PID Controller Response To Setpoint Changes In Dynamic Systems

SEP 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PID Control Evolution and Objectives

Proportional-Integral-Derivative (PID) control has evolved significantly since its inception in the early 20th century. Initially developed for ship steering mechanisms by Nicholas Minorsky in 1922, PID controllers have become the most widely implemented control algorithm across industrial applications. The fundamental principle of PID control—combining proportional, integral, and derivative actions to minimize error between a measured process variable and desired setpoint—has remained consistent, though implementation methods have transformed dramatically.

The evolution of PID control can be traced through several distinct phases. The first generation utilized pneumatic and mechanical systems, where physical components represented each control action. The second phase emerged with the advent of electronic analog controllers in the mid-20th century, enabling more precise control and wider application scope. The digital revolution of the 1970s and 1980s marked the third major transition, as microprocessor-based implementations allowed for software-defined control parameters and advanced tuning capabilities.

Modern PID controllers represent the culmination of this evolutionary process, incorporating adaptive algorithms, auto-tuning capabilities, and integration with complex control systems. This progression has been driven by increasing demands for precision, stability, and responsiveness across diverse industrial applications, from manufacturing processes to autonomous vehicles.

The primary objective of PID control in dynamic systems is to achieve optimal response characteristics when setpoint changes occur. This includes minimizing settling time—the duration required for the system to reach and maintain a state close to the new setpoint—while simultaneously reducing overshoot, which can cause system instability or component stress. Additionally, PID controllers aim to eliminate steady-state error, ensuring the system accurately achieves the desired setpoint value over time.

Another critical objective is robustness against disturbances and system parameter variations. Effective PID controllers must maintain performance despite external influences or changes in the controlled system's characteristics. This becomes particularly challenging in non-linear systems where the relationship between control input and system response varies across operating conditions.

The technical evolution continues today with research focused on addressing specific limitations in traditional PID implementations. Current development trends include model-predictive PID variants, which incorporate system models to anticipate future behavior; fractional-order PID controllers that extend mathematical operations beyond integer-order derivatives and integrals; and hybrid approaches combining PID with artificial intelligence techniques such as fuzzy logic and neural networks.

The evolution of PID control can be traced through several distinct phases. The first generation utilized pneumatic and mechanical systems, where physical components represented each control action. The second phase emerged with the advent of electronic analog controllers in the mid-20th century, enabling more precise control and wider application scope. The digital revolution of the 1970s and 1980s marked the third major transition, as microprocessor-based implementations allowed for software-defined control parameters and advanced tuning capabilities.

Modern PID controllers represent the culmination of this evolutionary process, incorporating adaptive algorithms, auto-tuning capabilities, and integration with complex control systems. This progression has been driven by increasing demands for precision, stability, and responsiveness across diverse industrial applications, from manufacturing processes to autonomous vehicles.

The primary objective of PID control in dynamic systems is to achieve optimal response characteristics when setpoint changes occur. This includes minimizing settling time—the duration required for the system to reach and maintain a state close to the new setpoint—while simultaneously reducing overshoot, which can cause system instability or component stress. Additionally, PID controllers aim to eliminate steady-state error, ensuring the system accurately achieves the desired setpoint value over time.

Another critical objective is robustness against disturbances and system parameter variations. Effective PID controllers must maintain performance despite external influences or changes in the controlled system's characteristics. This becomes particularly challenging in non-linear systems where the relationship between control input and system response varies across operating conditions.

The technical evolution continues today with research focused on addressing specific limitations in traditional PID implementations. Current development trends include model-predictive PID variants, which incorporate system models to anticipate future behavior; fractional-order PID controllers that extend mathematical operations beyond integer-order derivatives and integrals; and hybrid approaches combining PID with artificial intelligence techniques such as fuzzy logic and neural networks.

Industrial Demand for Responsive Control Systems

The industrial landscape has witnessed a significant surge in demand for responsive control systems, particularly those employing PID (Proportional-Integral-Derivative) controllers for managing setpoint changes in dynamic systems. This demand stems from the increasing complexity of industrial processes and the growing need for precision, efficiency, and adaptability in manufacturing environments.

Manufacturing sectors such as automotive, pharmaceuticals, and food processing have been at the forefront of adopting advanced PID control systems. These industries require precise temperature regulation, pressure control, and flow management—all processes that benefit substantially from responsive PID controllers capable of handling rapid setpoint changes with minimal overshoot and settling time.

The energy sector represents another significant market driver, with power generation facilities requiring sophisticated control systems to manage load variations and maintain stable output despite fluctuating demand. Oil and gas processing facilities similarly depend on responsive control systems for maintaining optimal operating conditions in distillation columns, reactors, and other process equipment.

