PID Controller Applications In HVAC And Building Automation

SEP 5, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PID Control Evolution in Building Systems

The evolution of PID control in building systems has undergone significant transformation since its initial application in the 1950s. Early implementations were primarily analog systems with limited functionality, focusing on basic temperature control through pneumatic controllers. These systems operated with minimal feedback mechanisms and required constant manual adjustments, resulting in inefficient energy usage and inconsistent comfort levels.

The 1970s energy crisis marked a pivotal turning point, accelerating the development of more sophisticated control systems. Digital PID controllers emerged in the 1980s, enabling more precise control algorithms and the integration of multiple environmental parameters beyond just temperature. This period saw the first microprocessor-based building automation systems that could handle complex control sequences and store historical performance data.

By the 1990s, networked building automation systems became prevalent, allowing for centralized monitoring and control of multiple HVAC components across entire facilities. The introduction of standardized communication protocols such as BACnet and LonWorks facilitated interoperability between different manufacturers' equipment, significantly expanding system capabilities and integration options.

The early 2000s witnessed the emergence of adaptive and self-tuning PID controllers that could automatically adjust their parameters based on changing building conditions. These systems incorporated fuzzy logic and neural network approaches to optimize performance without human intervention, dramatically improving both comfort and energy efficiency.

The current generation of building automation systems features cloud-connected controllers with advanced analytics capabilities. Modern PID implementations now incorporate predictive algorithms that anticipate building needs based on weather forecasts, occupancy patterns, and historical performance data. Machine learning techniques enable continuous optimization of control parameters, with some systems achieving energy savings of 15-30% compared to traditional control methods.

Wireless sensor networks have revolutionized data collection, providing granular environmental information across building zones without extensive wiring infrastructure. This has enabled more responsive and precise control strategies, particularly in retrofit applications where installing new wiring would be prohibitively expensive.

The most recent development is the integration of PID control with IoT platforms, creating truly intelligent building systems that can participate in demand response programs, integrate with renewable energy sources, and optimize for both occupant comfort and energy market conditions simultaneously. These systems represent the culmination of decades of evolution, transforming simple feedback controllers into sophisticated building intelligence systems.

The 1970s energy crisis marked a pivotal turning point, accelerating the development of more sophisticated control systems. Digital PID controllers emerged in the 1980s, enabling more precise control algorithms and the integration of multiple environmental parameters beyond just temperature. This period saw the first microprocessor-based building automation systems that could handle complex control sequences and store historical performance data.

By the 1990s, networked building automation systems became prevalent, allowing for centralized monitoring and control of multiple HVAC components across entire facilities. The introduction of standardized communication protocols such as BACnet and LonWorks facilitated interoperability between different manufacturers' equipment, significantly expanding system capabilities and integration options.

The early 2000s witnessed the emergence of adaptive and self-tuning PID controllers that could automatically adjust their parameters based on changing building conditions. These systems incorporated fuzzy logic and neural network approaches to optimize performance without human intervention, dramatically improving both comfort and energy efficiency.

The current generation of building automation systems features cloud-connected controllers with advanced analytics capabilities. Modern PID implementations now incorporate predictive algorithms that anticipate building needs based on weather forecasts, occupancy patterns, and historical performance data. Machine learning techniques enable continuous optimization of control parameters, with some systems achieving energy savings of 15-30% compared to traditional control methods.

Wireless sensor networks have revolutionized data collection, providing granular environmental information across building zones without extensive wiring infrastructure. This has enabled more responsive and precise control strategies, particularly in retrofit applications where installing new wiring would be prohibitively expensive.

The most recent development is the integration of PID control with IoT platforms, creating truly intelligent building systems that can participate in demand response programs, integrate with renewable energy sources, and optimize for both occupant comfort and energy market conditions simultaneously. These systems represent the culmination of decades of evolution, transforming simple feedback controllers into sophisticated building intelligence systems.

HVAC Market Demand Analysis

The global HVAC market has experienced substantial growth in recent years, driven by increasing urbanization, rising disposable incomes, and growing awareness of indoor air quality. As of 2023, the global HVAC market is valued at approximately 198 billion USD, with projections indicating a compound annual growth rate (CAGR) of 5.9% through 2030.

