Tuning Methods For PID Controllers In Industrial Applications

SEP 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PID Control Evolution and Objectives

Proportional-Integral-Derivative (PID) control has evolved significantly since its inception in the early 20th century. The first documented implementation of PID control dates back to 1911 when Elmer Sperry developed an automatic ship steering mechanism. However, it was Nicolas Minorsky's theoretical work in 1922 that formalized the mathematical foundation of PID controllers, establishing the relationship between system stability and the three control parameters.

The 1930s and 1940s witnessed the industrial adoption of pneumatic PID controllers, primarily in process industries. These early controllers were entirely mechanical, utilizing air pressure differentials to achieve proportional, integral, and derivative actions. The post-World War II era marked a transition toward electronic PID controllers, which offered improved precision and reliability compared to their pneumatic predecessors.

The digital revolution of the 1970s and 1980s transformed PID control implementation. Microprocessors enabled the development of digital PID controllers with enhanced functionality, including auto-tuning capabilities, adaptive control algorithms, and more sophisticated control strategies. This period also saw the emergence of distributed control systems (DCS), integrating PID control into comprehensive plant-wide automation frameworks.

Modern PID controllers have evolved to address increasingly complex industrial requirements. Contemporary implementations incorporate advanced features such as anti-windup mechanisms, bumpless transfer between manual and automatic modes, and feed-forward compensation to handle disturbances proactively. The integration of artificial intelligence and machine learning techniques has further enhanced PID performance in nonlinear and time-varying systems.

The primary objective of PID control in industrial applications is to maintain process variables at desired setpoints with minimal deviation, despite disturbances and system changes. This fundamental goal encompasses several specific objectives: achieving rapid response to setpoint changes without excessive overshoot, effectively rejecting disturbances, ensuring robust performance despite model uncertainties, and maintaining stability across various operating conditions.

Another critical objective is operational simplicity. Despite the mathematical complexity underlying PID control, industrial implementations aim to provide intuitive interfaces for operators and maintenance personnel. This accessibility has contributed significantly to PID's enduring popularity in industrial settings, where practical considerations often outweigh theoretical elegance.

Looking forward, PID control continues to evolve toward greater autonomy and intelligence. Research focuses on self-tuning algorithms that can automatically adjust parameters in response to changing process dynamics, predictive capabilities that anticipate disturbances before they impact the system, and hybrid approaches that combine classical PID with advanced control methodologies to address increasingly complex industrial challenges.

The 1930s and 1940s witnessed the industrial adoption of pneumatic PID controllers, primarily in process industries. These early controllers were entirely mechanical, utilizing air pressure differentials to achieve proportional, integral, and derivative actions. The post-World War II era marked a transition toward electronic PID controllers, which offered improved precision and reliability compared to their pneumatic predecessors.

The digital revolution of the 1970s and 1980s transformed PID control implementation. Microprocessors enabled the development of digital PID controllers with enhanced functionality, including auto-tuning capabilities, adaptive control algorithms, and more sophisticated control strategies. This period also saw the emergence of distributed control systems (DCS), integrating PID control into comprehensive plant-wide automation frameworks.

Modern PID controllers have evolved to address increasingly complex industrial requirements. Contemporary implementations incorporate advanced features such as anti-windup mechanisms, bumpless transfer between manual and automatic modes, and feed-forward compensation to handle disturbances proactively. The integration of artificial intelligence and machine learning techniques has further enhanced PID performance in nonlinear and time-varying systems.

The primary objective of PID control in industrial applications is to maintain process variables at desired setpoints with minimal deviation, despite disturbances and system changes. This fundamental goal encompasses several specific objectives: achieving rapid response to setpoint changes without excessive overshoot, effectively rejecting disturbances, ensuring robust performance despite model uncertainties, and maintaining stability across various operating conditions.

Another critical objective is operational simplicity. Despite the mathematical complexity underlying PID control, industrial implementations aim to provide intuitive interfaces for operators and maintenance personnel. This accessibility has contributed significantly to PID's enduring popularity in industrial settings, where practical considerations often outweigh theoretical elegance.

Looking forward, PID control continues to evolve toward greater autonomy and intelligence. Research focuses on self-tuning algorithms that can automatically adjust parameters in response to changing process dynamics, predictive capabilities that anticipate disturbances before they impact the system, and hybrid approaches that combine classical PID with advanced control methodologies to address increasingly complex industrial challenges.

Industrial Market Demand for Advanced Control Systems

The industrial automation market is experiencing a significant shift towards more sophisticated control systems, with PID controllers remaining at the core of process control strategies. Current market analysis indicates that the global industrial control systems market is projected to reach $181 billion by 2026, growing at a CAGR of 5.8% from 2021. Within this expanding market, PID controllers and their tuning methodologies represent a critical segment, with approximately 90% of all control loops in industrial applications utilizing some form of PID control.

