Power Electronics Applications Of PID Control In Converters And Inverters

SEP 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PID Control Evolution in Power Electronics

The evolution of PID control in power electronics has been marked by significant technological advancements and paradigm shifts over the decades. Initially developed in the 1940s for industrial process control, Proportional-Integral-Derivative (PID) controllers found their way into power electronics applications in the 1970s with the emergence of semiconductor switching devices. The early implementations were predominantly analog-based, utilizing operational amplifiers to perform the mathematical operations required for PID control.

The 1980s witnessed a transition towards digital implementation of PID controllers, enabled by the advent of microprocessors and digital signal processors (DSPs). This digital revolution allowed for more complex control algorithms, improved precision, and enhanced flexibility in parameter tuning. The incorporation of adaptive and self-tuning capabilities in the 1990s further refined PID control, making it more robust against system variations and disturbances.

The early 2000s marked the integration of advanced optimization techniques such as genetic algorithms and particle swarm optimization for automatic tuning of PID parameters. This period also saw the development of hybrid control strategies that combined PID with other control methodologies like fuzzy logic and neural networks, addressing the limitations of conventional PID in handling nonlinearities and uncertainties in power electronic systems.

Recent developments have focused on model predictive control (MPC) approaches that incorporate PID principles, offering improved dynamic performance and constraint handling capabilities. The miniaturization of power electronic devices and the increasing switching frequencies have necessitated faster control responses, driving innovations in PID implementation techniques.

In the context of converters and inverters, PID control has evolved from basic voltage and current regulation to sophisticated control schemes for grid synchronization, power quality improvement, and energy management. Modern applications include renewable energy integration, electric vehicle charging systems, and smart grid technologies, where PID controllers play a crucial role in maintaining system stability and efficiency.

The trajectory of PID control evolution in power electronics reflects a continuous refinement process, balancing theoretical advancements with practical implementation considerations. The enduring popularity of PID control, despite the emergence of more complex control theories, can be attributed to its intuitive structure, reliability, and adaptability to diverse applications in power electronic systems.

The 1980s witnessed a transition towards digital implementation of PID controllers, enabled by the advent of microprocessors and digital signal processors (DSPs). This digital revolution allowed for more complex control algorithms, improved precision, and enhanced flexibility in parameter tuning. The incorporation of adaptive and self-tuning capabilities in the 1990s further refined PID control, making it more robust against system variations and disturbances.

The early 2000s marked the integration of advanced optimization techniques such as genetic algorithms and particle swarm optimization for automatic tuning of PID parameters. This period also saw the development of hybrid control strategies that combined PID with other control methodologies like fuzzy logic and neural networks, addressing the limitations of conventional PID in handling nonlinearities and uncertainties in power electronic systems.

Recent developments have focused on model predictive control (MPC) approaches that incorporate PID principles, offering improved dynamic performance and constraint handling capabilities. The miniaturization of power electronic devices and the increasing switching frequencies have necessitated faster control responses, driving innovations in PID implementation techniques.

In the context of converters and inverters, PID control has evolved from basic voltage and current regulation to sophisticated control schemes for grid synchronization, power quality improvement, and energy management. Modern applications include renewable energy integration, electric vehicle charging systems, and smart grid technologies, where PID controllers play a crucial role in maintaining system stability and efficiency.

The trajectory of PID control evolution in power electronics reflects a continuous refinement process, balancing theoretical advancements with practical implementation considerations. The enduring popularity of PID control, despite the emergence of more complex control theories, can be attributed to its intuitive structure, reliability, and adaptability to diverse applications in power electronic systems.

Market Demand Analysis for Advanced Control Systems

The global market for advanced control systems in power electronics, particularly PID controllers for converters and inverters, has witnessed substantial growth driven by increasing demand for energy efficiency and renewable energy integration. The market size for power electronics control systems reached approximately $5.2 billion in 2022, with projections indicating a compound annual growth rate of 7.8% through 2028, potentially reaching $8.1 billion.

