Auto-Tuning Strategies For PID Controllers In Real-Time Systems

SEP 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PID Control Evolution and Objectives

Proportional-Integral-Derivative (PID) control has evolved significantly since its inception in the early 20th century. Initially developed for ship steering mechanisms by Nicholas Minorsky in 1922, PID controllers have become ubiquitous across various industrial applications due to their simplicity, reliability, and effectiveness. The fundamental principle of PID control—combining proportional, integral, and derivative actions to minimize error between a measured process variable and desired setpoint—remains unchanged, though implementation methods have advanced considerably.

The evolution of PID control can be traced through several distinct phases. The first phase featured pneumatic and mechanical implementations, where physical components performed the control functions. The second phase emerged with the advent of electronic circuits in the mid-20th century, enabling more precise control and wider application scope. The digital revolution marked the third phase, where microprocessors allowed for software-based PID implementations with enhanced flexibility and functionality.

In recent decades, PID control has undergone further refinement with the integration of adaptive techniques, fuzzy logic, and neural networks, creating hybrid systems that maintain the core PID structure while addressing its limitations. These advancements have been particularly important for real-time systems where performance requirements are increasingly demanding.

The primary objective of auto-tuning strategies for PID controllers in real-time systems is to optimize control performance while minimizing human intervention. This includes achieving rapid convergence to desired setpoints, maintaining stability across varying operating conditions, and ensuring robustness against disturbances and system uncertainties. Auto-tuning aims to replace the traditional manual tuning process, which is time-consuming and requires significant expertise.

Another critical objective is adaptability to changing system dynamics. Real-time systems often operate in environments where parameters may shift due to aging, environmental factors, or operational changes. Auto-tuning mechanisms must detect these variations and adjust controller parameters accordingly to maintain optimal performance throughout the system's lifecycle.

Energy efficiency represents an increasingly important objective, particularly in battery-powered or resource-constrained real-time systems. Modern auto-tuning strategies seek to balance control performance with energy consumption, optimizing the control effort to achieve desired outcomes with minimal resource utilization.

The integration of auto-tuning PID controllers with broader system architectures constitutes another key objective. As industrial systems become more interconnected through IoT and Industry 4.0 initiatives, PID controllers must interface effectively with higher-level control systems, data analytics platforms, and enterprise resource planning systems, necessitating standardized communication protocols and interoperability features.

The evolution of PID control can be traced through several distinct phases. The first phase featured pneumatic and mechanical implementations, where physical components performed the control functions. The second phase emerged with the advent of electronic circuits in the mid-20th century, enabling more precise control and wider application scope. The digital revolution marked the third phase, where microprocessors allowed for software-based PID implementations with enhanced flexibility and functionality.

In recent decades, PID control has undergone further refinement with the integration of adaptive techniques, fuzzy logic, and neural networks, creating hybrid systems that maintain the core PID structure while addressing its limitations. These advancements have been particularly important for real-time systems where performance requirements are increasingly demanding.

The primary objective of auto-tuning strategies for PID controllers in real-time systems is to optimize control performance while minimizing human intervention. This includes achieving rapid convergence to desired setpoints, maintaining stability across varying operating conditions, and ensuring robustness against disturbances and system uncertainties. Auto-tuning aims to replace the traditional manual tuning process, which is time-consuming and requires significant expertise.

Another critical objective is adaptability to changing system dynamics. Real-time systems often operate in environments where parameters may shift due to aging, environmental factors, or operational changes. Auto-tuning mechanisms must detect these variations and adjust controller parameters accordingly to maintain optimal performance throughout the system's lifecycle.

Energy efficiency represents an increasingly important objective, particularly in battery-powered or resource-constrained real-time systems. Modern auto-tuning strategies seek to balance control performance with energy consumption, optimizing the control effort to achieve desired outcomes with minimal resource utilization.

The integration of auto-tuning PID controllers with broader system architectures constitutes another key objective. As industrial systems become more interconnected through IoT and Industry 4.0 initiatives, PID controllers must interface effectively with higher-level control systems, data analytics platforms, and enterprise resource planning systems, necessitating standardized communication protocols and interoperability features.