Manufacturing sectors, particularly in chemical processing, oil and gas, pharmaceuticals, and food and beverage industries, are driving substantial demand for advanced PID control systems. These industries require precise process control to maintain product quality, optimize energy consumption, and ensure operational safety. The pharmaceutical industry, for example, has seen a 12% increase in adoption of advanced PID control systems over the past three years due to stringent regulatory requirements and the need for precision in batch processing.

Market research indicates that end-users are increasingly demanding PID controllers with self-tuning capabilities, adaptive algorithms, and integration with Industry 4.0 technologies. The ability to automatically adjust control parameters in response to changing process conditions represents a significant value proposition, with surveys showing that 78% of process engineers consider auto-tuning features essential when selecting new control systems.

Energy efficiency concerns are also shaping market demands, as properly tuned PID controllers can reduce energy consumption by 15-30% compared to poorly tuned systems. This efficiency factor has become a major selling point, particularly in energy-intensive industries where even small percentage improvements translate to substantial cost savings.

Regional analysis reveals that Asia-Pacific represents the fastest-growing market for advanced control systems, with China and India leading industrial automation investments. North America and Europe maintain significant market shares, with emphasis on retrofitting existing systems with more sophisticated PID tuning methodologies rather than complete system replacements.

The market is also witnessing increased demand for PID controllers that can seamlessly integrate with IoT platforms and cloud-based monitoring systems. This connectivity requirement is driven by the broader digital transformation trend in manufacturing, with 67% of industrial companies planning to increase investments in connected control systems over the next five years.

Vendor analysis indicates that customers are prioritizing user-friendly tuning interfaces, robust performance under varying conditions, and comprehensive technical support when selecting PID control solutions. The market increasingly values solutions that bridge the growing skills gap in industrial settings, allowing less experienced operators to achieve optimal control performance through guided or automated tuning procedures.

Manufacturing sectors, particularly in chemical processing, oil and gas, pharmaceuticals, and food and beverage industries, are driving substantial demand for advanced PID control systems. These industries require precise process control to maintain product quality, optimize energy consumption, and ensure operational safety. The pharmaceutical industry, for example, has seen a 12% increase in adoption of advanced PID control systems over the past three years due to stringent regulatory requirements and the need for precision in batch processing.

Market research indicates that end-users are increasingly demanding PID controllers with self-tuning capabilities, adaptive algorithms, and integration with Industry 4.0 technologies. The ability to automatically adjust control parameters in response to changing process conditions represents a significant value proposition, with surveys showing that 78% of process engineers consider auto-tuning features essential when selecting new control systems.

Energy efficiency concerns are also shaping market demands, as properly tuned PID controllers can reduce energy consumption by 15-30% compared to poorly tuned systems. This efficiency factor has become a major selling point, particularly in energy-intensive industries where even small percentage improvements translate to substantial cost savings.

Regional analysis reveals that Asia-Pacific represents the fastest-growing market for advanced control systems, with China and India leading industrial automation investments. North America and Europe maintain significant market shares, with emphasis on retrofitting existing systems with more sophisticated PID tuning methodologies rather than complete system replacements.

The market is also witnessing increased demand for PID controllers that can seamlessly integrate with IoT platforms and cloud-based monitoring systems. This connectivity requirement is driven by the broader digital transformation trend in manufacturing, with 67% of industrial companies planning to increase investments in connected control systems over the next five years.

Vendor analysis indicates that customers are prioritizing user-friendly tuning interfaces, robust performance under varying conditions, and comprehensive technical support when selecting PID control solutions. The market increasingly values solutions that bridge the growing skills gap in industrial settings, allowing less experienced operators to achieve optimal control performance through guided or automated tuning procedures.

Current PID Tuning Challenges and Limitations

Despite the widespread adoption of PID controllers in industrial applications, several significant challenges and limitations persist in current tuning methodologies. Traditional manual tuning approaches, while still common, are highly dependent on operator experience and intuition, leading to inconsistent performance across different installations and maintenance cycles. This subjective nature of manual tuning creates substantial variability in control system performance and often results in sub-optimal parameter selection.

The Ziegler-Nichols method, though systematic, frequently produces aggressive control actions with excessive overshoot, making it unsuitable for processes where stability margins are critical. Additionally, this method assumes linear system behavior, which rarely holds true in complex industrial environments where nonlinearities, time delays, and disturbances are prevalent.

Model-based tuning methods require accurate process models, but obtaining such models remains challenging in industrial settings. System identification procedures often demand specialized expertise and can be time-consuming, particularly for complex multivariable processes. The model-reality mismatch problem continues to plague even sophisticated tuning approaches, as real-world processes evolve over time due to equipment aging, environmental changes, and varying operating conditions.

Auto-tuning algorithms, while promising, still struggle with robustness across diverse operating conditions. Many commercial auto-tuners perform adequately during commissioning but fail to adapt to changing process dynamics during normal operation. This limitation becomes particularly problematic in batch processes or systems with varying time constants and gain characteristics.