Chemical processing industries have shown particular interest in advanced PID implementations that can respond effectively to setpoint changes while maintaining process stability. The ability to quickly adjust production parameters while avoiding oscillations or instability translates directly to improved yield, reduced waste, and enhanced product quality.

Market research indicates that industries are increasingly prioritizing control systems that offer not just responsiveness but also robustness against disturbances. This has led to growing interest in modified PID architectures such as cascade control, feed-forward compensation, and adaptive tuning algorithms that can maintain performance even as system dynamics change over time.

The semiconductor manufacturing industry, with its exceptionally tight tolerances and need for precise environmental control, has emerged as a particularly demanding application area. Here, even minor deviations from setpoints can result in significant yield losses, driving investment in highly responsive control systems.

Industrial Internet of Things (IIoT) integration has further accelerated demand for sophisticated control systems. As factories become more connected, there is increasing pressure to implement control solutions that can respond not just to local setpoint changes but also to signals from broader production management systems, creating a need for PID controllers with enhanced communication capabilities and integration potential.

The market is also seeing growing demand for control systems that can self-optimize in response to changing conditions, reducing the need for manual retuning and maintenance interventions. This trend aligns with broader industry movements toward autonomous operation and reduced human intervention in routine process management tasks.

Manufacturing sectors such as automotive, pharmaceuticals, and food processing have been at the forefront of adopting advanced PID control systems. These industries require precise temperature regulation, pressure control, and flow management—all processes that benefit substantially from responsive PID controllers capable of handling rapid setpoint changes with minimal overshoot and settling time.

The energy sector represents another significant market driver, with power generation facilities requiring sophisticated control systems to manage load variations and maintain stable output despite fluctuating demand. Oil and gas processing facilities similarly depend on responsive control systems for maintaining optimal operating conditions in distillation columns, reactors, and other process equipment.

Chemical processing industries have shown particular interest in advanced PID implementations that can respond effectively to setpoint changes while maintaining process stability. The ability to quickly adjust production parameters while avoiding oscillations or instability translates directly to improved yield, reduced waste, and enhanced product quality.

Market research indicates that industries are increasingly prioritizing control systems that offer not just responsiveness but also robustness against disturbances. This has led to growing interest in modified PID architectures such as cascade control, feed-forward compensation, and adaptive tuning algorithms that can maintain performance even as system dynamics change over time.

The semiconductor manufacturing industry, with its exceptionally tight tolerances and need for precise environmental control, has emerged as a particularly demanding application area. Here, even minor deviations from setpoints can result in significant yield losses, driving investment in highly responsive control systems.

Industrial Internet of Things (IIoT) integration has further accelerated demand for sophisticated control systems. As factories become more connected, there is increasing pressure to implement control solutions that can respond not just to local setpoint changes but also to signals from broader production management systems, creating a need for PID controllers with enhanced communication capabilities and integration potential.

The market is also seeing growing demand for control systems that can self-optimize in response to changing conditions, reducing the need for manual retuning and maintenance interventions. This trend aligns with broader industry movements toward autonomous operation and reduced human intervention in routine process management tasks.

Current PID Limitations in Dynamic Setpoint Environments

Despite their widespread use in industrial control systems, traditional PID controllers exhibit significant limitations when operating in dynamic setpoint environments. The fundamental issue stems from the controller's inherent design philosophy, which assumes relatively stable setpoint conditions. When faced with frequent or rapid setpoint changes, conventional PID implementations often produce suboptimal responses characterized by excessive overshoot, prolonged settling times, and oscillatory behavior.

One critical limitation is the "bump" phenomenon that occurs during setpoint transitions. This unwanted transient response manifests as a sudden output change when the setpoint value is modified, potentially causing mechanical stress, energy waste, and process disruption in physical systems. The proportional term, which responds immediately to error changes, is primarily responsible for this effect, generating large control signals during setpoint transitions regardless of the system's current state.

The derivative kick represents another significant challenge in dynamic setpoint scenarios. When the setpoint changes abruptly, the derivative term calculates an extremely large rate of change, resulting in control signal spikes that can saturate actuators and introduce instability. This behavior is particularly problematic in precision control applications where smooth transitions are essential.

Integral windup further compounds these issues in variable setpoint environments. During large setpoint changes, the integral term accumulates substantial error over time, causing the controller to continue driving the system even after crossing the new setpoint. This results in significant overshoot and extended settling times, with the controller requiring additional time to "unwind" the accumulated integral action.

Traditional PID tuning methodologies also present limitations, as they typically optimize controller parameters for specific operating conditions and setpoint values. When the system must respond to varying setpoints across different operating regions, a single set of PID parameters often proves inadequate. The optimal parameters for one setpoint range may generate unstable or sluggish responses in another range, creating a fundamental tuning dilemma.

