Compensation Of External Disturbances Using PID Control

SEP 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PID Control Evolution and Disturbance Rejection Goals

The evolution of PID control systems has been a cornerstone in the development of modern industrial automation since the early 20th century. Initially conceptualized in 1922 by Nicolas Minorsky for steering ships, PID controllers have undergone significant transformations to address increasingly complex disturbance rejection challenges. The fundamental principle of combining proportional, integral, and derivative actions has remained consistent, while implementation methodologies have evolved from pneumatic systems to electronic circuits, and now to sophisticated digital algorithms.

The technological trajectory of PID control has been characterized by progressive enhancements in robustness against external disturbances. Early implementations focused primarily on steady-state error reduction through proportional control, with limited capability to handle dynamic disturbances. The integration of integral action in the 1930s marked a significant advancement, enabling systems to eliminate persistent errors caused by constant external forces or loads.

By the 1950s, derivative action became more widely implemented, allowing systems to anticipate disturbance effects and respond proactively. This three-term control paradigm established the foundation for modern disturbance rejection strategies. The transition to digital implementation in the 1970s and 1980s further expanded capabilities, enabling more complex control algorithms and adaptive mechanisms.

Recent developments have focused on enhancing PID controllers' ability to compensate for specific categories of external disturbances. These include periodic disturbances (such as those caused by rotating machinery), stochastic disturbances (environmental factors like wind or temperature fluctuations), and transient disturbances (sudden load changes or impacts). Each category requires specialized tuning approaches and sometimes augmentation of the basic PID structure.

The primary technical goals in modern disturbance rejection using PID control include minimizing settling time after disturbance occurrence, reducing maximum deviation from setpoint, ensuring robustness across varying operating conditions, and achieving these objectives with minimal control effort. Additionally, there is growing emphasis on predictive capabilities, where controllers can anticipate and preemptively counteract disturbances before significant system deviation occurs.

Industry 4.0 initiatives have further expanded disturbance rejection goals to include self-tuning capabilities, where controllers automatically adjust parameters based on detected disturbance patterns. This represents a shift toward more autonomous control systems that can maintain optimal performance with minimal human intervention, even as external conditions change over time.

The convergence of traditional PID methodology with machine learning techniques represents the frontier of disturbance rejection technology, potentially enabling systems to recognize complex disturbance signatures and develop optimized compensation strategies through experience-based learning.

The technological trajectory of PID control has been characterized by progressive enhancements in robustness against external disturbances. Early implementations focused primarily on steady-state error reduction through proportional control, with limited capability to handle dynamic disturbances. The integration of integral action in the 1930s marked a significant advancement, enabling systems to eliminate persistent errors caused by constant external forces or loads.

By the 1950s, derivative action became more widely implemented, allowing systems to anticipate disturbance effects and respond proactively. This three-term control paradigm established the foundation for modern disturbance rejection strategies. The transition to digital implementation in the 1970s and 1980s further expanded capabilities, enabling more complex control algorithms and adaptive mechanisms.

Recent developments have focused on enhancing PID controllers' ability to compensate for specific categories of external disturbances. These include periodic disturbances (such as those caused by rotating machinery), stochastic disturbances (environmental factors like wind or temperature fluctuations), and transient disturbances (sudden load changes or impacts). Each category requires specialized tuning approaches and sometimes augmentation of the basic PID structure.

The primary technical goals in modern disturbance rejection using PID control include minimizing settling time after disturbance occurrence, reducing maximum deviation from setpoint, ensuring robustness across varying operating conditions, and achieving these objectives with minimal control effort. Additionally, there is growing emphasis on predictive capabilities, where controllers can anticipate and preemptively counteract disturbances before significant system deviation occurs.

Industry 4.0 initiatives have further expanded disturbance rejection goals to include self-tuning capabilities, where controllers automatically adjust parameters based on detected disturbance patterns. This represents a shift toward more autonomous control systems that can maintain optimal performance with minimal human intervention, even as external conditions change over time.

The convergence of traditional PID methodology with machine learning techniques represents the frontier of disturbance rejection technology, potentially enabling systems to recognize complex disturbance signatures and develop optimized compensation strategies through experience-based learning.

Market Applications for Disturbance-Resistant Control Systems

The PID control-based disturbance compensation systems have penetrated numerous industrial sectors, demonstrating remarkable versatility across diverse market applications. In manufacturing, these systems are extensively deployed in precision machining equipment where external vibrations, temperature fluctuations, and tool wear can significantly impact product quality. CNC machines equipped with advanced disturbance-resistant PID controllers achieve micron-level accuracy even under challenging factory conditions, resulting in higher yield rates and reduced material waste.

