Wind Turbine Pitch Control Using PID Algorithms

SEP 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Wind Turbine Pitch Control Background and Objectives

Wind turbine pitch control technology has evolved significantly over the past four decades, transitioning from simple mechanical systems to sophisticated electronic control mechanisms. The fundamental concept of pitch control involves adjusting the angle of wind turbine blades to optimize energy capture while protecting the turbine from excessive loads during high wind conditions. This dual functionality makes pitch control systems critical components in modern wind energy conversion systems.

The historical development of pitch control began in the 1980s with basic passive stall regulation systems. By the 1990s, active pitch control emerged, allowing turbines to respond dynamically to changing wind conditions. The early 2000s saw the integration of microprocessor-based control systems, which significantly improved response times and control precision. Today's advanced systems incorporate predictive algorithms and real-time monitoring capabilities that have dramatically enhanced turbine efficiency and reliability.

Current technological trends in wind turbine pitch control are primarily focused on improving control algorithm sophistication, particularly through the implementation of Proportional-Integral-Derivative (PID) control strategies. These algorithms offer a balance of responsiveness, stability, and adaptability that is essential for modern utility-scale wind turbines. The industry is witnessing a shift toward more advanced variants such as gain-scheduled PID controllers and adaptive PID systems that can self-tune based on operating conditions.

The primary technical objectives for modern pitch control systems using PID algorithms include maximizing energy capture across variable wind speeds, minimizing mechanical loads to extend turbine lifespan, ensuring rapid response to wind gusts and emergency conditions, and maintaining stable grid integration through precise power output control. Additionally, there is growing emphasis on fault tolerance and condition monitoring capabilities within these systems.

Looking forward, the evolution of pitch control technology is expected to incorporate more sophisticated machine learning approaches that can predict wind patterns and optimize blade positioning proactively rather than reactively. Integration with LIDAR (Light Detection and Ranging) technology is also emerging as a promising direction, allowing turbines to detect incoming wind conditions before they reach the blades.

The technical goals for next-generation pitch control systems include achieving sub-second response times, reducing pitch system energy consumption, implementing more robust fault detection algorithms, and developing standardized interfaces for seamless integration with overall turbine control systems. These advancements aim to support the industry's push toward larger turbines, offshore installations, and improved grid stability contributions.

The historical development of pitch control began in the 1980s with basic passive stall regulation systems. By the 1990s, active pitch control emerged, allowing turbines to respond dynamically to changing wind conditions. The early 2000s saw the integration of microprocessor-based control systems, which significantly improved response times and control precision. Today's advanced systems incorporate predictive algorithms and real-time monitoring capabilities that have dramatically enhanced turbine efficiency and reliability.

Current technological trends in wind turbine pitch control are primarily focused on improving control algorithm sophistication, particularly through the implementation of Proportional-Integral-Derivative (PID) control strategies. These algorithms offer a balance of responsiveness, stability, and adaptability that is essential for modern utility-scale wind turbines. The industry is witnessing a shift toward more advanced variants such as gain-scheduled PID controllers and adaptive PID systems that can self-tune based on operating conditions.

The primary technical objectives for modern pitch control systems using PID algorithms include maximizing energy capture across variable wind speeds, minimizing mechanical loads to extend turbine lifespan, ensuring rapid response to wind gusts and emergency conditions, and maintaining stable grid integration through precise power output control. Additionally, there is growing emphasis on fault tolerance and condition monitoring capabilities within these systems.

Looking forward, the evolution of pitch control technology is expected to incorporate more sophisticated machine learning approaches that can predict wind patterns and optimize blade positioning proactively rather than reactively. Integration with LIDAR (Light Detection and Ranging) technology is also emerging as a promising direction, allowing turbines to detect incoming wind conditions before they reach the blades.

The technical goals for next-generation pitch control systems include achieving sub-second response times, reducing pitch system energy consumption, implementing more robust fault detection algorithms, and developing standardized interfaces for seamless integration with overall turbine control systems. These advancements aim to support the industry's push toward larger turbines, offshore installations, and improved grid stability contributions.

Market Demand Analysis for Advanced Pitch Control Systems

The global market for advanced pitch control systems in wind turbines has experienced significant growth over the past decade, driven primarily by the expanding renewable energy sector and increasing demand for more efficient wind power generation. Current market analysis indicates that the wind turbine pitch control segment is valued at approximately $1.2 billion as of 2023, with projections suggesting a compound annual growth rate of 7.8% through 2030.