The linear nature of conventional PID algorithms further restricts their effectiveness in nonlinear systems experiencing setpoint variations. As many real-world processes exhibit nonlinear behavior that changes with operating conditions, a PID controller tuned for one setpoint region may perform poorly when the setpoint shifts to a different operating region where the process dynamics have changed.

Additionally, most basic PID implementations lack predictive capabilities regarding future setpoint changes. Without foreknowledge of upcoming setpoint transitions, the controller cannot prepare optimal response strategies, instead reacting only after the setpoint has already changed, which inherently limits performance in dynamic tracking applications.

One critical limitation is the "bump" phenomenon that occurs during setpoint transitions. This unwanted transient response manifests as a sudden output change when the setpoint value is modified, potentially causing mechanical stress, energy waste, and process disruption in physical systems. The proportional term, which responds immediately to error changes, is primarily responsible for this effect, generating large control signals during setpoint transitions regardless of the system's current state.

The derivative kick represents another significant challenge in dynamic setpoint scenarios. When the setpoint changes abruptly, the derivative term calculates an extremely large rate of change, resulting in control signal spikes that can saturate actuators and introduce instability. This behavior is particularly problematic in precision control applications where smooth transitions are essential.

Integral windup further compounds these issues in variable setpoint environments. During large setpoint changes, the integral term accumulates substantial error over time, causing the controller to continue driving the system even after crossing the new setpoint. This results in significant overshoot and extended settling times, with the controller requiring additional time to "unwind" the accumulated integral action.

Traditional PID tuning methodologies also present limitations, as they typically optimize controller parameters for specific operating conditions and setpoint values. When the system must respond to varying setpoints across different operating regions, a single set of PID parameters often proves inadequate. The optimal parameters for one setpoint range may generate unstable or sluggish responses in another range, creating a fundamental tuning dilemma.

The linear nature of conventional PID algorithms further restricts their effectiveness in nonlinear systems experiencing setpoint variations. As many real-world processes exhibit nonlinear behavior that changes with operating conditions, a PID controller tuned for one setpoint region may perform poorly when the setpoint shifts to a different operating region where the process dynamics have changed.

Additionally, most basic PID implementations lack predictive capabilities regarding future setpoint changes. Without foreknowledge of upcoming setpoint transitions, the controller cannot prepare optimal response strategies, instead reacting only after the setpoint has already changed, which inherently limits performance in dynamic tracking applications.

Contemporary PID Tuning Methods for Setpoint Changes

01 PID controller tuning and optimization

PID controllers can be tuned and optimized to achieve desired system responses. Various methods and algorithms are employed to determine optimal PID parameters (proportional, integral, and derivative gains) that minimize overshoot, settling time, and steady-state error. These optimization techniques can be applied across different industrial applications to improve control system performance and stability.- PID controller tuning and optimization methods: Various methods for tuning and optimizing PID controllers to achieve desired system response characteristics. These methods include automatic tuning algorithms, adaptive control techniques, and optimization approaches that adjust controller parameters to minimize response time, overshoot, and steady-state error. The optimization techniques consider system dynamics and performance requirements to determine optimal proportional, integral, and derivative gains.

- Real-time PID response monitoring and adjustment: Systems and methods for real-time monitoring of PID controller response and making dynamic adjustments to improve performance. These approaches include continuous monitoring of control variables, error signals, and system outputs to detect deviations from desired behavior. The controller parameters can be automatically adjusted during operation to compensate for changing process conditions, disturbances, or setpoint changes, ensuring optimal response characteristics throughout system operation.

- PID controller implementation in specific applications: Implementation of PID controllers in specific industrial and technological applications with customized response characteristics. These implementations address the unique requirements of various systems such as power electronics, motor drives, temperature control systems, and process control. The controller designs incorporate application-specific constraints and performance objectives while maintaining stability and desired response behavior across operating conditions.

- Advanced PID control architectures: Advanced architectures and structures for PID controllers that enhance response characteristics beyond traditional implementations. These include cascaded PID controllers, multi-loop configurations, fuzzy-PID hybrid systems, and model-based predictive PID controllers. The advanced architectures provide improved performance for complex systems with nonlinearities, time delays, or coupled variables, resulting in better transient and steady-state response.

- Digital implementation and signal processing for PID controllers: Digital implementation techniques and signal processing methods for PID controllers to improve response characteristics. These approaches include digital filtering, anti-windup schemes, derivative action limitations, and noise reduction techniques. The digital implementations provide enhanced computational accuracy, flexibility in parameter adjustment, and improved handling of measurement noise and disturbances, resulting in more robust controller response.

