Applications Of PID Controllers In Temperature Regulation Systems

SEP 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PID Temperature Control Evolution and Objectives

PID (Proportional-Integral-Derivative) controllers have evolved significantly since their inception in the early 20th century, becoming fundamental components in temperature regulation systems across various industries. The evolution of PID control in temperature management began with simple mechanical thermostats and has progressed to sophisticated digital implementations with adaptive capabilities.

In the 1930s and 1940s, the theoretical foundations of PID control were established, but practical applications in temperature control were limited by available technology. The 1950s saw the introduction of electronic PID controllers, which offered improved accuracy over mechanical systems but remained relatively expensive and complex to implement.

The microprocessor revolution of the 1970s and 1980s marked a turning point, enabling more affordable and versatile digital PID implementations. This period witnessed the integration of PID controllers into programmable logic controllers (PLCs) and dedicated temperature control units, significantly expanding their industrial applications.

By the 1990s and early 2000s, advanced algorithms enhanced traditional PID functionality, introducing features like auto-tuning, which automatically optimizes control parameters based on system response. This development addressed one of the persistent challenges in PID implementation—the need for precise tuning to achieve optimal performance.

Current technological trends are focused on intelligent PID systems that incorporate machine learning algorithms to adapt to changing process conditions and predict system behavior. These systems can automatically adjust parameters in response to external disturbances, load changes, or system aging, maintaining precise temperature control with minimal human intervention.

The primary objectives of modern PID temperature control systems include achieving faster response times, minimizing overshoot, reducing steady-state error, and enhancing robustness against disturbances. Energy efficiency has also emerged as a critical goal, particularly in applications like HVAC systems and industrial processes where temperature regulation accounts for significant energy consumption.

Another key objective is the seamless integration of PID controllers with IoT platforms and cloud-based monitoring systems, enabling remote management, predictive maintenance, and data analytics. This connectivity facilitates the optimization of temperature control strategies based on historical performance data and changing operational requirements.

Looking forward, the evolution of PID temperature control is likely to continue toward greater autonomy and intelligence, with systems capable of self-optimization and adaptation to complex, dynamic thermal environments. The integration of PID control with digital twins and simulation models promises to further enhance performance by enabling predictive control strategies based on comprehensive system understanding.

In the 1930s and 1940s, the theoretical foundations of PID control were established, but practical applications in temperature control were limited by available technology. The 1950s saw the introduction of electronic PID controllers, which offered improved accuracy over mechanical systems but remained relatively expensive and complex to implement.

The microprocessor revolution of the 1970s and 1980s marked a turning point, enabling more affordable and versatile digital PID implementations. This period witnessed the integration of PID controllers into programmable logic controllers (PLCs) and dedicated temperature control units, significantly expanding their industrial applications.

By the 1990s and early 2000s, advanced algorithms enhanced traditional PID functionality, introducing features like auto-tuning, which automatically optimizes control parameters based on system response. This development addressed one of the persistent challenges in PID implementation—the need for precise tuning to achieve optimal performance.

Current technological trends are focused on intelligent PID systems that incorporate machine learning algorithms to adapt to changing process conditions and predict system behavior. These systems can automatically adjust parameters in response to external disturbances, load changes, or system aging, maintaining precise temperature control with minimal human intervention.

The primary objectives of modern PID temperature control systems include achieving faster response times, minimizing overshoot, reducing steady-state error, and enhancing robustness against disturbances. Energy efficiency has also emerged as a critical goal, particularly in applications like HVAC systems and industrial processes where temperature regulation accounts for significant energy consumption.

Another key objective is the seamless integration of PID controllers with IoT platforms and cloud-based monitoring systems, enabling remote management, predictive maintenance, and data analytics. This connectivity facilitates the optimization of temperature control strategies based on historical performance data and changing operational requirements.

Looking forward, the evolution of PID temperature control is likely to continue toward greater autonomy and intelligence, with systems capable of self-optimization and adaptation to complex, dynamic thermal environments. The integration of PID control with digital twins and simulation models promises to further enhance performance by enabling predictive control strategies based on comprehensive system understanding.