Commercial buildings represent the largest segment of the HVAC market, accounting for nearly 40% of total demand. This is followed by residential applications at 35% and industrial applications at 25%. The demand for smart HVAC systems incorporating PID controllers has seen particularly strong growth, with market research indicating a 12% year-over-year increase in adoption rates for intelligent building automation systems.

Energy efficiency remains the primary driver for HVAC system upgrades and replacements. With energy costs constituting 30-40% of a building's operating expenses, building owners and facility managers are increasingly seeking solutions that optimize energy consumption. PID controller-based systems have demonstrated energy savings of 15-30% compared to conventional on/off control systems, creating a compelling value proposition for implementation.

Regulatory pressures are significantly influencing market dynamics. Stringent energy efficiency standards and environmental regulations, such as those outlined in ASHRAE 90.1 and various national building codes, are mandating more sophisticated control systems. The European Union's Energy Performance of Buildings Directive and similar regulations in North America and Asia are accelerating the transition toward advanced control technologies, including PID-based solutions.

The COVID-19 pandemic has dramatically increased awareness of indoor air quality (IAQ), creating new market opportunities for HVAC control systems. Research indicates that 78% of commercial building occupants now consider IAQ a critical factor in their workplace satisfaction. This has led to a 23% increase in demand for HVAC systems with precise humidity and ventilation control capabilities, areas where PID controllers excel.

Emerging markets, particularly in Asia-Pacific and the Middle East, represent the fastest-growing segments for HVAC automation. China and India alone account for 35% of new HVAC installations globally, with increasing adoption of building automation technologies. The retrofit market in developed economies also presents significant opportunities, with an estimated 60% of commercial buildings in North America and Europe requiring HVAC control system upgrades to meet current efficiency standards.

Consumer expectations are evolving toward more personalized comfort solutions. The demand for zone-based temperature control, which can be efficiently implemented using networked PID controllers, has increased by 18% annually since 2020. This trend aligns with broader smart building initiatives, where HVAC systems are increasingly integrated with other building systems through IoT platforms.

Commercial buildings represent the largest segment of the HVAC market, accounting for nearly 40% of total demand. This is followed by residential applications at 35% and industrial applications at 25%. The demand for smart HVAC systems incorporating PID controllers has seen particularly strong growth, with market research indicating a 12% year-over-year increase in adoption rates for intelligent building automation systems.

Energy efficiency remains the primary driver for HVAC system upgrades and replacements. With energy costs constituting 30-40% of a building's operating expenses, building owners and facility managers are increasingly seeking solutions that optimize energy consumption. PID controller-based systems have demonstrated energy savings of 15-30% compared to conventional on/off control systems, creating a compelling value proposition for implementation.

Regulatory pressures are significantly influencing market dynamics. Stringent energy efficiency standards and environmental regulations, such as those outlined in ASHRAE 90.1 and various national building codes, are mandating more sophisticated control systems. The European Union's Energy Performance of Buildings Directive and similar regulations in North America and Asia are accelerating the transition toward advanced control technologies, including PID-based solutions.

The COVID-19 pandemic has dramatically increased awareness of indoor air quality (IAQ), creating new market opportunities for HVAC control systems. Research indicates that 78% of commercial building occupants now consider IAQ a critical factor in their workplace satisfaction. This has led to a 23% increase in demand for HVAC systems with precise humidity and ventilation control capabilities, areas where PID controllers excel.

Emerging markets, particularly in Asia-Pacific and the Middle East, represent the fastest-growing segments for HVAC automation. China and India alone account for 35% of new HVAC installations globally, with increasing adoption of building automation technologies. The retrofit market in developed economies also presents significant opportunities, with an estimated 60% of commercial buildings in North America and Europe requiring HVAC control system upgrades to meet current efficiency standards.

Consumer expectations are evolving toward more personalized comfort solutions. The demand for zone-based temperature control, which can be efficiently implemented using networked PID controllers, has increased by 18% annually since 2020. This trend aligns with broader smart building initiatives, where HVAC systems are increasingly integrated with other building systems through IoT platforms.

Current PID Implementation Challenges

Despite the widespread adoption of PID controllers in HVAC and building automation systems, several significant implementation challenges persist that limit their optimal performance. Traditional PID controllers often struggle with the inherent non-linearity of HVAC systems, where the relationship between control inputs and system responses varies across different operating conditions. This non-linearity creates zones where controller performance deteriorates, particularly during transition periods between heating and cooling modes.