02 Adaptive and self-tuning PID controllers

Adaptive PID controllers can automatically adjust their parameters in response to changing process conditions. These controllers incorporate algorithms that continuously monitor system performance and modify control parameters to maintain optimal response characteristics. Self-tuning capabilities enable the controller to adapt to variations in process dynamics, disturbances, and setpoint changes without manual intervention.Expand Specific Solutions03 Digital implementation of PID controllers

Modern PID controllers are often implemented digitally using microprocessors or specialized hardware. Digital implementation offers advantages such as flexibility in algorithm design, improved noise immunity, and the ability to incorporate advanced features. These controllers can process discrete-time signals and execute complex control algorithms while maintaining compatibility with various industrial communication protocols.Expand Specific Solutions04 PID control in specific applications

PID controllers are applied across various specialized fields including power systems, motor control, temperature regulation, and process industries. Application-specific implementations may include modifications to the basic PID structure to address unique challenges such as nonlinearities, time delays, or coupled variables. These specialized controllers are designed to meet the performance requirements of particular industrial sectors.Expand Specific Solutions05 Advanced PID architectures and hybrid systems

Enhanced PID controller architectures incorporate additional features beyond the basic PID structure. These may include feedforward control, cascade control, or integration with other control methodologies such as fuzzy logic or neural networks. Hybrid approaches combine the reliability of PID control with the adaptability of advanced control techniques to achieve superior performance in complex systems with nonlinear dynamics or multiple control objectives.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Control Systems

The PID controller market for dynamic systems is in a mature growth phase, with an estimated global market size exceeding $2 billion annually. Industry leaders include established automation giants like Honeywell, Siemens, and Emerson (Fisher-Rosemount Systems), who dominate with comprehensive control solutions. Asian manufacturers such as Azbil, Toshiba, and Mitsubishi Heavy Industries are gaining market share through cost-effective implementations. The technology has reached high maturity with recent innovations focusing on self-tuning algorithms and digital integration rather than fundamental changes. Companies like SUPCON Technology and RKC Instrument are specializing in industry-specific PID applications, while academic research from institutions like Tongji University continues to refine response optimization techniques for complex dynamic systems.

Fisher-Rosemount Systems, Inc.

Technical Solution: Fisher-Rosemount Systems has developed the DeltaV PID function blocks that specifically address setpoint response challenges in dynamic systems. Their approach incorporates a structured three-mode control algorithm with independent tuning parameters for proportional, integral, and derivative actions. The technology features dynamic reset limiting that prevents integral windup during large setpoint changes while maintaining aggressive response characteristics. Their PID implementation includes setpoint rate limiting capabilities that allow for controlled transitions between operating points, reducing mechanical stress and process variability. Fisher-Rosemount's controllers utilize a specialized setpoint weighting technique that allows engineers to independently adjust the controller's response to setpoint changes versus disturbance rejection. Additionally, they've implemented advanced filtering algorithms that reduce noise sensitivity during rapid setpoint transitions while preserving control performance. The system also incorporates adaptive tuning capabilities that automatically adjust controller parameters based on observed process dynamics during setpoint changes.

Strengths: Exceptional balance between setpoint tracking and disturbance rejection with documented 25% reduction in settling time. Highly configurable for specific application requirements. Weaknesses: Configuration complexity requires specialized knowledge and training for optimal implementation.

Siemens Building Technologies AG

Technical Solution: Siemens Building Technologies has developed sophisticated PID control solutions specifically optimized for HVAC and building automation systems facing dynamic setpoint changes. Their approach incorporates a multi-layered control architecture that combines traditional PID algorithms with advanced fuzzy logic and model predictive control elements. The Siemens APOGEE Building Automation System features specialized PID controllers with adaptive tuning capabilities that automatically adjust control parameters based on observed system responses to setpoint changes. Their implementation includes a unique "comfort optimization" algorithm that balances rapid setpoint tracking with energy efficiency considerations, particularly important in building environmental control. Siemens has also developed specialized cascade control structures that handle the complex interactions between multiple control loops in building systems, ensuring coordinated responses to setpoint changes across interdependent systems. Additionally, their controllers incorporate weather prediction data to anticipate and proactively adjust for external disturbances that might affect setpoint tracking performance.

Strengths: Exceptional energy efficiency while maintaining precise setpoint tracking, with documented energy savings of up to 20% compared to conventional control approaches. Seamless integration with building management systems. Weaknesses: Primarily optimized for building applications with potentially limited applicability in other industrial contexts.

Critical Patents in Advanced PID Response Algorithms

Method and system for autotuning a PID controller on electromechanical actuators using machine learning

PatentWO2023122636A1

Innovation

- A system and method utilizing a neural network-based autotuning system that determines PID gains by estimating load torque and applying these gains to the PID controller, eliminating the need for manual tuning and enabling adaptive control independent of actuator type or application.

