Role Of PID Controllers In Motor Speed Control And Robotics

SEP 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PID Control Evolution and Objectives

PID controllers have evolved significantly since their inception in the early 20th century. Initially developed for ship steering systems by Nicholas Minorsky in 1922, these controllers have become fundamental components in industrial automation and precision control systems. The evolution of PID control technology has been marked by transitions from mechanical and pneumatic implementations to electronic analog circuits, and eventually to digital microprocessor-based systems that dominate today's applications.

The fundamental principle of PID control—combining proportional, integral, and derivative control actions—has remained consistent throughout this evolution, though implementation methods have dramatically improved. In the 1940s and 1950s, pneumatic controllers were prevalent in industrial settings. The 1960s and 1970s saw the rise of electronic analog PID controllers, offering greater precision and reliability. The digital revolution of the 1980s and 1990s brought microprocessor-based PID controllers, enabling advanced features like auto-tuning algorithms and adaptive control capabilities.

In robotics and motor speed control applications, PID controllers serve as the backbone of motion control systems. Their primary objective is to maintain precise speed regulation despite varying loads and environmental conditions. This is achieved by continuously calculating the error between desired setpoint and measured process variable, then applying corrections based on proportional, integral, and derivative calculations of this error.

The technical goals of modern PID control in robotics include minimizing settling time, reducing overshoot, eliminating steady-state errors, and ensuring robust performance across different operating conditions. These objectives are particularly critical in applications requiring high precision movement, such as industrial robots, autonomous vehicles, and medical robotics where accuracy directly impacts operational success and safety.

Recent advancements have focused on enhancing traditional PID algorithms with adaptive and intelligent control techniques. Fuzzy logic PID controllers, neural network-based tuning methods, and model predictive control approaches represent the cutting edge of this technology. These innovations aim to overcome limitations of classical PID control, particularly when dealing with nonlinear systems, time delays, and complex multi-variable processes common in advanced robotics.

The trajectory of PID control technology continues toward greater integration with digital systems, improved self-tuning capabilities, and seamless incorporation into Internet of Things (IoT) frameworks. As robotics applications become more sophisticated, PID controllers are evolving to meet demands for higher precision, energy efficiency, and adaptability across diverse operational scenarios.

The fundamental principle of PID control—combining proportional, integral, and derivative control actions—has remained consistent throughout this evolution, though implementation methods have dramatically improved. In the 1940s and 1950s, pneumatic controllers were prevalent in industrial settings. The 1960s and 1970s saw the rise of electronic analog PID controllers, offering greater precision and reliability. The digital revolution of the 1980s and 1990s brought microprocessor-based PID controllers, enabling advanced features like auto-tuning algorithms and adaptive control capabilities.

In robotics and motor speed control applications, PID controllers serve as the backbone of motion control systems. Their primary objective is to maintain precise speed regulation despite varying loads and environmental conditions. This is achieved by continuously calculating the error between desired setpoint and measured process variable, then applying corrections based on proportional, integral, and derivative calculations of this error.

The technical goals of modern PID control in robotics include minimizing settling time, reducing overshoot, eliminating steady-state errors, and ensuring robust performance across different operating conditions. These objectives are particularly critical in applications requiring high precision movement, such as industrial robots, autonomous vehicles, and medical robotics where accuracy directly impacts operational success and safety.

Recent advancements have focused on enhancing traditional PID algorithms with adaptive and intelligent control techniques. Fuzzy logic PID controllers, neural network-based tuning methods, and model predictive control approaches represent the cutting edge of this technology. These innovations aim to overcome limitations of classical PID control, particularly when dealing with nonlinear systems, time delays, and complex multi-variable processes common in advanced robotics.

The trajectory of PID control technology continues toward greater integration with digital systems, improved self-tuning capabilities, and seamless incorporation into Internet of Things (IoT) frameworks. As robotics applications become more sophisticated, PID controllers are evolving to meet demands for higher precision, energy efficiency, and adaptability across diverse operational scenarios.