Industrial Demand for Adaptive Control Systems

The industrial landscape is witnessing a significant shift towards more sophisticated control systems, with adaptive control mechanisms becoming increasingly essential across various sectors. Manufacturing facilities, process industries, and automation systems are actively seeking solutions that can dynamically adjust to changing operational conditions without human intervention. This growing demand for adaptive control systems is primarily driven by the need for improved production efficiency, reduced downtime, and enhanced product quality in increasingly complex industrial environments.

PID controllers, despite being the industry standard for decades, face limitations in their traditional implementation when confronted with non-linear processes, time-varying parameters, or unpredictable disturbances. Industries dealing with thermal processes, chemical reactions, and precision motion control are particularly vocal about the need for controllers that can self-adjust parameters in real-time. According to recent industry surveys, over 70% of manufacturing facilities report significant production inefficiencies due to sub-optimal control system performance.

The automotive manufacturing sector demonstrates a particularly strong demand for adaptive control systems, where assembly line robots require precise motion control under varying load conditions. Similarly, the pharmaceutical industry needs precise temperature and pressure control during batch processing, where conditions can change between production runs. These industries report that even minor improvements in control system adaptability can translate to millions in annual savings through reduced waste and energy consumption.

Energy management systems represent another growth area for adaptive control technologies. Smart grid operations, renewable energy integration, and building management systems all require controllers that can respond to fluctuating supply and demand conditions. The unpredictable nature of renewable energy sources has accelerated the need for control systems that can maintain stability while maximizing energy capture under variable environmental conditions.

Process industries, including oil and gas, chemical processing, and food production, are investing heavily in adaptive control technologies to maintain product quality despite variations in raw materials and environmental conditions. These industries report that traditional manually-tuned PID controllers require frequent adjustment, leading to inconsistent product quality and increased operational costs.

The market for adaptive control systems is projected to grow at a compound annual rate of 8.3% through 2028, with particularly strong demand in regions undergoing rapid industrial modernization. This growth is further accelerated by Industry 4.0 initiatives, which emphasize smart manufacturing and data-driven process optimization. As industrial operations become increasingly complex and automated, the demand for control systems that can autonomously adapt to changing conditions will continue to expand across all manufacturing sectors.

PID controllers, despite being the industry standard for decades, face limitations in their traditional implementation when confronted with non-linear processes, time-varying parameters, or unpredictable disturbances. Industries dealing with thermal processes, chemical reactions, and precision motion control are particularly vocal about the need for controllers that can self-adjust parameters in real-time. According to recent industry surveys, over 70% of manufacturing facilities report significant production inefficiencies due to sub-optimal control system performance.

The automotive manufacturing sector demonstrates a particularly strong demand for adaptive control systems, where assembly line robots require precise motion control under varying load conditions. Similarly, the pharmaceutical industry needs precise temperature and pressure control during batch processing, where conditions can change between production runs. These industries report that even minor improvements in control system adaptability can translate to millions in annual savings through reduced waste and energy consumption.

Energy management systems represent another growth area for adaptive control technologies. Smart grid operations, renewable energy integration, and building management systems all require controllers that can respond to fluctuating supply and demand conditions. The unpredictable nature of renewable energy sources has accelerated the need for control systems that can maintain stability while maximizing energy capture under variable environmental conditions.

Process industries, including oil and gas, chemical processing, and food production, are investing heavily in adaptive control technologies to maintain product quality despite variations in raw materials and environmental conditions. These industries report that traditional manually-tuned PID controllers require frequent adjustment, leading to inconsistent product quality and increased operational costs.

The market for adaptive control systems is projected to grow at a compound annual rate of 8.3% through 2028, with particularly strong demand in regions undergoing rapid industrial modernization. This growth is further accelerated by Industry 4.0 initiatives, which emphasize smart manufacturing and data-driven process optimization. As industrial operations become increasingly complex and automated, the demand for control systems that can autonomously adapt to changing conditions will continue to expand across all manufacturing sectors.

