Digital Versus Analog PID Controllers: What Are The Differences?

SEP 5, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PID Control Technology Background and Objectives

PID (Proportional-Integral-Derivative) control technology has evolved significantly since its inception in the late 19th century. Initially developed for ship steering mechanisms, PID controllers have become fundamental components in industrial automation, process control, and various engineering applications. The evolution from purely mechanical systems to electronic analog implementations marked the first major transition in PID technology, enabling more precise control and wider application scope.

The analog PID controllers dominated the industry throughout most of the 20th century, utilizing operational amplifiers and passive components to perform the mathematical operations required for proportional, integral, and derivative control actions. These controllers offered continuous signal processing with theoretically infinite resolution, making them particularly effective for systems requiring high-speed response.

With the advent of microprocessors and digital signal processing in the 1970s and 1980s, digital PID controllers emerged as viable alternatives. This technological shift represented a paradigm change in control system implementation, introducing programmability, flexibility, and advanced features previously unattainable with analog systems.

The fundamental objective of PID control technology remains consistent across both analog and digital implementations: to maintain a process variable at a desired setpoint by adjusting a control variable. However, the means by which this objective is achieved differs significantly between the two approaches, leading to distinct performance characteristics, implementation considerations, and application suitability.

Current technological trends indicate a continued shift toward digital implementations, with hybrid solutions emerging to leverage the strengths of both approaches. The integration of PID control with artificial intelligence, machine learning algorithms, and adaptive control strategies represents the cutting edge of development in this field, aiming to address increasingly complex control challenges in modern industrial systems.

The primary technical objectives in contemporary PID controller development focus on enhancing robustness against disturbances, improving adaptability to changing process dynamics, minimizing energy consumption, and simplifying configuration and tuning procedures. Additionally, there is growing emphasis on seamless integration with Industrial Internet of Things (IIoT) platforms, enabling remote monitoring, data analytics, and predictive maintenance capabilities.

Understanding the fundamental differences between analog and digital PID controllers is crucial for engineers and system designers to make informed decisions regarding controller selection, implementation, and optimization for specific applications. This technical exploration aims to elucidate these differences, examining their respective strengths, limitations, and optimal use cases in modern control systems.

The analog PID controllers dominated the industry throughout most of the 20th century, utilizing operational amplifiers and passive components to perform the mathematical operations required for proportional, integral, and derivative control actions. These controllers offered continuous signal processing with theoretically infinite resolution, making them particularly effective for systems requiring high-speed response.

With the advent of microprocessors and digital signal processing in the 1970s and 1980s, digital PID controllers emerged as viable alternatives. This technological shift represented a paradigm change in control system implementation, introducing programmability, flexibility, and advanced features previously unattainable with analog systems.

The fundamental objective of PID control technology remains consistent across both analog and digital implementations: to maintain a process variable at a desired setpoint by adjusting a control variable. However, the means by which this objective is achieved differs significantly between the two approaches, leading to distinct performance characteristics, implementation considerations, and application suitability.

Current technological trends indicate a continued shift toward digital implementations, with hybrid solutions emerging to leverage the strengths of both approaches. The integration of PID control with artificial intelligence, machine learning algorithms, and adaptive control strategies represents the cutting edge of development in this field, aiming to address increasingly complex control challenges in modern industrial systems.

The primary technical objectives in contemporary PID controller development focus on enhancing robustness against disturbances, improving adaptability to changing process dynamics, minimizing energy consumption, and simplifying configuration and tuning procedures. Additionally, there is growing emphasis on seamless integration with Industrial Internet of Things (IIoT) platforms, enabling remote monitoring, data analytics, and predictive maintenance capabilities.

Understanding the fundamental differences between analog and digital PID controllers is crucial for engineers and system designers to make informed decisions regarding controller selection, implementation, and optimization for specific applications. This technical exploration aims to elucidate these differences, examining their respective strengths, limitations, and optimal use cases in modern control systems.

Market Applications and Demand Analysis for PID Controllers

The PID controller market has witnessed substantial growth in recent years, driven by increasing industrial automation across various sectors. The global PID controller market was valued at approximately 2.1 billion USD in 2022 and is projected to grow at a CAGR of 6.3% through 2030, reflecting the strong demand for both analog and digital control solutions.