The automotive industry represents another significant market, with disturbance-resistant control systems being integral to vehicle stability control, active suspension systems, and engine management. Modern electric vehicles particularly benefit from these technologies, as they require precise torque control despite varying road conditions and battery charge states. Tesla's implementation of disturbance-resistant controllers has contributed to their vehicles' renowned handling characteristics and efficiency optimization.

Aerospace applications present perhaps the most demanding environment for control systems. Aircraft and spacecraft face extreme disturbances including atmospheric turbulence, thermal gradients, and mechanical vibrations. Disturbance-resistant PID controllers enable precise attitude control and navigation despite these challenges. The Mars rovers utilize sophisticated disturbance compensation techniques to maintain stability on uneven terrain while performing delicate scientific operations.

The renewable energy sector has emerged as a rapidly growing market for these technologies. Wind turbines employ disturbance-resistant control systems to optimize blade pitch and generator load despite unpredictable wind gusts and mechanical resonances. This optimization can increase energy capture by up to 8% compared to conventional control strategies, significantly improving the economic viability of wind farms.

Medical devices represent a specialized but high-value application area. Surgical robots require exceptional precision despite the complex disturbances of the human body environment. Intuitive Surgical's da Vinci system incorporates advanced disturbance compensation to filter out surgeon hand tremors while amplifying intentional movements, enabling procedures that would be impossible with human hands alone.

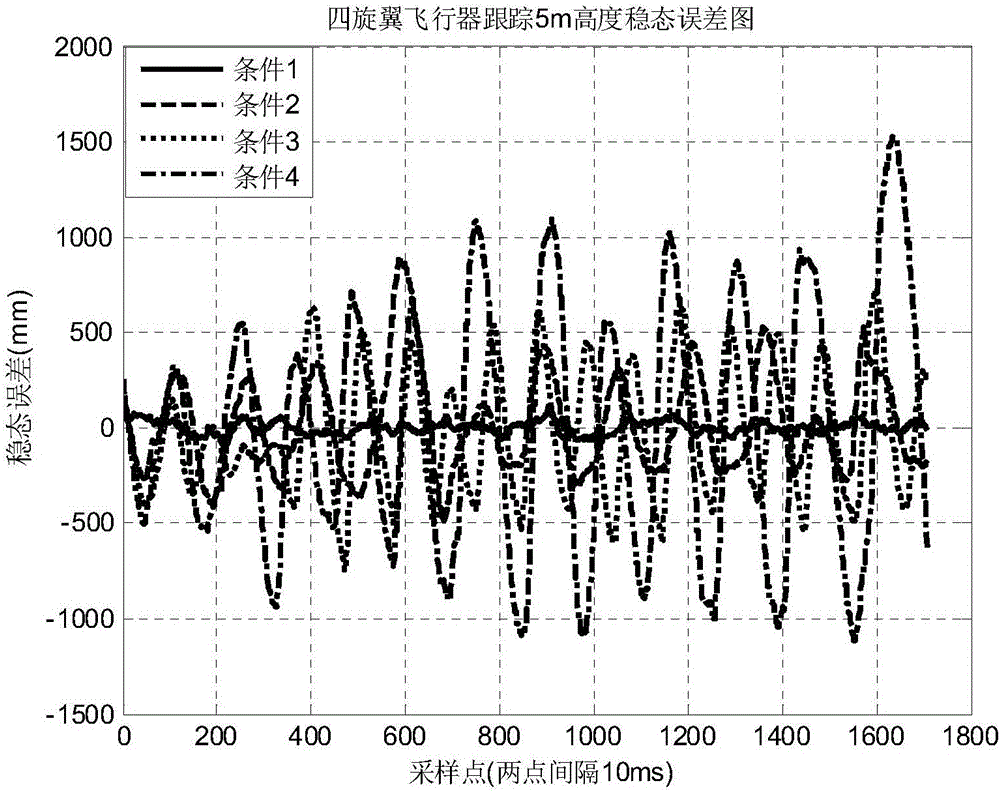

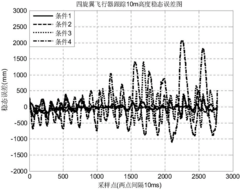

The consumer electronics market has also adopted these technologies, particularly in camera stabilization systems, drone flight controllers, and high-precision 3D printers. These applications demonstrate how formerly industrial-grade control technologies have been miniaturized and cost-optimized for consumer applications, creating entirely new product categories and capabilities.