Auto-Tuning Challenges in Real-Time Applications

Real-time systems present unique challenges for PID controller auto-tuning due to their strict timing constraints and operational requirements. The fundamental challenge lies in balancing tuning quality with computational efficiency, as real-time systems cannot afford lengthy optimization processes that might compromise system responsiveness. Traditional auto-tuning methods often require significant computational resources and time, making them impractical for systems with hard real-time constraints.

Timing determinism represents another critical challenge, as auto-tuning procedures must complete within predictable time frames to maintain system stability. Unpredictable tuning durations can lead to missed deadlines, potentially causing catastrophic failures in safety-critical applications such as aerospace systems, medical devices, or industrial automation.

Resource limitations further complicate auto-tuning implementation in real-time environments. Many embedded systems operate with constrained processing power, memory, and energy resources, necessitating lightweight tuning algorithms that can function effectively within these boundaries. This often requires compromises in tuning sophistication or accuracy.

System safety during the tuning process presents another significant hurdle. Auto-tuning typically involves perturbing the system to observe its response, which can temporarily push the system toward unstable states. In real-time applications controlling critical processes, these perturbations must be carefully managed to prevent dangerous conditions or damage to equipment.

The diversity of real-time applications also complicates the development of universal auto-tuning solutions. Different applications exhibit varying dynamics, disturbance patterns, and performance requirements, making it difficult to create one-size-fits-all tuning approaches. This necessitates adaptive methods that can recognize and accommodate application-specific characteristics.

Robustness against noise and disturbances represents another major challenge. Real-time systems often operate in noisy environments where sensor readings may be corrupted, making it difficult for auto-tuning algorithms to accurately identify system dynamics. Tuning methods must incorporate effective filtering and noise rejection techniques without introducing excessive computational overhead.

Finally, validation and verification of auto-tuning results in real-time contexts present unique difficulties. Traditional testing methodologies may be insufficient for guaranteeing that an auto-tuned controller will maintain stability and performance across all possible operating conditions, particularly in systems with complex, nonlinear, or time-varying dynamics.

Timing determinism represents another critical challenge, as auto-tuning procedures must complete within predictable time frames to maintain system stability. Unpredictable tuning durations can lead to missed deadlines, potentially causing catastrophic failures in safety-critical applications such as aerospace systems, medical devices, or industrial automation.

Resource limitations further complicate auto-tuning implementation in real-time environments. Many embedded systems operate with constrained processing power, memory, and energy resources, necessitating lightweight tuning algorithms that can function effectively within these boundaries. This often requires compromises in tuning sophistication or accuracy.

System safety during the tuning process presents another significant hurdle. Auto-tuning typically involves perturbing the system to observe its response, which can temporarily push the system toward unstable states. In real-time applications controlling critical processes, these perturbations must be carefully managed to prevent dangerous conditions or damage to equipment.

The diversity of real-time applications also complicates the development of universal auto-tuning solutions. Different applications exhibit varying dynamics, disturbance patterns, and performance requirements, making it difficult to create one-size-fits-all tuning approaches. This necessitates adaptive methods that can recognize and accommodate application-specific characteristics.

Robustness against noise and disturbances represents another major challenge. Real-time systems often operate in noisy environments where sensor readings may be corrupted, making it difficult for auto-tuning algorithms to accurately identify system dynamics. Tuning methods must incorporate effective filtering and noise rejection techniques without introducing excessive computational overhead.

Finally, validation and verification of auto-tuning results in real-time contexts present unique difficulties. Traditional testing methodologies may be insufficient for guaranteeing that an auto-tuned controller will maintain stability and performance across all possible operating conditions, particularly in systems with complex, nonlinear, or time-varying dynamics.