Market Analysis for PID Temperature Regulation Systems

The global market for PID temperature regulation systems has experienced robust growth, reaching approximately $3.2 billion in 2022 with projections to exceed $4.5 billion by 2027, representing a compound annual growth rate of 7.1%. This growth is primarily driven by increasing automation across multiple industries and the rising demand for precise temperature control in manufacturing processes.

Industrial manufacturing represents the largest market segment, accounting for nearly 38% of the total market share. Within this segment, chemical processing, food and beverage production, and pharmaceutical manufacturing are the primary adopters of PID temperature control systems. The pharmaceutical sector, in particular, has shown accelerated adoption rates due to stringent regulatory requirements for temperature-controlled environments in drug manufacturing and storage.

The HVAC industry constitutes the second-largest market segment at 27%, where PID controllers are increasingly replacing traditional on/off control systems due to their superior energy efficiency and temperature stability. Commercial buildings and data centers are driving significant demand in this segment, with energy savings of 15-20% commonly reported after implementing PID-based temperature regulation systems.

Geographically, Asia-Pacific dominates the market with a 42% share, led by China's massive manufacturing sector and rapid industrial automation initiatives. North America follows at 28%, with particularly strong demand in pharmaceutical and semiconductor industries. Europe accounts for 23% of the market, with Germany and France leading in adoption rates, particularly in automotive manufacturing applications.

The market is witnessing several notable trends, including the integration of PID controllers with IoT platforms, enabling remote monitoring and control capabilities. This connectivity feature has expanded the market potential by approximately 18% over the past three years. Additionally, there is growing demand for self-tuning PID controllers that can automatically optimize parameters based on system response, reducing installation and maintenance costs by up to 30%.

Customer requirements are increasingly focused on energy efficiency, with 76% of end-users citing energy savings as a primary purchase consideration. System reliability ranks second at 68%, followed by ease of integration with existing systems at 61%. These market preferences are driving manufacturers to develop more sophisticated PID solutions with enhanced features such as predictive maintenance capabilities and improved user interfaces.

Industrial manufacturing represents the largest market segment, accounting for nearly 38% of the total market share. Within this segment, chemical processing, food and beverage production, and pharmaceutical manufacturing are the primary adopters of PID temperature control systems. The pharmaceutical sector, in particular, has shown accelerated adoption rates due to stringent regulatory requirements for temperature-controlled environments in drug manufacturing and storage.

The HVAC industry constitutes the second-largest market segment at 27%, where PID controllers are increasingly replacing traditional on/off control systems due to their superior energy efficiency and temperature stability. Commercial buildings and data centers are driving significant demand in this segment, with energy savings of 15-20% commonly reported after implementing PID-based temperature regulation systems.

Geographically, Asia-Pacific dominates the market with a 42% share, led by China's massive manufacturing sector and rapid industrial automation initiatives. North America follows at 28%, with particularly strong demand in pharmaceutical and semiconductor industries. Europe accounts for 23% of the market, with Germany and France leading in adoption rates, particularly in automotive manufacturing applications.

The market is witnessing several notable trends, including the integration of PID controllers with IoT platforms, enabling remote monitoring and control capabilities. This connectivity feature has expanded the market potential by approximately 18% over the past three years. Additionally, there is growing demand for self-tuning PID controllers that can automatically optimize parameters based on system response, reducing installation and maintenance costs by up to 30%.

Customer requirements are increasingly focused on energy efficiency, with 76% of end-users citing energy savings as a primary purchase consideration. System reliability ranks second at 68%, followed by ease of integration with existing systems at 61%. These market preferences are driving manufacturers to develop more sophisticated PID solutions with enhanced features such as predictive maintenance capabilities and improved user interfaces.