The automotive industry represents another significant market, with disturbance-resistant control systems being integral to vehicle stability control, active suspension systems, and engine management. Modern electric vehicles particularly benefit from these technologies, as they require precise torque control despite varying road conditions and battery charge states. Tesla's implementation of disturbance-resistant controllers has contributed to their vehicles' renowned handling characteristics and efficiency optimization.

Aerospace applications present perhaps the most demanding environment for control systems. Aircraft and spacecraft face extreme disturbances including atmospheric turbulence, thermal gradients, and mechanical vibrations. Disturbance-resistant PID controllers enable precise attitude control and navigation despite these challenges. The Mars rovers utilize sophisticated disturbance compensation techniques to maintain stability on uneven terrain while performing delicate scientific operations.

The renewable energy sector has emerged as a rapidly growing market for these technologies. Wind turbines employ disturbance-resistant control systems to optimize blade pitch and generator load despite unpredictable wind gusts and mechanical resonances. This optimization can increase energy capture by up to 8% compared to conventional control strategies, significantly improving the economic viability of wind farms.

Medical devices represent a specialized but high-value application area. Surgical robots require exceptional precision despite the complex disturbances of the human body environment. Intuitive Surgical's da Vinci system incorporates advanced disturbance compensation to filter out surgeon hand tremors while amplifying intentional movements, enabling procedures that would be impossible with human hands alone.

The consumer electronics market has also adopted these technologies, particularly in camera stabilization systems, drone flight controllers, and high-precision 3D printers. These applications demonstrate how formerly industrial-grade control technologies have been miniaturized and cost-optimized for consumer applications, creating entirely new product categories and capabilities.

Current Limitations in External Disturbance Compensation

Despite the widespread adoption of PID control in industrial applications, several significant limitations persist in the compensation of external disturbances. Traditional PID controllers often struggle with time-varying disturbances, particularly those with unpredictable patterns or sudden changes in magnitude. This fundamental limitation stems from the reactive nature of PID control, which can only respond to disturbances after they have already affected the system, creating an inherent delay in compensation.

The performance of PID controllers is further constrained by the trade-off between disturbance rejection and setpoint tracking. Controllers optimized for robust disturbance rejection typically exhibit slower response times and increased overshoot during setpoint changes. This compromise becomes particularly problematic in systems requiring both precise disturbance handling and rapid reference tracking.

Frequency-dependent limitations represent another critical challenge. PID controllers demonstrate varying effectiveness across different frequency ranges, with performance degradation at higher frequencies. This characteristic makes them less suitable for systems exposed to high-frequency disturbances or those requiring wide bandwidth control, such as precision motion systems or advanced manufacturing equipment.

Model uncertainty presents a substantial obstacle to effective disturbance compensation. PID controllers tuned for nominal plant models may perform poorly when faced with parameter variations or unmodeled dynamics. This sensitivity to model mismatch can lead to deteriorated performance or even instability when the actual system deviates from the design assumptions.

The linear nature of conventional PID control imposes additional constraints when dealing with nonlinear disturbances or systems with nonlinear dynamics. Such scenarios often require gain scheduling or adaptive mechanisms that increase implementation complexity and may still deliver suboptimal performance under certain operating conditions.

Measurement noise amplification represents a practical limitation in real-world implementations. The derivative term in PID controllers is particularly susceptible to amplifying high-frequency measurement noise, potentially introducing additional disturbances into the system rather than mitigating existing ones. This often necessitates filtering techniques that can compromise the controller's responsiveness.

Multi-variable systems with coupled disturbances present perhaps the most significant challenge for traditional PID approaches. The decentralized nature of multiple SISO PID loops fails to account for cross-coupling effects, resulting in suboptimal disturbance rejection in complex systems with multiple inputs and outputs.

These limitations have driven research toward advanced control strategies such as disturbance observers, H-infinity control, and model predictive control, which aim to overcome the inherent constraints of conventional PID approaches in handling external disturbances.

The performance of PID controllers is further constrained by the trade-off between disturbance rejection and setpoint tracking. Controllers optimized for robust disturbance rejection typically exhibit slower response times and increased overshoot during setpoint changes. This compromise becomes particularly problematic in systems requiring both precise disturbance handling and rapid reference tracking.

Frequency-dependent limitations represent another critical challenge. PID controllers demonstrate varying effectiveness across different frequency ranges, with performance degradation at higher frequencies. This characteristic makes them less suitable for systems exposed to high-frequency disturbances or those requiring wide bandwidth control, such as precision motion systems or advanced manufacturing equipment.

