How Does A Cascade PID Controller Architecture Work?

SEP 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cascade PID Control Evolution and Objectives

Cascade PID control systems have evolved significantly since the inception of basic PID controllers in the early 20th century. The fundamental PID control concept, first formalized by Nicolas Minorsky in 1922, provided a mathematical foundation for automatic control systems. However, as industrial processes grew more complex, traditional single-loop PID controllers proved insufficient for systems with multiple interdependent variables or significant time delays.

The evolution of cascade control architecture emerged in the 1950s and 1960s as process industries required more sophisticated control strategies. This development was driven by the need to handle nested dynamic processes where disturbances in inner loops could significantly impact outer loop performance. Early implementations relied on analog computing elements, with pneumatic and later electronic controllers enabling the first practical cascade systems in chemical and petroleum industries.

By the 1970s and 1980s, the introduction of digital control systems revolutionized cascade PID implementation, allowing for more complex configurations and easier tuning. The development of distributed control systems (DCS) further enhanced cascade control capabilities by enabling seamless integration of multiple control loops across industrial processes.

The primary objective of cascade PID control is to improve system performance by addressing disturbances at their source before they propagate through the entire process. This architecture divides control responsibilities between multiple controllers, with an inner (secondary) loop responding rapidly to local disturbances while an outer (primary) loop maintains the overall process setpoint. This hierarchical structure significantly enhances disturbance rejection capabilities compared to single-loop controllers.

Another key objective is to manage processes with significantly different time constants. By isolating faster dynamics in the inner loop, cascade control effectively decouples time-dependent behaviors, allowing for more aggressive tuning of the faster loop while maintaining stability in the slower outer loop. This separation of time scales is particularly valuable in thermal processes, mechanical systems with backlash, and chemical reactions with varying response times.

Modern cascade PID implementations aim to optimize control performance while minimizing complexity and maintenance requirements. Contemporary objectives include adaptive tuning capabilities, seamless integration with model predictive control strategies, and robust performance under varying process conditions. The evolution continues with the integration of artificial intelligence techniques to enhance traditional cascade architectures, creating hybrid systems that combine classical control theory with machine learning for improved performance in nonlinear and time-varying processes.

The evolution of cascade control architecture emerged in the 1950s and 1960s as process industries required more sophisticated control strategies. This development was driven by the need to handle nested dynamic processes where disturbances in inner loops could significantly impact outer loop performance. Early implementations relied on analog computing elements, with pneumatic and later electronic controllers enabling the first practical cascade systems in chemical and petroleum industries.

By the 1970s and 1980s, the introduction of digital control systems revolutionized cascade PID implementation, allowing for more complex configurations and easier tuning. The development of distributed control systems (DCS) further enhanced cascade control capabilities by enabling seamless integration of multiple control loops across industrial processes.

The primary objective of cascade PID control is to improve system performance by addressing disturbances at their source before they propagate through the entire process. This architecture divides control responsibilities between multiple controllers, with an inner (secondary) loop responding rapidly to local disturbances while an outer (primary) loop maintains the overall process setpoint. This hierarchical structure significantly enhances disturbance rejection capabilities compared to single-loop controllers.

Another key objective is to manage processes with significantly different time constants. By isolating faster dynamics in the inner loop, cascade control effectively decouples time-dependent behaviors, allowing for more aggressive tuning of the faster loop while maintaining stability in the slower outer loop. This separation of time scales is particularly valuable in thermal processes, mechanical systems with backlash, and chemical reactions with varying response times.

Modern cascade PID implementations aim to optimize control performance while minimizing complexity and maintenance requirements. Contemporary objectives include adaptive tuning capabilities, seamless integration with model predictive control strategies, and robust performance under varying process conditions. The evolution continues with the integration of artificial intelligence techniques to enhance traditional cascade architectures, creating hybrid systems that combine classical control theory with machine learning for improved performance in nonlinear and time-varying processes.