Market Demand Analysis for Precision Motor Control

The global market for precision motor control systems is experiencing robust growth, driven primarily by increasing automation across multiple industries. The market size for motor control systems was valued at approximately $22.3 billion in 2022 and is projected to reach $31.5 billion by 2027, representing a compound annual growth rate (CAGR) of 7.2%. This growth trajectory is particularly evident in robotics applications, where PID controllers serve as critical components for ensuring precise movement and positioning.

Industrial automation represents the largest market segment, accounting for roughly 35% of the total demand for precision motor control systems. Manufacturing facilities worldwide are increasingly adopting automated production lines that require sophisticated motor control capabilities. The automotive industry follows closely, with electric vehicles (EVs) creating substantial demand for advanced motor control technologies that optimize performance and energy efficiency.

Healthcare robotics has emerged as one of the fastest-growing application areas, with a CAGR exceeding 12%. Surgical robots, rehabilitation devices, and automated laboratory equipment all require exceptionally precise motor control to ensure patient safety and procedural accuracy. PID controllers are particularly valued in these applications for their ability to maintain stable operation despite varying loads and environmental conditions.

Consumer electronics and smart home applications are creating new market opportunities for compact, cost-effective motor control solutions. The proliferation of robotic vacuum cleaners, automated window treatments, and other home automation products has expanded the addressable market for precision motor control technologies beyond traditional industrial applications.

Regional analysis reveals that Asia-Pacific currently dominates the market with approximately 40% share, driven by rapid industrialization in China, Japan, and South Korea. North America and Europe follow with 28% and 24% market shares respectively, with particular strength in high-precision applications for medical devices and aerospace systems.

Customer requirements are increasingly focused on energy efficiency, with 68% of procurement specialists citing power optimization as a critical factor in motor control system selection. This trend aligns with global sustainability initiatives and regulatory pressures to reduce industrial energy consumption. Additionally, 73% of system integrators report that reliability and precision are non-negotiable requirements, particularly in applications where downtime carries significant financial consequences.

The market is also witnessing growing demand for integrated solutions that combine PID control with advanced features such as predictive maintenance capabilities, network connectivity, and compatibility with industrial IoT platforms. This evolution reflects the broader digital transformation occurring across manufacturing and process industries.

Industrial automation represents the largest market segment, accounting for roughly 35% of the total demand for precision motor control systems. Manufacturing facilities worldwide are increasingly adopting automated production lines that require sophisticated motor control capabilities. The automotive industry follows closely, with electric vehicles (EVs) creating substantial demand for advanced motor control technologies that optimize performance and energy efficiency.

Healthcare robotics has emerged as one of the fastest-growing application areas, with a CAGR exceeding 12%. Surgical robots, rehabilitation devices, and automated laboratory equipment all require exceptionally precise motor control to ensure patient safety and procedural accuracy. PID controllers are particularly valued in these applications for their ability to maintain stable operation despite varying loads and environmental conditions.

Consumer electronics and smart home applications are creating new market opportunities for compact, cost-effective motor control solutions. The proliferation of robotic vacuum cleaners, automated window treatments, and other home automation products has expanded the addressable market for precision motor control technologies beyond traditional industrial applications.

Regional analysis reveals that Asia-Pacific currently dominates the market with approximately 40% share, driven by rapid industrialization in China, Japan, and South Korea. North America and Europe follow with 28% and 24% market shares respectively, with particular strength in high-precision applications for medical devices and aerospace systems.

Customer requirements are increasingly focused on energy efficiency, with 68% of procurement specialists citing power optimization as a critical factor in motor control system selection. This trend aligns with global sustainability initiatives and regulatory pressures to reduce industrial energy consumption. Additionally, 73% of system integrators report that reliability and precision are non-negotiable requirements, particularly in applications where downtime carries significant financial consequences.

The market is also witnessing growing demand for integrated solutions that combine PID control with advanced features such as predictive maintenance capabilities, network connectivity, and compatibility with industrial IoT platforms. This evolution reflects the broader digital transformation occurring across manufacturing and process industries.