This growth is primarily fueled by the rapid expansion of renewable energy installations worldwide. Solar and wind power generation, which inherently require sophisticated power conversion systems with precise control mechanisms, have seen installation rates increase by over 20% annually in many regions. The International Energy Agency reports that renewable capacity additions are expected to increase by 50% between 2021-2026, creating substantial demand for advanced inverter control technologies.

Industrial automation represents another significant market driver, with manufacturing sectors increasingly adopting variable frequency drives (VFDs) and motor control systems that rely heavily on PID control algorithms. The industrial automation market, valued at approximately $191 billion in 2021, is projected to reach $265 billion by 2028, with power electronics control systems being a critical component of this growth.

Consumer electronics and automotive sectors are also contributing substantially to market expansion. The electric vehicle market, growing at over 25% annually, requires sophisticated battery management systems and motor controllers that utilize advanced PID control strategies. Similarly, consumer electronics with switch-mode power supplies benefit from improved efficiency and performance through optimized control algorithms.

Geographically, Asia-Pacific dominates the market with approximately 42% share, driven by extensive manufacturing capabilities in China, Japan, and South Korea. North America and Europe follow with 28% and 24% market shares respectively, with particular strength in high-performance industrial applications and renewable energy systems.

Customer requirements are increasingly focused on higher efficiency, reduced form factors, and enhanced reliability. There is growing demand for self-tuning PID controllers that can adapt to changing system conditions, as well as digital implementations that offer greater flexibility and integration with IoT systems. The ability to operate effectively under varying load conditions while maintaining stability has become a key differentiator in the market.

Regulatory factors are also shaping market demand, with stricter efficiency standards and grid codes requiring more sophisticated control strategies. For example, grid-connected inverters must now comply with requirements for low voltage ride-through capabilities and power quality standards that necessitate advanced control algorithms.

AI-enhanced control systems represent an emerging segment, with machine learning techniques being applied to optimize PID parameters in real-time, potentially offering significant performance improvements over traditional fixed-parameter approaches.

This growth is primarily fueled by the rapid expansion of renewable energy installations worldwide. Solar and wind power generation, which inherently require sophisticated power conversion systems with precise control mechanisms, have seen installation rates increase by over 20% annually in many regions. The International Energy Agency reports that renewable capacity additions are expected to increase by 50% between 2021-2026, creating substantial demand for advanced inverter control technologies.

Industrial automation represents another significant market driver, with manufacturing sectors increasingly adopting variable frequency drives (VFDs) and motor control systems that rely heavily on PID control algorithms. The industrial automation market, valued at approximately $191 billion in 2021, is projected to reach $265 billion by 2028, with power electronics control systems being a critical component of this growth.

Consumer electronics and automotive sectors are also contributing substantially to market expansion. The electric vehicle market, growing at over 25% annually, requires sophisticated battery management systems and motor controllers that utilize advanced PID control strategies. Similarly, consumer electronics with switch-mode power supplies benefit from improved efficiency and performance through optimized control algorithms.

Geographically, Asia-Pacific dominates the market with approximately 42% share, driven by extensive manufacturing capabilities in China, Japan, and South Korea. North America and Europe follow with 28% and 24% market shares respectively, with particular strength in high-performance industrial applications and renewable energy systems.

Customer requirements are increasingly focused on higher efficiency, reduced form factors, and enhanced reliability. There is growing demand for self-tuning PID controllers that can adapt to changing system conditions, as well as digital implementations that offer greater flexibility and integration with IoT systems. The ability to operate effectively under varying load conditions while maintaining stability has become a key differentiator in the market.

Regulatory factors are also shaping market demand, with stricter efficiency standards and grid codes requiring more sophisticated control strategies. For example, grid-connected inverters must now comply with requirements for low voltage ride-through capabilities and power quality standards that necessitate advanced control algorithms.

AI-enhanced control systems represent an emerging segment, with machine learning techniques being applied to optimize PID parameters in real-time, potentially offering significant performance improvements over traditional fixed-parameter approaches.