Manufacturing industries represent the largest application segment for PID controllers, accounting for nearly 40% of the total market share. Within this sector, process industries such as chemical, petrochemical, and pharmaceutical manufacturing demonstrate particularly high adoption rates due to their need for precise temperature, pressure, and flow control. Digital PID controllers have gained significant traction in these industries due to their superior flexibility and integration capabilities with modern manufacturing execution systems.

The energy sector constitutes another major market for PID controllers, particularly in power generation and distribution systems. As renewable energy sources become more prevalent, the demand for sophisticated control systems has increased substantially. Digital PID controllers are preferred in this sector due to their ability to handle complex algorithms and remote monitoring capabilities, essential for managing distributed energy resources.

HVAC applications represent a rapidly growing market segment for PID controllers, with an estimated annual growth rate of 7.5%. Building automation systems increasingly rely on digital PID controllers to optimize energy consumption while maintaining comfort levels. The ability of digital controllers to implement adaptive control strategies and communicate with central building management systems has made them the dominant choice in new installations.

Automotive and transportation sectors have also emerged as significant consumers of PID controllers, particularly for engine management systems, autonomous vehicle development, and electric vehicle battery management. Digital controllers dominate this space due to their programmability and ability to implement complex control strategies.

Regional analysis reveals that Asia-Pacific holds the largest market share at approximately 35%, followed by North America and Europe. China and India are experiencing the fastest growth rates due to rapid industrialization and infrastructure development. The market in these regions shows a clear trend toward digital solutions, though analog controllers maintain relevance in specific applications requiring simplicity and reliability under harsh conditions.

End-user preferences indicate a gradual but definitive shift from analog to digital PID controllers across most industries. This transition is primarily driven by the increasing complexity of industrial processes, the need for data integration, and the growing emphasis on predictive maintenance and remote monitoring capabilities that digital systems can more readily provide.

Manufacturing industries represent the largest application segment for PID controllers, accounting for nearly 40% of the total market share. Within this sector, process industries such as chemical, petrochemical, and pharmaceutical manufacturing demonstrate particularly high adoption rates due to their need for precise temperature, pressure, and flow control. Digital PID controllers have gained significant traction in these industries due to their superior flexibility and integration capabilities with modern manufacturing execution systems.

The energy sector constitutes another major market for PID controllers, particularly in power generation and distribution systems. As renewable energy sources become more prevalent, the demand for sophisticated control systems has increased substantially. Digital PID controllers are preferred in this sector due to their ability to handle complex algorithms and remote monitoring capabilities, essential for managing distributed energy resources.

HVAC applications represent a rapidly growing market segment for PID controllers, with an estimated annual growth rate of 7.5%. Building automation systems increasingly rely on digital PID controllers to optimize energy consumption while maintaining comfort levels. The ability of digital controllers to implement adaptive control strategies and communicate with central building management systems has made them the dominant choice in new installations.

Automotive and transportation sectors have also emerged as significant consumers of PID controllers, particularly for engine management systems, autonomous vehicle development, and electric vehicle battery management. Digital controllers dominate this space due to their programmability and ability to implement complex control strategies.

Regional analysis reveals that Asia-Pacific holds the largest market share at approximately 35%, followed by North America and Europe. China and India are experiencing the fastest growth rates due to rapid industrialization and infrastructure development. The market in these regions shows a clear trend toward digital solutions, though analog controllers maintain relevance in specific applications requiring simplicity and reliability under harsh conditions.

End-user preferences indicate a gradual but definitive shift from analog to digital PID controllers across most industries. This transition is primarily driven by the increasing complexity of industrial processes, the need for data integration, and the growing emphasis on predictive maintenance and remote monitoring capabilities that digital systems can more readily provide.

Current State and Challenges in Digital vs Analog PID Implementation

The implementation of PID controllers has evolved significantly over the decades, with both analog and digital solutions coexisting in today's industrial landscape. Analog PID controllers, which have been in use since the 1940s, continue to maintain relevance in specific applications despite the digital revolution. Meanwhile, digital PID controllers have gained substantial market share since the 1980s due to their flexibility and integration capabilities.