Industrial Applications and Market Demand

Cascade PID control architecture has witnessed significant market penetration across diverse industrial sectors due to its superior performance characteristics compared to conventional single-loop PID controllers. The global industrial automation market, where cascade PID controllers represent a critical component, was valued at approximately $191.89 billion in 2021 and is projected to reach $355.44 billion by 2030, growing at a CAGR of 7.9% during this period.

Process industries, particularly oil and gas, chemical processing, and petrochemicals, demonstrate the highest adoption rates of cascade PID control systems. These sectors require precise temperature, pressure, and flow control in environments where process variables are susceptible to multiple disturbances. The chemical processing industry alone accounts for roughly 23% of the total cascade PID controller market, driven by stringent quality requirements and safety regulations.

Power generation represents another significant application domain, with thermal and nuclear power plants implementing cascade control for steam generators, turbine speed regulation, and combustion optimization. The power generation sector's demand for cascade PID solutions is expected to grow at 8.7% annually through 2028, outpacing the broader market average.

The pharmaceutical and biotechnology industries have emerged as rapidly expanding markets for advanced control architectures. Bioreactors, freeze-drying processes, and environmental chambers in these industries benefit substantially from the disturbance rejection capabilities of cascade control. Market analysis indicates that pharmaceutical manufacturing facilities implementing cascade PID systems report 15-20% improvements in batch consistency and reduced process variability.

Food and beverage processing plants increasingly deploy cascade control for pasteurization, fermentation, and drying operations. This sector values the enhanced stability and faster response times that cascade architectures provide, particularly for temperature-sensitive processes where product quality directly correlates with precise thermal management.

The automotive manufacturing sector utilizes cascade PID controllers in paint shops, heat treatment processes, and emissions control systems. As automotive production lines become more automated and energy-efficient, the demand for sophisticated control architectures continues to rise, with an estimated 30% of new automotive production facilities implementing cascade control strategies.

Geographically, Asia-Pacific represents the fastest-growing market for cascade PID implementations, driven by rapid industrialization in China, India, and Southeast Asian nations. North America and Europe maintain significant market shares, primarily due to modernization initiatives in existing industrial infrastructure and stringent regulatory requirements for process efficiency and emissions control.

Process industries, particularly oil and gas, chemical processing, and petrochemicals, demonstrate the highest adoption rates of cascade PID control systems. These sectors require precise temperature, pressure, and flow control in environments where process variables are susceptible to multiple disturbances. The chemical processing industry alone accounts for roughly 23% of the total cascade PID controller market, driven by stringent quality requirements and safety regulations.

Power generation represents another significant application domain, with thermal and nuclear power plants implementing cascade control for steam generators, turbine speed regulation, and combustion optimization. The power generation sector's demand for cascade PID solutions is expected to grow at 8.7% annually through 2028, outpacing the broader market average.

The pharmaceutical and biotechnology industries have emerged as rapidly expanding markets for advanced control architectures. Bioreactors, freeze-drying processes, and environmental chambers in these industries benefit substantially from the disturbance rejection capabilities of cascade control. Market analysis indicates that pharmaceutical manufacturing facilities implementing cascade PID systems report 15-20% improvements in batch consistency and reduced process variability.

Food and beverage processing plants increasingly deploy cascade control for pasteurization, fermentation, and drying operations. This sector values the enhanced stability and faster response times that cascade architectures provide, particularly for temperature-sensitive processes where product quality directly correlates with precise thermal management.

The automotive manufacturing sector utilizes cascade PID controllers in paint shops, heat treatment processes, and emissions control systems. As automotive production lines become more automated and energy-efficient, the demand for sophisticated control architectures continues to rise, with an estimated 30% of new automotive production facilities implementing cascade control strategies.

Geographically, Asia-Pacific represents the fastest-growing market for cascade PID implementations, driven by rapid industrialization in China, India, and Southeast Asian nations. North America and Europe maintain significant market shares, primarily due to modernization initiatives in existing industrial infrastructure and stringent regulatory requirements for process efficiency and emissions control.