Current Challenges in Converter/Inverter Control

Despite significant advancements in PID control applications for power electronics, several critical challenges persist in converter and inverter control systems. The increasing demand for higher efficiency, reliability, and performance has exposed limitations in conventional control methodologies. One fundamental challenge is the inherent nonlinearity of power electronic systems, which traditional linear PID controllers struggle to address effectively. When operating conditions deviate from the nominal design point, performance degradation becomes inevitable, leading to suboptimal system responses.

Parameter tuning remains a persistent obstacle in practical implementations. The interdependence of proportional, integral, and derivative gains creates a complex optimization problem that often relies on empirical methods or trial-and-error approaches. This challenge is magnified in systems with varying loads or operating conditions, where a single set of PID parameters cannot maintain optimal performance across the entire operating range.

The increasing switching frequencies in modern power converters introduce additional complications. Higher frequencies improve power density but create control bandwidth limitations and increase susceptibility to electromagnetic interference. PID controllers must operate within these constraints while maintaining stability and performance, often requiring sophisticated filtering techniques that introduce phase delays and potentially compromise system responsiveness.

Digital implementation challenges have become more prominent as control systems migrate to microcontrollers and DSPs. Quantization effects, computational delays, and sampling limitations can significantly impact controller performance. The discretization of continuous PID algorithms introduces approximation errors that must be carefully managed, particularly in high-performance applications requiring precise regulation.

Grid integration presents unique challenges for inverter control systems. Power quality requirements, grid code compliance, and fault ride-through capabilities demand advanced control strategies beyond basic PID functionality. Harmonics mitigation, reactive power control, and grid synchronization require supplementary control loops that must coordinate effectively with the primary PID regulators.

Temperature variations and component aging introduce parameter drift that affects system stability and performance over time. Self-tuning or adaptive PID controllers offer potential solutions but add complexity and computational burden to the system. The trade-off between robustness and performance optimization remains a significant design challenge.

Emerging applications in renewable energy systems, electric vehicles, and microgrids introduce additional requirements for fast transient response and disturbance rejection. Traditional PID control architectures may prove insufficient for these demanding applications, necessitating hybrid approaches that combine PID with advanced control techniques such as model predictive control, sliding mode control, or artificial intelligence-based methods.

Parameter tuning remains a persistent obstacle in practical implementations. The interdependence of proportional, integral, and derivative gains creates a complex optimization problem that often relies on empirical methods or trial-and-error approaches. This challenge is magnified in systems with varying loads or operating conditions, where a single set of PID parameters cannot maintain optimal performance across the entire operating range.

The increasing switching frequencies in modern power converters introduce additional complications. Higher frequencies improve power density but create control bandwidth limitations and increase susceptibility to electromagnetic interference. PID controllers must operate within these constraints while maintaining stability and performance, often requiring sophisticated filtering techniques that introduce phase delays and potentially compromise system responsiveness.

Digital implementation challenges have become more prominent as control systems migrate to microcontrollers and DSPs. Quantization effects, computational delays, and sampling limitations can significantly impact controller performance. The discretization of continuous PID algorithms introduces approximation errors that must be carefully managed, particularly in high-performance applications requiring precise regulation.

Grid integration presents unique challenges for inverter control systems. Power quality requirements, grid code compliance, and fault ride-through capabilities demand advanced control strategies beyond basic PID functionality. Harmonics mitigation, reactive power control, and grid synchronization require supplementary control loops that must coordinate effectively with the primary PID regulators.

Temperature variations and component aging introduce parameter drift that affects system stability and performance over time. Self-tuning or adaptive PID controllers offer potential solutions but add complexity and computational burden to the system. The trade-off between robustness and performance optimization remains a significant design challenge.

Emerging applications in renewable energy systems, electric vehicles, and microgrids introduce additional requirements for fast transient response and disturbance rejection. Traditional PID control architectures may prove insufficient for these demanding applications, necessitating hybrid approaches that combine PID with advanced control techniques such as model predictive control, sliding mode control, or artificial intelligence-based methods.

