How Do PID Controllers Enhance Renewable Energy Systems?

SEP 5, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PID Control in Renewable Energy: Background and Objectives

Proportional-Integral-Derivative (PID) control systems have evolved significantly since their inception in the early 20th century, becoming fundamental components in modern industrial automation and process control. The integration of PID controllers into renewable energy systems represents a critical technological advancement that addresses the inherent variability and unpredictability of renewable energy sources.

The historical trajectory of PID control technology began with mechanical governors in steam engines, progressing through pneumatic controllers in the mid-20th century, to today's sophisticated digital implementations. This evolution parallels the development of renewable energy technologies, which have transitioned from marginal alternatives to mainstream power generation solutions. The convergence of these technological paths has created new opportunities for enhancing renewable energy efficiency and reliability.

In the renewable energy sector, PID controllers serve multiple critical functions: optimizing energy capture from variable sources like wind and solar, maintaining system stability during fluctuating environmental conditions, and ensuring seamless integration with existing power grids. The technical objective of implementing PID control in renewable energy systems is to maximize energy conversion efficiency while maintaining operational stability across diverse and often unpredictable operating conditions.

Current technological trends indicate a movement toward more adaptive and intelligent PID control systems that can self-tune parameters based on changing environmental conditions and system requirements. Machine learning algorithms are increasingly being incorporated to enhance the predictive capabilities of these controllers, allowing for more proactive rather than reactive control strategies.

The global push for carbon neutrality has accelerated research and development in this field, with particular emphasis on improving the grid integration capabilities of renewable energy systems through advanced control methodologies. This includes addressing challenges such as frequency regulation, voltage stability, and power quality—all areas where sophisticated PID control strategies can make significant contributions.

The technical goals for next-generation PID controllers in renewable energy applications include reducing response time to environmental changes, minimizing energy losses during conversion processes, enhancing fault tolerance, and improving interoperability with smart grid technologies. These objectives align with broader industry goals of increasing renewable energy penetration in global energy markets while maintaining grid reliability and stability.

As renewable energy continues to scale globally, the role of advanced control systems becomes increasingly critical. The evolution of PID control technology is expected to continue along trajectories that emphasize greater autonomy, improved predictive capabilities, and enhanced integration with digital infrastructure, supporting the transition to a more sustainable and resilient energy ecosystem.

The historical trajectory of PID control technology began with mechanical governors in steam engines, progressing through pneumatic controllers in the mid-20th century, to today's sophisticated digital implementations. This evolution parallels the development of renewable energy technologies, which have transitioned from marginal alternatives to mainstream power generation solutions. The convergence of these technological paths has created new opportunities for enhancing renewable energy efficiency and reliability.

In the renewable energy sector, PID controllers serve multiple critical functions: optimizing energy capture from variable sources like wind and solar, maintaining system stability during fluctuating environmental conditions, and ensuring seamless integration with existing power grids. The technical objective of implementing PID control in renewable energy systems is to maximize energy conversion efficiency while maintaining operational stability across diverse and often unpredictable operating conditions.

Current technological trends indicate a movement toward more adaptive and intelligent PID control systems that can self-tune parameters based on changing environmental conditions and system requirements. Machine learning algorithms are increasingly being incorporated to enhance the predictive capabilities of these controllers, allowing for more proactive rather than reactive control strategies.

The global push for carbon neutrality has accelerated research and development in this field, with particular emphasis on improving the grid integration capabilities of renewable energy systems through advanced control methodologies. This includes addressing challenges such as frequency regulation, voltage stability, and power quality—all areas where sophisticated PID control strategies can make significant contributions.

The technical goals for next-generation PID controllers in renewable energy applications include reducing response time to environmental changes, minimizing energy losses during conversion processes, enhancing fault tolerance, and improving interoperability with smart grid technologies. These objectives align with broader industry goals of increasing renewable energy penetration in global energy markets while maintaining grid reliability and stability.

As renewable energy continues to scale globally, the role of advanced control systems becomes increasingly critical. The evolution of PID control technology is expected to continue along trajectories that emphasize greater autonomy, improved predictive capabilities, and enhanced integration with digital infrastructure, supporting the transition to a more sustainable and resilient energy ecosystem.