Tuning difficulties represent another major challenge, as optimal PID parameters vary significantly based on building characteristics, seasonal changes, and occupancy patterns. The manual tuning process is time-consuming and often results in sub-optimal settings that compromise energy efficiency and comfort. Many building automation systems lack adaptive tuning capabilities, leaving controllers vulnerable to performance degradation as building conditions evolve over time.

Interoperability issues between different building subsystems further complicate PID implementation. Modern buildings integrate multiple systems including HVAC, lighting, and security, each potentially operating with different control protocols and communication standards. This fragmentation creates coordination challenges when attempting to implement holistic control strategies that require seamless interaction between subsystems.

Time delays and system latency pose significant obstacles to effective PID control in building systems. HVAC responses typically involve substantial thermal inertia, with noticeable delays between control actions and measurable temperature changes. Standard PID algorithms often perform poorly when confronted with these delays, leading to oscillatory behavior or sluggish responses that compromise both comfort and energy efficiency.

Sensor limitations and measurement uncertainties introduce additional complications. PID controllers rely on accurate feedback, yet building automation systems frequently contend with sensor drift, calibration issues, and placement challenges that distort the control feedback loop. These measurement inaccuracies can trigger inappropriate control responses, particularly in zones with complex airflow patterns or thermal stratification.

Energy efficiency requirements increasingly conflict with traditional PID implementation approaches. Modern building standards demand sophisticated energy optimization that goes beyond the capabilities of conventional PID control. The controllers must balance multiple competing objectives—comfort, energy consumption, equipment wear—yet lack the predictive capabilities to make optimal trade-offs across these dimensions without additional algorithmic enhancements.

Human factors and interface challenges round out the implementation difficulties. Building operators often lack specialized knowledge to properly configure and maintain PID controllers, leading to widespread "set and forget" approaches that fail to adapt to changing building conditions and requirements.

Tuning difficulties represent another major challenge, as optimal PID parameters vary significantly based on building characteristics, seasonal changes, and occupancy patterns. The manual tuning process is time-consuming and often results in sub-optimal settings that compromise energy efficiency and comfort. Many building automation systems lack adaptive tuning capabilities, leaving controllers vulnerable to performance degradation as building conditions evolve over time.

Interoperability issues between different building subsystems further complicate PID implementation. Modern buildings integrate multiple systems including HVAC, lighting, and security, each potentially operating with different control protocols and communication standards. This fragmentation creates coordination challenges when attempting to implement holistic control strategies that require seamless interaction between subsystems.

Time delays and system latency pose significant obstacles to effective PID control in building systems. HVAC responses typically involve substantial thermal inertia, with noticeable delays between control actions and measurable temperature changes. Standard PID algorithms often perform poorly when confronted with these delays, leading to oscillatory behavior or sluggish responses that compromise both comfort and energy efficiency.

Sensor limitations and measurement uncertainties introduce additional complications. PID controllers rely on accurate feedback, yet building automation systems frequently contend with sensor drift, calibration issues, and placement challenges that distort the control feedback loop. These measurement inaccuracies can trigger inappropriate control responses, particularly in zones with complex airflow patterns or thermal stratification.

Energy efficiency requirements increasingly conflict with traditional PID implementation approaches. Modern building standards demand sophisticated energy optimization that goes beyond the capabilities of conventional PID control. The controllers must balance multiple competing objectives—comfort, energy consumption, equipment wear—yet lack the predictive capabilities to make optimal trade-offs across these dimensions without additional algorithmic enhancements.

Human factors and interface challenges round out the implementation difficulties. Building operators often lack specialized knowledge to properly configure and maintain PID controllers, leading to widespread "set and forget" approaches that fail to adapt to changing building conditions and requirements.