Current Auto-Tuning Implementations and Algorithms

01 Adaptive and self-tuning PID control methods

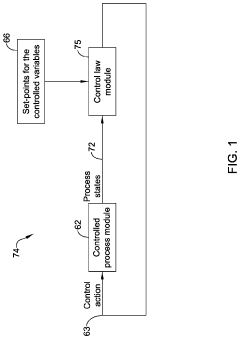

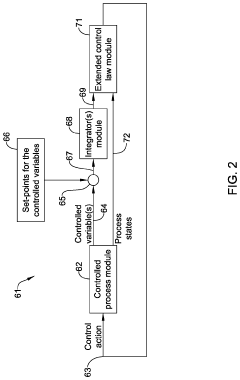

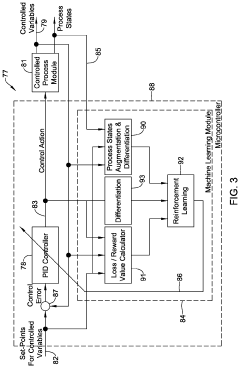

Adaptive and self-tuning PID controllers automatically adjust their parameters in response to changes in process dynamics or operating conditions. These systems continuously monitor process variables and performance metrics to optimize control parameters without manual intervention. This approach is particularly valuable for processes with time-varying characteristics or nonlinearities, ensuring consistent control performance despite changing conditions.- Adaptive and self-tuning PID control methods: Adaptive and self-tuning PID control methods automatically adjust controller parameters based on real-time system performance. These methods continuously monitor system responses and modify PID parameters to maintain optimal control despite changing process conditions or disturbances. The techniques often employ mathematical models to predict system behavior and calculate appropriate parameter adjustments, enabling robust performance across varying operating conditions without manual intervention.

- Model-based PID tuning approaches: Model-based PID tuning approaches utilize mathematical representations of the controlled process to determine optimal controller parameters. These methods identify system dynamics through process models and then calculate PID parameters that will achieve desired control performance metrics such as settling time, overshoot, and stability margins. The approach often involves system identification techniques to develop accurate process models before applying tuning rules that translate model characteristics into appropriate controller settings.

- Frequency response and relay-based auto-tuning: Frequency response and relay-based auto-tuning methods determine PID parameters by analyzing the system's response to specific test signals. These techniques often use relay feedback tests to identify critical points on the process frequency response, such as the ultimate gain and frequency. The controller then calculates appropriate PID parameters based on these identified characteristics, providing a practical approach that requires minimal prior knowledge of the system while avoiding complex mathematical modeling.

- Optimization-based PID tuning algorithms: Optimization-based PID tuning algorithms employ various computational techniques to find parameter values that minimize or maximize defined performance criteria. These methods use objective functions that quantify control performance, such as integral error metrics or time-domain specifications, and then apply optimization algorithms to find the parameter set that best satisfies these objectives. Techniques may include genetic algorithms, particle swarm optimization, or gradient-based methods to efficiently search the parameter space for optimal controller settings.

- Rule-based and heuristic PID auto-tuning: Rule-based and heuristic PID auto-tuning approaches apply established guidelines and practical knowledge to determine controller parameters. These methods often implement well-known tuning rules such as Ziegler-Nichols, Cohen-Coon, or ITAE-based formulas that relate process characteristics to recommended PID settings. The techniques typically involve a systematic procedure to identify key process attributes through simple tests, followed by the application of empirical formulas to calculate appropriate controller parameters based on the identified characteristics.

02 Model-based PID tuning techniques

Model-based tuning approaches rely on mathematical models of the controlled process to determine optimal PID parameters. These methods involve system identification to develop process models, followed by analytical calculations to derive controller settings that meet specific performance criteria. Model-based techniques can provide precise control for complex systems while balancing performance metrics such as response time, overshoot, and stability margins.Expand Specific Solutions03 Rule-based and heuristic auto-tuning strategies

Rule-based and heuristic approaches use predefined guidelines or expert knowledge to automatically determine PID parameters. These methods often employ pattern recognition to analyze system responses and apply established tuning rules. Common implementations include Ziegler-Nichols, Cohen-Coon, and other empirical methods that translate observed process behaviors into controller settings without requiring complex mathematical models.Expand Specific Solutions04 Optimization-based PID tuning algorithms

Optimization-based tuning strategies employ various algorithms to find PID parameters that minimize or maximize specific performance criteria. These methods use techniques such as genetic algorithms, particle swarm optimization, or gradient descent to search the parameter space for optimal controller settings. The approach allows for multi-objective optimization, balancing competing requirements like setpoint tracking, disturbance rejection, and control effort minimization.Expand Specific Solutions05 Frequency response and relay feedback methods