Current PID Implementation Challenges

Despite the widespread adoption of PID controllers in motor control and robotics, several significant implementation challenges persist that limit their optimal performance. One of the primary challenges is parameter tuning, which remains largely empirical and time-consuming. Engineers often resort to trial-and-error methods or heuristic approaches like Ziegler-Nichols, which may not yield optimal results across varying operating conditions. This manual tuning process becomes increasingly complex in multi-axis robotic systems where interdependencies between joints create cascading effects.

Environmental adaptability presents another substantial challenge. PID controllers configured for specific conditions often perform poorly when environmental factors change. Temperature variations, payload modifications, or mechanical wear can significantly alter system dynamics, requiring constant recalibration. This lack of adaptability is particularly problematic in field robotics and industrial automation where operating conditions frequently fluctuate.

Computational efficiency remains a concern in resource-constrained systems. While PID algorithms are relatively simple, high-frequency control loops in precision applications demand substantial processing power. This becomes especially challenging in embedded systems with limited computational resources, where engineers must balance control performance against power consumption and hardware costs.

Nonlinear system dynamics pose fundamental limitations to traditional PID implementations. Most robotic systems exhibit inherent nonlinearities due to friction, backlash, and complex kinematics. Standard PID controllers, designed for linear systems, struggle to maintain consistent performance across the entire operating range of these nonlinear systems, often requiring gain scheduling or more complex control architectures.

Noise sensitivity and signal quality issues further complicate PID implementation. Sensor noise can propagate through the derivative term, causing control instability. While filtering techniques can mitigate this problem, they introduce phase delays that compromise controller responsiveness. This trade-off between noise rejection and control bandwidth represents a persistent engineering challenge.

Integration windup occurs when actuators saturate but the controller continues to accumulate error. This leads to delayed response and potential instability when the system attempts to recover. Although anti-windup techniques exist, their implementation adds complexity and requires careful calibration to maintain overall system performance.

Finally, multi-objective control requirements often exceed the capabilities of standard PID architectures. Modern robotic applications frequently demand simultaneous optimization of multiple performance metrics—such as tracking accuracy, energy efficiency, and mechanical wear reduction—creating competing objectives that single-loop PID controllers struggle to balance effectively.

Environmental adaptability presents another substantial challenge. PID controllers configured for specific conditions often perform poorly when environmental factors change. Temperature variations, payload modifications, or mechanical wear can significantly alter system dynamics, requiring constant recalibration. This lack of adaptability is particularly problematic in field robotics and industrial automation where operating conditions frequently fluctuate.

Computational efficiency remains a concern in resource-constrained systems. While PID algorithms are relatively simple, high-frequency control loops in precision applications demand substantial processing power. This becomes especially challenging in embedded systems with limited computational resources, where engineers must balance control performance against power consumption and hardware costs.

Nonlinear system dynamics pose fundamental limitations to traditional PID implementations. Most robotic systems exhibit inherent nonlinearities due to friction, backlash, and complex kinematics. Standard PID controllers, designed for linear systems, struggle to maintain consistent performance across the entire operating range of these nonlinear systems, often requiring gain scheduling or more complex control architectures.

Noise sensitivity and signal quality issues further complicate PID implementation. Sensor noise can propagate through the derivative term, causing control instability. While filtering techniques can mitigate this problem, they introduce phase delays that compromise controller responsiveness. This trade-off between noise rejection and control bandwidth represents a persistent engineering challenge.

Integration windup occurs when actuators saturate but the controller continues to accumulate error. This leads to delayed response and potential instability when the system attempts to recover. Although anti-windup techniques exist, their implementation adds complexity and requires careful calibration to maintain overall system performance.

Finally, multi-objective control requirements often exceed the capabilities of standard PID architectures. Modern robotic applications frequently demand simultaneous optimization of multiple performance metrics—such as tracking accuracy, energy efficiency, and mechanical wear reduction—creating competing objectives that single-loop PID controllers struggle to balance effectively.