Modern PID Control Strategies

01 PID Controller Design and Implementation

PID (Proportional-Integral-Derivative) controllers are widely used in industrial control systems due to their robust performance and relatively simple implementation. The design involves tuning three parameters: proportional gain, integral time, and derivative time to achieve desired system response characteristics. Modern implementations often include digital processing techniques and adaptive algorithms to optimize control performance across varying operating conditions.- PID Controller Design and Implementation: PID controllers are designed and implemented in various systems to provide precise control of processes. The design involves determining appropriate proportional, integral, and derivative parameters to achieve desired system response characteristics. Implementation can be through analog circuits, digital processors, or specialized hardware modules. These controllers are widely used in industrial automation, motor control systems, and other applications requiring accurate regulation.

- Adaptive and Self-Tuning PID Controllers: Adaptive PID controllers can automatically adjust their parameters based on changing process conditions. These controllers incorporate algorithms that monitor system performance and modify control parameters to maintain optimal response. Self-tuning capabilities enable the controller to adapt to variations in the controlled system, improving robustness and performance across different operating conditions without manual intervention.

- PID Controllers in Power Electronics and Energy Systems: PID controllers are applied in power electronic systems for regulating voltage, current, and power flow. They play a crucial role in renewable energy systems, power converters, and grid integration applications. These controllers help maintain stability in power systems, optimize energy conversion efficiency, and ensure reliable operation under varying load conditions and environmental factors.

- Digital PID Control Algorithms and Optimization: Digital implementations of PID controllers utilize advanced algorithms for improved performance. These include techniques for parameter optimization, anti-windup mechanisms, and specialized filtering methods. Digital PID controllers can be implemented in microcontrollers, FPGAs, or dedicated processors, offering advantages such as flexibility, precision, and the ability to implement complex control strategies beyond traditional PID structures.

- PID Controllers for Motion Control and Robotics: PID controllers are extensively used in motion control systems and robotics applications. They provide precise positioning, velocity control, and trajectory following capabilities. In robotic systems, PID controllers help achieve accurate joint movements, maintain stability during dynamic operations, and compensate for disturbances. These controllers can be cascaded or combined with other control techniques to enhance performance in complex motion control scenarios.

02 Advanced PID Control Strategies

Advanced PID control strategies incorporate modifications to the basic PID structure to handle complex control challenges. These include cascade control, feed-forward compensation, gain scheduling, and auto-tuning capabilities. Such enhancements improve system response to disturbances, reduce overshoot, and maintain stability across a wider operating range compared to conventional PID controllers.Expand Specific Solutions03 PID Controllers in Power Electronics Applications

PID controllers are extensively used in power electronics for applications such as motor drives, power converters, and renewable energy systems. In these applications, the controllers regulate voltage, current, and frequency parameters to ensure stable operation. Specialized implementations may include anti-windup mechanisms, noise filtering, and harmonic compensation to address the unique challenges of power electronic systems.Expand Specific Solutions04 Digital and Microprocessor-based PID Implementation

Modern PID controllers are increasingly implemented using digital microprocessors and embedded systems, offering advantages in flexibility, precision, and additional functionality. These implementations allow for complex control algorithms, remote monitoring, and integration with other systems. Digital PID controllers can also incorporate self-diagnostics, automatic parameter adjustment, and communication capabilities for industrial IoT applications.Expand Specific Solutions05 PID Control for Specific Industrial Applications

PID controllers are tailored for specific industrial applications such as temperature control, pressure regulation, flow control, and motion systems. Each application requires specific tuning methodologies and modifications to the basic PID structure. Application-specific implementations may include specialized filtering, dead-time compensation, and nonlinear control elements to address the unique dynamics and requirements of different industrial processes.Expand Specific Solutions

Building Automation Industry Leaders

The PID controller market in HVAC and building automation is in a mature growth phase, with an expanding global market driven by increasing demand for energy efficiency and smart building solutions. The technology has reached high maturity levels, with established players like Johnson Controls (Tyco), Azbil, and Haier Smart Home leading implementation in commercial and residential applications. Emerging competitors include specialized automation firms like Distech Controls and Luffy AI, who are advancing PID technology through AI integration and adaptive control systems. Traditional HVAC manufacturers such as LG Electronics and Trane are incorporating more sophisticated PID controllers into their systems, while technology consultancies like Tata Consultancy Services provide integration expertise. The competitive landscape shows a blend of established industrial giants and innovative technology-focused companies driving continued evolution in control precision and energy optimization.

Haier Smart Home Co., Ltd.