Currently, analog PID controllers are predominantly implemented using operational amplifiers, resistors, and capacitors to perform the proportional, integral, and derivative operations. These hardware-based solutions offer real-time continuous processing with virtually zero latency, making them particularly valuable in high-speed control applications where microsecond response times are critical. Industries such as power electronics, certain medical devices, and high-frequency signal processing still rely heavily on analog implementations.

Digital PID controllers, conversely, are typically implemented using microcontrollers, DSPs (Digital Signal Processors), or FPGAs (Field-Programmable Gate Arrays). The market has seen significant growth in specialized digital controller ICs and software libraries that simplify implementation. Modern PLCs (Programmable Logic Controllers) and DCS (Distributed Control Systems) almost universally incorporate digital PID functionality as a standard feature.

A major challenge in analog PID implementation is component drift and temperature sensitivity, which necessitates periodic recalibration. Analog controllers also face limitations in implementing complex control algorithms beyond basic PID structures. The manufacturing precision of analog components directly impacts controller performance, creating consistency challenges in mass production environments.

Digital implementations face their own set of challenges, primarily centered around sampling and quantization effects. The discretization process introduces inherent delays that can destabilize high-speed control loops. Finite word length effects in fixed-point implementations can lead to quantization errors and limit cycles. Additionally, the execution time of the control algorithm can vary, introducing jitter that degrades control performance in time-critical applications.

Geographically, analog PID technology development remains strong in regions with established electronics manufacturing expertise, particularly Japan and Germany. Digital PID innovation clusters are more widely distributed, with significant development occurring in North America, Europe, and increasingly in China and South Korea, where semiconductor and software expertise intersect.

The industry is currently witnessing a convergence trend with hybrid solutions that leverage the strengths of both approaches. These systems typically employ analog front-ends for high-speed signal conditioning combined with digital processing for complex control algorithms and system integration. This hybrid approach represents a pragmatic response to the inherent limitations of purely digital or analog implementations.

Currently, analog PID controllers are predominantly implemented using operational amplifiers, resistors, and capacitors to perform the proportional, integral, and derivative operations. These hardware-based solutions offer real-time continuous processing with virtually zero latency, making them particularly valuable in high-speed control applications where microsecond response times are critical. Industries such as power electronics, certain medical devices, and high-frequency signal processing still rely heavily on analog implementations.

Digital PID controllers, conversely, are typically implemented using microcontrollers, DSPs (Digital Signal Processors), or FPGAs (Field-Programmable Gate Arrays). The market has seen significant growth in specialized digital controller ICs and software libraries that simplify implementation. Modern PLCs (Programmable Logic Controllers) and DCS (Distributed Control Systems) almost universally incorporate digital PID functionality as a standard feature.

A major challenge in analog PID implementation is component drift and temperature sensitivity, which necessitates periodic recalibration. Analog controllers also face limitations in implementing complex control algorithms beyond basic PID structures. The manufacturing precision of analog components directly impacts controller performance, creating consistency challenges in mass production environments.

Digital implementations face their own set of challenges, primarily centered around sampling and quantization effects. The discretization process introduces inherent delays that can destabilize high-speed control loops. Finite word length effects in fixed-point implementations can lead to quantization errors and limit cycles. Additionally, the execution time of the control algorithm can vary, introducing jitter that degrades control performance in time-critical applications.

Geographically, analog PID technology development remains strong in regions with established electronics manufacturing expertise, particularly Japan and Germany. Digital PID innovation clusters are more widely distributed, with significant development occurring in North America, Europe, and increasingly in China and South Korea, where semiconductor and software expertise intersect.

The industry is currently witnessing a convergence trend with hybrid solutions that leverage the strengths of both approaches. These systems typically employ analog front-ends for high-speed signal conditioning combined with digital processing for complex control algorithms and system integration. This hybrid approach represents a pragmatic response to the inherent limitations of purely digital or analog implementations.

Technical Comparison of Digital and Analog PID Solutions

01 Tuning methods for PID controller performance optimization

Various tuning methods can significantly impact PID controller performance. Advanced algorithms for parameter optimization help achieve desired control characteristics such as reduced overshoot, faster settling time, and improved stability. These methods include auto-tuning techniques, adaptive tuning approaches, and optimization algorithms that adjust PID parameters based on system response characteristics and performance requirements.- Tuning methods for PID controllers: Various tuning methods can be applied to PID controllers to optimize their performance. These methods include auto-tuning algorithms, adaptive tuning techniques, and model-based approaches that adjust controller parameters based on process characteristics. Proper tuning significantly affects controller performance metrics such as settling time, overshoot, and steady-state error, allowing for customization based on specific application requirements.