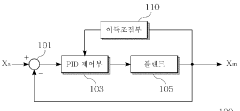

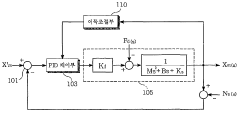

Modern PID Control Architectures

01 PID controller implementation for motor speed control

PID controllers are widely implemented for precise motor speed control in various applications. These systems use proportional, integral, and derivative control algorithms to maintain desired motor speeds by continuously adjusting control signals based on feedback from speed sensors. The implementation can be through hardware circuits or software algorithms that calculate the appropriate control signals to minimize speed errors and provide stable operation under varying load conditions.- PID controllers for motor speed control: PID controllers are widely used for precise motor speed control in various applications. These controllers continuously monitor the motor speed and adjust the control signal to maintain the desired speed. The proportional, integral, and derivative components of the controller work together to minimize error, eliminate steady-state offset, and improve response time. This approach ensures stable and accurate speed control even under varying load conditions.

- Adaptive PID control algorithms for speed regulation: Adaptive PID control algorithms automatically adjust their parameters based on system behavior and operating conditions. These algorithms can optimize control performance by modifying the proportional, integral, and derivative gains in real-time. This approach is particularly effective for systems with nonlinear characteristics or changing dynamics. Adaptive PID controllers provide improved speed regulation, faster response times, and better disturbance rejection compared to conventional fixed-parameter PID controllers.

- PID controllers for automotive engine speed control: PID controllers are implemented in automotive engine management systems to regulate engine speed. These controllers process inputs from various sensors to maintain optimal engine performance under different operating conditions. The control algorithms adjust fuel injection, ignition timing, and throttle position to achieve the desired engine speed. This approach improves fuel efficiency, reduces emissions, and enhances overall engine performance and drivability.

- Digital implementation of PID controllers for speed control: Digital implementations of PID controllers offer advantages for speed control applications, including improved precision, flexibility, and noise immunity. These controllers use microprocessors or digital signal processors to execute the control algorithms. Digital PID controllers can implement complex control strategies, store multiple parameter sets for different operating conditions, and provide diagnostic capabilities. They also facilitate integration with other digital systems and remote monitoring capabilities.

- Tuning methods for PID speed controllers: Various tuning methods are employed to optimize PID controller parameters for speed control applications. These methods include Ziegler-Nichols, Cohen-Coon, and auto-tuning algorithms that automatically determine appropriate proportional, integral, and derivative gains. Proper tuning ensures stable operation, minimal overshoot, fast response time, and good disturbance rejection. Advanced tuning techniques may incorporate fuzzy logic or neural networks to handle nonlinear systems and improve overall control performance.

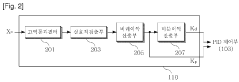

02 Adaptive and self-tuning PID control systems

Advanced PID control systems incorporate adaptive and self-tuning capabilities to optimize speed control performance. These systems can automatically adjust PID parameters based on changing operating conditions, system dynamics, or performance requirements. Self-tuning algorithms analyze system response and modify controller gains to maintain optimal performance, reducing the need for manual tuning and improving robustness against disturbances and parameter variations.Expand Specific Solutions03 PID control for automotive and engine speed applications

PID controllers are specifically designed for automotive and engine speed control applications. These systems regulate engine RPM, vehicle speed, or idle speed by processing feedback signals from sensors and generating appropriate control outputs. The controllers may include special features like anti-windup mechanisms, gain scheduling, or feedforward control to handle the nonlinear characteristics of engines and improve transient response during acceleration or deceleration events.Expand Specific Solutions04 Digital implementation and microcontroller-based PID speed control

Modern PID speed control systems are implemented using digital microcontrollers or embedded processors. These digital implementations offer advantages such as flexibility in algorithm modification, precise parameter tuning, and integration with other control functions. The systems typically include analog-to-digital converters for sensor inputs, digital signal processing for the PID algorithm, and pulse-width modulation outputs for actuator control, all managed by firmware that can be updated to improve performance.Expand Specific Solutions05 Industrial and specialized PID speed control applications

PID controllers are applied in specialized industrial settings for precise speed control of machinery and equipment. These applications include manufacturing systems, conveyor belts, robotics, and process control equipment where maintaining accurate speed is critical for product quality or operational safety. The controllers may incorporate industry-specific features such as communication protocols for integration with industrial networks, safety interlocks, or specialized filtering techniques to handle noise in harsh industrial environments.Expand Specific Solutions

