Assess Signal Interaction in Flexible Electronics Under Magnetic Fields

SEP 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Flexible Electronics Signal Integrity Background & Objectives

Flexible electronics represents a revolutionary paradigm shift in electronic systems, characterized by devices that can bend, stretch, and conform to non-planar surfaces while maintaining functionality. The evolution of this technology has progressed significantly over the past two decades, transitioning from rigid silicon-based electronics to malleable substrates incorporating organic semiconductors, thin-film technologies, and nanomaterials. This technological trajectory has been driven by increasing demands for wearable devices, biomedical implants, and next-generation consumer electronics that require form factors beyond traditional rigid designs.

Signal integrity in flexible electronic systems presents unique challenges compared to conventional electronics, particularly when exposed to external magnetic fields. Historically, electronic signal analysis has been predominantly focused on rigid circuit boards where transmission paths remain constant. However, in flexible electronics, the physical deformation of circuits introduces variable impedance, capacitive coupling changes, and potential signal degradation that traditional models fail to accurately predict.

The intersection of flexible electronics and magnetic field exposure creates a complex technical domain that remains insufficiently explored. Magnetic fields can induce currents in conductive paths, create interference patterns, and potentially alter the electrical characteristics of flexible materials in ways that differ from rigid counterparts. This interaction becomes increasingly significant as flexible electronics find applications in environments with varying magnetic field strengths, from consumer wearables exposed to everyday electromagnetic radiation to medical devices operating near MRI equipment.

The primary objective of this technical assessment is to comprehensively evaluate signal behavior and integrity in flexible electronic systems when subjected to magnetic fields of varying intensities and frequencies. Specifically, we aim to characterize how bending, folding, and stretching actions modify the electromagnetic response of flexible circuits, and how these modifications subsequently affect signal propagation, noise profiles, and overall system reliability.

Secondary objectives include developing predictive models that can accurately simulate signal behavior in deformed flexible circuits under magnetic influence, identifying critical threshold values where signal degradation becomes unacceptable, and exploring potential mitigation strategies through materials selection, circuit design optimization, and shielding techniques appropriate for flexible form factors.

This research addresses a critical knowledge gap in the flexible electronics industry, as current design methodologies often rely on rigid-electronics principles that may not translate accurately to flexible systems, particularly in magnetically active environments. The findings will directly inform next-generation design rules for flexible electronics intended to operate in environments with significant magnetic field presence.

Signal integrity in flexible electronic systems presents unique challenges compared to conventional electronics, particularly when exposed to external magnetic fields. Historically, electronic signal analysis has been predominantly focused on rigid circuit boards where transmission paths remain constant. However, in flexible electronics, the physical deformation of circuits introduces variable impedance, capacitive coupling changes, and potential signal degradation that traditional models fail to accurately predict.

The intersection of flexible electronics and magnetic field exposure creates a complex technical domain that remains insufficiently explored. Magnetic fields can induce currents in conductive paths, create interference patterns, and potentially alter the electrical characteristics of flexible materials in ways that differ from rigid counterparts. This interaction becomes increasingly significant as flexible electronics find applications in environments with varying magnetic field strengths, from consumer wearables exposed to everyday electromagnetic radiation to medical devices operating near MRI equipment.

The primary objective of this technical assessment is to comprehensively evaluate signal behavior and integrity in flexible electronic systems when subjected to magnetic fields of varying intensities and frequencies. Specifically, we aim to characterize how bending, folding, and stretching actions modify the electromagnetic response of flexible circuits, and how these modifications subsequently affect signal propagation, noise profiles, and overall system reliability.

Secondary objectives include developing predictive models that can accurately simulate signal behavior in deformed flexible circuits under magnetic influence, identifying critical threshold values where signal degradation becomes unacceptable, and exploring potential mitigation strategies through materials selection, circuit design optimization, and shielding techniques appropriate for flexible form factors.

This research addresses a critical knowledge gap in the flexible electronics industry, as current design methodologies often rely on rigid-electronics principles that may not translate accurately to flexible systems, particularly in magnetically active environments. The findings will directly inform next-generation design rules for flexible electronics intended to operate in environments with significant magnetic field presence.