The increasing complexity of modern industrial processes presents another significant challenge. Many systems exhibit strong coupling between variables, significant dead time, inverse response behaviors, and other complex dynamics that standard PID tuning methods were not designed to handle effectively. In such cases, even well-tuned PID controllers may deliver unsatisfactory performance.

Computational limitations also persist in industrial controllers. While advanced tuning algorithms exist in academic literature, many cannot be implemented in standard industrial hardware due to memory and processing constraints. This creates a gap between theoretical advances and practical implementations in the field.

Finally, there is a growing skills gap in industry as experienced control engineers retire. New engineers often lack practical tuning experience, and knowledge transfer remains challenging. This human factor compounds the technical limitations of current tuning methodologies and represents a significant industry-wide challenge that technological solutions alone cannot address.

The Ziegler-Nichols method, though systematic, frequently produces aggressive control actions with excessive overshoot, making it unsuitable for processes where stability margins are critical. Additionally, this method assumes linear system behavior, which rarely holds true in complex industrial environments where nonlinearities, time delays, and disturbances are prevalent.

Model-based tuning methods require accurate process models, but obtaining such models remains challenging in industrial settings. System identification procedures often demand specialized expertise and can be time-consuming, particularly for complex multivariable processes. The model-reality mismatch problem continues to plague even sophisticated tuning approaches, as real-world processes evolve over time due to equipment aging, environmental changes, and varying operating conditions.

Auto-tuning algorithms, while promising, still struggle with robustness across diverse operating conditions. Many commercial auto-tuners perform adequately during commissioning but fail to adapt to changing process dynamics during normal operation. This limitation becomes particularly problematic in batch processes or systems with varying time constants and gain characteristics.

The increasing complexity of modern industrial processes presents another significant challenge. Many systems exhibit strong coupling between variables, significant dead time, inverse response behaviors, and other complex dynamics that standard PID tuning methods were not designed to handle effectively. In such cases, even well-tuned PID controllers may deliver unsatisfactory performance.

Computational limitations also persist in industrial controllers. While advanced tuning algorithms exist in academic literature, many cannot be implemented in standard industrial hardware due to memory and processing constraints. This creates a gap between theoretical advances and practical implementations in the field.

Finally, there is a growing skills gap in industry as experienced control engineers retire. New engineers often lack practical tuning experience, and knowledge transfer remains challenging. This human factor compounds the technical limitations of current tuning methodologies and represents a significant industry-wide challenge that technological solutions alone cannot address.