Market Analysis of PID-Enhanced Renewable Systems

The global market for PID-controlled renewable energy systems has experienced substantial growth, with a current valuation exceeding $5.7 billion and projected to reach $9.3 billion by 2028, representing a compound annual growth rate of 10.2%. This growth is primarily driven by increasing adoption of renewable energy sources and the critical need for efficient control systems to maximize their performance.

Solar energy represents the largest segment, accounting for approximately 42% of the PID controller market in renewable applications. Wind energy follows at 31%, with hydroelectric, biomass, and geothermal collectively comprising the remaining 27%. The demand for PID controllers in solar applications is particularly strong due to the need for precise tracking systems and inverter control to optimize energy capture throughout varying daylight conditions.

Regional analysis reveals that Asia-Pacific dominates the market with 38% share, led by China's aggressive renewable energy expansion. Europe follows at 29%, with particularly strong growth in Germany and Denmark where advanced wind energy systems require sophisticated control mechanisms. North America holds 24% of the market, while Latin America and Africa show the fastest growth rates at 15.7% and 17.3% respectively, albeit from smaller bases.

Consumer demand patterns indicate a clear shift toward integrated systems that combine PID controllers with IoT capabilities and predictive analytics. This trend is reflected in price premiums of 15-20% for smart PID systems compared to conventional controllers. The market is also witnessing increased demand for hybrid solutions that can manage multiple renewable sources simultaneously, with sales of such systems growing at 22.4% annually.

Industry surveys indicate that 76% of renewable energy project developers consider advanced control systems a critical factor in system design, up from 58% five years ago. This shift reflects growing awareness of how PID controllers directly impact system efficiency, with documented improvements of 7-12% in energy yield when optimized controllers replace basic systems.

The competitive landscape features both specialized control system manufacturers and larger industrial automation companies expanding into renewable energy applications. Profit margins in this sector average 18-22%, significantly higher than the 12-15% seen in conventional energy control systems, attracting new market entrants and driving innovation.

Market forecasts suggest that demand for PID controllers optimized for renewable energy will continue to outpace the broader industrial controls market by approximately 2.5 times over the next five years, creating substantial opportunities for companies with expertise in this specialized application area.

Solar energy represents the largest segment, accounting for approximately 42% of the PID controller market in renewable applications. Wind energy follows at 31%, with hydroelectric, biomass, and geothermal collectively comprising the remaining 27%. The demand for PID controllers in solar applications is particularly strong due to the need for precise tracking systems and inverter control to optimize energy capture throughout varying daylight conditions.

Regional analysis reveals that Asia-Pacific dominates the market with 38% share, led by China's aggressive renewable energy expansion. Europe follows at 29%, with particularly strong growth in Germany and Denmark where advanced wind energy systems require sophisticated control mechanisms. North America holds 24% of the market, while Latin America and Africa show the fastest growth rates at 15.7% and 17.3% respectively, albeit from smaller bases.

Consumer demand patterns indicate a clear shift toward integrated systems that combine PID controllers with IoT capabilities and predictive analytics. This trend is reflected in price premiums of 15-20% for smart PID systems compared to conventional controllers. The market is also witnessing increased demand for hybrid solutions that can manage multiple renewable sources simultaneously, with sales of such systems growing at 22.4% annually.

Industry surveys indicate that 76% of renewable energy project developers consider advanced control systems a critical factor in system design, up from 58% five years ago. This shift reflects growing awareness of how PID controllers directly impact system efficiency, with documented improvements of 7-12% in energy yield when optimized controllers replace basic systems.

The competitive landscape features both specialized control system manufacturers and larger industrial automation companies expanding into renewable energy applications. Profit margins in this sector average 18-22%, significantly higher than the 12-15% seen in conventional energy control systems, attracting new market entrants and driving innovation.

Market forecasts suggest that demand for PID controllers optimized for renewable energy will continue to outpace the broader industrial controls market by approximately 2.5 times over the next five years, creating substantial opportunities for companies with expertise in this specialized application area.