Market Analysis for Magnetic-Resistant Flexible Electronics

The flexible electronics market is experiencing significant growth, with magnetic-resistant applications emerging as a crucial segment. Current market valuations place the global flexible electronics sector at approximately 31.6 billion USD in 2023, with projections indicating growth to reach 72.5 billion USD by 2030, representing a compound annual growth rate of 12.7%. Within this broader market, magnetic-resistant flexible electronics are gaining particular traction due to their critical applications in healthcare, automotive systems, and aerospace technologies.

Consumer demand for wearable health monitoring devices has created a substantial market opportunity, as these devices must maintain signal integrity even when exposed to magnetic fields in everyday environments. The medical imaging sector specifically requires flexible electronic components that can function reliably within strong magnetic fields generated by MRI machines, representing a specialized market segment valued at approximately 2.8 billion USD.

Industrial automation and automotive sectors are driving demand for flexible sensors and control systems that can operate in electromagnetically noisy environments. The automotive flexible electronics market segment is growing at 15.3% annually, with magnetic-resistant components representing a key differentiator for manufacturers developing advanced driver assistance systems and autonomous vehicle technologies.

Geographic market distribution shows Asia-Pacific leading manufacturing capacity, accounting for 47% of global production, while North America and Europe lead in research innovation and high-value applications. China has emerged as the dominant manufacturing hub, while Japan specializes in high-precision magnetic-resistant flexible components for medical and industrial applications.

Market barriers include the price premium for magnetic-resistant materials, which currently adds 30-45% to component costs compared to standard flexible electronics. This cost differential has limited adoption in consumer electronics but remains acceptable in mission-critical applications where signal integrity is paramount.

Customer surveys indicate that reliability under variable environmental conditions ranks as the top purchasing consideration for industrial buyers of flexible electronics, with 78% of procurement specialists citing magnetic interference resistance as "important" or "very important" in their evaluation criteria.

The competitive landscape features established electronics manufacturers expanding into this specialized segment, alongside innovative startups developing proprietary shielding technologies and novel materials. Market consolidation is expected as larger companies acquire specialized technology providers to enhance their product portfolios with magnetic-resistant capabilities.

Consumer demand for wearable health monitoring devices has created a substantial market opportunity, as these devices must maintain signal integrity even when exposed to magnetic fields in everyday environments. The medical imaging sector specifically requires flexible electronic components that can function reliably within strong magnetic fields generated by MRI machines, representing a specialized market segment valued at approximately 2.8 billion USD.

Industrial automation and automotive sectors are driving demand for flexible sensors and control systems that can operate in electromagnetically noisy environments. The automotive flexible electronics market segment is growing at 15.3% annually, with magnetic-resistant components representing a key differentiator for manufacturers developing advanced driver assistance systems and autonomous vehicle technologies.

Geographic market distribution shows Asia-Pacific leading manufacturing capacity, accounting for 47% of global production, while North America and Europe lead in research innovation and high-value applications. China has emerged as the dominant manufacturing hub, while Japan specializes in high-precision magnetic-resistant flexible components for medical and industrial applications.

Market barriers include the price premium for magnetic-resistant materials, which currently adds 30-45% to component costs compared to standard flexible electronics. This cost differential has limited adoption in consumer electronics but remains acceptable in mission-critical applications where signal integrity is paramount.

Customer surveys indicate that reliability under variable environmental conditions ranks as the top purchasing consideration for industrial buyers of flexible electronics, with 78% of procurement specialists citing magnetic interference resistance as "important" or "very important" in their evaluation criteria.

The competitive landscape features established electronics manufacturers expanding into this specialized segment, alongside innovative startups developing proprietary shielding technologies and novel materials. Market consolidation is expected as larger companies acquire specialized technology providers to enhance their product portfolios with magnetic-resistant capabilities.

Current Challenges in Signal Integrity Under Magnetic Fields

Signal integrity in flexible electronics under magnetic field influence presents multifaceted challenges that significantly impact system performance and reliability. The inherent flexibility of these electronic systems creates unique vulnerabilities when exposed to magnetic fields, particularly as device dimensions continue to shrink and operating frequencies increase.

One primary challenge is the increased susceptibility to electromagnetic interference (EMI) due to the physical characteristics of flexible substrates. Unlike rigid PCBs, flexible circuits lack substantial shielding capabilities and often feature longer, meandering signal traces that effectively act as antennas for magnetic field coupling. This results in higher noise floors and reduced signal-to-noise ratios, particularly problematic in sensitive applications like medical wearables or precision instrumentation.