The demand for advanced pitch control systems utilizing PID algorithms stems from several key market factors. First, there is increasing pressure on wind farm operators to maximize energy production while minimizing operational costs. Advanced pitch control systems can improve turbine efficiency by 3-5%, which translates to substantial revenue increases over a turbine's operational lifetime. For utility-scale wind farms, even a 1% improvement in efficiency can result in hundreds of thousands of dollars in additional annual revenue.

Regulatory frameworks worldwide are also driving market demand. Many countries have implemented renewable energy targets that necessitate more efficient wind power generation. The European Union's Green Deal aims for climate neutrality by 2050, while China's 14th Five-Year Plan emphasizes wind power development with targets to increase wind capacity by 50% by 2025. These policies create a favorable environment for technologies that enhance wind turbine performance.

The offshore wind sector represents a particularly promising market segment for advanced pitch control systems. Offshore installations face more extreme and variable wind conditions, making sophisticated pitch control essential for operational stability and equipment longevity. With offshore wind capacity expected to increase tenfold by 2030, this segment presents substantial growth opportunities for advanced control technologies.

End-users are increasingly demanding pitch control systems with predictive maintenance capabilities and remote monitoring features. The integration of PID algorithms with machine learning and IoT technologies is becoming a significant market differentiator. Systems that can adapt to changing environmental conditions in real-time and predict potential failures before they occur command premium pricing in the market.

Regional analysis shows that Europe currently leads the market for advanced pitch control systems, accounting for approximately 38% of global demand, followed by Asia-Pacific at 32% and North America at 24%. However, the fastest growth is expected in emerging markets, particularly in Latin America and Southeast Asia, where wind power installation is accelerating rapidly.

The market is also witnessing increased demand for retrofit solutions, as operators of existing wind farms seek to upgrade older turbines with more sophisticated control systems. This retrofit segment is growing at 9.2% annually, outpacing the overall market growth rate and representing a significant opportunity for technology providers.

The demand for advanced pitch control systems utilizing PID algorithms stems from several key market factors. First, there is increasing pressure on wind farm operators to maximize energy production while minimizing operational costs. Advanced pitch control systems can improve turbine efficiency by 3-5%, which translates to substantial revenue increases over a turbine's operational lifetime. For utility-scale wind farms, even a 1% improvement in efficiency can result in hundreds of thousands of dollars in additional annual revenue.

Regulatory frameworks worldwide are also driving market demand. Many countries have implemented renewable energy targets that necessitate more efficient wind power generation. The European Union's Green Deal aims for climate neutrality by 2050, while China's 14th Five-Year Plan emphasizes wind power development with targets to increase wind capacity by 50% by 2025. These policies create a favorable environment for technologies that enhance wind turbine performance.

The offshore wind sector represents a particularly promising market segment for advanced pitch control systems. Offshore installations face more extreme and variable wind conditions, making sophisticated pitch control essential for operational stability and equipment longevity. With offshore wind capacity expected to increase tenfold by 2030, this segment presents substantial growth opportunities for advanced control technologies.

End-users are increasingly demanding pitch control systems with predictive maintenance capabilities and remote monitoring features. The integration of PID algorithms with machine learning and IoT technologies is becoming a significant market differentiator. Systems that can adapt to changing environmental conditions in real-time and predict potential failures before they occur command premium pricing in the market.

Regional analysis shows that Europe currently leads the market for advanced pitch control systems, accounting for approximately 38% of global demand, followed by Asia-Pacific at 32% and North America at 24%. However, the fastest growth is expected in emerging markets, particularly in Latin America and Southeast Asia, where wind power installation is accelerating rapidly.

The market is also witnessing increased demand for retrofit solutions, as operators of existing wind farms seek to upgrade older turbines with more sophisticated control systems. This retrofit segment is growing at 9.2% annually, outpacing the overall market growth rate and representing a significant opportunity for technology providers.

Current State and Challenges in PID-Based Pitch Control

PID-based pitch control systems remain the dominant approach in wind turbine control due to their reliability, simplicity, and effectiveness. Currently, most commercial wind turbines employ conventional PID controllers with fixed parameters that are tuned during commissioning. These systems have demonstrated reasonable performance under normal operating conditions but face significant limitations when confronted with the increasingly complex demands of modern wind energy systems.