- Comparative analysis of PID controller variants: Different variants of PID controllers, including standard PID, cascaded PID, fuzzy PID, and model predictive controllers, exhibit varying performance characteristics. These differences manifest in response time, disturbance rejection capabilities, and robustness to system changes. The selection of controller type depends on the specific application requirements, with some variants performing better in certain industrial scenarios than others.

- Implementation platforms and hardware considerations: The hardware platform used to implement PID controllers significantly impacts their performance. Controllers implemented on dedicated hardware like PLCs may offer different response characteristics compared to those implemented on general-purpose computing platforms. Hardware considerations include processing speed, memory constraints, communication interfaces, and real-time capabilities, all of which affect the controller's ability to maintain precise control under various operating conditions.

- Advanced PID control strategies: Advanced PID control strategies incorporate additional features beyond basic proportional, integral, and derivative actions to enhance performance. These include gain scheduling, anti-windup mechanisms, feed-forward control, and self-learning capabilities. Such advanced strategies can significantly improve control performance in complex systems with nonlinearities, time delays, or changing dynamics, resulting in better disturbance rejection and setpoint tracking.

- Performance evaluation metrics and benchmarking: Various metrics are used to evaluate and compare PID controller performance, including rise time, settling time, overshoot percentage, steady-state error, and integral performance indices. Benchmarking methodologies allow for objective comparison between different controller implementations and tuning methods. These evaluation approaches help in selecting the most appropriate controller configuration for specific industrial applications and process requirements.

02 Comparative analysis of PID controller variants

Different PID controller variants exhibit distinct performance characteristics. Standard PID controllers, fuzzy PID controllers, and model predictive controllers each offer unique advantages in specific applications. Performance differences include response time, robustness to disturbances, and ability to handle nonlinear systems. The selection of controller type depends on the specific requirements of the application and the nature of the process being controlled.Expand Specific Solutions03 Implementation platforms and hardware effects on PID performance

The hardware platform and implementation method significantly affect PID controller performance. Digital implementations on microcontrollers, FPGAs, or PLCs each introduce different computational delays, precision limitations, and sampling rate constraints. Hardware-specific optimizations can enhance control loop execution speed and precision, while real-time operating systems provide more deterministic performance compared to general-purpose computing environments.Expand Specific Solutions04 Advanced PID architectures for improved performance

Enhanced PID architectures incorporate additional features to overcome limitations of traditional controllers. Cascaded PID structures, feed-forward compensation, and anti-windup mechanisms significantly improve performance in challenging control scenarios. These advanced architectures provide better disturbance rejection, reduced integral windup, and improved handling of systems with time delays or nonlinearities, resulting in more robust control performance across varying operating conditions.Expand Specific Solutions05 Application-specific PID performance considerations

PID controller performance varies significantly across different application domains. In process industries, temperature control systems may prioritize minimal overshoot, while motion control applications require fast response times. Industry-specific tuning methods and performance metrics have been developed to address these unique requirements. The performance evaluation criteria must be tailored to the specific application context, considering factors such as energy efficiency, wear on actuators, and process constraints.Expand Specific Solutions

Major Manufacturers and Competitive Landscape

The digital versus analog PID controller market is currently in a mature growth phase, with an estimated global market size exceeding $2 billion. Digital controllers are rapidly gaining market share due to their flexibility and integration capabilities. Leading semiconductor companies like Texas Instruments, Infineon Technologies, and Microchip Technology dominate the digital controller segment, leveraging their expertise in microcontroller development. Traditional automation specialists such as Beckhoff Automation and Robert Bosch maintain strong positions in industrial applications. Research institutions including Huazhong University of Science & Technology and Indian Institute of Technology Madras are advancing controller theory, particularly in adaptive algorithms. The technology has reached high maturity in conventional applications, while innovations in self-tuning capabilities and IoT integration represent emerging growth areas where companies like NXP Semiconductors and Nordic Semiconductor are focusing their development efforts.