The non-linear behavior of signal propagation under varying magnetic field strengths presents another significant obstacle. Research indicates that flexible circuits experience disproportionate impedance variations when subjected to magnetic fields, with impedance changes of up to 15-20% observed in polyimide-based flexible circuits under moderate field strengths (0.5-1 Tesla). These variations create unpredictable signal reflections and standing waves that degrade overall signal integrity.

Material-specific challenges further complicate the landscape. Conductive polymers and carbon-based materials commonly used in flexible electronics exhibit magnetoresistance effects that alter their electrical properties under magnetic fields. These changes are often temperature-dependent and non-uniform across the substrate, creating localized "hot spots" of signal degradation that are difficult to predict through conventional simulation methods.

The dynamic nature of flexible electronics introduces additional complexities. As these devices bend, fold, or stretch during normal operation, the interaction between magnetic fields and signal paths constantly changes. This creates time-variant electromagnetic coupling scenarios that conventional static analysis tools struggle to model accurately. Current simulation frameworks typically show error margins exceeding 30% when predicting signal behavior in dynamically deforming flexible circuits under magnetic influence.

Crosstalk management represents another critical challenge. The compact nature of flexible electronics often necessitates dense routing with minimal separation between signal lines. When exposed to magnetic fields, the coupling coefficients between adjacent traces increase dramatically, sometimes by factors of 3-5× compared to field-free conditions. This enhanced coupling creates complex interference patterns that conventional crosstalk mitigation techniques cannot adequately address.

Power integrity issues compound these challenges, as magnetic fields can induce eddy currents in power distribution networks, creating localized voltage drops and ground bounce effects that further compromise signal integrity throughout the system.

One primary challenge is the increased susceptibility to electromagnetic interference (EMI) due to the physical characteristics of flexible substrates. Unlike rigid PCBs, flexible circuits lack substantial shielding capabilities and often feature longer, meandering signal traces that effectively act as antennas for magnetic field coupling. This results in higher noise floors and reduced signal-to-noise ratios, particularly problematic in sensitive applications like medical wearables or precision instrumentation.

The non-linear behavior of signal propagation under varying magnetic field strengths presents another significant obstacle. Research indicates that flexible circuits experience disproportionate impedance variations when subjected to magnetic fields, with impedance changes of up to 15-20% observed in polyimide-based flexible circuits under moderate field strengths (0.5-1 Tesla). These variations create unpredictable signal reflections and standing waves that degrade overall signal integrity.

Material-specific challenges further complicate the landscape. Conductive polymers and carbon-based materials commonly used in flexible electronics exhibit magnetoresistance effects that alter their electrical properties under magnetic fields. These changes are often temperature-dependent and non-uniform across the substrate, creating localized "hot spots" of signal degradation that are difficult to predict through conventional simulation methods.

The dynamic nature of flexible electronics introduces additional complexities. As these devices bend, fold, or stretch during normal operation, the interaction between magnetic fields and signal paths constantly changes. This creates time-variant electromagnetic coupling scenarios that conventional static analysis tools struggle to model accurately. Current simulation frameworks typically show error margins exceeding 30% when predicting signal behavior in dynamically deforming flexible circuits under magnetic influence.

Crosstalk management represents another critical challenge. The compact nature of flexible electronics often necessitates dense routing with minimal separation between signal lines. When exposed to magnetic fields, the coupling coefficients between adjacent traces increase dramatically, sometimes by factors of 3-5× compared to field-free conditions. This enhanced coupling creates complex interference patterns that conventional crosstalk mitigation techniques cannot adequately address.

Power integrity issues compound these challenges, as magnetic fields can induce eddy currents in power distribution networks, creating localized voltage drops and ground bounce effects that further compromise signal integrity throughout the system.

Existing Signal Protection Solutions for Magnetic Environments

01 Flexible electronic interfaces for signal transmission

Flexible electronic interfaces enable efficient signal transmission in wearable and portable devices. These interfaces incorporate conductive materials that maintain functionality during bending and stretching, allowing for reliable signal interaction even when the device is subjected to physical deformation. The flexible nature of these interfaces makes them ideal for applications where traditional rigid electronics would fail, such as in body-worn sensors or foldable displays.- Flexible electronic interfaces for signal transmission: Flexible electronic interfaces enable efficient signal transmission in wearable and portable devices. These interfaces incorporate bendable substrates and conductive materials that maintain signal integrity even when flexed or stretched. The technology allows for seamless integration of electronic components on non-rigid surfaces, facilitating better human-machine interaction while ensuring reliable signal processing and data transfer in various applications.