The global landscape of PID-based pitch control reveals varying levels of technological sophistication. European manufacturers, particularly those from Germany and Denmark, have pioneered advanced adaptive PID algorithms that dynamically adjust parameters based on operating conditions. In contrast, emerging markets in Asia are predominantly implementing basic PID systems with limited adaptability, though rapid advancement is occurring in China where significant research investments are being made.

A primary technical challenge facing current PID-based pitch control is the inherent non-linearity of wind turbine aerodynamics. Traditional PID controllers, designed for linear systems, struggle to maintain optimal performance across the entire operating range of a turbine. This limitation becomes particularly problematic during extreme weather events or rapid wind speed fluctuations, where linear approximations break down.

Parameter tuning represents another significant hurdle. The conventional approach of manual tuning during commissioning is time-consuming and often results in sub-optimal performance. While auto-tuning algorithms have been developed, they frequently fail to account for the complex interactions between mechanical loads, aerodynamic forces, and electrical systems.

Computational limitations also constrain current implementations. The sampling rates of most commercial systems (typically 10-50 Hz) are insufficient for capturing high-frequency dynamics, particularly in larger turbines where blade flexibility introduces complex modal behaviors. This limitation is exacerbated by communication delays in distributed control architectures.

The integration of PID pitch control with other turbine subsystems presents additional challenges. Interactions between pitch control, generator torque control, and yaw systems can lead to unexpected behaviors and reduced overall system efficiency. Current solutions typically employ simplified decoupling strategies that fail to optimize the entire turbine system holistically.

Reliability concerns persist despite decades of refinement. Pitch systems remain among the most failure-prone components in wind turbines, with control system faults accounting for approximately 23% of pitch-related downtime according to recent industry reliability surveys. Environmental factors such as lightning strikes, extreme temperatures, and salt corrosion further complicate the design of robust control systems.

The global landscape of PID-based pitch control reveals varying levels of technological sophistication. European manufacturers, particularly those from Germany and Denmark, have pioneered advanced adaptive PID algorithms that dynamically adjust parameters based on operating conditions. In contrast, emerging markets in Asia are predominantly implementing basic PID systems with limited adaptability, though rapid advancement is occurring in China where significant research investments are being made.

A primary technical challenge facing current PID-based pitch control is the inherent non-linearity of wind turbine aerodynamics. Traditional PID controllers, designed for linear systems, struggle to maintain optimal performance across the entire operating range of a turbine. This limitation becomes particularly problematic during extreme weather events or rapid wind speed fluctuations, where linear approximations break down.

Parameter tuning represents another significant hurdle. The conventional approach of manual tuning during commissioning is time-consuming and often results in sub-optimal performance. While auto-tuning algorithms have been developed, they frequently fail to account for the complex interactions between mechanical loads, aerodynamic forces, and electrical systems.

Computational limitations also constrain current implementations. The sampling rates of most commercial systems (typically 10-50 Hz) are insufficient for capturing high-frequency dynamics, particularly in larger turbines where blade flexibility introduces complex modal behaviors. This limitation is exacerbated by communication delays in distributed control architectures.

The integration of PID pitch control with other turbine subsystems presents additional challenges. Interactions between pitch control, generator torque control, and yaw systems can lead to unexpected behaviors and reduced overall system efficiency. Current solutions typically employ simplified decoupling strategies that fail to optimize the entire turbine system holistically.

Reliability concerns persist despite decades of refinement. Pitch systems remain among the most failure-prone components in wind turbines, with control system faults accounting for approximately 23% of pitch-related downtime according to recent industry reliability surveys. Environmental factors such as lightning strikes, extreme temperatures, and salt corrosion further complicate the design of robust control systems.

Current PID Algorithm Implementation Approaches

01 PID control algorithms for aircraft pitch stability

PID controllers are implemented in aircraft systems to maintain pitch stability during flight. These algorithms continuously monitor the aircraft's attitude and make real-time adjustments to control surfaces to maintain the desired pitch angle. The control systems use feedback mechanisms to correct deviations from the target pitch, enhancing flight safety and performance in various atmospheric conditions.- PID control algorithms for aircraft pitch stability: PID controllers are implemented in aircraft systems to maintain pitch stability during flight. These algorithms continuously monitor the aircraft's pitch angle and make real-time adjustments to control surfaces to ensure stable flight conditions. The control systems use feedback mechanisms to compare actual pitch with desired pitch, applying proportional, integral, and derivative calculations to minimize error and prevent oscillations. These systems are particularly important during turbulence or when executing maneuvers that could affect pitch stability.