Current Implementation Challenges

Despite the significant advancements in cascade PID controller architecture, several implementation challenges persist that limit its optimal performance in various applications. One of the primary challenges is the increased complexity in tuning multiple control loops. Unlike single-loop PID controllers, cascade systems require sequential tuning of inner and outer loops, with the inner loop typically requiring 3-5 times faster response than the outer loop. This interdependency creates a complex parameter space that often necessitates specialized expertise or advanced auto-tuning algorithms.

Hardware limitations present another significant challenge, particularly in resource-constrained environments. Cascade PID implementations demand higher computational resources and sampling rates, especially for the inner loop which must operate at significantly higher frequencies. This requirement can strain embedded systems with limited processing capabilities, leading to compromises in control performance or necessitating more expensive hardware solutions.

The stability analysis of cascade systems introduces additional complexity compared to single-loop controllers. The interaction between loops can create unforeseen stability issues, particularly when disturbances affect both loops simultaneously. Traditional stability analysis methods often prove insufficient for capturing these complex interactions, requiring more sophisticated approaches such as state-space modeling or frequency domain analysis techniques.

Sensor placement and quality significantly impact cascade PID performance. The inner loop typically requires sensors with higher precision and faster response times, which increases implementation costs. Suboptimal sensor placement can introduce measurement delays that destabilize the control system, while sensor noise can propagate through the cascade structure and potentially amplify through the control loops.

Implementation challenges also extend to handling non-linearities in the controlled process. While cascade control can improve performance for certain types of non-linearities, it may struggle with others, particularly when they occur in the inner loop process. This often necessitates additional compensation techniques such as gain scheduling or adaptive control mechanisms, further increasing system complexity.

Communication delays between controller components present growing challenges, especially in distributed control systems where controllers may be physically separated. These delays can significantly degrade performance or even destabilize the system if not properly accounted for in the control design.

Finally, there remains a significant knowledge gap in industry regarding proper implementation practices. Many engineers lack specialized training in cascade control, leading to suboptimal implementations that fail to realize the full benefits of the architecture. This challenge is compounded by insufficient documentation and standardization of best practices across different application domains.

Hardware limitations present another significant challenge, particularly in resource-constrained environments. Cascade PID implementations demand higher computational resources and sampling rates, especially for the inner loop which must operate at significantly higher frequencies. This requirement can strain embedded systems with limited processing capabilities, leading to compromises in control performance or necessitating more expensive hardware solutions.

The stability analysis of cascade systems introduces additional complexity compared to single-loop controllers. The interaction between loops can create unforeseen stability issues, particularly when disturbances affect both loops simultaneously. Traditional stability analysis methods often prove insufficient for capturing these complex interactions, requiring more sophisticated approaches such as state-space modeling or frequency domain analysis techniques.

Sensor placement and quality significantly impact cascade PID performance. The inner loop typically requires sensors with higher precision and faster response times, which increases implementation costs. Suboptimal sensor placement can introduce measurement delays that destabilize the control system, while sensor noise can propagate through the cascade structure and potentially amplify through the control loops.

Implementation challenges also extend to handling non-linearities in the controlled process. While cascade control can improve performance for certain types of non-linearities, it may struggle with others, particularly when they occur in the inner loop process. This often necessitates additional compensation techniques such as gain scheduling or adaptive control mechanisms, further increasing system complexity.

Communication delays between controller components present growing challenges, especially in distributed control systems where controllers may be physically separated. These delays can significantly degrade performance or even destabilize the system if not properly accounted for in the control design.

Finally, there remains a significant knowledge gap in industry regarding proper implementation practices. Many engineers lack specialized training in cascade control, leading to suboptimal implementations that fail to realize the full benefits of the architecture. This challenge is compounded by insufficient documentation and standardization of best practices across different application domains.

Mainstream Cascade PID Architectures

01 Cascade PID controller architecture and design

Cascade PID controllers consist of multiple PID loops arranged in a hierarchical structure, where the output of one controller becomes the setpoint for another. This architecture allows for improved control of processes with multiple dynamics or disturbances. The design typically involves an outer loop that controls the primary variable and an inner loop that controls a secondary variable, providing faster response to disturbances and better overall system stability.- Cascade PID controller architecture and implementation: Cascade PID control systems utilize multiple control loops where the output of one controller becomes the setpoint for another. This architecture typically consists of an outer (master) loop and an inner (slave) loop, allowing for more responsive control of complex processes with multiple variables or disturbances. The inner loop typically controls faster dynamics while the outer loop manages slower process variables, resulting in improved overall system stability and disturbance rejection capabilities.