Technical Solution: Haier Smart Home has developed an integrated PID control framework for their smart HVAC systems that incorporates their proprietary "U+ Smart Life Platform" technology. Their approach implements multi-variable PID control that simultaneously manages temperature, humidity, and air quality parameters through a single coordinated system. Haier's controllers feature adaptive PID algorithms with gain scheduling capabilities that automatically adjust control parameters based on operating conditions and seasonal requirements. The company has integrated machine learning techniques with traditional PID control to create self-optimizing systems that improve performance over time based on usage patterns and user preferences. Their smart home ecosystem implements distributed PID control architecture where individual room controllers communicate with a central system to optimize whole-building performance while maintaining personalized comfort zones. Haier has also pioneered the use of voice-activated interfaces that allow users to adjust PID control parameters and setpoints through natural language commands[9][10].

Strengths: Seamless integration with Haier's comprehensive smart home ecosystem; intuitive user interfaces that simplify complex control adjustments; excellent energy efficiency through coordinated whole-home optimization. Weaknesses: Full functionality requires investment in multiple Haier smart devices; some advanced features depend on continuous internet connectivity; system complexity can make troubleshooting challenging for typical HVAC technicians.

Azbil Corp.

Technical Solution: Azbil Corporation has developed advanced PID controller solutions for HVAC and building automation systems that incorporate their proprietary Model Predictive Adaptive Control (MPAC) technology. Their systems utilize self-tuning PID algorithms that automatically adjust parameters based on building thermal characteristics and occupancy patterns. Azbil's controllers feature fuzzy logic integration with traditional PID control to handle non-linear HVAC processes more effectively. Their savic-net™ G5 building management system implements multi-variable PID control strategies that coordinate multiple HVAC components simultaneously while minimizing energy consumption. The company has also pioneered the use of wireless sensor networks with their PID controllers to enable more flexible installation and comprehensive zone control without extensive wiring requirements[1][3].

Strengths: Superior energy efficiency through predictive algorithms that anticipate building needs; robust self-tuning capabilities that reduce commissioning time and maintenance requirements; seamless integration with IoT platforms. Weaknesses: Higher initial implementation costs compared to conventional systems; requires more sophisticated setup and configuration; proprietary protocols may limit integration with third-party systems.

Key PID Tuning Innovations

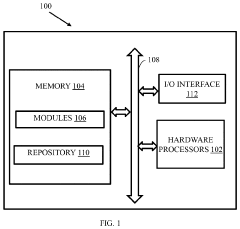

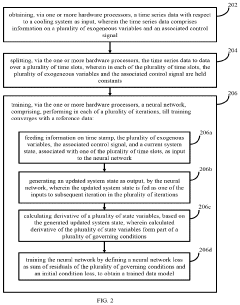

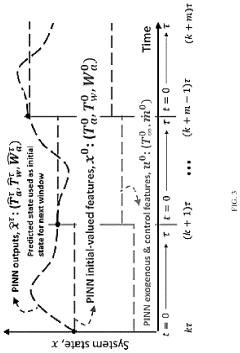

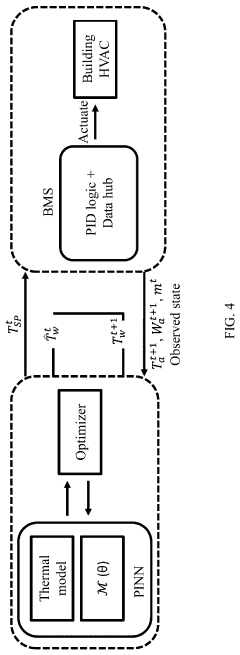

Method and system for physics aware control of HVAC equipment

PatentPendingUS20240167713A1

Innovation

- A method and system that utilize a trained neural network to generate control signal recommendations by splitting time series data into time slots with constant exogenous variables and control signals, calculating derivatives, and defining a loss function to converge with reference data, allowing for physics-aware control of HVAC systems.

HVAC system using model predictive control with distributed low-level airside optimization

PatentWO2018005180A1

Innovation

- A decentralized HVAC system architecture that includes high-level and low-level model predictive controllers, where high-level controllers generate optimal load profiles and temperature setpoints for airside and waterside systems, and low-level controllers optimize zone temperatures and energy allocation, reducing computational complexity and enabling efficient energy cost optimization.