- Adaptive PID tuning methods for pitch control: Adaptive PID tuning techniques automatically adjust controller parameters based on changing flight conditions. These methods analyze system response in real-time and modify proportional, integral, and derivative gains to optimize pitch control performance. Adaptive algorithms can account for variations in aircraft loading, speed, altitude, and environmental conditions, ensuring consistent pitch control across different operating scenarios. These systems often incorporate machine learning or fuzzy logic to improve parameter selection and control response over time.

- Integration of PID with other control techniques for enhanced pitch performance: Hybrid control systems combine PID algorithms with other control methodologies to enhance pitch control performance. These integrated approaches may incorporate fuzzy logic, neural networks, or model predictive control alongside traditional PID controllers. The hybrid systems leverage the reliability of PID control while addressing its limitations through complementary techniques. This integration allows for more robust pitch control across a wider range of operating conditions and can better handle nonlinearities in aircraft dynamics.

- Real-time optimization of PID parameters for pitch control: Real-time optimization techniques continuously adjust PID controller parameters to maintain optimal pitch control performance. These systems use computational algorithms to analyze control performance metrics and iteratively refine controller settings during operation. The optimization processes consider multiple objectives such as response time, overshoot minimization, and energy efficiency. By dynamically adjusting controller parameters, these systems can adapt to changing aircraft conditions or environmental disturbances while maintaining precise pitch control.

- Application of PID control in specific pitch-critical systems: PID control algorithms are implemented in various pitch-critical systems across different industries. These applications include wind turbine blade pitch control, marine vessel stabilization, drone attitude control, and missile guidance systems. Each implementation adapts the fundamental PID principles to address the specific requirements and constraints of the particular system. The controllers are designed to handle the unique dynamics, response characteristics, and disturbance patterns relevant to each application while maintaining stable and accurate pitch control.

02 Adaptive PID tuning for pitch control systems

Adaptive PID tuning methods automatically adjust controller parameters based on real-time performance metrics and changing flight conditions. These systems can self-optimize the proportional, integral, and derivative gains to maintain optimal pitch control despite variations in aircraft loading, speed, or altitude. This adaptive approach improves control precision and system robustness compared to fixed-parameter PID controllers.Expand Specific Solutions03 PID-based pitch control for unmanned aerial vehicles

Specialized PID algorithms are designed for unmanned aerial vehicles (UAVs) to provide precise pitch control with minimal computational requirements. These controllers account for the unique dynamics and weight constraints of drones and autonomous aircraft. The algorithms often incorporate disturbance rejection capabilities to maintain stable flight paths despite wind gusts or other external forces.Expand Specific Solutions04 Hybrid PID control strategies for enhanced pitch performance

Hybrid control approaches combine PID algorithms with other control methodologies such as fuzzy logic, neural networks, or model predictive control to overcome the limitations of traditional PID controllers. These hybrid systems provide improved pitch control performance, particularly in nonlinear flight regimes or during rapid maneuvers. The integration of multiple control strategies allows for better handling of complex aerodynamic interactions.Expand Specific Solutions05 PID implementation for engine and propulsion pitch control

PID controllers are applied to engine and propulsion systems to regulate pitch angles of propellers, turbine blades, or thrust vectoring mechanisms. These control systems optimize engine performance and efficiency by maintaining ideal pitch settings based on operating conditions. The algorithms account for mechanical constraints while providing responsive adjustments to changing power demands or environmental conditions.Expand Specific Solutions

Leading Players in Wind Turbine Control Systems

The wind turbine pitch control market using PID algorithms is currently in a growth phase, with increasing adoption driven by the global shift towards renewable energy. The market size is expanding significantly as wind power installations continue to rise worldwide, projected to reach substantial value by 2030. Technologically, the field shows varying maturity levels among key players. Industry leaders like Vestas Wind Systems, Goldwind Science & Technology, and GE Renewable Technologies have developed sophisticated PID control systems with advanced features, while companies such as Siemens Gamesa and Woodward are focusing on innovative adaptive algorithms. Chinese manufacturers including CRRC Zhuzhou Institute and Guodian United Power are rapidly advancing their technological capabilities, narrowing the gap with Western counterparts through significant R&D investments in optimized pitch control solutions.