Modern PID Tuning Techniques and Implementation

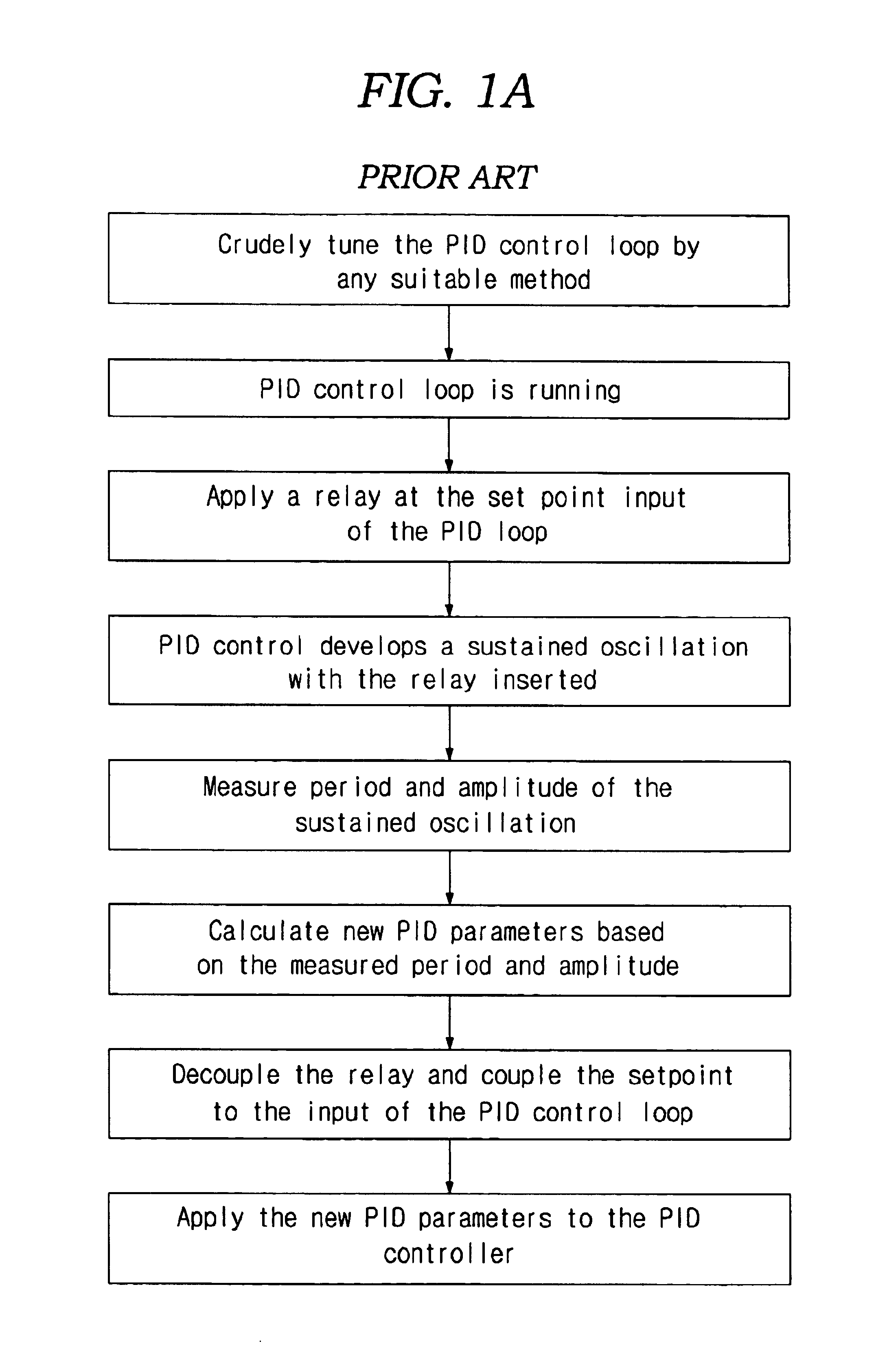

01 Classical PID Tuning Methods

Classical methods for tuning PID controllers include Ziegler-Nichols, Cohen-Coon, and relay feedback approaches. These methods involve systematic procedures to determine the proportional, integral, and derivative parameters based on process characteristics. They typically rely on step response analysis or ultimate gain and period measurements to establish controller settings that balance performance metrics like rise time, overshoot, and settling time.- Classical PID Tuning Methods: Classical methods for tuning PID controllers include Ziegler-Nichols, Cohen-Coon, and other rule-based approaches. These methods involve systematic procedures to determine the proportional, integral, and derivative parameters based on process characteristics. They typically rely on step response analysis or ultimate gain and period measurements to establish initial controller settings that can be further refined for optimal performance.