Model uncertainty presents a substantial obstacle to effective disturbance compensation. PID controllers tuned for nominal plant models may perform poorly when faced with parameter variations or unmodeled dynamics. This sensitivity to model mismatch can lead to deteriorated performance or even instability when the actual system deviates from the design assumptions.

The linear nature of conventional PID control imposes additional constraints when dealing with nonlinear disturbances or systems with nonlinear dynamics. Such scenarios often require gain scheduling or adaptive mechanisms that increase implementation complexity and may still deliver suboptimal performance under certain operating conditions.

Measurement noise amplification represents a practical limitation in real-world implementations. The derivative term in PID controllers is particularly susceptible to amplifying high-frequency measurement noise, potentially introducing additional disturbances into the system rather than mitigating existing ones. This often necessitates filtering techniques that can compromise the controller's responsiveness.

Multi-variable systems with coupled disturbances present perhaps the most significant challenge for traditional PID approaches. The decentralized nature of multiple SISO PID loops fails to account for cross-coupling effects, resulting in suboptimal disturbance rejection in complex systems with multiple inputs and outputs.

These limitations have driven research toward advanced control strategies such as disturbance observers, H-infinity control, and model predictive control, which aim to overcome the inherent constraints of conventional PID approaches in handling external disturbances.

Mainstream PID Compensation Techniques and Implementations

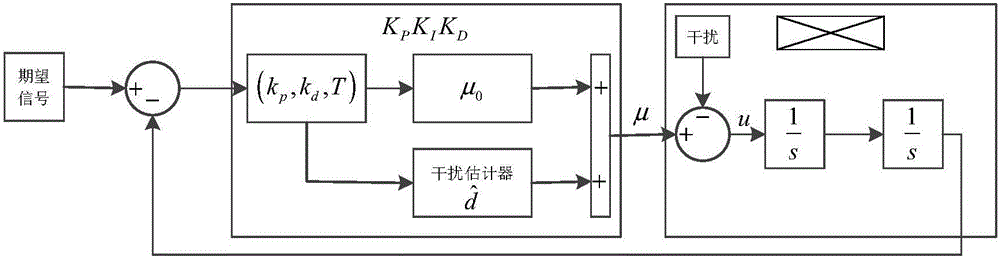

01 Disturbance observer-based PID control

Disturbance observer (DOB) techniques can be integrated with PID controllers to estimate and compensate for external disturbances. The observer monitors system behavior and identifies deviations caused by disturbances, allowing the controller to generate appropriate compensation signals. This approach enhances the robustness of PID control systems against various external factors without requiring direct measurement of the disturbances.- Feedforward compensation techniques for disturbance rejection: Feedforward compensation is used in PID control systems to anticipate and counteract external disturbances before they affect the process output. This approach involves measuring or estimating disturbances directly and incorporating this information into the control algorithm. By adding a feedforward term to the traditional PID structure, the controller can respond to disturbances proactively rather than reactively, significantly improving disturbance rejection performance while maintaining setpoint tracking capabilities.

- Advanced observer-based disturbance estimation: Observer-based methods estimate unmeasurable disturbances affecting control systems by using mathematical models of the process dynamics. These techniques include disturbance observers (DOB), extended state observers (ESO), and unknown input observers that reconstruct disturbance signals based on available measurements. The estimated disturbance is then used to modify the control signal, effectively compensating for external influences. This approach is particularly valuable when direct measurement of disturbances is impractical or when the disturbance characteristics are unknown.

- Adaptive and robust PID tuning for disturbance handling: Adaptive PID control systems automatically adjust controller parameters in response to changing disturbance conditions. These systems continuously monitor process performance and modify PID gains to maintain optimal disturbance rejection. Robust tuning methods focus on designing PID parameters that provide acceptable performance across a wide range of disturbance scenarios, ensuring stability even under worst-case conditions. These approaches are particularly valuable in applications where disturbance characteristics vary significantly over time.

- Multi-loop and cascade control structures for disturbance compensation: Multi-loop and cascade control architectures improve disturbance rejection by using hierarchical or parallel controller arrangements. In cascade control, an inner control loop handles fast disturbances while an outer loop maintains overall process objectives. Multi-loop structures distribute control responsibilities across several controllers, each addressing specific disturbance sources. These architectures are particularly effective when disturbances enter the process at different points or have varying dynamics, allowing for targeted compensation strategies at each level of the control hierarchy.