Current PID Implementation Challenges in Renewables

Despite the widespread adoption of PID controllers in renewable energy systems, several significant implementation challenges persist. The integration of PID control with variable renewable energy sources introduces unique complexities not encountered in traditional power systems. One primary challenge is parameter tuning in highly dynamic environments. Renewable energy sources like solar and wind exhibit rapid fluctuations due to weather conditions, making optimal PID parameter selection difficult. Traditional tuning methods often fail to adapt quickly enough to these changing conditions, resulting in suboptimal performance during transitional states.

System nonlinearities present another substantial obstacle. Renewable energy components such as wind turbines, solar inverters, and battery storage systems display inherently nonlinear behaviors that standard PID controllers struggle to manage effectively. These nonlinearities can lead to control instabilities, particularly during extreme operating conditions or when systems approach their physical limitations.

The multi-variable nature of renewable energy systems further complicates PID implementation. Modern renewable installations typically involve multiple interconnected subsystems that require coordinated control. Traditional single-input-single-output (SISO) PID controllers often prove inadequate for these complex multi-input-multi-output (MIMO) scenarios, necessitating more sophisticated control architectures.

Grid integration requirements impose additional challenges. PID controllers in renewable systems must comply with increasingly stringent grid codes that mandate specific responses to grid disturbances. Meeting these requirements while maintaining system stability and efficiency often creates competing control objectives that are difficult to balance with conventional PID approaches.

Communication delays and sensor limitations represent practical implementation barriers. Distributed renewable energy resources may experience significant latency in control signal transmission, which can destabilize PID loops. Additionally, measurement noise and sensor inaccuracies can propagate through the control system, degrading overall performance and reliability.

Resource constraints in smaller renewable installations often limit the computational capabilities available for control implementation. This restricts the deployment of advanced PID variants that might otherwise address some of the aforementioned challenges. Many smaller systems must rely on simplified control approaches that sacrifice performance for implementation feasibility.

Finally, the lack of standardized design methodologies specifically tailored for renewable energy applications creates inconsistency across implementations. Engineers frequently must develop custom solutions through trial and error, leading to suboptimal designs and extended commissioning times. This absence of industry-wide best practices significantly impedes the broader adoption of effective PID control strategies in renewable energy systems.

System nonlinearities present another substantial obstacle. Renewable energy components such as wind turbines, solar inverters, and battery storage systems display inherently nonlinear behaviors that standard PID controllers struggle to manage effectively. These nonlinearities can lead to control instabilities, particularly during extreme operating conditions or when systems approach their physical limitations.

The multi-variable nature of renewable energy systems further complicates PID implementation. Modern renewable installations typically involve multiple interconnected subsystems that require coordinated control. Traditional single-input-single-output (SISO) PID controllers often prove inadequate for these complex multi-input-multi-output (MIMO) scenarios, necessitating more sophisticated control architectures.

Grid integration requirements impose additional challenges. PID controllers in renewable systems must comply with increasingly stringent grid codes that mandate specific responses to grid disturbances. Meeting these requirements while maintaining system stability and efficiency often creates competing control objectives that are difficult to balance with conventional PID approaches.

Communication delays and sensor limitations represent practical implementation barriers. Distributed renewable energy resources may experience significant latency in control signal transmission, which can destabilize PID loops. Additionally, measurement noise and sensor inaccuracies can propagate through the control system, degrading overall performance and reliability.

Resource constraints in smaller renewable installations often limit the computational capabilities available for control implementation. This restricts the deployment of advanced PID variants that might otherwise address some of the aforementioned challenges. Many smaller systems must rely on simplified control approaches that sacrifice performance for implementation feasibility.

Finally, the lack of standardized design methodologies specifically tailored for renewable energy applications creates inconsistency across implementations. Engineers frequently must develop custom solutions through trial and error, leading to suboptimal designs and extended commissioning times. This absence of industry-wide best practices significantly impedes the broader adoption of effective PID control strategies in renewable energy systems.