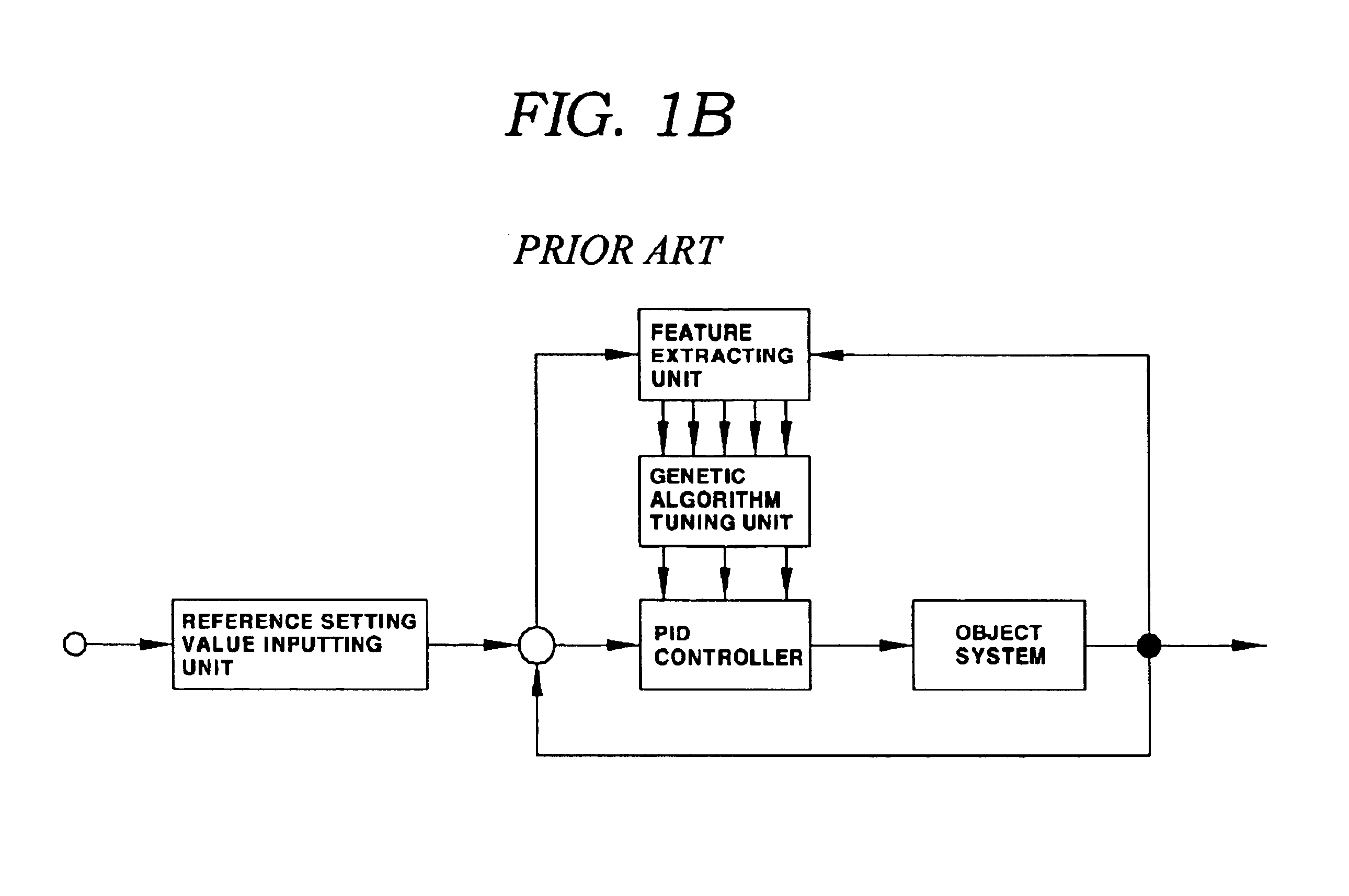

- Adaptive and Self-Tuning PID Controllers: Adaptive PID control systems automatically adjust their parameters in response to changing process conditions or disturbances. These systems incorporate algorithms that continuously monitor process performance and modify controller settings to maintain optimal control. Self-tuning controllers can identify process models in real-time and update PID parameters accordingly, making them particularly useful for processes with varying dynamics or non-linear characteristics.

- Model-Based PID Tuning Approaches: Model-based tuning approaches use mathematical models of the controlled process to determine optimal PID parameters. These methods involve system identification techniques to develop process models, followed by analytical procedures to calculate controller settings that meet specific performance criteria. Model-based approaches can provide more precise control than empirical methods, especially for complex systems with multiple variables or significant time delays.

- Optimization-Based PID Tuning: Optimization-based tuning methods employ various algorithms such as genetic algorithms, particle swarm optimization, or neural networks to find optimal PID parameters. These approaches define performance objectives like minimizing settling time, overshoot, or energy consumption, and use computational techniques to search for parameter values that best achieve these objectives. They are particularly effective for complex systems where traditional methods may not yield satisfactory results.

- Auto-Tuning and Industrial Implementation: Auto-tuning features in industrial PID controllers enable automatic configuration of control parameters with minimal user intervention. These systems typically incorporate relay feedback tests or other identification methods to determine process characteristics and calculate appropriate PID settings. Modern industrial controllers often include advanced auto-tuning algorithms with user-friendly interfaces, making sophisticated control techniques accessible to operators without extensive control theory knowledge.

02 Adaptive and Self-Tuning PID Controllers

Adaptive PID control systems automatically adjust their parameters in response to changing process conditions or disturbances. These systems incorporate algorithms that continuously monitor process variables and performance metrics, then modify controller settings to maintain optimal control. Self-tuning controllers can identify process models in real-time and recalculate appropriate PID parameters without manual intervention, making them suitable for processes with varying dynamics or nonlinearities.Expand Specific Solutions03 Model-Based PID Tuning Techniques

Model-based tuning approaches use mathematical representations of the controlled process to determine optimal PID parameters. These methods involve system identification to develop process models, followed by controller design based on desired closed-loop performance criteria. Internal Model Control (IMC) and model predictive techniques allow for more precise tuning that accounts for process dynamics, time delays, and constraints, resulting in improved control performance compared to empirical methods.Expand Specific Solutions04 Optimization-Based PID Tuning

Optimization algorithms are employed to find PID parameters that minimize specific performance indices or cost functions. These methods use techniques such as genetic algorithms, particle swarm optimization, or gradient descent to search for optimal controller settings. By defining appropriate objective functions that balance control performance metrics like error minimization, control effort, and robustness, these approaches can achieve superior tuning results for complex systems with multiple competing requirements.Expand Specific Solutions05 Auto-Tuning and Industrial Implementation

Auto-tuning methods provide practical solutions for industrial PID controller implementation. These techniques incorporate automated procedures that temporarily perturb the process, analyze the response, and calculate appropriate controller settings. Modern industrial controllers often include built-in auto-tuning capabilities that simplify commissioning and maintenance. These implementations may combine multiple tuning approaches with user-friendly interfaces to accommodate various process types and performance requirements.Expand Specific Solutions

Leading Companies and Research Institutions in PID Control

The PID controller tuning methods market is in a mature growth phase, characterized by established technologies and steady innovation. The global industrial automation control market, which includes PID controllers, is valued at approximately $180 billion with consistent annual growth of 5-7%. Leading players like Siemens AG, ABB Group, and Honeywell International demonstrate high technical maturity through advanced adaptive tuning algorithms and self-learning capabilities. Companies such as Azbil Corp. and National Instruments offer specialized solutions integrating AI and machine learning for optimized control performance. Emerging players like SUPCON Technology and Nanjing Keyuan are gaining market share through cost-effective implementations tailored for specific industrial applications. The competitive landscape shows a balance between established multinational corporations with comprehensive offerings and specialized firms focusing on niche applications or regional markets.