- Tuning methods for cascade PID controllers: Various tuning methodologies have been developed specifically for cascade PID controllers to optimize their performance. These methods include sequential tuning approaches where the inner loop is tuned first followed by the outer loop, as well as simultaneous tuning techniques that consider the interaction between loops. Advanced tuning algorithms may incorporate adaptive or self-tuning capabilities that adjust controller parameters based on changing process conditions or performance metrics, ensuring optimal control performance across varying operating conditions.

- Performance enhancement techniques for cascade control: Performance of cascade PID controllers can be enhanced through various techniques including anti-windup mechanisms, feedforward control integration, and dynamic gain scheduling. These enhancements help address common issues such as integral windup, setpoint tracking, and disturbance rejection. By incorporating these techniques, cascade control systems can achieve faster response times, reduced overshoot, and improved stability across a wider operating range, particularly in systems with significant time delays or nonlinearities.

- Application-specific cascade control implementations: Cascade PID control has been successfully implemented across various industrial applications with specific adaptations to meet unique requirements. These applications include motion control systems, temperature regulation in industrial processes, pressure control in hydraulic systems, and precision positioning mechanisms. Each implementation typically features customized controller structures, specialized filtering techniques, or industry-specific modifications to address particular challenges such as mechanical resonance, thermal inertia, or variable process dynamics.

- Advanced and intelligent cascade control strategies: Recent developments in cascade control include integration with advanced control methodologies such as fuzzy logic, neural networks, and model predictive control. These hybrid approaches combine the reliability of traditional cascade PID with the adaptability of intelligent control techniques. Such systems can automatically adjust to changing process dynamics, compensate for nonlinearities, and optimize performance based on multiple objectives simultaneously. These advanced strategies often incorporate online parameter estimation and real-time optimization algorithms to continuously improve control performance.

02 Tuning methods for cascade PID controllers

Various tuning methods are employed to optimize cascade PID controller performance. These include model-based approaches, auto-tuning algorithms, and adaptive tuning techniques. Proper tuning of both inner and outer loops is critical, with the inner loop typically tuned for fast response while the outer loop is tuned for stability. Advanced tuning methods may incorporate fuzzy logic, neural networks, or genetic algorithms to achieve optimal control parameters.Expand Specific Solutions03 Performance enhancement techniques for cascade control

Performance of cascade PID controllers can be enhanced through various techniques including anti-windup mechanisms, feedforward control, gain scheduling, and disturbance rejection methods. These enhancements help overcome limitations of traditional PID control by addressing nonlinearities, time delays, and external disturbances. Implementation of these techniques results in improved transient response, reduced settling time, and minimized steady-state error.Expand Specific Solutions04 Application-specific cascade control implementations

Cascade PID controllers are implemented in various industrial applications with specific requirements. These include motion control systems, temperature regulation in process industries, pressure control in hydraulic systems, and speed control in electric drives. Each application requires customized cascade control strategies to address unique challenges such as varying time constants, load disturbances, or environmental factors that affect control performance.Expand Specific Solutions05 Digital implementation and advanced algorithms

Modern cascade PID controllers leverage digital implementation techniques and advanced algorithms to achieve superior performance. These include microcontroller-based implementations, FPGA platforms, and industrial PCs running specialized control software. Advanced algorithms incorporate predictive elements, state estimation, and hybrid control strategies that combine PID with other control methods. Digital implementations also enable features like auto-diagnostics, remote tuning, and integration with industrial communication protocols.Expand Specific Solutions

Leading Vendors and Control System Providers

The cascade PID controller architecture market is in a growth phase, with increasing adoption across industrial automation sectors. The market size is expanding due to rising demand for precise control systems in complex processes. Technologically, this field shows varying maturity levels among key players. Academic institutions like Beihang University and Sichuan University are advancing theoretical frameworks, while industrial leaders such as State Grid Corp. of China, NARI Group, and Guodian Nanjing Automation are implementing practical applications in power systems. Companies like Spiro Control and BYD are developing specialized implementations for sustainability and electric vehicles respectively. The integration of cascade PID with emerging technologies like IoT and AI represents the next frontier, with companies like Guangdong Mingyang Information Technology positioning themselves at this intersection.