Vestas Wind Systems A/S

Technical Solution: Vestas has developed an advanced pitch control system utilizing a multi-variable PID algorithm that adapts to changing wind conditions. Their solution incorporates a cascaded control structure with an outer loop for speed regulation and an inner loop for pitch angle control. The system features gain scheduling techniques that adjust PID parameters based on wind speed ranges, optimizing performance across operational conditions. Vestas implements a unique anti-windup mechanism to prevent integrator saturation during rapid wind changes, ensuring stable operation during extreme weather events. Their pitch control system also incorporates feed-forward control based on wind speed measurements to anticipate load changes before they affect turbine speed, reducing mechanical stress and improving response time. The system utilizes LIDAR technology for wind speed prediction, allowing proactive pitch adjustments before wind gusts reach the turbine blades[1][3].

Strengths: Superior adaptation to varying wind conditions through gain scheduling; reduced mechanical loads through predictive control; excellent stability during extreme weather events. Weaknesses: Higher implementation complexity requiring sophisticated sensors; increased computational demands; higher initial cost compared to simpler control systems.

Goldwind Science & Technology Co., Ltd.

Technical Solution: Goldwind has pioneered a direct-drive permanent magnet synchronous generator (PMSG) technology that works in conjunction with their advanced pitch control system. Their pitch control solution utilizes a cascaded PID structure with an outer loop controlling rotor speed and an inner loop managing pitch position. The system features adaptive gain scheduling that adjusts controller parameters based on both wind speed and turbine operational state. Goldwind's approach incorporates a unique "soft cut-out" strategy during high wind events, gradually reducing power output through coordinated pitch and torque control rather than abrupt shutdown. Their pitch system employs a feed-forward component based on wind speed measurement and turbulence intensity estimation to anticipate load changes. The control algorithm includes specialized logic for extreme conditions such as wind shear and wind veer, adjusting individual blade pitch to minimize asymmetric loading. Goldwind's system also features a learning algorithm that continuously optimizes pitch response based on historical performance data[7][9].

Strengths: Excellent integration with direct-drive PMSG technology reducing mechanical complexity; adaptive algorithms provide optimal performance across diverse conditions; sophisticated extreme weather handling capabilities. Weaknesses: Requires precise sensor calibration and maintenance; higher computational demands than simpler systems; more complex implementation requiring specialized expertise.