National Instruments Corp.

Technical Solution: National Instruments has pioneered software-centric PID tuning methods through their LabVIEW platform, offering a flexible approach to industrial control applications. Their PID toolkit implements multiple tuning methodologies including Ziegler-Nichols, Cohen-Coon, and Tyreus-Luyben methods, allowing engineers to select the most appropriate technique for specific process characteristics[2]. The company's approach emphasizes visual programming interfaces that enable real-time monitoring and adjustment of PID parameters, facilitating iterative optimization. National Instruments' controllers feature auto-tuning capabilities that use process reaction curve analysis to automatically determine initial PID parameters, significantly reducing commissioning time[4]. Their system also incorporates advanced features such as bumpless transfer between manual and automatic control modes, and setpoint weighting to independently optimize setpoint tracking and disturbance rejection performance. The platform supports model-based predictive tuning that uses process identification to create mathematical models for optimal parameter selection.

Strengths: Highly flexible and customizable control solutions that can be tailored to specific application requirements. Excellent visualization tools for monitoring controller performance and diagnosing issues. Weaknesses: Requires significant computational resources for complex implementations, and may have steeper learning curve for users without programming background.

SUPCON Technology Co., Ltd.

Technical Solution: SUPCON Technology has developed innovative PID tuning methods specifically optimized for the process industries through their SUPMAX DCS platform. Their approach combines traditional PID algorithms with advanced Chinese control theory innovations, creating solutions particularly well-suited to the chemical, petrochemical, and power generation sectors. SUPCON's controllers implement a unique two-stage tuning methodology that first establishes basic stability using simplified process models, then optimizes performance through iterative refinement based on actual process response[9]. Their system features specialized algorithms for common industrial challenges in Asian manufacturing environments, including modified Smith Predictor structures for long dead-time processes commonly found in large-scale chemical plants. SUPCON has developed industry-specific tuning rules that account for the particular characteristics of regional industrial equipment and processes. Their controllers incorporate intelligent anti-disturbance mechanisms that can identify and compensate for common process disruptions before they significantly impact controlled variables. For energy efficiency, SUPCON's tuning methods include specialized algorithms that balance control performance with actuator movement minimization, reducing wear and energy consumption[10]. The company has also implemented advanced loop diagnostic tools that provide early warning of control performance degradation and suggest specific tuning adjustments.

Strengths: Excellent adaptation to regional industrial characteristics and equipment commonly found in Asian manufacturing facilities. Cost-effective implementation with good balance between advanced features and practical usability. Weaknesses: Less extensive third-party integration options compared to Western competitors, and documentation primarily in Chinese may limit accessibility for international users.