Chongqing University

Technical Solution: Chongqing University has developed innovative cascade PID controller architectures for power systems and industrial automation applications. Their research implements a multi-loop structure where the primary controller establishes setpoints for secondary controllers in a hierarchical arrangement. In power system applications, the outer loop manages grid stability parameters while inner loops control specific generator responses or power electronic converters. Their implementation features advanced algorithms for auto-tuning both loops simultaneously using model identification techniques that capture the dynamic relationships between loops. Chongqing University's cascade architecture incorporates specialized disturbance observers that estimate and compensate for external perturbations, significantly improving rejection capabilities. Their controllers employ adaptive mechanisms that adjust PID parameters based on operating conditions and system changes, enabling robust performance across varying loads and disturbances. The research team has developed novel anti-windup schemes specifically designed for cascade structures that prevent saturation propagation between loops.

Strengths: Excellent theoretical foundation with rigorous stability analysis ensuring robust performance under varying conditions. Their approach offers superior disturbance rejection compared to conventional single-loop controllers, particularly for systems with significant time delays. Weaknesses: Higher implementation complexity requiring more computational resources. The academic approach sometimes prioritizes theoretical optimality over practical implementation considerations.

Bendix Commercial Vehicle Systems LLC

Technical Solution: Bendix has developed an advanced cascade PID controller architecture for commercial vehicle braking systems. Their approach utilizes a hierarchical structure where the primary PID controller generates setpoints for secondary controllers. In their implementation, the outer loop manages vehicle stability parameters while inner loops control specific brake actuator responses. The system processes feedback from multiple sensors including wheel speed, vehicle acceleration, and brake pressure to optimize braking performance. Bendix's cascade architecture incorporates anti-windup mechanisms to prevent integral term saturation during rapid transient responses, which is critical for emergency braking scenarios. Their controllers feature adaptive gain scheduling that adjusts PID parameters based on vehicle speed, load conditions, and road surface characteristics, enabling robust performance across diverse operating conditions.

Strengths: Superior disturbance rejection capabilities and improved stability margins compared to single-loop controllers. The hierarchical structure allows optimization of both fast local responses and overall system objectives. Weaknesses: Increased computational complexity requiring more powerful onboard processors, and more challenging tuning process due to interdependencies between control loops.

Key Algorithms and Mathematical Foundations

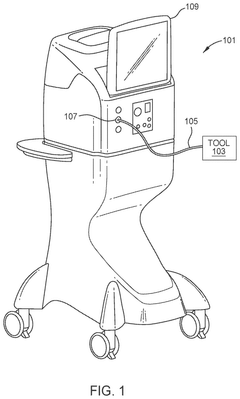

Methods and systems for providing control stability in a vacuum generation system using cascade proportional-integral-derivative (PID) controller

PatentActiveUS12214116B2

Innovation

- A cascade proportional-integral-derivative (PID) controller system is implemented, comprising an outer loop PID controller that adjusts the supply air pressure set point based on vacuum pressure feedback, and an inner loop PID controller that adjusts the voltage to the proportional valve based on supply air pressure feedback, thereby maintaining stability and efficiency across varying supply air pressures.