Current PID Technology Landscape and Challenges

The global PID controller market for temperature regulation systems has witnessed significant growth, currently valued at approximately $2.3 billion with a projected CAGR of 5.8% through 2028. This growth is primarily driven by increasing automation across industries including HVAC, food processing, pharmaceuticals, and semiconductor manufacturing, where precise temperature control is critical for operational efficiency and product quality.

Despite their widespread adoption, PID controllers face several technological challenges in temperature regulation applications. Traditional PID algorithms often struggle with non-linear thermal systems, exhibiting limitations in handling variable time delays and thermal inertia inherent in many heating and cooling processes. This results in suboptimal performance characterized by overshoot, oscillation, and extended settling times, particularly in systems with complex thermal dynamics.

The geographical distribution of PID technology development shows concentration in industrial hubs across North America, Europe, and East Asia. North American and European markets focus predominantly on advanced algorithm development and integration with IoT platforms, while Asian manufacturers have gained significant market share through cost-effective hardware solutions with improving algorithmic capabilities.

Current technological constraints include the persistent challenge of auto-tuning in variable-load environments. While adaptive PID controllers have emerged to address this issue, they often require complex implementation and system-specific customization. Additionally, the integration of PID controllers with wireless sensor networks presents challenges related to data transmission reliability, power consumption, and security vulnerabilities.

Energy efficiency remains another significant challenge, as traditional PID control strategies may not optimize energy consumption while maintaining precise temperature regulation. This has led to increased research in predictive control algorithms that can anticipate system behavior and minimize energy usage while maintaining control performance.

The miniaturization of temperature control systems for portable and space-constrained applications has introduced additional challenges related to heat dissipation, component density, and power management. These constraints have pushed manufacturers toward developing more integrated solutions that combine sensing, processing, and actuation in compact packages.

Interoperability between different control systems and communication protocols continues to be a barrier to seamless integration in Industry 4.0 environments. While standards like OPC UA have improved connectivity, legacy systems and proprietary protocols still fragment the industrial control landscape, limiting the potential for comprehensive temperature management across complex manufacturing processes.

Despite their widespread adoption, PID controllers face several technological challenges in temperature regulation applications. Traditional PID algorithms often struggle with non-linear thermal systems, exhibiting limitations in handling variable time delays and thermal inertia inherent in many heating and cooling processes. This results in suboptimal performance characterized by overshoot, oscillation, and extended settling times, particularly in systems with complex thermal dynamics.

The geographical distribution of PID technology development shows concentration in industrial hubs across North America, Europe, and East Asia. North American and European markets focus predominantly on advanced algorithm development and integration with IoT platforms, while Asian manufacturers have gained significant market share through cost-effective hardware solutions with improving algorithmic capabilities.

Current technological constraints include the persistent challenge of auto-tuning in variable-load environments. While adaptive PID controllers have emerged to address this issue, they often require complex implementation and system-specific customization. Additionally, the integration of PID controllers with wireless sensor networks presents challenges related to data transmission reliability, power consumption, and security vulnerabilities.

Energy efficiency remains another significant challenge, as traditional PID control strategies may not optimize energy consumption while maintaining precise temperature regulation. This has led to increased research in predictive control algorithms that can anticipate system behavior and minimize energy usage while maintaining control performance.

The miniaturization of temperature control systems for portable and space-constrained applications has introduced additional challenges related to heat dissipation, component density, and power management. These constraints have pushed manufacturers toward developing more integrated solutions that combine sensing, processing, and actuation in compact packages.

Interoperability between different control systems and communication protocols continues to be a barrier to seamless integration in Industry 4.0 environments. While standards like OPC UA have improved connectivity, legacy systems and proprietary protocols still fragment the industrial control landscape, limiting the potential for comprehensive temperature management across complex manufacturing processes.