Energy Efficiency Regulations

Energy efficiency regulations have become increasingly stringent worldwide, significantly impacting the design and implementation of HVAC systems and building automation technologies. The European Union's Energy Performance of Buildings Directive (EPBD) and the United States' ASHRAE Standard 90.1 represent cornerstone regulatory frameworks that mandate specific energy performance requirements for building systems. These regulations have accelerated the adoption of advanced PID control strategies as essential tools for achieving compliance while maintaining occupant comfort.

Recent amendments to these regulations have placed greater emphasis on dynamic system performance rather than just static efficiency ratings. For instance, the 2021 revisions to the International Energy Conservation Code (IECC) now require HVAC systems to demonstrate optimal performance across varying load conditions—a requirement that sophisticated PID control algorithms are uniquely positioned to address. These regulations typically mandate 15-30% energy consumption reductions compared to previous standards, creating a strong market driver for advanced control solutions.

The regulatory landscape also increasingly focuses on whole-building energy management approaches. China's GB 50189 standard and Singapore's Green Mark certification system exemplify this trend, requiring integrated building management systems with precise control capabilities. PID controllers serve as fundamental components in these systems, enabling the fine-tuned operation necessary to meet these comprehensive efficiency targets.

Carbon reduction targets embedded in regulations like the UK's Building Regulations Part L have further elevated the importance of responsive HVAC control. These regulations establish maximum carbon emission rates for buildings, indirectly necessitating sophisticated control strategies that minimize energy waste through precise temperature regulation and equipment cycling optimization—functions where properly tuned PID controllers excel.

Equipment-specific regulations have also emerged, such as the European Union's Ecodesign Directive, which establishes minimum efficiency requirements for HVAC components. These regulations often include provisions for control system performance, recognizing that even high-efficiency equipment operates sub-optimally without advanced control strategies. This has prompted manufacturers to integrate more sophisticated PID algorithms directly into equipment.

Compliance verification mechanisms within these regulations increasingly require documented evidence of system performance, including control system responsiveness and stability. Building commissioning protocols now commonly include PID loop tuning verification as a mandatory step before occupancy certification. This regulatory emphasis has elevated PID controller implementation from a best practice to a compliance necessity in many jurisdictions.

The global trend toward performance-based rather than prescriptive regulations has created a regulatory environment that inherently favors adaptive and self-tuning PID control strategies. These advanced approaches allow building systems to continuously optimize operation while maintaining documented compliance with increasingly complex energy efficiency requirements.

Recent amendments to these regulations have placed greater emphasis on dynamic system performance rather than just static efficiency ratings. For instance, the 2021 revisions to the International Energy Conservation Code (IECC) now require HVAC systems to demonstrate optimal performance across varying load conditions—a requirement that sophisticated PID control algorithms are uniquely positioned to address. These regulations typically mandate 15-30% energy consumption reductions compared to previous standards, creating a strong market driver for advanced control solutions.

The regulatory landscape also increasingly focuses on whole-building energy management approaches. China's GB 50189 standard and Singapore's Green Mark certification system exemplify this trend, requiring integrated building management systems with precise control capabilities. PID controllers serve as fundamental components in these systems, enabling the fine-tuned operation necessary to meet these comprehensive efficiency targets.

Carbon reduction targets embedded in regulations like the UK's Building Regulations Part L have further elevated the importance of responsive HVAC control. These regulations establish maximum carbon emission rates for buildings, indirectly necessitating sophisticated control strategies that minimize energy waste through precise temperature regulation and equipment cycling optimization—functions where properly tuned PID controllers excel.

Equipment-specific regulations have also emerged, such as the European Union's Ecodesign Directive, which establishes minimum efficiency requirements for HVAC components. These regulations often include provisions for control system performance, recognizing that even high-efficiency equipment operates sub-optimally without advanced control strategies. This has prompted manufacturers to integrate more sophisticated PID algorithms directly into equipment.

Compliance verification mechanisms within these regulations increasingly require documented evidence of system performance, including control system responsiveness and stability. Building commissioning protocols now commonly include PID loop tuning verification as a mandatory step before occupancy certification. This regulatory emphasis has elevated PID controller implementation from a best practice to a compliance necessity in many jurisdictions.