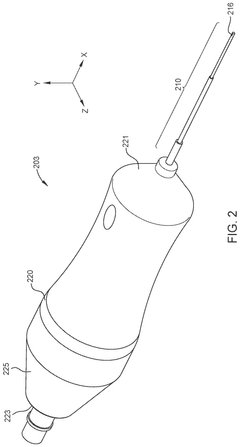

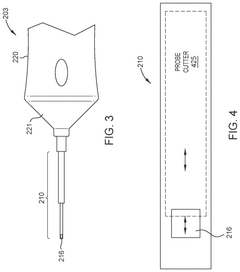

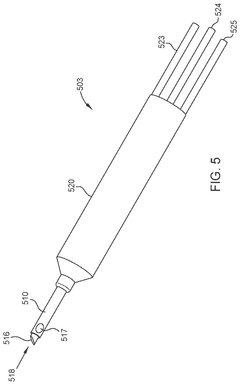

Mechanisms for controlling different electromechanical systems of an electrosurgical instrument

PatentWO2019130109A1

Innovation

- A surgical instrument with an ultrasonic blade and clamp arm, coupled with a control circuit that monitors parameters to switch between different electromechanical systems based on predetermined thresholds, allowing for adaptive energy delivery and tissue interaction.

Performance Metrics and Tuning Methodologies

Evaluating cascade PID controller performance requires specific metrics that differ from traditional single-loop PID systems. The primary performance indicators include settling time, which measures how quickly both the inner and outer loops reach steady state after disturbances; overshoot percentage, which quantifies the maximum deviation beyond the setpoint; and steady-state error, which evaluates the controller's precision during stable operation. Robustness metrics such as gain margin and phase margin are particularly critical in cascade systems to ensure stability across both control loops under varying operating conditions.

Disturbance rejection capability serves as another essential metric, measuring how effectively the cascade architecture mitigates both external disturbances and process variations. This is typically quantified through integral error measurements including IAE (Integral Absolute Error), ISE (Integral Squared Error), and ITAE (Integral Time-weighted Absolute Error), with cascade controllers generally demonstrating superior performance compared to single-loop alternatives.

Tuning methodologies for cascade PID controllers follow a structured approach beginning with the inner loop. The Ziegler-Nichols method remains popular for initial parameter estimation, though it typically requires refinement. The recommended sequence involves first stabilizing the inner loop while keeping the outer loop in manual mode, followed by tuning the outer loop once the inner loop demonstrates satisfactory performance. This sequential approach prevents interference between loops during the tuning process.

Advanced tuning techniques include relay-feedback methods, which automatically determine critical gain and period values, and model-based approaches that utilize mathematical process models to calculate optimal controller parameters. Computational intelligence techniques such as genetic algorithms and particle swarm optimization have emerged as powerful tools for simultaneously optimizing multiple parameters across both control loops, particularly valuable for complex nonlinear systems.

Practical implementation considerations include anti-windup mechanisms to prevent integral term saturation, which becomes more complex in cascade architectures due to potential windup in both controllers. Additionally, bumpless transfer techniques ensure smooth transitions when switching between manual and automatic control modes, critical for maintaining process stability during operational changes.

Disturbance rejection capability serves as another essential metric, measuring how effectively the cascade architecture mitigates both external disturbances and process variations. This is typically quantified through integral error measurements including IAE (Integral Absolute Error), ISE (Integral Squared Error), and ITAE (Integral Time-weighted Absolute Error), with cascade controllers generally demonstrating superior performance compared to single-loop alternatives.

Tuning methodologies for cascade PID controllers follow a structured approach beginning with the inner loop. The Ziegler-Nichols method remains popular for initial parameter estimation, though it typically requires refinement. The recommended sequence involves first stabilizing the inner loop while keeping the outer loop in manual mode, followed by tuning the outer loop once the inner loop demonstrates satisfactory performance. This sequential approach prevents interference between loops during the tuning process.

Advanced tuning techniques include relay-feedback methods, which automatically determine critical gain and period values, and model-based approaches that utilize mathematical process models to calculate optimal controller parameters. Computational intelligence techniques such as genetic algorithms and particle swarm optimization have emerged as powerful tools for simultaneously optimizing multiple parameters across both control loops, particularly valuable for complex nonlinear systems.

Practical implementation considerations include anti-windup mechanisms to prevent integral term saturation, which becomes more complex in cascade architectures due to potential windup in both controllers. Additionally, bumpless transfer techniques ensure smooth transitions when switching between manual and automatic control modes, critical for maintaining process stability during operational changes.