Contemporary PID Implementation Methodologies

01 PID controller design for precise temperature regulation

PID controllers are designed with specific parameters to achieve precise temperature regulation in various systems. These controllers continuously monitor temperature deviations and adjust heating or cooling elements accordingly. The proportional, integral, and derivative components work together to minimize overshoot, reduce settling time, and maintain stable temperature conditions even when external disturbances occur.- PID controller design for precise temperature regulation: PID controllers are designed with specific parameters to achieve precise temperature regulation in various systems. These controllers use proportional, integral, and derivative components to minimize error between the desired temperature setpoint and the actual measured temperature. The design focuses on optimizing response time, reducing overshoot, and maintaining stability across different operating conditions. Advanced algorithms may be implemented to automatically tune PID parameters for optimal performance.

- Adaptive PID control systems for temperature management: Adaptive PID control systems can automatically adjust their parameters based on changing process conditions or environmental factors. These systems continuously monitor temperature response characteristics and modify control parameters to maintain optimal performance. Adaptive algorithms may include fuzzy logic, neural networks, or model-based approaches that enable the controller to learn from past performance and improve temperature regulation over time. This approach is particularly valuable in systems with variable loads or changing thermal dynamics.

- Integration of PID controllers in industrial heating applications: PID controllers are integrated into various industrial heating systems to maintain precise temperature control in manufacturing processes. These implementations include specialized hardware configurations, communication protocols, and safety features designed for industrial environments. The controllers may be part of larger distributed control systems with multiple temperature zones, cascaded control loops, or supervisory systems. Industrial implementations often include additional features such as data logging, alarm management, and remote monitoring capabilities.

- Energy-efficient PID control strategies for temperature systems: Energy-efficient PID control strategies focus on maintaining required temperature levels while minimizing energy consumption. These approaches include optimized setpoint scheduling, duty cycle management, and predictive control algorithms that anticipate heating or cooling needs. Advanced techniques may incorporate weather forecasting, occupancy detection, or thermal modeling to further reduce energy usage. The controllers may also implement specialized algorithms that balance temperature stability with energy conservation goals.

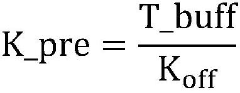

- Smart PID temperature controllers with connectivity features: Modern PID temperature controllers incorporate smart features and connectivity options that enhance their functionality and ease of use. These controllers may include wireless communication capabilities, cloud integration, mobile applications for remote monitoring and control, and compatibility with Internet of Things (IoT) platforms. Additional features often include touchscreen interfaces, data analytics capabilities, predictive maintenance alerts, and integration with building management systems or home automation networks.

02 Adaptive PID control algorithms for temperature systems

Adaptive PID control algorithms automatically adjust controller parameters based on changing system conditions. These algorithms incorporate self-tuning mechanisms that analyze temperature response patterns and modify control parameters accordingly. This approach is particularly effective for systems with variable thermal loads or changing environmental conditions, ensuring optimal temperature regulation across different operating scenarios.Expand Specific Solutions03 Integration of PID controllers with IoT and smart systems

Modern temperature regulation systems integrate PID controllers with Internet of Things (IoT) technology and smart systems. These integrated solutions enable remote monitoring and control of temperature parameters, data collection for predictive maintenance, and coordination with other building management systems. The combination of traditional PID control with digital connectivity enhances overall system efficiency and provides advanced temperature management capabilities.Expand Specific Solutions04 Multi-zone temperature control using PID controllers

Multi-zone temperature control systems employ multiple PID controllers to regulate temperatures in different areas independently. These systems coordinate the operation of several controllers to maintain specific temperature profiles across various zones. Advanced implementations include cascade control structures and zone-specific parameter optimization to account for thermal interactions between adjacent areas while ensuring precise temperature regulation in each zone.Expand Specific Solutions05 Energy-efficient PID control strategies for temperature management

Energy-efficient PID control strategies focus on optimizing temperature regulation while minimizing energy consumption. These approaches include dynamic setpoint adjustment, duty cycle optimization, and integration with predictive models to anticipate heating or cooling needs. Advanced implementations incorporate weather forecasting data and occupancy patterns to further enhance energy efficiency while maintaining desired temperature conditions.Expand Specific Solutions

Leading Manufacturers and Competitive Landscape

The PID controller temperature regulation market is in a mature growth phase, characterized by established technologies and widespread adoption across industries. The global market size for temperature control systems is estimated at $3-4 billion annually, with steady growth of 5-7% driven by industrial automation and smart manufacturing trends. Technologically, major players like OMRON, Azbil, and SUPCON Group have achieved high maturity levels with advanced adaptive PID algorithms, while academic institutions such as Huazhong University and Zhejiang University contribute significant research innovations. Emerging players like Beijing Jingyi Automation and Senseair are focusing on specialized applications in semiconductor and environmental monitoring sectors, creating a competitive landscape balanced between established multinational corporations and innovative niche providers.