- Frequency-domain disturbance compensation techniques: Frequency-domain approaches to disturbance compensation analyze and counteract disturbances based on their spectral characteristics. These methods include notch filters for periodic disturbances, resonant controllers for specific frequency components, and frequency-selective filtering techniques. By identifying the frequency content of disturbances, controllers can be designed to provide targeted attenuation at problematic frequencies while maintaining desired performance in other frequency ranges. This approach is particularly effective for systems affected by oscillatory or harmonic disturbances.

02 Adaptive PID control strategies for disturbance rejection

Adaptive PID control systems can automatically adjust their parameters in response to detected external disturbances. These systems continuously monitor performance metrics and modify control gains to maintain optimal performance despite changing disturbance conditions. By dynamically updating controller parameters, these systems can effectively compensate for various types of disturbances while maintaining stability and performance objectives.Expand Specific Solutions03 Feedforward compensation with PID control

Feedforward compensation techniques can be combined with traditional PID control to anticipate and counteract external disturbances before they significantly affect the system. This approach uses models or measurements of disturbances to generate preemptive control actions that work alongside the feedback-based PID control. The feedforward component directly addresses known disturbances while the PID component handles residual errors, resulting in improved disturbance rejection performance.Expand Specific Solutions04 Multi-loop PID control for complex disturbance compensation

Multi-loop PID control architectures can be implemented to address complex disturbance scenarios in systems with multiple inputs and outputs. These configurations use cascaded or parallel PID controllers, each targeting specific aspects of disturbance rejection. The coordinated operation of multiple control loops allows for more comprehensive disturbance compensation than single-loop approaches, particularly in systems where disturbances affect multiple system variables simultaneously.Expand Specific Solutions05 Frequency-selective PID compensation techniques

Frequency-selective PID compensation techniques target disturbances with specific frequency characteristics. These approaches modify the standard PID structure to enhance rejection of disturbances in particular frequency bands while maintaining normal operation in others. Methods include notch filters, band-pass structures, and frequency-weighted control designs that can be tuned to address periodic disturbances or those with known spectral properties, providing more effective compensation than standard PID implementations.Expand Specific Solutions

Leading Companies and Research Institutions in PID Control

The PID control for external disturbance compensation market is in a growth phase, with increasing demand across industrial automation and precision control systems. The market is expanding due to rising adoption in manufacturing, robotics, and process industries, with an estimated global value exceeding $2 billion. Technologically, the field shows varying maturity levels, with established players like OMRON Corp. and Meidensha Corp. offering commercial solutions, while academic institutions such as Zhejiang University and Northeastern University drive theoretical advancements. Companies like Suzhou Inovance Technology and RKC Instrument focus on industrial applications, while research institutions like Xi'an Thermal Power Research Institute develop specialized implementations. The integration of PID control with emerging technologies like AI and IoT represents the frontier of development in this field.

OMRON Corp.

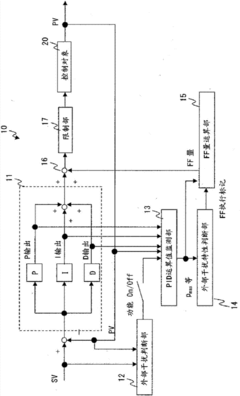

Technical Solution: OMRON has developed advanced PID control systems with disturbance rejection capabilities through their CJ2 and NX series controllers. Their technology implements a two-degree-of-freedom PID algorithm that separately handles setpoint tracking and disturbance rejection. The system incorporates a disturbance observer that estimates external disturbances in real-time and feeds this information back into the control loop to generate compensatory control signals. OMRON's implementation includes adaptive tuning mechanisms that automatically adjust PID parameters based on the detected disturbance characteristics. Their controllers feature a "feed-forward" compensation mechanism that predicts the effect of measurable disturbances before they impact the system, allowing for proactive compensation rather than reactive correction. Additionally, OMRON has integrated advanced filtering techniques to distinguish between normal process variations and actual external disturbances, reducing unnecessary control actions.

Strengths: Highly refined algorithms with decades of industrial implementation experience; seamless integration with their extensive automation ecosystem; robust performance in manufacturing environments with varying disturbance profiles. Weaknesses: Proprietary systems that may limit integration with third-party components; relatively higher cost compared to generic PID solutions; requires specific expertise to fully optimize performance.

RKC Instrument, Inc.