The global trend toward performance-based rather than prescriptive regulations has created a regulatory environment that inherently favors adaptive and self-tuning PID control strategies. These advanced approaches allow building systems to continuously optimize operation while maintaining documented compliance with increasingly complex energy efficiency requirements.

Cost-Benefit Analysis

The implementation of PID controllers in HVAC and building automation systems presents a compelling economic case when analyzed through a comprehensive cost-benefit framework. Initial investment costs for PID-based control systems typically range from $5,000 to $50,000 depending on building size and complexity, encompassing hardware components, installation labor, and commissioning expenses. While this represents a significant upfront expenditure, the return on investment timeline generally falls between 1-3 years for most commercial applications.

Energy consumption reduction constitutes the primary financial benefit, with properly tuned PID controllers delivering 15-30% energy savings compared to conventional on/off control systems. For a medium-sized commercial building, this translates to approximately $10,000-$30,000 in annual utility cost reductions. The precise savings vary based on climate zone, building envelope characteristics, and occupancy patterns.

Maintenance cost reductions represent another significant economic advantage. PID controllers minimize equipment cycling, reducing mechanical wear and extending the operational lifespan of HVAC components by an estimated 15-25%. This extension translates to deferred capital expenditures and decreased annual maintenance costs of approximately 10-20%, representing thousands of dollars in savings for typical commercial installations.

Occupant comfort improvements, while more challenging to quantify financially, yield measurable productivity benefits. Research indicates that optimal thermal comfort conditions facilitated by precise PID control can increase workplace productivity by 2-4%. For commercial environments, this productivity enhancement can exceed the direct energy savings in economic value.

Implementation challenges must be factored into the cost-benefit equation. PID controller tuning requires specialized expertise, with improper parameter selection potentially negating efficiency gains. Training costs for facility personnel typically range from $1,500-$5,000, representing an often overlooked expense component.

Advanced PID implementations incorporating adaptive algorithms and machine learning capabilities command premium pricing but deliver enhanced performance metrics. These systems demonstrate 5-10% additional efficiency improvements compared to standard PID implementations, particularly in buildings with variable occupancy patterns or complex zoning requirements.

The lifecycle economic assessment reveals that PID controllers maintain favorable economics throughout their operational lifespan, with diminishing returns typically occurring only after 10-15 years when technology obsolescence becomes a factor. Sensitivity analysis indicates that even with energy price fluctuations of ±20%, PID control systems maintain positive economic returns across most commercial building applications.

Energy consumption reduction constitutes the primary financial benefit, with properly tuned PID controllers delivering 15-30% energy savings compared to conventional on/off control systems. For a medium-sized commercial building, this translates to approximately $10,000-$30,000 in annual utility cost reductions. The precise savings vary based on climate zone, building envelope characteristics, and occupancy patterns.

Maintenance cost reductions represent another significant economic advantage. PID controllers minimize equipment cycling, reducing mechanical wear and extending the operational lifespan of HVAC components by an estimated 15-25%. This extension translates to deferred capital expenditures and decreased annual maintenance costs of approximately 10-20%, representing thousands of dollars in savings for typical commercial installations.

Occupant comfort improvements, while more challenging to quantify financially, yield measurable productivity benefits. Research indicates that optimal thermal comfort conditions facilitated by precise PID control can increase workplace productivity by 2-4%. For commercial environments, this productivity enhancement can exceed the direct energy savings in economic value.

Implementation challenges must be factored into the cost-benefit equation. PID controller tuning requires specialized expertise, with improper parameter selection potentially negating efficiency gains. Training costs for facility personnel typically range from $1,500-$5,000, representing an often overlooked expense component.

Advanced PID implementations incorporating adaptive algorithms and machine learning capabilities command premium pricing but deliver enhanced performance metrics. These systems demonstrate 5-10% additional efficiency improvements compared to standard PID implementations, particularly in buildings with variable occupancy patterns or complex zoning requirements.

The lifecycle economic assessment reveals that PID controllers maintain favorable economics throughout their operational lifespan, with diminishing returns typically occurring only after 10-15 years when technology obsolescence becomes a factor. Sensitivity analysis indicates that even with energy price fluctuations of ±20%, PID control systems maintain positive economic returns across most commercial building applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!