Texas Instruments Incorporated

Technical Solution: Texas Instruments has developed comprehensive digital PID controller solutions through their C2000 microcontroller family specifically designed for real-time control applications. Their digital PID implementation leverages high-performance 32-bit processors with specialized hardware accelerators for control loop calculations, enabling sampling rates up to 200 kHz[1]. TI's digital controllers feature adaptive algorithms that can automatically tune PID parameters based on system response, significantly reducing commissioning time. Their controllers incorporate anti-windup mechanisms and bumpless transfer capabilities when switching between manual and automatic modes. TI has also developed specialized software libraries and graphical configuration tools that simplify the implementation of complex control strategies, allowing engineers to visualize control loop performance in real-time and make adjustments without extensive programming knowledge[2].

Strengths: Highly configurable with parameter adjustment during operation; excellent noise immunity through digital filtering; ability to implement complex control algorithms beyond basic PID; comprehensive development tools. Weaknesses: Higher implementation complexity; potential for quantization errors; higher power consumption compared to analog solutions; latency issues in high-speed applications.

Beckhoff Automation GmbH & Co. KG

Technical Solution: Beckhoff Automation has pioneered TwinCAT (The Windows Control and Automation Technology), an advanced software-based digital PID control system that transforms standard PCs into real-time controllers. Their approach integrates PID functionality directly into their PC-based control architecture, allowing for microsecond-level execution cycles[3]. Beckhoff's digital controllers feature multi-core support that enables parallel processing of multiple control loops without interference. Their system implements sophisticated auto-tuning algorithms that can identify system parameters and automatically configure optimal PID settings. Beckhoff's controllers can seamlessly switch between different control strategies (P, PI, PID) based on process requirements and operating conditions. The platform also provides comprehensive data logging capabilities, allowing for detailed analysis of control performance over time and facilitating continuous improvement of control parameters[4].

Strengths: Exceptional flexibility with software-defined control parameters; seamless integration with higher-level systems; advanced diagnostics and monitoring capabilities; ability to implement complex control strategies. Weaknesses: Dependency on PC hardware reliability; potential for operating system interruptions affecting real-time performance; higher initial cost compared to dedicated analog controllers.

Key Patents and Innovations in PID Control Systems

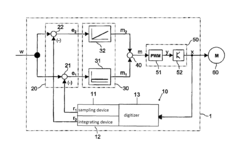

Closed-loop control method and closed-loop control device with multi-channel feedback

PatentActiveUS8203300B2

Innovation

- A method that combines sampling and averaging feedback variables to generate control deviations, using a first feedback variable sampled at a specific frequency and a second feedback variable averaged over time, allowing for precise control by comparing these with a command variable to generate a controller output variable that accurately follows the command.

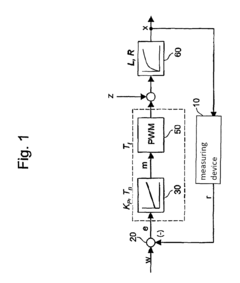

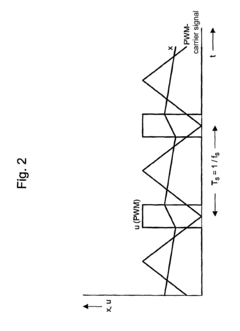

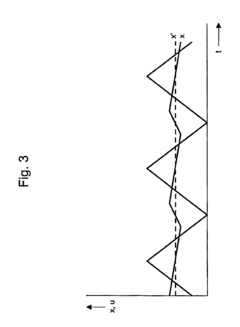

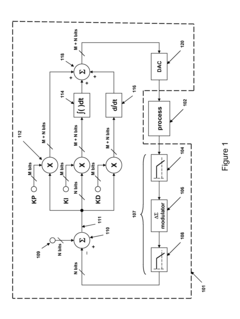

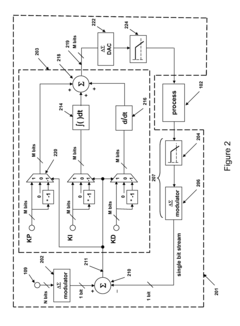

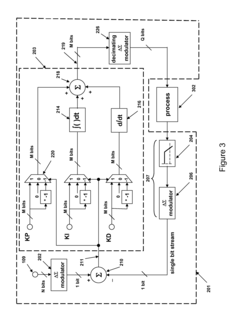

Oversampling PID Controller for Integration with a Delta-Sigma Analog-to-Digital Converter

PatentActiveUS20090237282A1

Innovation

- A digital controller structure employing a delta-sigma modulator to produce one-bit signals for measured and set-point values, using subtraction to calculate control signals, eliminating the need for multi-bit multiplications by utilizing a control block with multiplexers to select partial sums based on control error signals.