Technical Solution: RKC Instrument has pioneered specialized PID controllers with enhanced disturbance rejection capabilities through their PF900/901 and FB series. Their technology employs a multi-layered approach to disturbance compensation, starting with a fast-response primary control loop complemented by a secondary adaptive loop that specifically targets external disturbances. RKC's controllers implement an advanced disturbance observer that continuously monitors process variables for deviations caused by external factors and calculates appropriate compensatory actions. Their proprietary "Brilliant PID" algorithm incorporates predictive elements that anticipate the system's response to both control inputs and disturbances, allowing for more effective compensation. The controllers feature automatic disturbance classification that categorizes disturbances based on frequency characteristics and magnitude, applying optimized compensation strategies for each type. Additionally, RKC has developed specialized anti-windup mechanisms that prevent integral saturation during large disturbances, maintaining control stability even under extreme conditions.

Strengths: Exceptional performance in temperature control applications with frequent load changes; intuitive user interface that simplifies complex disturbance rejection setup; excellent stability in processes with variable time delays. Weaknesses: More specialized for thermal processes than general automation applications; limited scalability for very large distributed control systems; higher initial configuration complexity for optimal disturbance rejection.

Key Patents and Algorithms for Disturbance Rejection

PID parameter adjusting method based on interference compensator

PatentActiveCN106094510A

Innovation

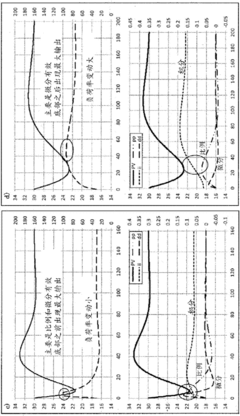

- The PID controller is regarded as a combination of a PD controller and an interference compensator. The PID parameters are adjusted through virtual proportional gain, virtual differential gain and virtual filter constants to form a new parameter mapping relationship and simplify the parameter tuning process.

Control apparatus

PatentActiveCN107077104A

Innovation

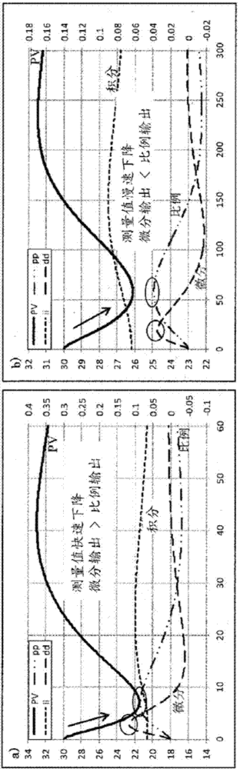

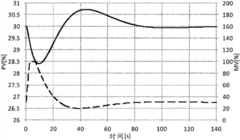

- A control device is designed. Through the PID operation part, the external interference judgment part, the correction amount operation part and the correction amount addition operation part, the temperature change characteristics are analyzed in real time, the control output is calculated and corrected, and the overshoot is suppressed.