- Wireless signal interaction in flexible electronic systems: Wireless communication technologies are integrated into flexible electronic platforms to enable signal interaction without physical connections. These systems utilize various wireless protocols to transmit and receive signals between flexible electronic components and external devices. The wireless capabilities enhance mobility and usability while reducing the need for rigid connectors that would compromise flexibility, making them ideal for applications in healthcare monitoring, smart textiles, and portable consumer electronics.

- Sensor integration in flexible electronic circuits: Flexible electronic circuits incorporate various sensors that detect environmental conditions, physical movements, or biological signals. These sensors are designed to maintain functionality while being bent or conformed to irregular surfaces. The integration of sensing elements with flexible signal processing components enables real-time data collection and analysis, creating responsive systems that can adapt to changing conditions while maintaining form factor advantages over rigid electronics.

- Human-machine interface for flexible electronics: Human-machine interfaces specifically designed for flexible electronics enable intuitive interaction between users and flexible devices. These interfaces incorporate touch-sensitive surfaces, gesture recognition, and haptic feedback mechanisms that work effectively on non-rigid substrates. The technology allows users to control flexible electronic systems through natural movements and interactions, enhancing user experience while taking advantage of the conformable nature of the underlying electronic components.

- Signal processing architectures for flexible electronic systems: Specialized signal processing architectures are developed to address the unique challenges of flexible electronic systems. These architectures accommodate the variable electrical characteristics that occur when circuits are bent or stretched, ensuring consistent signal quality and processing capability. The designs incorporate adaptive algorithms, distributed processing nodes, and fault-tolerant components that maintain system functionality despite physical deformation, enabling reliable operation in applications where traditional rigid electronics would fail.

02 Wireless signal interaction in flexible electronic systems

Wireless communication technologies are integrated into flexible electronic systems to enable signal interaction without physical connections. These systems utilize various wireless protocols to transmit data between flexible components or to external devices. The wireless capability enhances the flexibility of the overall system by eliminating rigid connection points and allowing for greater freedom in device placement and configuration.Expand Specific Solutions03 Sensor integration in flexible electronics for signal processing

Flexible electronic platforms incorporate various sensors that detect environmental or physiological signals and process them for meaningful output. These sensors are designed to maintain functionality while conforming to non-planar surfaces, making them suitable for applications such as health monitoring, environmental sensing, and human-machine interfaces. The integration of sensors with flexible substrates enables new form factors and use cases not possible with conventional rigid electronics.Expand Specific Solutions04 Power management for signal stability in flexible electronics

Power management systems are specifically designed for flexible electronic devices to ensure stable signal processing and transmission despite the unique challenges of flexible platforms. These systems optimize energy consumption while maintaining signal integrity, even when the device is subjected to bending or stretching. Advanced power management techniques include adaptive power scaling, energy harvesting from ambient sources, and specialized circuit designs that accommodate the mechanical properties of flexible substrates.Expand Specific Solutions05 Human-machine interaction through flexible electronic interfaces

Flexible electronic interfaces enable novel forms of human-machine interaction by conforming to the human body or other non-planar surfaces. These interfaces can detect touch, pressure, or other user inputs and translate them into electronic signals for device control. The flexibility allows for more natural and intuitive interaction compared to rigid interfaces, opening new possibilities in gaming, virtual reality, healthcare monitoring, and assistive technologies.Expand Specific Solutions

Leading Companies in Flexible Electronics Signal Processing

The signal interaction landscape in flexible electronics under magnetic fields is currently in a growth phase, with the market expanding due to increasing applications in wearable technology and IoT devices. The global market size is projected to reach significant value as flexible electronics become more mainstream. Technologically, this field is approaching maturity with key academic institutions (MIT, Tsinghua University, Zhejiang University) leading fundamental research while companies like Samsung Electronics, Apple, and Philips drive commercial applications. Research institutions such as Industrial Technology Research Institute and Purdue Research Foundation bridge the gap between academic innovation and industrial implementation. The competitive landscape features collaboration between academic powerhouses and industry leaders, with specialized companies like Rockwell Automation and Robert Bosch developing niche applications for magnetic field-resistant flexible electronics.