Frequency response and relay feedback methods determine PID parameters by analyzing the system's behavior in the frequency domain or through controlled oscillations. These techniques include relay auto-tuning, which induces limit cycles in the process to identify critical frequency and gain information. The approach provides a practical way to determine PID settings with minimal process disruption and without requiring detailed process models.Expand Specific Solutions

Leading Vendors in Industrial Control Systems

The PID controller auto-tuning market is currently in a growth phase, with increasing adoption across industrial automation and real-time systems. The global market size is estimated to exceed $500 million, driven by Industry 4.0 initiatives and smart manufacturing trends. Leading industrial automation companies like Siemens AG, Honeywell International, and Azbil Corp. have developed mature PID auto-tuning technologies with advanced algorithms. Academic institutions including Shanghai Jiao Tong University and North China Electric Power University are actively researching next-generation adaptive control strategies. The competitive landscape shows established players (National Instruments, Mitsubishi Electric) focusing on integration with IoT platforms, while newer entrants like OPPO Mobile are exploring applications in consumer electronics, indicating technology diffusion beyond traditional industrial sectors.

National Instruments Corp.

Technical Solution: National Instruments has pioneered auto-tuning PID strategies specifically designed for real-time systems through their LabVIEW platform. Their approach combines frequency response methods with iterative optimization techniques to automatically determine optimal PID parameters. The system first performs process identification using either frequency domain analysis or time-domain step response tests, then applies sophisticated algorithms to calculate controller parameters. NI's auto-tuning technology incorporates gain scheduling capabilities that allow for automatic adjustment of PID parameters based on operating conditions, making it particularly effective for systems with varying dynamics. Their controllers also feature adaptive mechanisms that continuously monitor control performance metrics such as overshoot, settling time, and steady-state error, automatically fine-tuning parameters to maintain optimal performance despite process changes or disturbances[2][5].

Strengths: Excellent integration with data acquisition hardware; intuitive graphical programming interface; extensive support for rapid prototyping and testing. Weaknesses: May require significant expertise to fully utilize advanced features; potential performance limitations in extremely high-speed applications; higher initial investment compared to standalone controllers.

Honeywell International Technologies Ltd.

Technical Solution: Honeywell has developed advanced auto-tuning PID controllers for real-time systems that utilize pattern recognition algorithms to identify process dynamics. Their technology incorporates adaptive control strategies that continuously monitor system performance and automatically adjust PID parameters in response to changing process conditions. Honeywell's Experion PKS platform features auto-tuning capabilities that employ both model-based and rule-based approaches, allowing for optimal control across various industrial applications. The system uses a combination of relay feedback methods and step response analysis to identify process models, then applies sophisticated optimization algorithms to determine ideal PID parameters. Their controllers also implement anti-windup mechanisms and setpoint weighting to enhance control performance in challenging conditions, particularly in processes with significant time delays or nonlinearities[1][3].

Strengths: Robust performance across diverse industrial applications; seamless integration with existing control systems; advanced disturbance rejection capabilities. Weaknesses: Higher implementation costs compared to simpler solutions; requires significant computational resources for complex processes; potential challenges in highly nonlinear systems.

Critical Patents in PID Parameter Optimization

PID controller autotuner using machine learning approaches

PatentActiveUS20210341895A1

Innovation

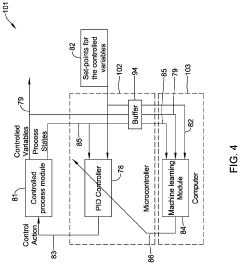

- The proposed solution incorporates a modified reinforcement learning approach that preprocesses data to include integral action, allowing the PID controller to track set-points without steady-state offsets by time-differentiating and augmenting process states with control errors, enabling the production of both linear and non-linear PI or PID controllers with integral action.