Critical Patents and Algorithms in PID Controller Tuning

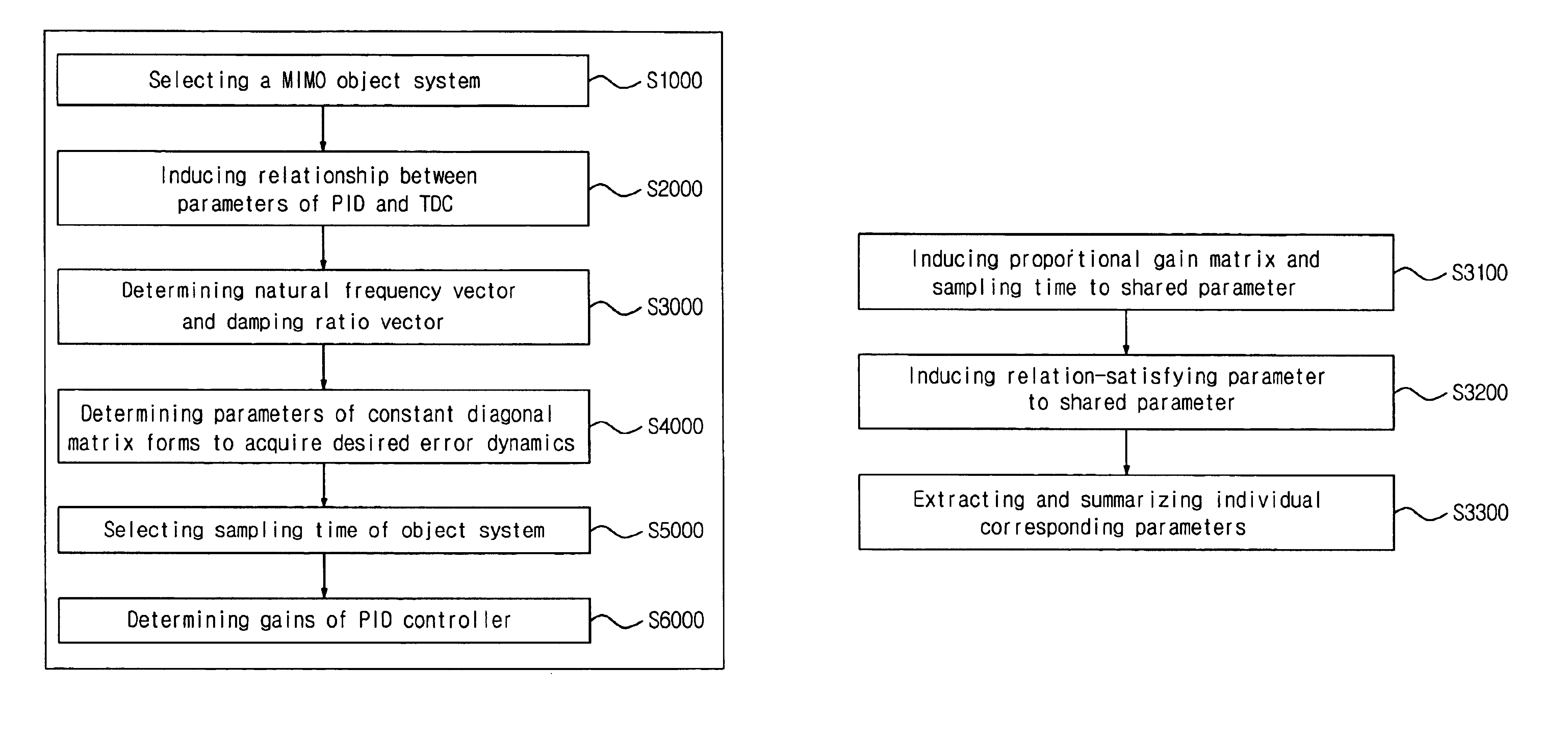

Method for tuning PID controllers applicable to nonlinear systems

PatentInactiveUS6937908B2

Innovation

- A method for tuning PID controllers in a closed loop system that uses equivalent relationships between PID gains and time delay control parameters, selecting natural frequency and damping ratio vectors to achieve desired error dynamics, and determining PID gains without additional equipment, applicable to nonlinear MIMO systems.

Industry-Specific PID Tuning Requirements

Different industries present unique challenges and requirements for PID controller tuning, necessitating specialized approaches tailored to specific operational environments. In process industries such as chemical manufacturing, PID controllers must handle slow dynamics with significant time delays, requiring robust tuning methods like Smith Predictors or Modified Cohen-Coon techniques that specifically address these characteristics. Tuning parameters in these environments often prioritize stability over rapid response, with typical proportional bands of 100-300% and integral times of 1-10 minutes to accommodate the inherent process delays.

The power generation sector demands PID tuning that ensures exceptional stability while managing complex multi-variable interactions. Cascade control structures are commonly implemented, with primary controllers tuned conservatively (low proportional gain, longer integral times) while secondary loops utilize more aggressive settings. The critical nature of power systems requires tuning methods that prioritize robustness against disturbances, often employing specialized techniques like Robust Loop Shaping.

Automotive applications present contrasting requirements, where rapid response times and minimal overshoot are essential for systems like engine control and emission management. PID tuning in this sector frequently employs gain scheduling techniques to adapt controller parameters based on operating conditions, with typical response times under 100 milliseconds and overshoot tolerances below 2%.

The pharmaceutical industry presents unique challenges where batch processes predominate. Here, PID tuning must accommodate changing dynamics throughout batch progression, often implementing adaptive tuning algorithms that continuously adjust parameters. Regulatory compliance adds another dimension, requiring documented tuning methodologies that meet FDA validation standards, with comprehensive audit trails for all parameter changes.

HVAC systems require PID tuning that balances energy efficiency with comfort, typically employing slower response characteristics with minimal overshoot. These systems often utilize weather-predictive algorithms integrated with PID control, requiring specialized tuning approaches that account for anticipated environmental changes rather than simply reacting to current conditions.

Oil and gas applications demand robust tuning methods capable of handling extreme operating conditions and safety-critical processes. These environments frequently employ model-based predictive tuning approaches with built-in constraint handling, particularly for multivariable processes like distillation columns where interactions between control loops can significantly impact system stability and performance.

The power generation sector demands PID tuning that ensures exceptional stability while managing complex multi-variable interactions. Cascade control structures are commonly implemented, with primary controllers tuned conservatively (low proportional gain, longer integral times) while secondary loops utilize more aggressive settings. The critical nature of power systems requires tuning methods that prioritize robustness against disturbances, often employing specialized techniques like Robust Loop Shaping.