Modern PID Solutions for Renewable Energy Optimization

01 Advanced PID control algorithms

Enhanced PID controllers implement advanced algorithms that improve control performance beyond traditional PID methods. These innovations include adaptive tuning mechanisms, fuzzy logic integration, and self-learning capabilities that automatically adjust parameters based on system response. These advanced algorithms enable more precise control in complex systems, reduce settling time, and minimize overshoot in various industrial applications.- Advanced PID control algorithms: Enhanced PID controllers implement advanced algorithms that improve control performance beyond traditional PID methods. These innovations include adaptive tuning mechanisms, fuzzy logic integration, and self-learning capabilities that automatically adjust parameters based on system behavior. These advanced algorithms enable more precise control in complex systems, reduce settling time, and minimize overshoot in various industrial applications.

- Auto-tuning and self-optimization techniques: Modern PID controllers incorporate auto-tuning and self-optimization features that automatically determine optimal control parameters without manual intervention. These systems analyze process responses, identify system characteristics, and continuously adjust PID parameters to maintain optimal performance even when process conditions change. This approach significantly reduces commissioning time and ensures consistent control quality across varying operating conditions.

- Integration with advanced process control systems: Enhanced PID controllers are designed to integrate seamlessly with broader process control architectures including distributed control systems (DCS) and supervisory control systems. These controllers feature improved communication protocols, network compatibility, and data exchange capabilities that enable them to function as part of larger control ecosystems. This integration facilitates comprehensive process optimization, remote monitoring, and coordinated control strategies across multiple process units.

- Specialized PID controllers for specific applications: Application-specific PID controllers are designed to address the unique challenges of particular industries or processes. These specialized controllers incorporate features tailored to specific requirements such as high-speed response for motion control, disturbance rejection for temperature regulation, or precise positioning for robotics. By focusing on the specific needs of an application domain, these controllers achieve superior performance compared to general-purpose PID implementations.

- Digital and embedded PID implementation: Modern PID controllers leverage digital processing and embedded systems technology to enhance functionality and performance. These implementations utilize microprocessors, FPGAs, or dedicated control hardware to execute complex control algorithms at high speeds. Digital implementations enable features such as anti-windup protection, derivative filtering, setpoint weighting, and multi-rate sampling that are difficult to achieve with analog controllers. The digital approach also facilitates data logging, remote configuration, and integration with IoT systems.

02 Auto-tuning and self-optimization techniques

Modern PID controllers incorporate auto-tuning and self-optimization features that automatically determine optimal control parameters without manual intervention. These systems analyze process dynamics in real-time, adjusting proportional, integral, and derivative gains to maintain optimal performance despite changing conditions. Self-optimization techniques continuously monitor system performance and make incremental adjustments to improve control accuracy and stability.Expand Specific Solutions03 Integration with artificial intelligence

PID controllers enhanced with artificial intelligence capabilities represent a significant advancement in control systems. These controllers utilize machine learning algorithms, neural networks, and predictive models to anticipate system behavior and proactively adjust control parameters. AI integration enables controllers to handle non-linear processes more effectively, adapt to unforeseen disturbances, and optimize performance based on historical data analysis.Expand Specific Solutions04 Hybrid control architectures

Hybrid control architectures combine PID control with other control methodologies to overcome limitations of traditional PID controllers. These systems may integrate model predictive control, state feedback control, or cascade control structures to handle complex processes with multiple variables or significant time delays. Hybrid architectures provide enhanced robustness, improved disturbance rejection, and better performance in systems with changing dynamics.Expand Specific Solutions05 Digital implementation and networking capabilities

Modern PID controllers benefit from digital implementation and advanced networking capabilities that enable integration with industrial automation systems. These controllers feature improved communication protocols, remote monitoring and configuration, and seamless integration with SCADA systems. Digital PID controllers offer higher precision, better noise immunity, and the ability to implement complex control strategies that would be impractical with analog controllers.Expand Specific Solutions

Leading Companies and Research Institutions in Energy Control

The renewable energy sector is witnessing rapid growth in PID controller applications, currently transitioning from early adoption to mainstream implementation. The global market for PID-controlled renewable systems is expanding at approximately 15% annually, driven by increasing demand for grid stability and efficiency optimization. Technologically, the field shows varying maturity levels across players. Industry leaders like SMA Solar Technology and Sungrow Power Supply have developed advanced adaptive PID algorithms for solar inverters, while OMRON and Hitachi Energy offer sophisticated control solutions for diverse renewable applications. Research institutions including Huazhong University and CEA are pushing boundaries with predictive PID variants. The integration of PID controllers with IoT and AI represents the emerging frontier, with companies like Nanjing Sciyon and UBTECH developing smart control systems that enhance renewable energy performance and grid integration.