Leading Companies in Motor Control Solutions

The PID controller market in motor speed control and robotics is currently in a growth phase, with increasing adoption across industrial automation, renewable energy, and automotive sectors. The market size is expanding due to the rising demand for precise motion control in robotics and manufacturing. Technologically, PID controllers have reached maturity with established players like FANUC, YASKAWA Electric, and Siemens leading innovation through advanced implementations. These companies offer sophisticated control systems integrating PID algorithms with AI and IoT capabilities. Meanwhile, automotive companies like Geely and Chery are increasingly incorporating PID-based systems in electric vehicles and autonomous driving technologies. Academic institutions such as Beihang University and Renmin University are contributing significant research to enhance PID controller performance and applications in next-generation robotics.

FANUC Corp.

Technical Solution: FANUC has developed advanced PID control systems for their robotic applications that focus on high-precision motion control. Their technology implements adaptive PID algorithms that automatically adjust parameters based on load variations and operational conditions. FANUC's controllers utilize a multi-loop control architecture where the position loop, velocity loop, and current loop are cascaded with individual PID parameters for each loop. This enables precise coordination of multiple robot axes simultaneously. Their latest servo systems incorporate feed-forward compensation alongside traditional PID control to minimize following errors during high-speed movements. FANUC has also implemented friction compensation algorithms that work in conjunction with PID control to overcome static and dynamic friction effects in robotic joints[1]. Their digital signal processors allow PID calculations to be performed at extremely high frequencies (up to 8kHz), enabling responsive control even in demanding industrial applications[3].

Strengths: Exceptional precision and repeatability in industrial robotics; robust performance across varying loads; advanced disturbance rejection capabilities. Weaknesses: Higher implementation complexity requiring specialized knowledge; premium pricing compared to simpler control solutions; requires periodic recalibration in certain applications.

Stäubli Faverges SCA

Technical Solution: Stäubli has developed sophisticated PID control systems for their high-precision industrial robots and automation solutions. Their technology implements a distributed control architecture where PID algorithms run on dedicated processors for each robot joint, enabling extremely fast control loops (up to 10kHz) for superior dynamic performance. Stäubli's controllers feature advanced trajectory generation that works in conjunction with PID control to achieve smooth acceleration profiles and minimize mechanical stress. Their proprietary "uniVAL drive" system implements cascaded PID loops with feed-forward compensation to achieve positioning accuracy down to micrometers even during continuous path operations. Stäubli has also developed specialized friction models that complement their PID controllers to compensate for non-linear behaviors in robotic joints, particularly important in their clean room and pharmaceutical applications where smooth motion is critical[9]. Their latest controllers incorporate learning algorithms that continuously refine PID parameters based on repetitive task execution, improving accuracy over time[10].

Strengths: Exceptional positioning accuracy and repeatability; superior performance in precision applications like electronics assembly; excellent path-following capabilities for continuous processes. Weaknesses: Higher system complexity requiring specialized maintenance; premium pricing positioning in the market; more complex setup and commissioning compared to standard industrial robots.

Critical PID Tuning Methodologies

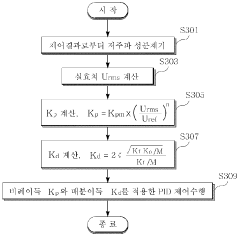

PID controller for controlling the motion of a motor and a control method thereof

PatentWO2011027933A1

Innovation

- A proportional calculus control device and method that calculates an effective value using a high-pass filter to determine adaptive proportional and differential gains, adjusting the control bandwidth to improve tracking performance and reduce hunting by applying an effective value-based gain scheduling algorithm.

Yaw control using mean motor speed reference as feedback

PatentPendingIN202217060104A

Innovation

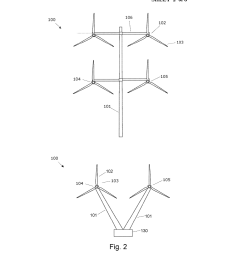

- A method is introduced where a motor controller calculates a mean motor speed reference to determine a required motor torque reference, creating a virtual master drive that ensures even load distribution among yaw drive actuators, with features like torque and speed limiting to prevent overloading and optimize power use, using a PID control and torque limiter to manage motor operations effectively.