Real-time Performance Metrics and Benchmarking

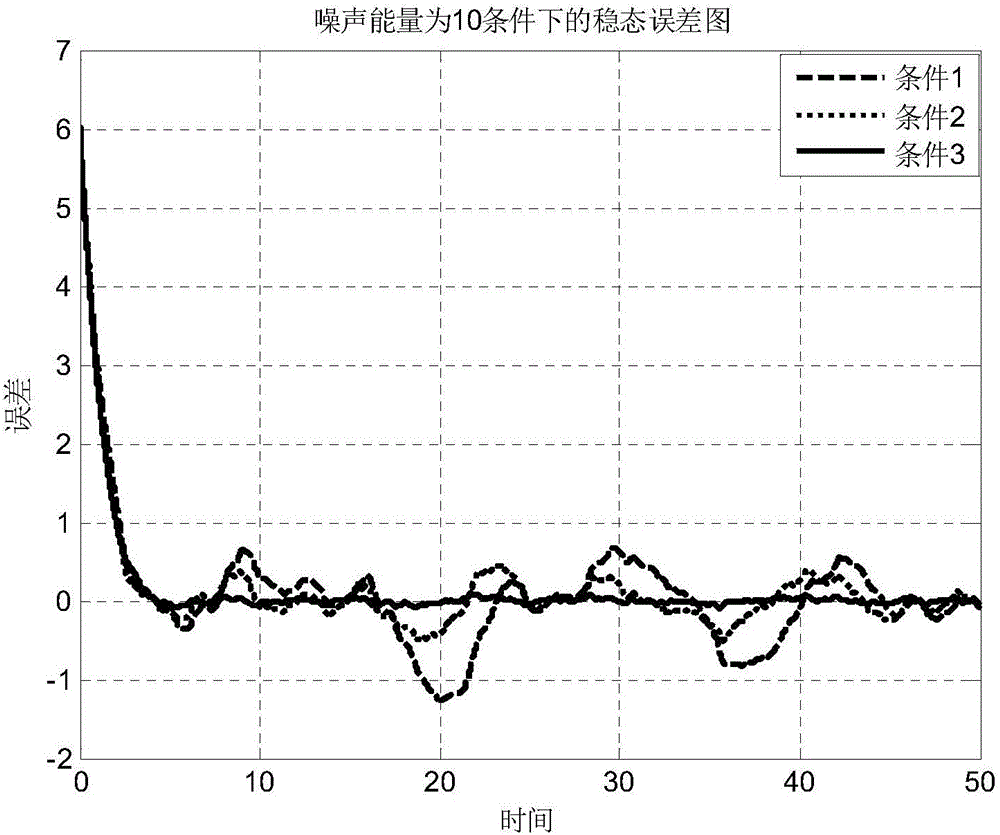

Effective evaluation of PID control systems for disturbance compensation requires comprehensive real-time performance metrics and benchmarking methodologies. The industry has established several key performance indicators that provide quantitative assessment of control system effectiveness in handling external disturbances.

Response time metrics serve as primary indicators, measuring how quickly a PID controller can detect and counteract disturbances. In high-precision manufacturing environments, response times below 10ms are increasingly becoming standard, while critical aerospace applications often demand sub-millisecond reactions to maintain stability during unexpected environmental changes.

Overshoot percentage represents another crucial metric, quantifying the maximum deviation beyond the setpoint following a disturbance. Modern PID implementations typically aim for overshoot values below 5%, with advanced algorithms achieving less than 2% in optimal conditions. This metric directly impacts product quality in manufacturing processes and energy efficiency in HVAC systems.

Settling time measurements evaluate the duration required for the system to return within an acceptable error band after disturbance occurrence. Benchmark standards vary by industry, with robotics applications typically requiring settling times under 200ms, while process control systems may accept longer periods depending on the specific application requirements.

Integral error metrics, including IAE (Integral of Absolute Error) and ITAE (Integral of Time-weighted Absolute Error), provide comprehensive evaluation of error accumulation during disturbance events. These metrics have become increasingly important as they correlate strongly with energy consumption and operational costs in industrial applications.

Robustness indicators quantify a controller's ability to maintain performance across varying operating conditions. Modern benchmarking approaches employ Monte Carlo simulations with randomized disturbance patterns to establish statistical confidence in controller performance. Industry leaders typically report 95% confidence intervals for their performance claims.

Computational efficiency metrics have gained prominence with the implementation of PID controllers in resource-constrained embedded systems. Standard benchmarks measure CPU utilization, memory footprint, and execution time variability. Leading implementations maintain deterministic execution with jitter below 1% even under maximum system load.

Cross-platform performance comparison frameworks have emerged to standardize evaluation across hardware implementations. These frameworks, such as the Control System Performance Test Suite (CSPTS) and Industrial Control Benchmark Initiative (ICBI), provide standardized disturbance profiles and scoring methodologies that enable objective comparison between different PID implementations and tuning approaches.

Response time metrics serve as primary indicators, measuring how quickly a PID controller can detect and counteract disturbances. In high-precision manufacturing environments, response times below 10ms are increasingly becoming standard, while critical aerospace applications often demand sub-millisecond reactions to maintain stability during unexpected environmental changes.

Overshoot percentage represents another crucial metric, quantifying the maximum deviation beyond the setpoint following a disturbance. Modern PID implementations typically aim for overshoot values below 5%, with advanced algorithms achieving less than 2% in optimal conditions. This metric directly impacts product quality in manufacturing processes and energy efficiency in HVAC systems.

Settling time measurements evaluate the duration required for the system to return within an acceptable error band after disturbance occurrence. Benchmark standards vary by industry, with robotics applications typically requiring settling times under 200ms, while process control systems may accept longer periods depending on the specific application requirements.

Integral error metrics, including IAE (Integral of Absolute Error) and ITAE (Integral of Time-weighted Absolute Error), provide comprehensive evaluation of error accumulation during disturbance events. These metrics have become increasingly important as they correlate strongly with energy consumption and operational costs in industrial applications.

Robustness indicators quantify a controller's ability to maintain performance across varying operating conditions. Modern benchmarking approaches employ Monte Carlo simulations with randomized disturbance patterns to establish statistical confidence in controller performance. Industry leaders typically report 95% confidence intervals for their performance claims.