Key Technical Innovations in Pitch Control Algorithms

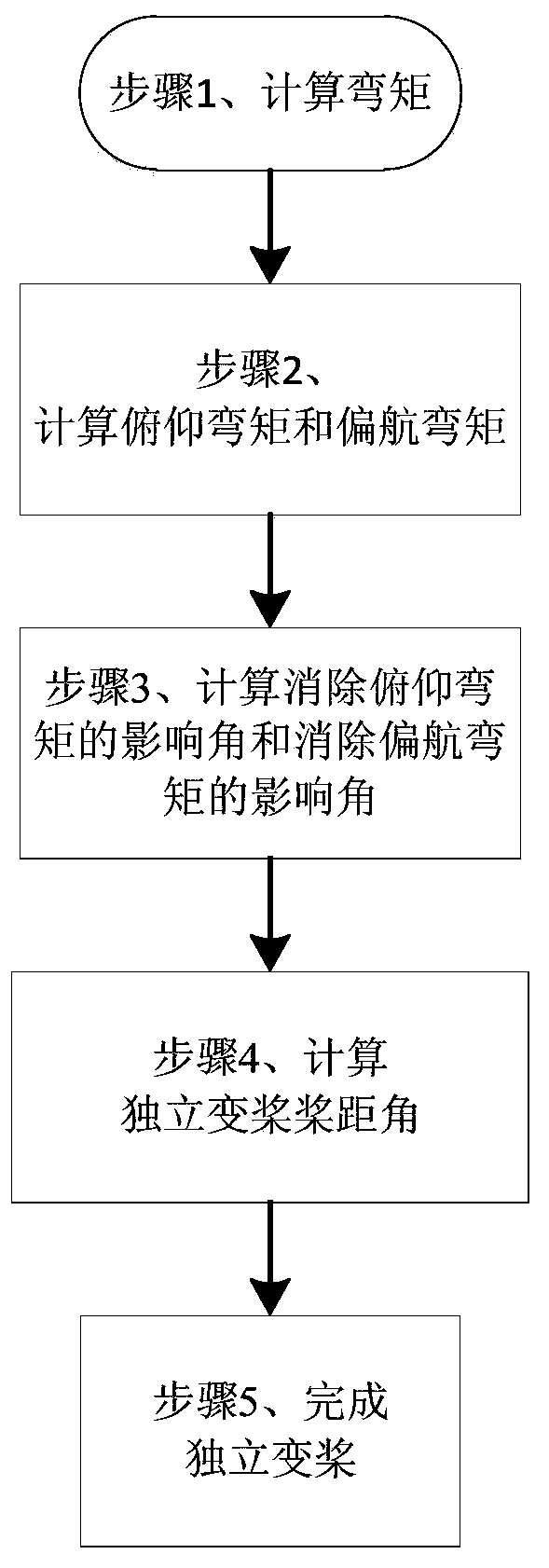

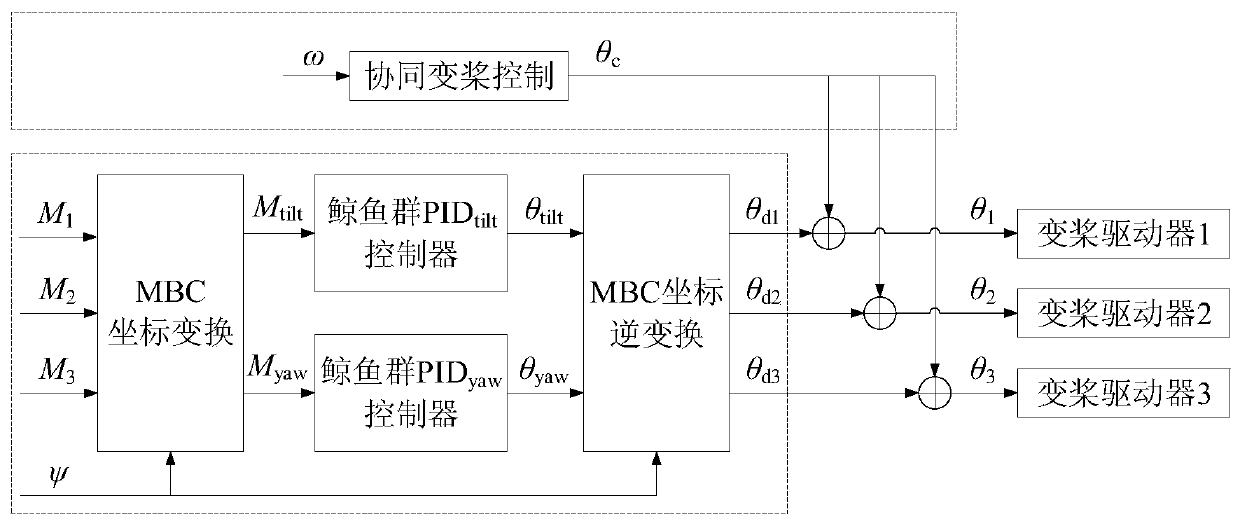

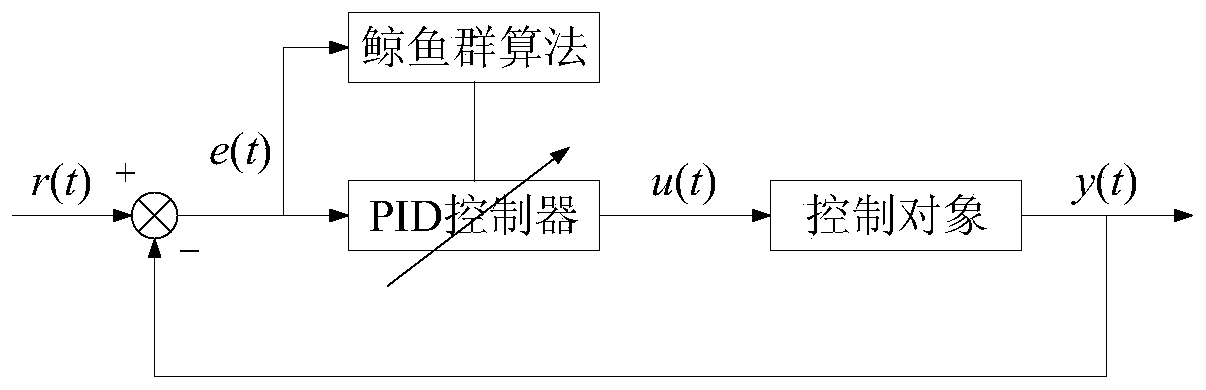

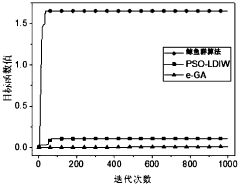

Whale group PID independent pitch control method for large wind turbine unit

PatentActiveCN110425084A

Innovation

- Application of improved WSA-IC algorithm for PID parameter tuning in wind turbine independent pitch control, addressing the multi-modal optimization problem with better solution quality.

- Enhanced global search capability that efficiently identifies and escapes from local optima during the iteration process, saving unnecessary function evaluations.

- Algorithm design that eliminates the need for manual parameter setting for different problems and doesn't require precise matching between population size and number of optimal solutions.

Grid Integration and Stability Considerations

The integration of wind turbines with PID-controlled pitch systems into electrical grids presents significant challenges for power system stability and reliability. As wind penetration increases in modern power systems, the dynamic behavior of pitch-controlled turbines during grid disturbances becomes increasingly critical. The variable nature of wind energy, combined with the response characteristics of PID pitch control systems, can introduce power fluctuations that impact frequency regulation and voltage stability across the grid.

Grid codes worldwide have evolved to require wind turbines to provide grid support functions similar to conventional generators. PID pitch control algorithms must therefore be designed not only for optimal energy capture but also to enable turbines to respond appropriately to grid events. This includes capabilities such as fault ride-through, frequency response, and reactive power support. The tuning of PID parameters significantly influences how effectively turbines can provide these grid services while maintaining their own operational stability.

Synchronization between pitch control actions and grid requirements represents a key technical challenge. Fast-acting pitch systems using well-tuned PID controllers can help mitigate power quality issues by reducing flicker and harmonics injection. However, the mechanical limitations of pitch actuation systems create inherent constraints on response times that must be considered when designing grid integration strategies.