Method and system for autotuning a PID controller on electromechanical actuators using machine learning

PatentWO2023122636A1

Innovation

- A system and method utilizing a neural network-based autotuning system that determines PID gains by estimating load torque and applying these gains to the PID controller, eliminating the need for manual tuning and enabling adaptive control independent of actuator type or application.

Performance Metrics and Evaluation Standards

Evaluating the performance of auto-tuning PID controllers in real-time systems requires comprehensive metrics and standardized evaluation frameworks. These metrics must capture both the transient and steady-state behavior of control systems while considering the unique constraints of real-time applications.

Rise time, settling time, and overshoot percentage serve as fundamental metrics for assessing controller responsiveness. In real-time systems, these parameters must be carefully balanced against system constraints. For instance, a controller with minimal rise time might consume excessive computational resources, potentially compromising other system functions. The integral absolute error (IAE) and integral squared error (ISE) provide quantitative measures of control accuracy over time, with ISE penalizing larger errors more heavily.

Robustness metrics are particularly critical for auto-tuning strategies. The gain margin and phase margin indicate a controller's ability to maintain stability despite system variations. For real-time applications, these margins must be sufficient to accommodate unexpected disturbances without requiring frequent retuning. The sensitivity function, which measures the system's response to disturbances, offers valuable insights into controller performance under varying operating conditions.

Computational efficiency metrics address the resource constraints inherent in real-time systems. These include CPU utilization, memory footprint, and convergence time of the auto-tuning algorithm. A well-designed auto-tuning strategy should achieve optimal control parameters without imposing excessive computational burden or causing deadline misses in the real-time scheduler.

Standardized test scenarios form an essential component of evaluation frameworks. Step response tests reveal a controller's ability to track setpoint changes, while disturbance rejection tests assess its capacity to maintain stability under external perturbations. For real-time systems, these tests must be conducted under varying computational loads to ensure consistent performance across different operating conditions.

Cross-platform benchmarking enables comparison between different auto-tuning strategies across hardware configurations. This approach involves standardized test beds with well-defined computational resources and timing constraints. The IEEE 1012 standard for software verification and validation provides guidelines for ensuring the reliability of auto-tuning implementations in safety-critical applications.

Industry-specific standards further refine evaluation criteria for particular domains. For instance, automotive applications follow ISO 26262 for functional safety, while industrial control systems adhere to IEC 61508. These standards establish minimum performance requirements and validation procedures for control systems in their respective domains.

Rise time, settling time, and overshoot percentage serve as fundamental metrics for assessing controller responsiveness. In real-time systems, these parameters must be carefully balanced against system constraints. For instance, a controller with minimal rise time might consume excessive computational resources, potentially compromising other system functions. The integral absolute error (IAE) and integral squared error (ISE) provide quantitative measures of control accuracy over time, with ISE penalizing larger errors more heavily.

Robustness metrics are particularly critical for auto-tuning strategies. The gain margin and phase margin indicate a controller's ability to maintain stability despite system variations. For real-time applications, these margins must be sufficient to accommodate unexpected disturbances without requiring frequent retuning. The sensitivity function, which measures the system's response to disturbances, offers valuable insights into controller performance under varying operating conditions.

Computational efficiency metrics address the resource constraints inherent in real-time systems. These include CPU utilization, memory footprint, and convergence time of the auto-tuning algorithm. A well-designed auto-tuning strategy should achieve optimal control parameters without imposing excessive computational burden or causing deadline misses in the real-time scheduler.

Standardized test scenarios form an essential component of evaluation frameworks. Step response tests reveal a controller's ability to track setpoint changes, while disturbance rejection tests assess its capacity to maintain stability under external perturbations. For real-time systems, these tests must be conducted under varying computational loads to ensure consistent performance across different operating conditions.

Cross-platform benchmarking enables comparison between different auto-tuning strategies across hardware configurations. This approach involves standardized test beds with well-defined computational resources and timing constraints. The IEEE 1012 standard for software verification and validation provides guidelines for ensuring the reliability of auto-tuning implementations in safety-critical applications.

Industry-specific standards further refine evaluation criteria for particular domains. For instance, automotive applications follow ISO 26262 for functional safety, while industrial control systems adhere to IEC 61508. These standards establish minimum performance requirements and validation procedures for control systems in their respective domains.