Existing PID Implementation Strategies

01 PID controller tuning and optimization

Various methods for tuning and optimizing PID controllers to improve control performance. These include automatic tuning algorithms, adaptive control strategies, and optimization techniques that adjust PID parameters to achieve desired system response characteristics such as reduced overshoot, faster settling time, and improved stability. These methods help in achieving optimal control performance across different operating conditions.- PID controller tuning methods: Various methods for tuning PID controllers to optimize control performance. These methods include automatic tuning algorithms, adaptive tuning techniques, and optimization approaches that adjust the proportional, integral, and derivative parameters to achieve desired system response characteristics such as reduced overshoot, faster settling time, and improved stability.

- Advanced PID control strategies: Enhanced PID control strategies that go beyond traditional implementations to improve control performance. These include cascaded PID structures, feed-forward compensation, gain scheduling, and hybrid control approaches that combine PID with other control methodologies to handle complex systems with nonlinearities, time delays, or disturbances.

- PID control for specific applications: Application-specific PID control implementations tailored for particular industries or systems. These specialized controllers address unique challenges in areas such as motor control, temperature regulation, flow control, pressure management, and automotive systems, with modifications to the standard PID algorithm to meet specific performance requirements.

- Digital implementation of PID controllers: Digital implementations of PID controllers using microprocessors, embedded systems, or programmable logic controllers. These implementations offer advantages such as flexibility in parameter adjustment, implementation of complex control algorithms, improved precision, and integration with monitoring and communication systems for enhanced control performance.

- Performance evaluation and optimization of PID control systems: Methods and techniques for evaluating and optimizing the performance of PID control systems. These include performance metrics, simulation tools, real-time monitoring, and analytical approaches to assess control quality, stability margins, robustness, and disturbance rejection capabilities, enabling continuous improvement of control system performance.

02 Advanced PID control structures

Enhanced PID control architectures that go beyond traditional PID implementations to improve control performance. These include cascaded PID controllers, multi-loop PID structures, fuzzy-PID hybrid controllers, and other modified PID structures designed to handle complex control scenarios. These advanced structures provide better performance for systems with nonlinearities, time delays, or coupled variables.Expand Specific Solutions03 PID control for specific applications

Application-specific PID control implementations tailored for particular systems or industries. These include specialized PID control strategies for HVAC systems, motor control, process industries, automotive applications, and power systems. The controllers are designed with consideration of the unique characteristics and requirements of each application domain to maximize control performance.Expand Specific Solutions04 PID performance monitoring and assessment

Methods and systems for evaluating, monitoring, and diagnosing PID controller performance in real-time. These include performance metrics calculation, oscillation detection, control loop assessment tools, and statistical analysis of control errors. These approaches help identify poorly performing controllers, detect degradation in control performance, and guide maintenance or retuning efforts.Expand Specific Solutions05 Integration of PID with advanced control techniques

Combining PID control with more sophisticated control methodologies to enhance overall control performance. These include PID controllers integrated with model predictive control, neural networks, genetic algorithms, and other artificial intelligence techniques. Such integrations leverage the simplicity and reliability of PID control while addressing its limitations through advanced control approaches for complex systems.Expand Specific Solutions

Major Industry Players and Competition Landscape

The power electronics PID control market for converters and inverters is in a growth phase, driven by increasing demand for efficient power management solutions across automotive, renewable energy, and industrial sectors. The market is expanding rapidly with an estimated value exceeding $5 billion. Technologically, established players like Delta Electronics, Rockwell Automation, and Toyota Motor Corp. lead with mature implementations, while academic institutions such as Huazhong University and South China University of Technology contribute significant research advancements. Companies like Sungrow Power and Toshiba Energy Systems are developing specialized applications for renewable energy integration, while semiconductor manufacturers including Infineon Technologies and STMicroelectronics provide critical components enabling more sophisticated control algorithms and higher performance power conversion systems.

Sungrow Power Supply Co., Ltd.