Virtual inertia provision has emerged as an important consideration for wind farms utilizing PID pitch control. By modifying pitch control algorithms to temporarily increase power output during frequency drops, wind turbines can simulate the inertial response traditionally provided by conventional synchronous generators. This capability becomes increasingly valuable as power systems transition toward higher renewable penetration levels.

The coordination of multiple wind turbines within a wind farm presents additional complexity for grid stability. Distributed PID control architectures that account for wake effects and turbine interactions can optimize overall farm performance and grid support capabilities. Advanced control schemes often incorporate hierarchical structures where individual turbine PID controllers operate under farm-level coordination systems that interface with grid operators.

Energy storage integration with pitch-controlled wind turbines offers promising solutions for enhancing grid stability. Hybrid systems combining batteries or other storage technologies with optimized PID pitch control can provide more predictable power output and enhanced grid services. The control algorithms must be designed to manage the interplay between pitch adjustments and storage charging/discharging to maximize grid benefits while minimizing component stress.

Grid codes worldwide have evolved to require wind turbines to provide grid support functions similar to conventional generators. PID pitch control algorithms must therefore be designed not only for optimal energy capture but also to enable turbines to respond appropriately to grid events. This includes capabilities such as fault ride-through, frequency response, and reactive power support. The tuning of PID parameters significantly influences how effectively turbines can provide these grid services while maintaining their own operational stability.

Synchronization between pitch control actions and grid requirements represents a key technical challenge. Fast-acting pitch systems using well-tuned PID controllers can help mitigate power quality issues by reducing flicker and harmonics injection. However, the mechanical limitations of pitch actuation systems create inherent constraints on response times that must be considered when designing grid integration strategies.

Virtual inertia provision has emerged as an important consideration for wind farms utilizing PID pitch control. By modifying pitch control algorithms to temporarily increase power output during frequency drops, wind turbines can simulate the inertial response traditionally provided by conventional synchronous generators. This capability becomes increasingly valuable as power systems transition toward higher renewable penetration levels.