Real-time Performance Metrics

Real-time performance metrics serve as critical indicators for evaluating PID controller effectiveness in motor speed control and robotics applications. These metrics provide immediate feedback on system behavior, allowing for dynamic adjustments and optimization of control parameters. The most fundamental metric is response time, which measures how quickly the controller can adjust motor speed to match the desired setpoint after receiving a command signal. In high-precision robotics, response times of milliseconds or microseconds are often required to ensure smooth operation.

Error metrics constitute another essential category, with steady-state error measuring the difference between the desired and actual motor speed during stable operation. For robotic applications requiring precise positioning, steady-state errors must typically remain below 1% to maintain accuracy. Overshoot percentage quantifies how much the system exceeds the target value before stabilizing, with lower values indicating better damping characteristics and reduced oscillation.

Settling time represents the duration required for motor speed to reach and remain within a specified tolerance band of the target value. This metric directly impacts operational efficiency in robotics, as shorter settling times enable faster task execution and transitions between movements. For industrial robots performing repetitive tasks, optimized settling times can significantly increase throughput.

Stability margins, including phase margin and gain margin, provide crucial information about the robustness of the control system against disturbances and parameter variations. Higher stability margins indicate greater resilience to unexpected loads or mechanical variations, which is particularly important in variable-environment robotics applications.

Energy consumption metrics track the power efficiency of the control system, measuring how much electrical energy is required to maintain desired motor speeds. This becomes increasingly important in battery-powered robotic systems where energy conservation directly impacts operational duration. Advanced PID implementations often incorporate energy optimization algorithms that balance performance requirements against power constraints.

Jitter measurement quantifies the consistency of control loop execution timing, with lower jitter values indicating more predictable system behavior. In collaborative robotics where humans and machines work together, consistent timing is essential for safety and coordination. Modern control systems typically aim for jitter values below 1% of the control cycle time to ensure reliable operation.

These real-time metrics collectively provide a comprehensive framework for evaluating and optimizing PID controller performance in motor control applications, enabling engineers to fine-tune parameters for specific robotic requirements and operational conditions.

Error metrics constitute another essential category, with steady-state error measuring the difference between the desired and actual motor speed during stable operation. For robotic applications requiring precise positioning, steady-state errors must typically remain below 1% to maintain accuracy. Overshoot percentage quantifies how much the system exceeds the target value before stabilizing, with lower values indicating better damping characteristics and reduced oscillation.

Settling time represents the duration required for motor speed to reach and remain within a specified tolerance band of the target value. This metric directly impacts operational efficiency in robotics, as shorter settling times enable faster task execution and transitions between movements. For industrial robots performing repetitive tasks, optimized settling times can significantly increase throughput.

Stability margins, including phase margin and gain margin, provide crucial information about the robustness of the control system against disturbances and parameter variations. Higher stability margins indicate greater resilience to unexpected loads or mechanical variations, which is particularly important in variable-environment robotics applications.

Energy consumption metrics track the power efficiency of the control system, measuring how much electrical energy is required to maintain desired motor speeds. This becomes increasingly important in battery-powered robotic systems where energy conservation directly impacts operational duration. Advanced PID implementations often incorporate energy optimization algorithms that balance performance requirements against power constraints.

Jitter measurement quantifies the consistency of control loop execution timing, with lower jitter values indicating more predictable system behavior. In collaborative robotics where humans and machines work together, consistent timing is essential for safety and coordination. Modern control systems typically aim for jitter values below 1% of the control cycle time to ensure reliable operation.

These real-time metrics collectively provide a comprehensive framework for evaluating and optimizing PID controller performance in motor control applications, enabling engineers to fine-tune parameters for specific robotic requirements and operational conditions.

