods designed for rigid electronics and the unique requirements of flexible electronic systems. This discrepancy necessitates the development of specialized protocols that account for the mechanical stress, bending, and stretching that flexible electronics routinely undergo.

Several international organizations, including IEC (International Electrotechnical Commission), ASTM International, and IEEE, have begun initiatives to establish standardized testing frameworks. The IEC 60068 series, while primarily focused on environmental testing for electronic equipment, has seen recent modifications to incorporate considerations for flexible substrates and interconnects. Similarly, ASTM B117 salt spray testing has been adapted with specific parameters for flexible electronic components.

Key testing protocols currently under development include accelerated environmental testing, combined mechanical-environmental stress testing, and electrochemical impedance spectroscopy (EIS) specifically calibrated for thin-film flexible circuits. These protocols aim to simulate real-world conditions while providing quantifiable metrics for corrosion resistance assessment.

The industry has recognized the need for multi-parameter testing approaches that simultaneously evaluate mechanical integrity and electrochemical stability. For instance, the bend-and-soak test methodology combines cyclic mechanical deformation with exposure to corrosive environments, providing more realistic performance predictions than isolated testing procedures.

Standardized reporting metrics represent another crucial aspect of these protocols. Parameters such as time-to-failure under specified conditions, impedance changes over time, and visual degradation scoring systems are being formalized to enable meaningful comparisons between different flexible electronic systems and protective strategies.

Interlaboratory validation studies have emerged as essential for establishing the reliability and reproducibility of these testing protocols. Several consortia involving academic institutions, national laboratories, and industry partners are conducting round-robin testing to validate proposed standards and identify potential sources of variability in test results.

The development of in-situ monitoring techniques has significantly enhanced the value of corrosion testing protocols. Real-time impedance monitoring, optical coherence tomography, and specialized flexible sensor arrays embedded within test specimens allow for continuous assessment of degradation processes without interrupting the testing environment.

Several international organizations, including IEC (International Electrotechnical Commission), ASTM International, and IEEE, have begun initiatives to establish standardized testing frameworks. The IEC 60068 series, while primarily focused on environmental testing for electronic equipment, has seen recent modifications to incorporate considerations for flexible substrates and interconnects. Similarly, ASTM B117 salt spray testing has been adapted with specific parameters for flexible electronic components.

Key testing protocols currently under development include accelerated environmental testing, combined mechanical-environmental stress testing, and electrochemical impedance spectroscopy (EIS) specifically calibrated for thin-film flexible circuits. These protocols aim to simulate real-world conditions while providing quantifiable metrics for corrosion resistance assessment.

The industry has recognized the need for multi-parameter testing approaches that simultaneously evaluate mechanical integrity and electrochemical stability. For instance, the bend-and-soak test methodology combines cyclic mechanical deformation with exposure to corrosive environments, providing more realistic performance predictions than isolated testing procedures.

Standardized reporting metrics represent another crucial aspect of these protocols. Parameters such as time-to-failure under specified conditions, impedance changes over time, and visual degradation scoring systems are being formalized to enable meaningful comparisons between different flexible electronic systems and protective strategies.

Interlaboratory validation studies have emerged as essential for establishing the reliability and reproducibility of these testing protocols. Several consortia involving academic institutions, national laboratories, and industry partners are conducting round-robin testing to validate proposed standards and identify potential sources of variability in test results.

The development of in-situ monitoring techniques has significantly enhanced the value of corrosion testing protocols. Real-time impedance monitoring, optical coherence tomography, and specialized flexible sensor arrays embedded within test specimens allow for continuous assessment of degradation processes without interrupting the testing environment.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!