Performance Metrics and Benchmarking Methodologies

Evaluating the performance of PID controllers requires systematic benchmarking methodologies and well-defined metrics that can accurately capture the differences between digital and analog implementations. These metrics serve as quantitative indicators for comparing controller efficiency, reliability, and suitability for specific applications.

Response time represents a critical performance metric, typically measured through step response tests. Digital PID controllers generally demonstrate faster response times in complex systems due to their programmable nature, while analog controllers may exhibit superior performance in simple systems with minimal processing overhead. The settling time—duration required for the system to reach and maintain a steady state within a specified error band—provides valuable insights into controller stability.

Overshoot percentage quantifies how much a system exceeds its target value during transient response. Analog PID controllers often display smoother transitions with potentially lower overshoot in certain applications, whereas digital controllers can be programmed to minimize overshoot through advanced algorithms, though at the cost of increased computational complexity.

Steady-state error measurement reveals a controller's precision in maintaining the desired setpoint during stable operation. Digital controllers typically offer superior steady-state error performance due to their ability to implement complex error correction algorithms and adaptive control strategies that continuously optimize performance parameters.

Noise immunity testing evaluates controller performance under various noise conditions. Analog controllers may be more susceptible to electrical noise and environmental interference, while digital controllers can implement sophisticated filtering algorithms to mitigate noise effects, though they remain vulnerable to quantization noise from analog-to-digital conversion processes.

Bandwidth analysis determines the frequency range within which the controller operates effectively. Digital controllers often provide wider bandwidth capabilities through software-defined parameters, whereas analog controllers may offer more predictable performance within their designed frequency range without sampling-related limitations.

Power consumption comparison reveals significant differences, with analog controllers generally consuming less power in simple applications, making them suitable for battery-operated devices. Digital controllers typically require more power due to their processing requirements but can implement power-saving algorithms for improved efficiency in complex systems.

Robustness testing evaluates controller performance under varying operating conditions and parameter uncertainties. Digital controllers demonstrate superior adaptability through programmable gain scheduling and adaptive control algorithms, while analog controllers may require physical component replacements to accommodate significant parameter changes.

Standardized benchmarking protocols such as IAE (Integral Absolute Error), ISE (Integral Square Error), and ITAE (Integral Time-weighted Absolute Error) provide comprehensive frameworks for quantitative performance evaluation across different controller implementations, enabling objective comparison between digital and analog PID solutions.

Response time represents a critical performance metric, typically measured through step response tests. Digital PID controllers generally demonstrate faster response times in complex systems due to their programmable nature, while analog controllers may exhibit superior performance in simple systems with minimal processing overhead. The settling time—duration required for the system to reach and maintain a steady state within a specified error band—provides valuable insights into controller stability.

Overshoot percentage quantifies how much a system exceeds its target value during transient response. Analog PID controllers often display smoother transitions with potentially lower overshoot in certain applications, whereas digital controllers can be programmed to minimize overshoot through advanced algorithms, though at the cost of increased computational complexity.

Steady-state error measurement reveals a controller's precision in maintaining the desired setpoint during stable operation. Digital controllers typically offer superior steady-state error performance due to their ability to implement complex error correction algorithms and adaptive control strategies that continuously optimize performance parameters.

Noise immunity testing evaluates controller performance under various noise conditions. Analog controllers may be more susceptible to electrical noise and environmental interference, while digital controllers can implement sophisticated filtering algorithms to mitigate noise effects, though they remain vulnerable to quantization noise from analog-to-digital conversion processes.

Bandwidth analysis determines the frequency range within which the controller operates effectively. Digital controllers often provide wider bandwidth capabilities through software-defined parameters, whereas analog controllers may offer more predictable performance within their designed frequency range without sampling-related limitations.

Power consumption comparison reveals significant differences, with analog controllers generally consuming less power in simple applications, making them suitable for battery-operated devices. Digital controllers typically require more power due to their processing requirements but can implement power-saving algorithms for improved efficiency in complex systems.