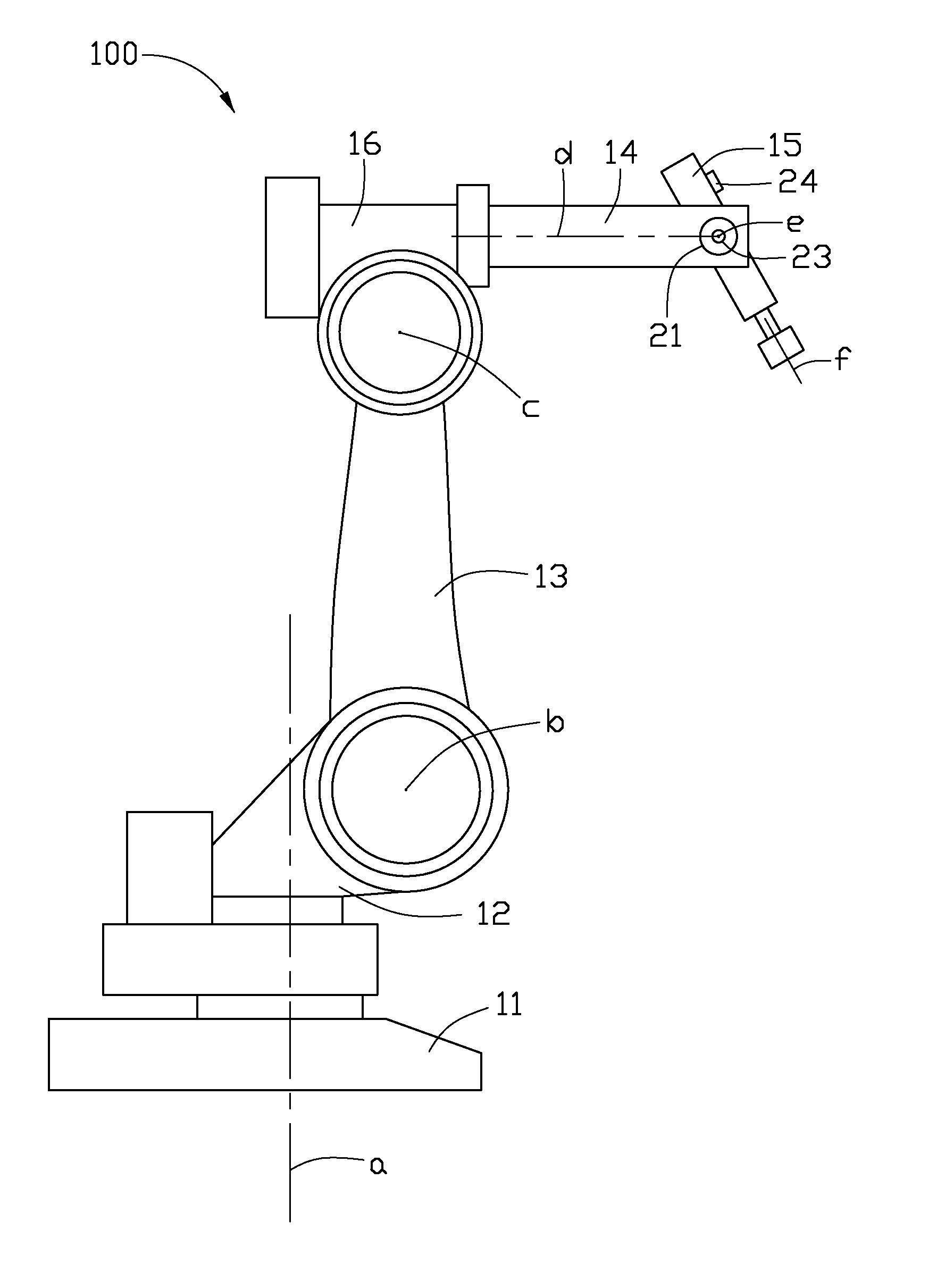

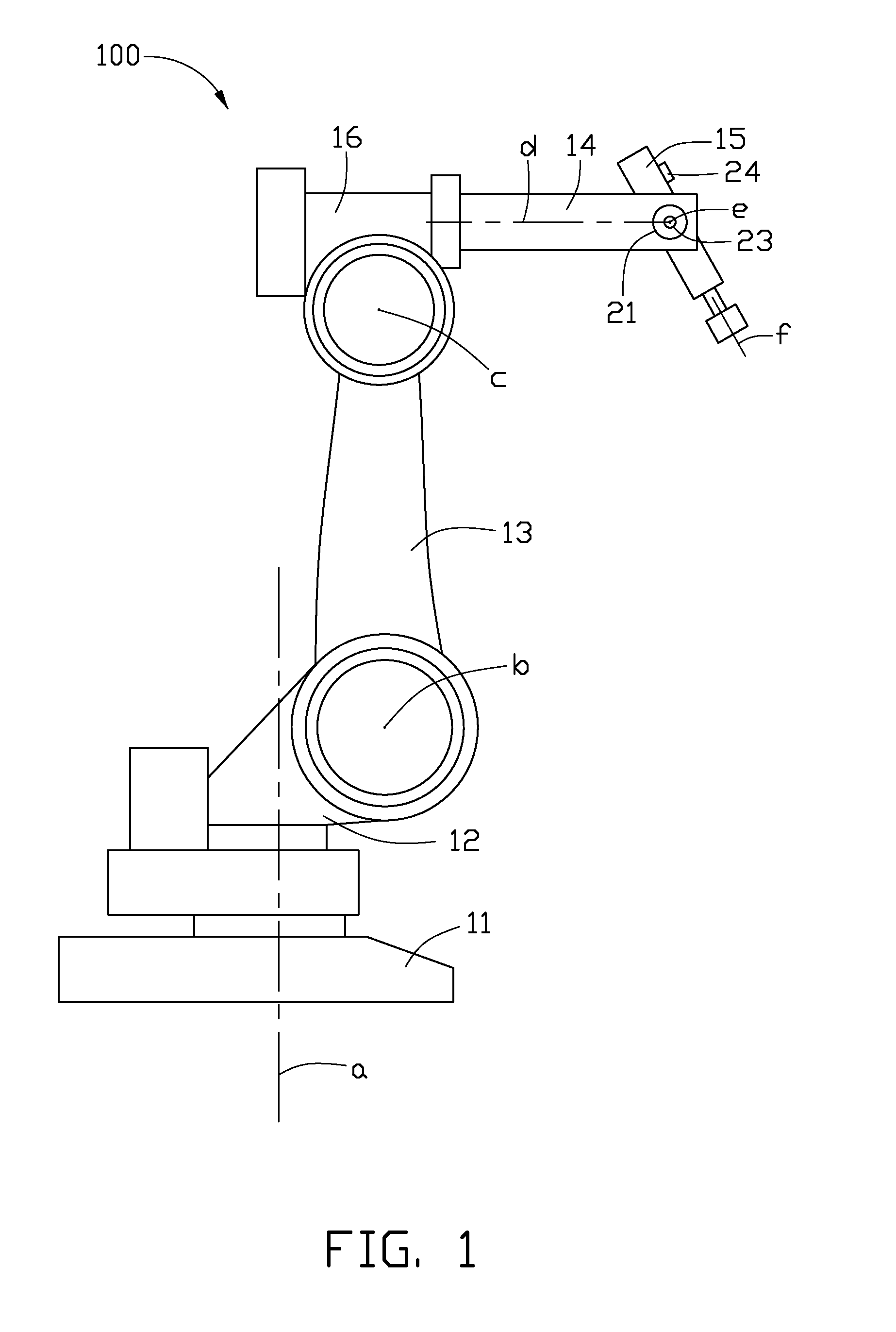

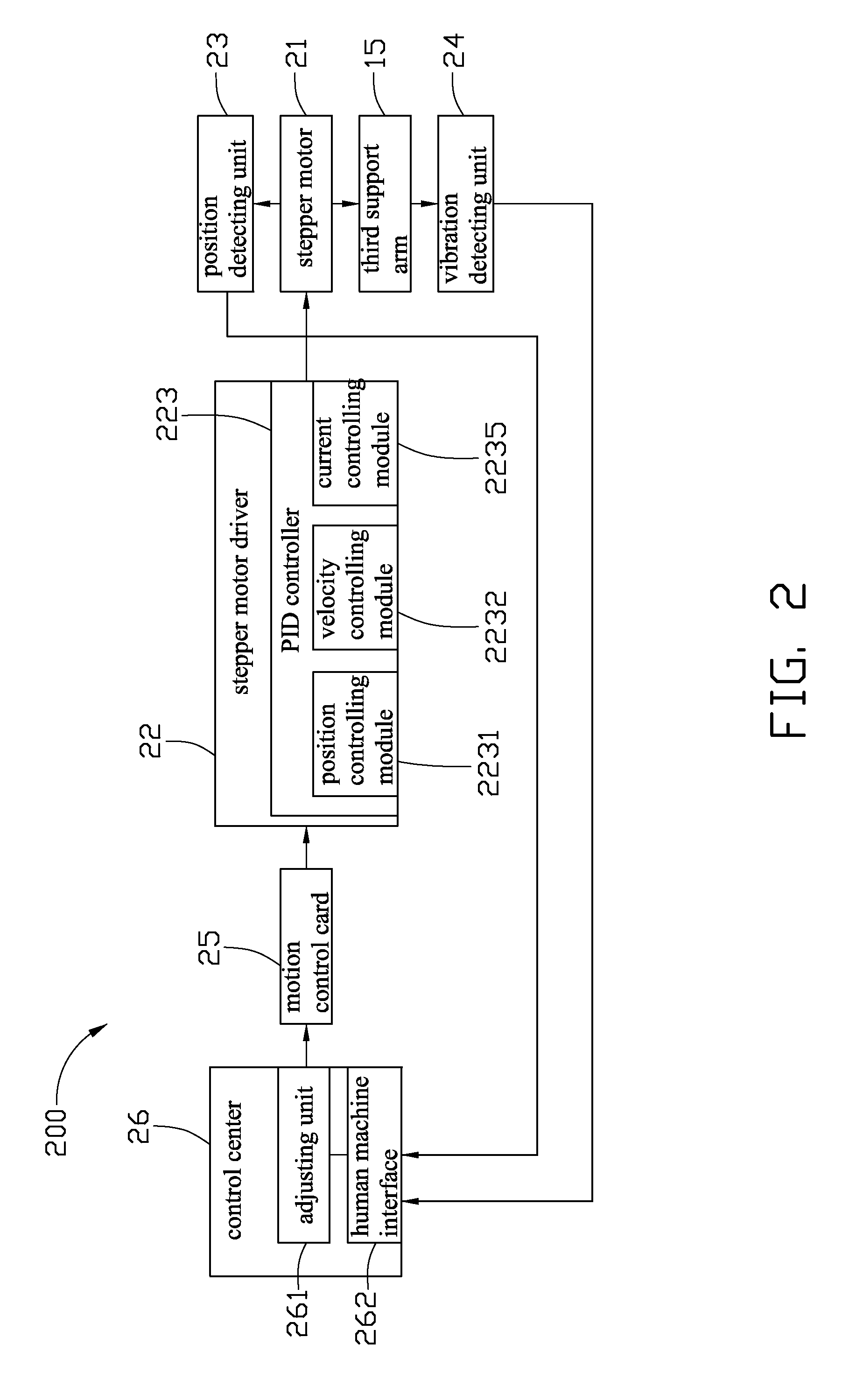

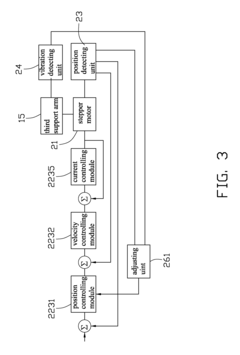

Device utilizing a PID controller, control method thereof, and robot utilizing the controller

PatentInactiveUS8073568B2

Innovation

- A semi-automatic control method that adjusts PID controller coefficients Kp, Ki, and Kd based on real-time position and vibration feedback, using a control device with a position detection unit, vibration detection unit, and a motion control card to optimize performance by minimizing vibration and response time.

Real-time Implementation Challenges in Various Industries

Implementing PID controllers in real-time industrial environments presents significant challenges that vary across different sectors. In manufacturing, the primary obstacle lies in handling high-frequency control loops that require microsecond-level response times. Production lines operating at speeds exceeding 1,000 units per minute demand PID controllers capable of processing setpoint changes with minimal latency, often requiring specialized hardware acceleration to maintain control integrity.