OMRON Corp.

Technical Solution: OMRON has developed advanced PID controllers for temperature regulation systems that incorporate their proprietary "2-PID" control algorithm. This technology uses a combination of two PID control loops working in tandem to achieve superior temperature stability. Their E5_C series temperature controllers feature auto-tuning capabilities that automatically determine optimal PID parameters by analyzing the thermal characteristics of the controlled system[1]. OMRON's controllers also implement adaptive control mechanisms that continuously adjust PID parameters in response to changing process conditions, significantly reducing temperature fluctuations. Their temperature regulation systems incorporate disturbance rejection algorithms that can predict and compensate for external factors affecting temperature stability, such as ambient temperature changes or door openings in refrigeration systems[3]. Additionally, OMRON has integrated IoT connectivity into their controllers, allowing for remote monitoring, data collection, and analysis to optimize temperature control performance across multiple systems.

Strengths: Superior disturbance rejection capabilities, highly accurate temperature control (±0.1°C in many applications), and extensive auto-tuning functionality that simplifies setup. Weaknesses: Higher initial cost compared to basic controllers, and the advanced features may require more technical expertise to fully utilize.

Azbil Corp.

Technical Solution: Azbil Corporation (formerly Yamatake) has pioneered advanced PID control technologies specifically designed for precise temperature regulation systems. Their flagship SDC series controllers implement a multi-tiered PID approach called "Super Control" that combines conventional PID control with fuzzy logic and model predictive elements[2]. This hybrid approach enables their systems to handle both steady-state regulation and transient responses effectively. Azbil's controllers feature "Just-FiTTER" auto-tuning technology that can identify optimal PID parameters with minimal process disruption, even in systems with significant thermal lag[4]. Their temperature regulation solutions incorporate "Heat/Cool" control algorithms that manage both heating and cooling actuators with a single controller, maintaining precise temperature even in applications requiring rapid temperature changes. Azbil has also developed specialized PID variants for different thermal applications, including high-precision laboratory equipment, industrial furnaces, and HVAC systems, each optimized for the specific thermal dynamics of these environments.

Strengths: Exceptional stability in systems with long time delays, sophisticated auto-tuning capabilities that require minimal user intervention, and specialized algorithms for different thermal applications. Weaknesses: Complex configuration options may overwhelm less experienced users, and premium pricing positions their solutions at the higher end of the market.

Key Patents and Innovations in PID Control Systems

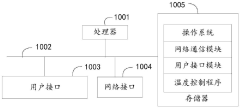

Temperature control method, device and equipment and readable storage medium

PatentPendingCN117311419A

Innovation

- By heating the temperature control object to the preset heating threshold and then stopping the heating, it is predicted based on the real-time temperature and temperature change rate whether the target temperature can be reached. If it can be reached, the preset PID control strategy is used to control after the target temperature, which is divided into multiple Control phases to reduce PID parameter dependencies and debugging time.

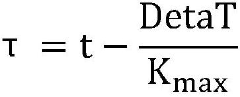

PID (Proportion Integration Differentiation) temperature control adjusting method and device and computer readable storage medium

PatentPendingCN117687294A

Innovation

- By obtaining the temperature difference between the ambient temperature and the set temperature, based on the linear correspondence between the temperature difference and the integral control item, the starting initial value of the integral control item is determined, and the control signal is output based on the starting initial value and the set temperature to adjust the proportion , the output parameters of the integral and differential control items until the controlled equipment reaches the set temperature.