Computational efficiency metrics have gained prominence with the implementation of PID controllers in resource-constrained embedded systems. Standard benchmarks measure CPU utilization, memory footprint, and execution time variability. Leading implementations maintain deterministic execution with jitter below 1% even under maximum system load.

Cross-platform performance comparison frameworks have emerged to standardize evaluation across hardware implementations. These frameworks, such as the Control System Performance Test Suite (CSPTS) and Industrial Control Benchmark Initiative (ICBI), provide standardized disturbance profiles and scoring methodologies that enable objective comparison between different PID implementations and tuning approaches.

Industry-Specific Implementation Challenges

The implementation of PID control for external disturbance compensation faces unique challenges across different industries, requiring tailored approaches to overcome sector-specific obstacles. In manufacturing environments, particularly in precision machining, vibrations from adjacent equipment create unpredictable disturbances that standard PID configurations struggle to address. These disturbances often occur at frequencies that overlap with the system's operational bandwidth, making traditional filtering approaches ineffective without compromising response time.

Process industries present a different set of challenges, where chemical reactions and fluid dynamics introduce nonlinear disturbances that vary with process conditions. PID controllers in these environments must contend with time-varying parameters and significant dead time, which can lead to instability when disturbance patterns change. The presence of exothermic reactions further complicates compensation strategies, as thermal disturbances propagate through systems with complex dynamics that resist accurate modeling.

Automotive applications face challenges related to rapidly changing operating conditions. Vehicle systems must compensate for road irregularities, crosswinds, and load variations while maintaining performance across diverse environmental conditions. The limited computational resources in automotive electronic control units often restrict the implementation of advanced disturbance observers that could otherwise enhance PID performance.

Aerospace systems encounter extreme environmental variations that affect controller performance. High-altitude operations experience temperature fluctuations that alter system dynamics, while aerodynamic disturbances change dramatically across the flight envelope. These systems require adaptive PID strategies that can maintain stability despite significant parameter variations, yet certification requirements often limit the complexity of implementable solutions.

In renewable energy systems, particularly wind turbines, stochastic weather patterns create disturbances that are difficult to predict yet critically impact energy production. PID controllers must balance power optimization against mechanical stress reduction, with disturbances spanning multiple time scales from seconds (wind gusts) to hours (weather fronts). The remote deployment of these systems also limits maintenance opportunities, requiring robust implementations that can maintain performance despite component degradation.

Medical devices present perhaps the most stringent challenges, where patient safety concerns limit the aggressiveness of disturbance rejection. Physiological variations between patients create disturbances that cannot be fully characterized during design, requiring PID implementations that prioritize robustness over optimal performance. Regulatory frameworks further constrain implementation options, often necessitating simplified approaches that can be thoroughly validated despite the complex disturbance environments they must operate within.

Process industries present a different set of challenges, where chemical reactions and fluid dynamics introduce nonlinear disturbances that vary with process conditions. PID controllers in these environments must contend with time-varying parameters and significant dead time, which can lead to instability when disturbance patterns change. The presence of exothermic reactions further complicates compensation strategies, as thermal disturbances propagate through systems with complex dynamics that resist accurate modeling.

Automotive applications face challenges related to rapidly changing operating conditions. Vehicle systems must compensate for road irregularities, crosswinds, and load variations while maintaining performance across diverse environmental conditions. The limited computational resources in automotive electronic control units often restrict the implementation of advanced disturbance observers that could otherwise enhance PID performance.

Aerospace systems encounter extreme environmental variations that affect controller performance. High-altitude operations experience temperature fluctuations that alter system dynamics, while aerodynamic disturbances change dramatically across the flight envelope. These systems require adaptive PID strategies that can maintain stability despite significant parameter variations, yet certification requirements often limit the complexity of implementable solutions.

In renewable energy systems, particularly wind turbines, stochastic weather patterns create disturbances that are difficult to predict yet critically impact energy production. PID controllers must balance power optimization against mechanical stress reduction, with disturbances spanning multiple time scales from seconds (wind gusts) to hours (weather fronts). The remote deployment of these systems also limits maintenance opportunities, requiring robust implementations that can maintain performance despite component degradation.

Medical devices present perhaps the most stringent challenges, where patient safety concerns limit the aggressiveness of disturbance rejection. Physiological variations between patients create disturbances that cannot be fully characterized during design, requiring PID implementations that prioritize robustness over optimal performance. Regulatory frameworks further constrain implementation options, often necessitating simplified approaches that can be thoroughly validated despite the complex disturbance environments they must operate within.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!