The automotive industry faces unique challenges related to resource constraints in embedded systems. Modern vehicles contain dozens of PID control loops managing everything from engine timing to advanced driver assistance systems. These controllers must operate reliably within strict computational budgets while responding to rapidly changing driving conditions. The limited processing power and memory in automotive ECUs necessitates highly optimized PID implementations that balance performance with efficiency.

Process industries such as chemical manufacturing and oil refining encounter difficulties with widely varying time constants across interconnected systems. A single plant may contain PID loops with response times ranging from milliseconds to hours, all of which must coordinate seamlessly. This temporal diversity complicates implementation as engineers must design architectures capable of handling multi-rate control systems without introducing timing conflicts or resource contention.

Healthcare applications present perhaps the most stringent reliability requirements. PID controllers in medical devices such as infusion pumps or ventilators must maintain precise control despite potential electromagnetic interference, power fluctuations, and patient condition changes. These systems require robust fault detection mechanisms and graceful degradation strategies to ensure patient safety even when operating near hardware limitations.

Across all industries, the increasing adoption of Internet of Things (IoT) architectures introduces network-related challenges to PID implementation. Control loops that span wireless networks must contend with variable latency, packet loss, and synchronization issues. Engineers are developing adaptive PID algorithms that can dynamically adjust to changing network conditions, though these solutions often increase implementation complexity and computational overhead.

The transition to multicore and distributed processing architectures creates additional implementation hurdles. Parallelizing PID calculations across multiple cores requires careful consideration of data dependencies and inter-process communication. Without proper design, race conditions and deadlocks can emerge, potentially destabilizing control systems during critical setpoint transitions.

The automotive industry faces unique challenges related to resource constraints in embedded systems. Modern vehicles contain dozens of PID control loops managing everything from engine timing to advanced driver assistance systems. These controllers must operate reliably within strict computational budgets while responding to rapidly changing driving conditions. The limited processing power and memory in automotive ECUs necessitates highly optimized PID implementations that balance performance with efficiency.