Energy Efficiency Considerations in PID Systems

Energy efficiency has emerged as a critical consideration in the design and implementation of PID control systems for temperature regulation. Modern industrial processes and consumer applications alike demand solutions that not only provide precise temperature control but also minimize energy consumption. PID controllers, when properly optimized, can significantly reduce energy usage while maintaining desired temperature parameters.

The relationship between control accuracy and energy consumption presents an important trade-off in PID system design. Aggressive control settings may achieve rapid temperature stabilization but often at the cost of energy efficiency due to overshooting and subsequent correction cycles. Studies indicate that properly tuned PID controllers can reduce energy consumption by 15-30% compared to poorly tuned systems, while maintaining equivalent or superior temperature regulation performance.

Advanced PID algorithms incorporate energy-saving features such as adaptive gain scheduling and sleep modes during periods of stability. These innovations allow systems to dynamically adjust control parameters based on the difference between setpoint and actual temperature, applying more aggressive control only when necessary and conserving energy during steady-state operation.

Heat loss analysis has become an integral component of energy-efficient PID system design. By modeling thermal characteristics of the controlled environment, modern systems can anticipate heat dissipation patterns and adjust heating or cooling outputs preemptively, rather than reactively. This predictive approach minimizes unnecessary energy expenditure while maintaining tight temperature tolerances.

The integration of PID controllers with variable frequency drives (VFDs) and modulating valves represents another significant advancement in energy efficiency. Rather than the traditional on/off control that operates at full capacity, these systems allow proportional power application, delivering precisely the energy required to maintain temperature setpoints without wasteful cycling.

Recovery strategies following temperature disturbances also impact energy efficiency. Optimized PID parameters can be designed to prioritize energy conservation during recovery phases, accepting slightly longer stabilization times in exchange for substantial energy savings. Research indicates that such approaches can reduce recovery energy consumption by up to 40% with minimal impact on process quality.

Recent developments in machine learning algorithms have enabled self-optimizing PID systems that continuously refine control parameters based on historical performance data and energy consumption metrics. These systems effectively "learn" the most energy-efficient control strategies for specific applications over time, adapting to changes in environmental conditions and system characteristics without human intervention.

The relationship between control accuracy and energy consumption presents an important trade-off in PID system design. Aggressive control settings may achieve rapid temperature stabilization but often at the cost of energy efficiency due to overshooting and subsequent correction cycles. Studies indicate that properly tuned PID controllers can reduce energy consumption by 15-30% compared to poorly tuned systems, while maintaining equivalent or superior temperature regulation performance.

Advanced PID algorithms incorporate energy-saving features such as adaptive gain scheduling and sleep modes during periods of stability. These innovations allow systems to dynamically adjust control parameters based on the difference between setpoint and actual temperature, applying more aggressive control only when necessary and conserving energy during steady-state operation.

Heat loss analysis has become an integral component of energy-efficient PID system design. By modeling thermal characteristics of the controlled environment, modern systems can anticipate heat dissipation patterns and adjust heating or cooling outputs preemptively, rather than reactively. This predictive approach minimizes unnecessary energy expenditure while maintaining tight temperature tolerances.

The integration of PID controllers with variable frequency drives (VFDs) and modulating valves represents another significant advancement in energy efficiency. Rather than the traditional on/off control that operates at full capacity, these systems allow proportional power application, delivering precisely the energy required to maintain temperature setpoints without wasteful cycling.

Recovery strategies following temperature disturbances also impact energy efficiency. Optimized PID parameters can be designed to prioritize energy conservation during recovery phases, accepting slightly longer stabilization times in exchange for substantial energy savings. Research indicates that such approaches can reduce recovery energy consumption by up to 40% with minimal impact on process quality.

Recent developments in machine learning algorithms have enabled self-optimizing PID systems that continuously refine control parameters based on historical performance data and energy consumption metrics. These systems effectively "learn" the most energy-efficient control strategies for specific applications over time, adapting to changes in environmental conditions and system characteristics without human intervention.