Safety Considerations in Autonomous Control Systems

Safety considerations are paramount when implementing auto-tuning strategies for PID controllers in autonomous control systems. The inherent complexity of these systems, coupled with their operation in dynamic environments, necessitates robust safety mechanisms. Failure in PID control systems can lead to catastrophic consequences, especially in critical applications such as autonomous vehicles, industrial robotics, or medical devices.

A fundamental safety approach involves implementing parameter constraints during the auto-tuning process. By establishing strict boundaries for proportional, integral, and derivative gains, the system can prevent excessive control actions that might lead to instability or physical damage. These constraints must be carefully calibrated based on system dynamics and operational requirements to ensure both safety and performance.

Real-time monitoring systems represent another critical safety layer. These systems continuously evaluate controller performance against predefined safety thresholds, enabling immediate intervention when anomalies are detected. Advanced implementations incorporate predictive analytics to anticipate potential control failures before they manifest, allowing for preemptive corrective actions.

Redundancy in control architectures significantly enhances safety profiles. Dual or triple redundant PID controllers operating in parallel can provide fault tolerance through voting mechanisms or seamless failover capabilities. This approach ensures that a single controller failure does not compromise the entire system's operational integrity.

Graceful degradation strategies are essential for maintaining basic functionality during partial system failures. When auto-tuning mechanisms or primary control loops encounter issues, the system should revert to conservative, pre-validated parameter sets that prioritize stability over performance optimization. This ensures continued safe operation, albeit potentially at reduced efficiency.

Comprehensive validation protocols must be established before deploying auto-tuning PID controllers in safety-critical applications. These should include extensive simulation testing across diverse operational scenarios, hardware-in-the-loop validation, and gradual deployment methodologies. Particular attention should be paid to edge cases and rare event handling, as these often represent the highest safety risks.

Regulatory compliance represents a final but crucial consideration. Auto-tuning PID controllers in autonomous systems must adhere to relevant industry standards such as IEC 61508 for functional safety, ISO 26262 for automotive applications, or domain-specific regulations. Documentation of safety analysis, risk assessments, and mitigation strategies is not merely a regulatory requirement but a fundamental aspect of responsible engineering practice in autonomous control systems.

A fundamental safety approach involves implementing parameter constraints during the auto-tuning process. By establishing strict boundaries for proportional, integral, and derivative gains, the system can prevent excessive control actions that might lead to instability or physical damage. These constraints must be carefully calibrated based on system dynamics and operational requirements to ensure both safety and performance.

Real-time monitoring systems represent another critical safety layer. These systems continuously evaluate controller performance against predefined safety thresholds, enabling immediate intervention when anomalies are detected. Advanced implementations incorporate predictive analytics to anticipate potential control failures before they manifest, allowing for preemptive corrective actions.

Redundancy in control architectures significantly enhances safety profiles. Dual or triple redundant PID controllers operating in parallel can provide fault tolerance through voting mechanisms or seamless failover capabilities. This approach ensures that a single controller failure does not compromise the entire system's operational integrity.

Graceful degradation strategies are essential for maintaining basic functionality during partial system failures. When auto-tuning mechanisms or primary control loops encounter issues, the system should revert to conservative, pre-validated parameter sets that prioritize stability over performance optimization. This ensures continued safe operation, albeit potentially at reduced efficiency.

Comprehensive validation protocols must be established before deploying auto-tuning PID controllers in safety-critical applications. These should include extensive simulation testing across diverse operational scenarios, hardware-in-the-loop validation, and gradual deployment methodologies. Particular attention should be paid to edge cases and rare event handling, as these often represent the highest safety risks.

Regulatory compliance represents a final but crucial consideration. Auto-tuning PID controllers in autonomous systems must adhere to relevant industry standards such as IEC 61508 for functional safety, ISO 26262 for automotive applications, or domain-specific regulations. Documentation of safety analysis, risk assessments, and mitigation strategies is not merely a regulatory requirement but a fundamental aspect of responsible engineering practice in autonomous control systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!