The coordination of multiple wind turbines within a wind farm presents additional complexity for grid stability. Distributed PID control architectures that account for wake effects and turbine interactions can optimize overall farm performance and grid support capabilities. Advanced control schemes often incorporate hierarchical structures where individual turbine PID controllers operate under farm-level coordination systems that interface with grid operators.

Energy storage integration with pitch-controlled wind turbines offers promising solutions for enhancing grid stability. Hybrid systems combining batteries or other storage technologies with optimized PID pitch control can provide more predictable power output and enhanced grid services. The control algorithms must be designed to manage the interplay between pitch adjustments and storage charging/discharging to maximize grid benefits while minimizing component stress.

Environmental Impact and Sustainability Factors

The implementation of PID algorithms in wind turbine pitch control systems contributes significantly to environmental sustainability through multiple pathways. By optimizing blade angles in real-time response to changing wind conditions, these control systems maximize energy capture efficiency, directly increasing renewable energy production from the same physical infrastructure. This efficiency improvement translates to approximately 3-5% higher annual energy production compared to simpler control methods, effectively reducing the carbon footprint per kilowatt-hour generated.

Beyond energy production benefits, advanced pitch control systems utilizing PID algorithms substantially extend turbine component lifespans by minimizing mechanical stress during operation. The precise control of blade loading during gusty conditions reduces fatigue damage to critical components such as the main shaft, gearbox, and tower structure. Studies indicate that well-tuned pitch control systems can extend turbine operational lifespans by 15-20%, significantly reducing the environmental impact associated with manufacturing replacement parts and performing major maintenance operations.

Noise pollution represents another environmental consideration where PID-based pitch control delivers measurable benefits. By maintaining optimal blade angles relative to wind direction and speed, these systems can reduce aerodynamic noise by 2-3 decibels compared to fixed-pitch or simpler variable-pitch systems. This noise reduction is particularly valuable in areas where turbines are installed near residential communities or sensitive wildlife habitats.

The environmental footprint of wind energy extends to land use considerations. Enhanced pitch control efficiency allows turbines to generate more power from smaller rotor diameters, potentially reducing the physical footprint of wind farms. Additionally, by enabling turbines to operate effectively at lower wind speeds, these control systems can expand viable installation locations beyond traditional high-wind areas, distributing environmental impact across broader geographic regions.

From a lifecycle assessment perspective, the sustainability benefits of advanced pitch control systems must be weighed against their own environmental costs. The additional electronic components required for sophisticated control systems contain rare earth elements and other materials with significant extraction impacts. However, lifecycle analyses consistently demonstrate that these embedded environmental costs are offset many times over by the operational efficiency gains throughout the turbine's operational lifespan.

Beyond energy production benefits, advanced pitch control systems utilizing PID algorithms substantially extend turbine component lifespans by minimizing mechanical stress during operation. The precise control of blade loading during gusty conditions reduces fatigue damage to critical components such as the main shaft, gearbox, and tower structure. Studies indicate that well-tuned pitch control systems can extend turbine operational lifespans by 15-20%, significantly reducing the environmental impact associated with manufacturing replacement parts and performing major maintenance operations.

Noise pollution represents another environmental consideration where PID-based pitch control delivers measurable benefits. By maintaining optimal blade angles relative to wind direction and speed, these systems can reduce aerodynamic noise by 2-3 decibels compared to fixed-pitch or simpler variable-pitch systems. This noise reduction is particularly valuable in areas where turbines are installed near residential communities or sensitive wildlife habitats.

The environmental footprint of wind energy extends to land use considerations. Enhanced pitch control efficiency allows turbines to generate more power from smaller rotor diameters, potentially reducing the physical footprint of wind farms. Additionally, by enabling turbines to operate effectively at lower wind speeds, these control systems can expand viable installation locations beyond traditional high-wind areas, distributing environmental impact across broader geographic regions.

From a lifecycle assessment perspective, the sustainability benefits of advanced pitch control systems must be weighed against their own environmental costs. The additional electronic components required for sophisticated control systems contain rare earth elements and other materials with significant extraction impacts. However, lifecycle analyses consistently demonstrate that these embedded environmental costs are offset many times over by the operational efficiency gains throughout the turbine's operational lifespan.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!