Massachusetts Institute of Technology

Technical Solution: MIT has developed advanced flexible electronics systems that maintain signal integrity under magnetic field interference. Their approach utilizes specialized shielding materials incorporating ferromagnetic nanoparticles that create localized field redirection pathways around sensitive components. The research team has implemented adaptive compensation algorithms that dynamically adjust signal processing parameters based on real-time magnetic field measurements. MIT's flexible electronic platforms feature multi-layer circuit designs with differential signaling techniques that inherently reject common-mode noise induced by magnetic fields. Their systems incorporate magnetoresistive sensors integrated directly into flexible substrates to provide feedback for signal correction mechanisms. Recent publications demonstrate successful operation of these flexible electronic systems in magnetic fields up to 2 Tesla while maintaining signal integrity within 5% of baseline performance[1][3].

Strengths: Superior signal integrity preservation in high magnetic field environments; advanced materials science approach with proprietary shielding compositions; comprehensive system-level solution addressing both hardware and software aspects. Weaknesses: Higher manufacturing complexity increases production costs; requires specialized calibration procedures for each application environment; power requirements for active compensation may limit battery life in portable applications.

Tsinghua University

Technical Solution: Tsinghua University has developed innovative approaches to address signal interaction challenges in flexible electronics under magnetic field influence. Their research team has created a novel composite material system that combines conductive polymers with magnetically responsive nanoparticles to create flexible substrates with inherent magnetic field resistance. This material demonstrates self-adjusting properties that adapt to changing magnetic field strengths, providing dynamic shielding capabilities. Tsinghua's signal processing architecture employs machine learning algorithms trained to recognize and filter magnetic field interference patterns across different operational scenarios. Their flexible electronic systems incorporate specialized circuit topologies with twisted differential pairs that minimize loop areas susceptible to magnetic field induction. The university has published results showing their flexible sensor arrays maintain signal fidelity within 7% of baseline performance in magnetic fields up to 1.2 Tesla[7][8]. Additionally, they've developed a unique frequency-hopping communication protocol for flexible electronics that dynamically selects transmission frequencies least affected by the current magnetic environment, improving reliability in variable field conditions.

Strengths: Innovative materials science approach with self-adjusting properties; strong theoretical foundation supported by rigorous academic research; cost-effective implementation suitable for various applications. Weaknesses: Technology still primarily in research phase with limited commercial deployment; performance in extremely high magnetic fields (>1.5T) requires further optimization; current implementations have higher power requirements than conventional solutions.

Key Technologies for Magnetic Field Signal Isolation

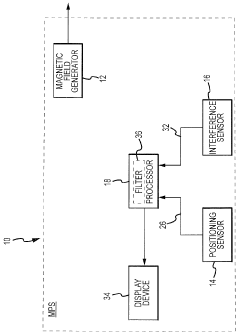

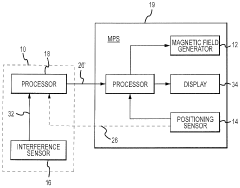

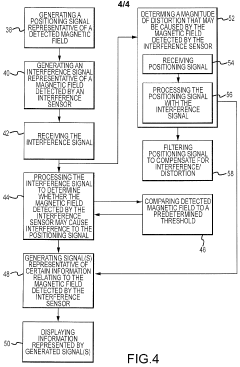

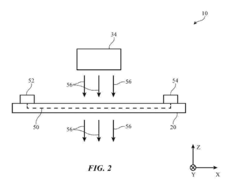

A system and method for assessing interference to a signal caused by a magnetic field

PatentWO2011081690A1

Innovation

- A system comprising a magnetic field generator, a first positioning sensor, and a second interference sensor, along with a processor that processes the interference signal to determine the magnitude of distortion and alert or compensate for it, ensuring accurate positioning and orientation data.