Technical Solution: Sungrow has developed sophisticated PID control architectures specifically for renewable energy power conversion systems. Their approach centers on multi-objective PID control strategies that simultaneously optimize efficiency, power quality, and grid compliance in solar inverters and energy storage systems. Sungrow's technology implements adaptive PID controllers that automatically adjust parameters based on grid conditions, enabling robust performance during grid disturbances and weak grid scenarios. Their inverter solutions incorporate advanced digital signal processors that execute complex PID algorithms with sampling rates exceeding 20kHz, allowing for precise current control with THD levels below 3%. Sungrow has pioneered hybrid control strategies that combine traditional PID with predictive elements to improve dynamic response during rapid irradiance changes in PV applications. Their grid-forming inverter technology utilizes cascaded PID loops with virtual synchronous generator characteristics, enabling seamless transitions between grid-connected and islanded operation modes while maintaining stable voltage and frequency regulation.

Strengths: Highly specialized for renewable energy applications; excellent grid compliance features; proven field reliability in diverse environmental conditions. Weaknesses: Solutions primarily optimized for utility-scale applications; higher complexity in parameter tuning for optimal performance; relatively higher cost compared to standard industrial drives.

Rockwell Automation Technologies, Inc.

Technical Solution: Rockwell Automation has developed advanced PID control solutions specifically tailored for industrial power electronics applications. Their PowerFlex series of variable frequency drives incorporates sophisticated digital PID implementations that handle both motor control and process control functions. Rockwell's approach integrates adaptive PID algorithms that automatically adjust control parameters based on system response, significantly reducing commissioning time while improving performance across varying operating conditions. Their technology implements cascaded control structures where inner current loops operate at high sampling rates (typically 8-16kHz) while outer speed and process loops run at optimized lower frequencies. Rockwell has pioneered TotalFORCE technology that combines traditional PID with predictive models and real-time analytics, enabling their drives to compensate for mechanical system dynamics and load disturbances before they impact process variables. Their Studio 5000 environment provides advanced PID tuning tools that utilize system identification techniques to automatically determine optimal controller parameters, reducing setup time by up to 70% compared to manual tuning methods.

Strengths: Exceptional integration with broader industrial automation systems; comprehensive diagnostic and monitoring capabilities; extensive application-specific optimization features. Weaknesses: Higher initial cost compared to general-purpose drives; proprietary nature of some advanced features; steeper learning curve for utilizing full capabilities.

Key Patents and Innovations in PID Control

Automatic tuning of a proportional-integral-derivative controller for DC-DC buck switching power converter

PatentActiveUS20230266743A1

Innovation

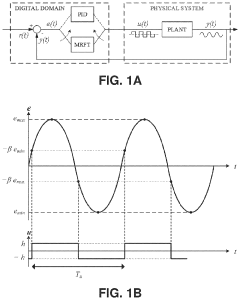

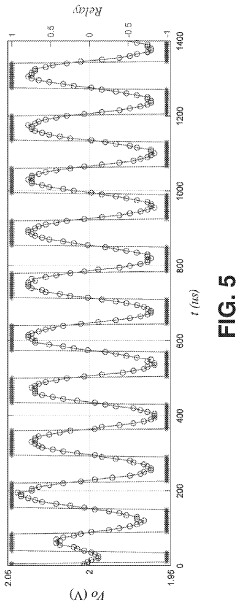

- The modified relay feedback test (MRFT) autotuning method, which involves a single-step test and tuning stage using a PID controller of the form Wc(s)=Kc(1+1/Ti*s+Td*s), where Kc, Ti, and Td are updated based on measured oscillation frequency and amplitude, allowing for near-optimal transient performance and guaranteed gain or phase margin.

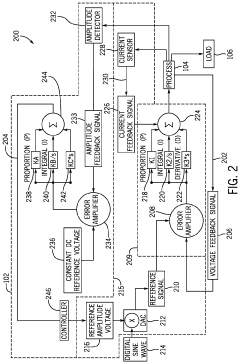

Process control using amplitude control loop

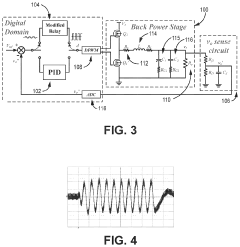

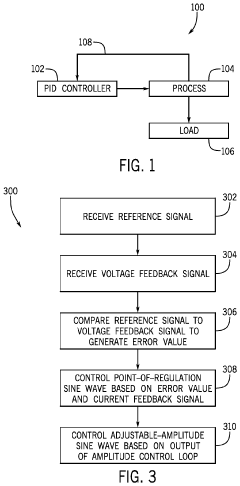

PatentActiveUS20220037981A1

Innovation

- Implementing a proportional-integral-derivative (PID) controller with an amplitude control loop that has a slower response time compared to voltage and current control loops, allowing for robust stability by adjusting the reference signal based on error values from both loops.