Automotive applications present contrasting requirements, where rapid response times and minimal overshoot are essential for systems like engine control and emission management. PID tuning in this sector frequently employs gain scheduling techniques to adapt controller parameters based on operating conditions, with typical response times under 100 milliseconds and overshoot tolerances below 2%.

The pharmaceutical industry presents unique challenges where batch processes predominate. Here, PID tuning must accommodate changing dynamics throughout batch progression, often implementing adaptive tuning algorithms that continuously adjust parameters. Regulatory compliance adds another dimension, requiring documented tuning methodologies that meet FDA validation standards, with comprehensive audit trails for all parameter changes.

HVAC systems require PID tuning that balances energy efficiency with comfort, typically employing slower response characteristics with minimal overshoot. These systems often utilize weather-predictive algorithms integrated with PID control, requiring specialized tuning approaches that account for anticipated environmental changes rather than simply reacting to current conditions.

Oil and gas applications demand robust tuning methods capable of handling extreme operating conditions and safety-critical processes. These environments frequently employ model-based predictive tuning approaches with built-in constraint handling, particularly for multivariable processes like distillation columns where interactions between control loops can significantly impact system stability and performance.

Performance Metrics and Validation Methods for PID Controllers

Effective evaluation of PID controller performance is essential for ensuring optimal control system operation in industrial applications. The selection of appropriate performance metrics depends on the specific control objectives and process characteristics. Traditional time-domain metrics include rise time, settling time, overshoot percentage, and steady-state error. These metrics provide quantitative measures of the transient and steady-state behavior of the controlled system. For oscillatory processes, metrics such as decay ratio and damping factor become particularly relevant in assessing the stability margins of the control loop.

Frequency-domain metrics offer complementary insights into controller performance. Gain margin, phase margin, and bandwidth measurements help evaluate robustness against process variations and disturbances. The sensitivity function and complementary sensitivity function provide mathematical frameworks for analyzing disturbance rejection capabilities and noise attenuation properties respectively.

Integral error criteria represent another category of performance metrics widely used in industrial settings. The Integral Absolute Error (IAE), Integral Square Error (ISE), Integral Time-weighted Absolute Error (ITAE), and Integral Time-weighted Square Error (ITSE) each emphasize different aspects of control performance. ISE penalizes large errors more heavily, while ITAE places greater emphasis on persistent errors occurring later in the response.

Validation methods for PID controllers typically follow a structured approach. Simulation-based validation using accurate process models allows for safe testing of controller parameters before implementation. Step response tests, frequency response analysis, and disturbance rejection tests form the core of experimental validation procedures. These tests should be conducted under various operating conditions to ensure robust performance across the entire operating range.

Statistical validation techniques have gained prominence in modern industrial applications. Methods such as variance analysis, power spectral density estimation, and confidence interval calculations provide rigorous frameworks for quantifying controller performance reliability. Monte Carlo simulations help assess controller robustness against parameter uncertainties and process variations.

Industrial standards and guidelines, including ISA-5.9, ANSI/ISA-75.25.01, and IEC 61131-3, offer standardized procedures for controller performance assessment. These standards ensure consistency in evaluation methodologies across different industrial sectors and facilitate meaningful comparisons between alternative control strategies. Adherence to these standards is particularly important in regulated industries where documentation of control system performance is mandatory.

Frequency-domain metrics offer complementary insights into controller performance. Gain margin, phase margin, and bandwidth measurements help evaluate robustness against process variations and disturbances. The sensitivity function and complementary sensitivity function provide mathematical frameworks for analyzing disturbance rejection capabilities and noise attenuation properties respectively.

Integral error criteria represent another category of performance metrics widely used in industrial settings. The Integral Absolute Error (IAE), Integral Square Error (ISE), Integral Time-weighted Absolute Error (ITAE), and Integral Time-weighted Square Error (ITSE) each emphasize different aspects of control performance. ISE penalizes large errors more heavily, while ITAE places greater emphasis on persistent errors occurring later in the response.

Validation methods for PID controllers typically follow a structured approach. Simulation-based validation using accurate process models allows for safe testing of controller parameters before implementation. Step response tests, frequency response analysis, and disturbance rejection tests form the core of experimental validation procedures. These tests should be conducted under various operating conditions to ensure robust performance across the entire operating range.

Statistical validation techniques have gained prominence in modern industrial applications. Methods such as variance analysis, power spectral density estimation, and confidence interval calculations provide rigorous frameworks for quantifying controller performance reliability. Monte Carlo simulations help assess controller robustness against parameter uncertainties and process variations.

Industrial standards and guidelines, including ISA-5.9, ANSI/ISA-75.25.01, and IEC 61131-3, offer standardized procedures for controller performance assessment. These standards ensure consistency in evaluation methodologies across different industrial sectors and facilitate meaningful comparisons between alternative control strategies. Adherence to these standards is particularly important in regulated industries where documentation of control system performance is mandatory.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!