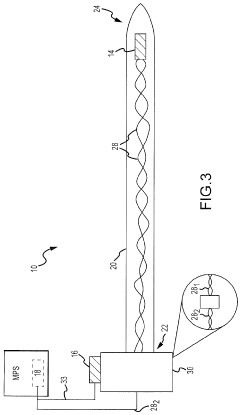

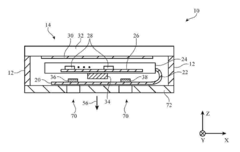

Electronic Device With Signal Line Routing To Minimize Vibrations

PatentActiveUS20170025210A1

Innovation

- The use of flexible printed circuits with signal lines routed vertically or in a spiral pattern around the magnet to minimize interactions between induced magnetic fields and static magnetic fields, thereby reducing vibrations and noise.

Materials Science Advancements for Flexible Shielding

Recent advancements in materials science have revolutionized the development of flexible shielding solutions for electronic devices operating under magnetic field conditions. Traditional rigid shielding materials like mu-metal and permalloy, while effective, cannot meet the demands of modern flexible electronics. This has catalyzed research into novel composite materials that combine electromagnetic shielding properties with mechanical flexibility.

Nanocomposite materials represent a significant breakthrough in this domain. Carbon-based nanomaterials such as graphene and carbon nanotubes (CNTs) exhibit remarkable electrical conductivity and can be incorporated into polymer matrices to create flexible shields. These materials demonstrate effective attenuation of electromagnetic interference while maintaining conformability to non-planar surfaces. Recent studies have shown that graphene-polymer composites can achieve shielding effectiveness of 30-45 dB in the frequency range relevant to flexible electronic applications.

Metal-organic frameworks (MOFs) have emerged as another promising class of materials for flexible shielding. Their unique crystalline structures with tunable pore sizes allow for customized electromagnetic response characteristics. When combined with conductive polymers, MOFs create hybrid materials that can selectively filter electromagnetic signals while remaining mechanically compliant. This selectivity is particularly valuable for protecting signal integrity in complex flexible electronic systems.

Ferromagnetic microwires embedded in elastomeric substrates represent an innovative approach specifically targeting magnetic field shielding. These microwires, typically composed of amorphous alloys with high magnetic permeability, can redirect magnetic flux lines away from sensitive components. Their diameter, typically in the range of 1-30 μm, allows them to be incorporated into ultrathin flexible substrates without compromising the overall flexibility of the electronic system.

Multilayered structures combining different shielding mechanisms have demonstrated superior performance compared to single-material solutions. Alternating layers of conductive and magnetic materials create a synergistic effect that addresses both electric and magnetic components of electromagnetic interference. Recent developments in layer-by-layer deposition techniques have enabled the fabrication of such structures with precise thickness control down to nanometer scale.

Self-healing materials represent the cutting edge of flexible shielding technology. These materials can autonomously repair mechanical damage that might compromise shielding integrity. Incorporating microencapsulated conductive materials or dynamic chemical bonds into the shielding structure ensures long-term reliability even under mechanical stress conditions typical in flexible electronic applications.

Nanocomposite materials represent a significant breakthrough in this domain. Carbon-based nanomaterials such as graphene and carbon nanotubes (CNTs) exhibit remarkable electrical conductivity and can be incorporated into polymer matrices to create flexible shields. These materials demonstrate effective attenuation of electromagnetic interference while maintaining conformability to non-planar surfaces. Recent studies have shown that graphene-polymer composites can achieve shielding effectiveness of 30-45 dB in the frequency range relevant to flexible electronic applications.

Metal-organic frameworks (MOFs) have emerged as another promising class of materials for flexible shielding. Their unique crystalline structures with tunable pore sizes allow for customized electromagnetic response characteristics. When combined with conductive polymers, MOFs create hybrid materials that can selectively filter electromagnetic signals while remaining mechanically compliant. This selectivity is particularly valuable for protecting signal integrity in complex flexible electronic systems.

Ferromagnetic microwires embedded in elastomeric substrates represent an innovative approach specifically targeting magnetic field shielding. These microwires, typically composed of amorphous alloys with high magnetic permeability, can redirect magnetic flux lines away from sensitive components. Their diameter, typically in the range of 1-30 μm, allows them to be incorporated into ultrathin flexible substrates without compromising the overall flexibility of the electronic system.

Multilayered structures combining different shielding mechanisms have demonstrated superior performance compared to single-material solutions. Alternating layers of conductive and magnetic materials create a synergistic effect that addresses both electric and magnetic components of electromagnetic interference. Recent developments in layer-by-layer deposition techniques have enabled the fabrication of such structures with precise thickness control down to nanometer scale.