Robustness testing evaluates controller performance under varying operating conditions and parameter uncertainties. Digital controllers demonstrate superior adaptability through programmable gain scheduling and adaptive control algorithms, while analog controllers may require physical component replacements to accommodate significant parameter changes.

Standardized benchmarking protocols such as IAE (Integral Absolute Error), ISE (Integral Square Error), and ITAE (Integral Time-weighted Absolute Error) provide comprehensive frameworks for quantitative performance evaluation across different controller implementations, enabling objective comparison between digital and analog PID solutions.

Industry-Specific Implementation Considerations

The implementation of PID controllers varies significantly across industries due to specific operational requirements, environmental conditions, and performance expectations. In manufacturing sectors, digital PID controllers are increasingly preferred for precision machinery and automated production lines where exact repeatability and integration with computerized systems are paramount. These controllers offer the advantage of easy parameter adjustment and data logging capabilities that support quality control initiatives and continuous improvement processes.

Conversely, process industries such as chemical and petrochemical plants often rely on a mix of both analog and digital controllers. Analog PID controllers remain valuable in hazardous environments where intrinsic safety is critical, as they can operate without the risk of software failures that might compromise safety systems. Additionally, their inherent simplicity makes them less susceptible to electromagnetic interference, which can be prevalent in industrial settings with high-power equipment.

The energy sector presents unique challenges for PID implementation. Power generation facilities typically employ digital controllers for main process control due to their superior ability to handle complex algorithms and multiple input/output relationships. However, analog controllers are still utilized in backup systems and critical safety circuits where response time is crucial and system reliability cannot be compromised by potential software bugs or cyber threats.

In transportation and automotive applications, digital PID controllers dominate due to their compatibility with electronic control units (ECUs) and ability to implement adaptive control strategies. These controllers can adjust parameters based on changing conditions, essential for optimizing fuel efficiency and emissions control in modern vehicles. The aerospace industry similarly favors digital implementations for flight control systems, where redundancy and fail-safe mechanisms are built into the controller architecture.

Healthcare equipment manufacturers face stringent regulatory requirements that influence controller selection. Digital PID controllers provide the documentation and validation capabilities necessary for compliance, while offering precise control for life-critical applications. However, certain medical devices still incorporate analog controllers in subsystems where simplicity and reliability outweigh the need for advanced features.

The selection between digital and analog PID controllers ultimately depends on industry-specific factors including safety requirements, environmental conditions, integration needs, maintenance capabilities, and long-term support considerations. Organizations must carefully evaluate these factors against their operational context to determine the most appropriate controller technology for their applications.

Conversely, process industries such as chemical and petrochemical plants often rely on a mix of both analog and digital controllers. Analog PID controllers remain valuable in hazardous environments where intrinsic safety is critical, as they can operate without the risk of software failures that might compromise safety systems. Additionally, their inherent simplicity makes them less susceptible to electromagnetic interference, which can be prevalent in industrial settings with high-power equipment.

The energy sector presents unique challenges for PID implementation. Power generation facilities typically employ digital controllers for main process control due to their superior ability to handle complex algorithms and multiple input/output relationships. However, analog controllers are still utilized in backup systems and critical safety circuits where response time is crucial and system reliability cannot be compromised by potential software bugs or cyber threats.

In transportation and automotive applications, digital PID controllers dominate due to their compatibility with electronic control units (ECUs) and ability to implement adaptive control strategies. These controllers can adjust parameters based on changing conditions, essential for optimizing fuel efficiency and emissions control in modern vehicles. The aerospace industry similarly favors digital implementations for flight control systems, where redundancy and fail-safe mechanisms are built into the controller architecture.

Healthcare equipment manufacturers face stringent regulatory requirements that influence controller selection. Digital PID controllers provide the documentation and validation capabilities necessary for compliance, while offering precise control for life-critical applications. However, certain medical devices still incorporate analog controllers in subsystems where simplicity and reliability outweigh the need for advanced features.

The selection between digital and analog PID controllers ultimately depends on industry-specific factors including safety requirements, environmental conditions, integration needs, maintenance capabilities, and long-term support considerations. Organizations must carefully evaluate these factors against their operational context to determine the most appropriate controller technology for their applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!