Integration with Industry 4.0 Technologies

Cascade PID controllers are increasingly becoming integral components within Industry 4.0 frameworks, enabling sophisticated control mechanisms that align with smart manufacturing principles. The integration of cascade PID architectures with Industry 4.0 technologies creates powerful synergies that enhance production efficiency, quality control, and system responsiveness across industrial environments.

Cloud computing platforms now offer specialized services for implementing and managing cascade PID control systems remotely. These platforms provide computational resources for complex cascade control algorithms while enabling real-time monitoring and adjustment of control parameters from anywhere in the world. This cloud-based approach facilitates the implementation of advanced control strategies without requiring extensive on-site computational infrastructure.

Industrial Internet of Things (IIoT) networks significantly enhance cascade PID implementations by connecting multiple sensors and actuators across production environments. This connectivity allows cascade controllers to access a broader range of process variables and control points, creating more comprehensive control loops. The distributed nature of IIoT systems enables cascade controllers to operate across physically separated processes while maintaining tight coordination between primary and secondary loops.

Digital twin technology represents another transformative integration point for cascade PID controllers. By creating virtual replicas of physical production systems, engineers can simulate and optimize cascade control strategies before deployment. These digital twins enable parameter tuning and control strategy validation without disrupting actual production, significantly reducing implementation risks and commissioning time.

Machine learning algorithms are increasingly being incorporated into cascade PID architectures to enable adaptive control capabilities. These algorithms can analyze historical performance data to automatically adjust controller parameters in response to changing process conditions or equipment degradation. This self-tuning capability addresses one of the traditional challenges of cascade control—maintaining optimal performance as system characteristics evolve over time.

Edge computing deployments near production equipment support low-latency cascade control implementations critical for high-speed processes. By processing control algorithms closer to the physical equipment, edge computing minimizes communication delays between primary and secondary loops, enabling more responsive control actions and improved stability in time-sensitive applications.

Augmented reality interfaces are emerging as valuable tools for visualizing cascade control performance in industrial settings. Maintenance technicians and process engineers can use AR displays to observe real-time controller behavior, visualize the relationships between primary and secondary loops, and identify potential issues before they impact production quality or efficiency.

Cloud computing platforms now offer specialized services for implementing and managing cascade PID control systems remotely. These platforms provide computational resources for complex cascade control algorithms while enabling real-time monitoring and adjustment of control parameters from anywhere in the world. This cloud-based approach facilitates the implementation of advanced control strategies without requiring extensive on-site computational infrastructure.

Industrial Internet of Things (IIoT) networks significantly enhance cascade PID implementations by connecting multiple sensors and actuators across production environments. This connectivity allows cascade controllers to access a broader range of process variables and control points, creating more comprehensive control loops. The distributed nature of IIoT systems enables cascade controllers to operate across physically separated processes while maintaining tight coordination between primary and secondary loops.

Digital twin technology represents another transformative integration point for cascade PID controllers. By creating virtual replicas of physical production systems, engineers can simulate and optimize cascade control strategies before deployment. These digital twins enable parameter tuning and control strategy validation without disrupting actual production, significantly reducing implementation risks and commissioning time.

Machine learning algorithms are increasingly being incorporated into cascade PID architectures to enable adaptive control capabilities. These algorithms can analyze historical performance data to automatically adjust controller parameters in response to changing process conditions or equipment degradation. This self-tuning capability addresses one of the traditional challenges of cascade control—maintaining optimal performance as system characteristics evolve over time.

Edge computing deployments near production equipment support low-latency cascade control implementations critical for high-speed processes. By processing control algorithms closer to the physical equipment, edge computing minimizes communication delays between primary and secondary loops, enabling more responsive control actions and improved stability in time-sensitive applications.

Augmented reality interfaces are emerging as valuable tools for visualizing cascade control performance in industrial settings. Maintenance technicians and process engineers can use AR displays to observe real-time controller behavior, visualize the relationships between primary and secondary loops, and identify potential issues before they impact production quality or efficiency.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!