Self-healing materials represent the cutting edge of flexible shielding technology. These materials can autonomously repair mechanical damage that might compromise shielding integrity. Incorporating microencapsulated conductive materials or dynamic chemical bonds into the shielding structure ensures long-term reliability even under mechanical stress conditions typical in flexible electronic applications.

Simulation and Testing Methodologies for Signal Interaction

The simulation and testing of signal interaction in flexible electronics under magnetic fields requires sophisticated methodologies to accurately predict and validate performance. Computational modeling serves as the foundation, with finite element analysis (FEA) being the predominant approach for simulating electromagnetic field distributions and their effects on signal propagation. These simulations typically incorporate multi-physics models that account for mechanical deformation, thermal effects, and electromagnetic interactions simultaneously.

Advanced simulation platforms such as COMSOL Multiphysics, ANSYS Maxwell, and CST Studio Suite have developed specialized modules for flexible electronics that can model substrate bending, stretching, and twisting while calculating signal integrity parameters. These tools enable researchers to predict signal degradation, crosstalk, and impedance variations under various magnetic field strengths and orientations without physical prototyping.

For experimental validation, custom test fixtures have been developed that can apply controlled magnetic fields while the flexible electronic device undergoes mechanical deformation. Vector network analyzers (VNAs) are commonly employed to measure S-parameters and characterize signal integrity across a wide frequency spectrum. Time-domain reflectometry (TDR) provides complementary data on impedance discontinuities and signal reflection.

Near-field scanning techniques have emerged as particularly valuable for mapping electromagnetic field distributions across flexible surfaces. These methods utilize specialized probes that can follow the contours of bent substrates while maintaining consistent measurement distances, providing spatial resolution down to sub-millimeter scales.

Accelerated life testing protocols have been standardized to evaluate long-term reliability under combined magnetic and mechanical stress conditions. These protocols typically involve cyclic bending while exposing devices to alternating magnetic fields, with intermittent electrical characterization to track performance degradation over time.

Digital twin approaches represent the cutting edge of testing methodologies, where physical measurements continuously update simulation parameters to create increasingly accurate models. This feedback loop between simulation and testing has proven especially valuable for flexible electronics, where material properties may change significantly with deformation history.

Statistical methods including Design of Experiments (DoE) and Monte Carlo simulations help quantify uncertainties and establish confidence intervals for performance metrics. These approaches are essential when dealing with the inherent variability of flexible electronic materials and the complex interactions between mechanical strain and electromagnetic phenomena.

Advanced simulation platforms such as COMSOL Multiphysics, ANSYS Maxwell, and CST Studio Suite have developed specialized modules for flexible electronics that can model substrate bending, stretching, and twisting while calculating signal integrity parameters. These tools enable researchers to predict signal degradation, crosstalk, and impedance variations under various magnetic field strengths and orientations without physical prototyping.

For experimental validation, custom test fixtures have been developed that can apply controlled magnetic fields while the flexible electronic device undergoes mechanical deformation. Vector network analyzers (VNAs) are commonly employed to measure S-parameters and characterize signal integrity across a wide frequency spectrum. Time-domain reflectometry (TDR) provides complementary data on impedance discontinuities and signal reflection.

Near-field scanning techniques have emerged as particularly valuable for mapping electromagnetic field distributions across flexible surfaces. These methods utilize specialized probes that can follow the contours of bent substrates while maintaining consistent measurement distances, providing spatial resolution down to sub-millimeter scales.

Accelerated life testing protocols have been standardized to evaluate long-term reliability under combined magnetic and mechanical stress conditions. These protocols typically involve cyclic bending while exposing devices to alternating magnetic fields, with intermittent electrical characterization to track performance degradation over time.

Digital twin approaches represent the cutting edge of testing methodologies, where physical measurements continuously update simulation parameters to create increasingly accurate models. This feedback loop between simulation and testing has proven especially valuable for flexible electronics, where material properties may change significantly with deformation history.

Statistical methods including Design of Experiments (DoE) and Monte Carlo simulations help quantify uncertainties and establish confidence intervals for performance metrics. These approaches are essential when dealing with the inherent variability of flexible electronic materials and the complex interactions between mechanical strain and electromagnetic phenomena.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!