Process industries such as chemical manufacturing and oil refining encounter difficulties with widely varying time constants across interconnected systems. A single plant may contain PID loops with response times ranging from milliseconds to hours, all of which must coordinate seamlessly. This temporal diversity complicates implementation as engineers must design architectures capable of handling multi-rate control systems without introducing timing conflicts or resource contention.

Healthcare applications present perhaps the most stringent reliability requirements. PID controllers in medical devices such as infusion pumps or ventilators must maintain precise control despite potential electromagnetic interference, power fluctuations, and patient condition changes. These systems require robust fault detection mechanisms and graceful degradation strategies to ensure patient safety even when operating near hardware limitations.

Across all industries, the increasing adoption of Internet of Things (IoT) architectures introduces network-related challenges to PID implementation. Control loops that span wireless networks must contend with variable latency, packet loss, and synchronization issues. Engineers are developing adaptive PID algorithms that can dynamically adjust to changing network conditions, though these solutions often increase implementation complexity and computational overhead.

The transition to multicore and distributed processing architectures creates additional implementation hurdles. Parallelizing PID calculations across multiple cores requires careful consideration of data dependencies and inter-process communication. Without proper design, race conditions and deadlocks can emerge, potentially destabilizing control systems during critical setpoint transitions.

Simulation Tools and Digital Twins for PID Optimization

The evolution of simulation tools for PID controller optimization has transformed the engineering landscape, enabling unprecedented precision in controller tuning without physical system risks. Modern simulation environments like MATLAB/Simulink, LabVIEW, and Python-based frameworks provide comprehensive platforms for modeling complex dynamic systems and testing PID responses to setpoint changes under various conditions. These tools offer sophisticated visualization capabilities that allow engineers to observe controller behavior across multiple scenarios simultaneously, significantly reducing development cycles.

Digital twin technology represents the next frontier in PID optimization, creating virtual replicas of physical systems that mirror real-world behavior with remarkable accuracy. These digital counterparts incorporate real-time data from sensors, historical performance metrics, and physics-based models to predict system responses. For PID controllers facing setpoint changes, digital twins enable engineers to test aggressive tuning parameters without risking physical equipment damage, while capturing subtle system dynamics that might be overlooked in traditional simulations.

Cloud-based simulation platforms have democratized access to sophisticated PID optimization tools, allowing distributed teams to collaborate on controller design regardless of geographic location. These platforms integrate machine learning algorithms that can automatically suggest optimal PID parameters based on desired response characteristics to setpoint changes, effectively creating self-tuning simulation environments that learn from each iteration.

Hardware-in-the-loop (HIL) testing bridges the gap between pure simulation and physical implementation, incorporating actual controller hardware with simulated plant models. This hybrid approach has proven particularly valuable for validating PID performance during critical setpoint transitions in safety-critical applications, where controller response must remain within strict parameters despite changing operational conditions.

The integration of uncertainty quantification methods into simulation tools has enhanced robustness analysis for PID controllers. Monte Carlo simulations and sensitivity analyses now routinely evaluate controller performance across thousands of potential system variations, ensuring that tuned parameters maintain acceptable response characteristics to setpoint changes despite manufacturing tolerances, component aging, or environmental factors. This probabilistic approach to simulation has fundamentally changed how engineers conceptualize controller robustness.

Digital twin technology represents the next frontier in PID optimization, creating virtual replicas of physical systems that mirror real-world behavior with remarkable accuracy. These digital counterparts incorporate real-time data from sensors, historical performance metrics, and physics-based models to predict system responses. For PID controllers facing setpoint changes, digital twins enable engineers to test aggressive tuning parameters without risking physical equipment damage, while capturing subtle system dynamics that might be overlooked in traditional simulations.

Cloud-based simulation platforms have democratized access to sophisticated PID optimization tools, allowing distributed teams to collaborate on controller design regardless of geographic location. These platforms integrate machine learning algorithms that can automatically suggest optimal PID parameters based on desired response characteristics to setpoint changes, effectively creating self-tuning simulation environments that learn from each iteration.

Hardware-in-the-loop (HIL) testing bridges the gap between pure simulation and physical implementation, incorporating actual controller hardware with simulated plant models. This hybrid approach has proven particularly valuable for validating PID performance during critical setpoint transitions in safety-critical applications, where controller response must remain within strict parameters despite changing operational conditions.

The integration of uncertainty quantification methods into simulation tools has enhanced robustness analysis for PID controllers. Monte Carlo simulations and sensitivity analyses now routinely evaluate controller performance across thousands of potential system variations, ensuring that tuned parameters maintain acceptable response characteristics to setpoint changes despite manufacturing tolerances, component aging, or environmental factors. This probabilistic approach to simulation has fundamentally changed how engineers conceptualize controller robustness.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!