Industry-Specific PID Applications and Requirements

PID controllers demonstrate remarkable versatility across diverse industrial sectors, each presenting unique temperature regulation requirements. In manufacturing, particularly semiconductor fabrication, PID systems maintain ultra-precise temperature control within ±0.1°C to ensure product quality and process reliability. These environments demand sophisticated tuning methodologies and often incorporate cascade control structures to manage the complex thermal dynamics of semiconductor processing equipment.

The pharmaceutical and biotechnology industries implement PID controllers in critical applications such as bioreactors, lyophilizers, and sterilization equipment. These sectors require validated control systems that comply with FDA regulations and GMP standards, necessitating specialized documentation, calibration protocols, and redundancy features. Temperature stability directly impacts product efficacy and patient safety, making robust disturbance rejection capabilities essential.

Food processing presents distinct challenges for PID implementation, including rapid production cycles, varying batch sizes, and strict food safety requirements. Controllers in this sector must accommodate frequent setpoint changes while maintaining HACCP compliance. Many systems incorporate specialized features such as anti-windup mechanisms to handle the frequent transitions between heating and cooling phases characteristic of food processing operations.

HVAC applications represent one of the largest markets for PID temperature control, with requirements focusing on energy efficiency, occupant comfort, and system longevity. Modern building automation systems integrate PID controllers with adaptive tuning capabilities to optimize performance across seasonal variations and occupancy patterns. The economic impact of even minor improvements in control efficiency can be substantial given the energy consumption of commercial buildings.

In chemical processing, PID controllers operate in hazardous environments where temperature excursions can trigger safety incidents. These applications demand intrinsically safe implementations, often incorporating model predictive control elements to handle the nonlinear thermal behavior of chemical reactions. Specialized PID variants such as split-range controllers are frequently deployed to manage both heating and cooling elements within a single control loop.

The automotive industry employs PID controllers in engine cooling systems, catalytic converters, and battery thermal management for electric vehicles. These applications must function reliably under extreme temperature variations and vibration conditions, requiring robust hardware implementations and fault-tolerant software architectures. The emergence of electric vehicles has created new demands for precise battery temperature regulation to optimize charging efficiency and extend battery life.

The pharmaceutical and biotechnology industries implement PID controllers in critical applications such as bioreactors, lyophilizers, and sterilization equipment. These sectors require validated control systems that comply with FDA regulations and GMP standards, necessitating specialized documentation, calibration protocols, and redundancy features. Temperature stability directly impacts product efficacy and patient safety, making robust disturbance rejection capabilities essential.

Food processing presents distinct challenges for PID implementation, including rapid production cycles, varying batch sizes, and strict food safety requirements. Controllers in this sector must accommodate frequent setpoint changes while maintaining HACCP compliance. Many systems incorporate specialized features such as anti-windup mechanisms to handle the frequent transitions between heating and cooling phases characteristic of food processing operations.

HVAC applications represent one of the largest markets for PID temperature control, with requirements focusing on energy efficiency, occupant comfort, and system longevity. Modern building automation systems integrate PID controllers with adaptive tuning capabilities to optimize performance across seasonal variations and occupancy patterns. The economic impact of even minor improvements in control efficiency can be substantial given the energy consumption of commercial buildings.

In chemical processing, PID controllers operate in hazardous environments where temperature excursions can trigger safety incidents. These applications demand intrinsically safe implementations, often incorporating model predictive control elements to handle the nonlinear thermal behavior of chemical reactions. Specialized PID variants such as split-range controllers are frequently deployed to manage both heating and cooling elements within a single control loop.

The automotive industry employs PID controllers in engine cooling systems, catalytic converters, and battery thermal management for electric vehicles. These applications must function reliably under extreme temperature variations and vibration conditions, requiring robust hardware implementations and fault-tolerant software architectures. The emergence of electric vehicles has created new demands for precise battery temperature regulation to optimize charging efficiency and extend battery life.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!