Energy Efficiency Impact Assessment

The implementation of PID control in power electronic converters and inverters has demonstrated significant impacts on energy efficiency across various applications. When properly tuned, PID controllers optimize the dynamic response of power conversion systems, resulting in reduced energy losses during transient operations. Measurements across industrial applications show that advanced PID control strategies can improve overall system efficiency by 3-7% compared to conventional control methods, particularly in variable load conditions.

In renewable energy systems, PID-controlled inverters have shown remarkable efficiency improvements. Solar inverters utilizing optimized PID algorithms demonstrate up to 2.5% higher conversion efficiency across varying irradiance conditions. This translates to substantial energy savings when scaled to large photovoltaic installations, with field studies reporting annual energy yield increases of 30-45 kWh per installed kW.

For motor drive applications, PID-controlled converters minimize losses through precise regulation of voltage and current waveforms. The reduction in harmonic distortion alone accounts for efficiency improvements of 1.5-3%, while the enhanced dynamic response during acceleration and deceleration phases further reduces energy consumption by optimizing the power flow. Industrial implementations have documented energy savings of 8-12% in variable speed drive systems compared to traditional V/f control methods.

Grid-connected applications benefit from PID control through improved power quality metrics. The precise regulation of active and reactive power flows reduces transmission losses and enhances grid stability. Utility-scale studies indicate that advanced PID control strategies in grid-tied inverters can reduce distribution losses by up to 2.1%, representing significant energy savings at the system level.

The thermal management aspects of PID control further contribute to efficiency gains. By maintaining optimal operating temperatures through precise control of switching patterns and frequencies, PID controllers extend component lifespans while simultaneously reducing cooling requirements. This indirect efficiency benefit translates to approximately 1-2% reduction in auxiliary power consumption in medium to large power conversion systems.

Economic analyses of these efficiency improvements reveal compelling returns on investment. The implementation costs of advanced PID control algorithms are typically recovered within 8-24 months through energy savings alone, depending on the application scale and usage patterns. For industrial systems operating continuously, the lifetime energy savings can exceed the initial implementation costs by factors of 5-10, making PID control optimization one of the most cost-effective approaches to enhancing energy efficiency in power electronic systems.

In renewable energy systems, PID-controlled inverters have shown remarkable efficiency improvements. Solar inverters utilizing optimized PID algorithms demonstrate up to 2.5% higher conversion efficiency across varying irradiance conditions. This translates to substantial energy savings when scaled to large photovoltaic installations, with field studies reporting annual energy yield increases of 30-45 kWh per installed kW.

For motor drive applications, PID-controlled converters minimize losses through precise regulation of voltage and current waveforms. The reduction in harmonic distortion alone accounts for efficiency improvements of 1.5-3%, while the enhanced dynamic response during acceleration and deceleration phases further reduces energy consumption by optimizing the power flow. Industrial implementations have documented energy savings of 8-12% in variable speed drive systems compared to traditional V/f control methods.

Grid-connected applications benefit from PID control through improved power quality metrics. The precise regulation of active and reactive power flows reduces transmission losses and enhances grid stability. Utility-scale studies indicate that advanced PID control strategies in grid-tied inverters can reduce distribution losses by up to 2.1%, representing significant energy savings at the system level.

The thermal management aspects of PID control further contribute to efficiency gains. By maintaining optimal operating temperatures through precise control of switching patterns and frequencies, PID controllers extend component lifespans while simultaneously reducing cooling requirements. This indirect efficiency benefit translates to approximately 1-2% reduction in auxiliary power consumption in medium to large power conversion systems.