Safety Standards in Robotic Control Systems

Safety standards in robotic control systems have evolved significantly with the integration of PID controllers in motor speed control applications. These standards are critical for ensuring that robotic systems operate safely in various environments, particularly when human-robot interaction is involved. The International Organization for Standardization (ISO) has established several key standards, including ISO 10218 and ISO/TS 15066, which specifically address safety requirements for industrial robots and collaborative robot systems.

PID controllers play a crucial role in maintaining safety parameters by providing precise control over motor speed and position. This precision enables robots to operate within defined safety boundaries, preventing unexpected movements that could pose risks to humans or equipment. The implementation of safety-rated PID control loops ensures that when a safety violation is detected, the system can respond with appropriate deceleration profiles rather than abrupt stops that might cause mechanical stress or instability.

Risk assessment methodologies for robotic systems with PID controllers have become increasingly sophisticated. These assessments consider factors such as maximum allowable speed, torque limitations, and emergency stop capabilities. Modern safety standards require redundant monitoring systems that continuously verify the performance of PID controllers, ensuring they maintain operation within safety parameters even under fault conditions.

Functional safety standards like IEC 61508 and its application-specific derivative IEC 62061 provide frameworks for ensuring that control systems, including PID implementations, achieve required safety integrity levels (SIL). These standards mandate systematic approaches to identifying potential failure modes in control algorithms and implementing appropriate mitigation strategies.

The emergence of collaborative robotics has introduced new safety paradigms where PID controllers must balance performance with safety constraints. Power and force limiting features, often implemented through modified PID control strategies, allow robots to detect collisions and respond appropriately by reducing force or stopping movement. These capabilities are essential for compliance with ISO/TS 15066, which specifies safety requirements for collaborative robot applications.

Safety certification processes for robotic control systems require extensive validation of PID controller performance under various operating conditions and failure scenarios. This includes testing response times, stability margins, and behavior during component failures. Documentation of these tests and the underlying control algorithms is mandatory for regulatory approval in many industries, particularly in medical robotics, automotive manufacturing, and aerospace applications.

As robotics continues to expand into new domains, safety standards are evolving to address emerging challenges, including the integration of artificial intelligence with traditional PID control systems. These hybrid approaches must maintain the deterministic safety guarantees of conventional control while leveraging the adaptability of modern machine learning techniques.

PID controllers play a crucial role in maintaining safety parameters by providing precise control over motor speed and position. This precision enables robots to operate within defined safety boundaries, preventing unexpected movements that could pose risks to humans or equipment. The implementation of safety-rated PID control loops ensures that when a safety violation is detected, the system can respond with appropriate deceleration profiles rather than abrupt stops that might cause mechanical stress or instability.

Risk assessment methodologies for robotic systems with PID controllers have become increasingly sophisticated. These assessments consider factors such as maximum allowable speed, torque limitations, and emergency stop capabilities. Modern safety standards require redundant monitoring systems that continuously verify the performance of PID controllers, ensuring they maintain operation within safety parameters even under fault conditions.

Functional safety standards like IEC 61508 and its application-specific derivative IEC 62061 provide frameworks for ensuring that control systems, including PID implementations, achieve required safety integrity levels (SIL). These standards mandate systematic approaches to identifying potential failure modes in control algorithms and implementing appropriate mitigation strategies.

The emergence of collaborative robotics has introduced new safety paradigms where PID controllers must balance performance with safety constraints. Power and force limiting features, often implemented through modified PID control strategies, allow robots to detect collisions and respond appropriately by reducing force or stopping movement. These capabilities are essential for compliance with ISO/TS 15066, which specifies safety requirements for collaborative robot applications.

Safety certification processes for robotic control systems require extensive validation of PID controller performance under various operating conditions and failure scenarios. This includes testing response times, stability margins, and behavior during component failures. Documentation of these tests and the underlying control algorithms is mandatory for regulatory approval in many industries, particularly in medical robotics, automotive manufacturing, and aerospace applications.

As robotics continues to expand into new domains, safety standards are evolving to address emerging challenges, including the integration of artificial intelligence with traditional PID control systems. These hybrid approaches must maintain the deterministic safety guarantees of conventional control while leveraging the adaptability of modern machine learning techniques.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!