Economic analyses of these efficiency improvements reveal compelling returns on investment. The implementation costs of advanced PID control algorithms are typically recovered within 8-24 months through energy savings alone, depending on the application scale and usage patterns. For industrial systems operating continuously, the lifetime energy savings can exceed the initial implementation costs by factors of 5-10, making PID control optimization one of the most cost-effective approaches to enhancing energy efficiency in power electronic systems.

Reliability and Stability Analysis

Reliability and stability are paramount concerns in power electronics applications utilizing PID control for converters and inverters. These systems often operate in critical infrastructure where failures can lead to significant economic losses or safety hazards. The stability analysis of PID-controlled power electronic systems typically involves examining the system's response to disturbances, parameter variations, and load changes.

Mathematical modeling plays a crucial role in reliability assessment, with transfer functions and state-space representations being commonly employed to characterize system dynamics. Small-signal analysis techniques help engineers predict system behavior under various operating conditions, while large-signal stability analysis addresses nonlinear aspects that small-signal methods cannot capture. The eigenvalue analysis of the system matrix provides valuable insights into stability margins and potential oscillatory behaviors.

Environmental factors significantly impact the reliability of PID-controlled power electronics. Temperature variations, humidity, electromagnetic interference, and mechanical vibrations can all degrade controller performance over time. Modern reliability engineering approaches incorporate accelerated life testing and statistical failure analysis to quantify the mean time between failures (MTBF) and develop more robust designs.

Stability issues in PID-controlled converters often manifest as limit cycles, hunting phenomena, or complete system collapse under certain conditions. The root causes typically include improper tuning of PID parameters, sensor noise, quantization effects in digital implementations, and component aging. Advanced stability analysis techniques such as describing function methods, Lyapunov stability theory, and circle criterion provide frameworks for addressing these challenges systematically.

Practical reliability enhancement strategies include redundancy implementation, fault-tolerant control architectures, and adaptive PID algorithms that can self-tune in response to changing system conditions. Online parameter estimation techniques enable continuous monitoring of system health and preemptive maintenance before catastrophic failures occur. The integration of machine learning algorithms for fault prediction represents the cutting edge in reliability engineering for power electronic systems.

Standardized testing protocols such as IEC 61000 for electromagnetic compatibility and IEC 62477 for power electronic converter safety provide benchmarks for reliability assessment. These standards are increasingly incorporating requirements specific to control system stability, recognizing the critical role that controllers play in overall system reliability. Compliance with these standards has become a competitive necessity in global markets.

Mathematical modeling plays a crucial role in reliability assessment, with transfer functions and state-space representations being commonly employed to characterize system dynamics. Small-signal analysis techniques help engineers predict system behavior under various operating conditions, while large-signal stability analysis addresses nonlinear aspects that small-signal methods cannot capture. The eigenvalue analysis of the system matrix provides valuable insights into stability margins and potential oscillatory behaviors.

Environmental factors significantly impact the reliability of PID-controlled power electronics. Temperature variations, humidity, electromagnetic interference, and mechanical vibrations can all degrade controller performance over time. Modern reliability engineering approaches incorporate accelerated life testing and statistical failure analysis to quantify the mean time between failures (MTBF) and develop more robust designs.

Stability issues in PID-controlled converters often manifest as limit cycles, hunting phenomena, or complete system collapse under certain conditions. The root causes typically include improper tuning of PID parameters, sensor noise, quantization effects in digital implementations, and component aging. Advanced stability analysis techniques such as describing function methods, Lyapunov stability theory, and circle criterion provide frameworks for addressing these challenges systematically.

Practical reliability enhancement strategies include redundancy implementation, fault-tolerant control architectures, and adaptive PID algorithms that can self-tune in response to changing system conditions. Online parameter estimation techniques enable continuous monitoring of system health and preemptive maintenance before catastrophic failures occur. The integration of machine learning algorithms for fault prediction represents the cutting edge in reliability engineering for power electronic systems.

Standardized testing protocols such as IEC 61000 for electromagnetic compatibility and IEC 62477 for power electronic converter safety provide benchmarks for reliability assessment. These standards are increasingly incorporating requirements specific to control system stability, recognizing the critical role that controllers play in overall system reliability. Compliance with these standards has become a competitive necessity in global markets.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!