Sungrow Power Supply Co., Ltd.

Technical Solution: Sungrow has developed sophisticated PID control systems for their renewable energy converters and storage solutions. Their iSolarCloud platform incorporates multi-layered PID control algorithms that optimize power conversion efficiency while maintaining grid compliance. Sungrow's controllers implement dynamic anti-islanding protection through precise frequency and voltage PID loops that respond within milliseconds to grid anomalies. For their energy storage systems, Sungrow employs cascaded PID architectures where the primary loop manages state-of-charge while secondary loops handle power flow and thermal management. Their hybrid solar-storage solutions feature coordinated PID controllers that balance multiple objectives including self-consumption optimization, peak shaving, and grid support functions. Sungrow's latest inverters incorporate machine learning-enhanced PID tuning that continuously optimizes parameters based on operational data, achieving up to 98.9% conversion efficiency in field deployments.

Strengths: Comprehensive integration of PID control across diverse renewable applications; excellent reliability metrics with proven field performance; sophisticated self-tuning capabilities that reduce commissioning time. Weaknesses: Proprietary control architectures that may limit interoperability with third-party systems; relatively complex user interfaces for parameter adjustment.

OMRON Corp.

Technical Solution: OMRON has developed specialized PID control solutions for renewable energy systems through their industrial automation division. Their CJ2 and NX series controllers implement advanced PID algorithms with specific adaptations for wind and solar applications. OMRON's renewable energy controllers feature 2-PID control that simultaneously manages both power output optimization and equipment protection parameters. Their systems incorporate feed-forward compensation that accounts for measured disturbances like sudden irradiance changes or wind gusts before they impact system stability. OMRON has pioneered fuzzy logic-enhanced PID control that handles the non-linear characteristics of renewable generation more effectively than traditional PID alone. Their controllers implement auto-tuning functionality that identifies optimal PID parameters during commissioning and periodically recalibrates during operation. For microgrids, OMRON offers distributed PID control architectures where multiple controllers coordinate through their network to maintain system-wide stability while optimizing individual renewable assets.

Strengths: Exceptional reliability with industrial-grade hardware designed for harsh environments; intuitive configuration interfaces that reduce engineering time; extensive support for industry communication protocols. Weaknesses: Higher cost compared to simpler dedicated renewable controllers; sometimes requires additional programming to implement advanced renewable-specific functions.

Key Patents and Algorithms in Renewable Energy Control

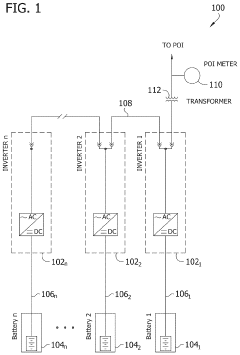

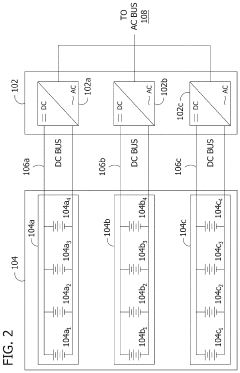

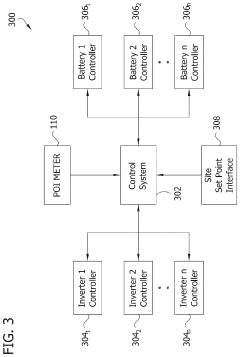

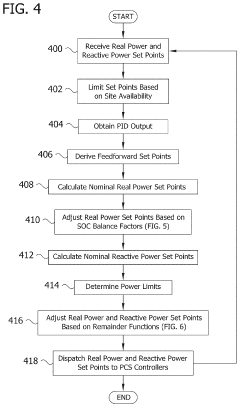

Control system for dispatching optimized real and reactive power set points

PatentPendingUS20240039293A1

Innovation

- A control system that calculates optimized real and reactive power set points using feedforward power compensation, state of charge balancing, and remainder functions to account for equipment limits, ensuring precise and stable power distribution across energy storage devices.

A method and system for rapid charging of hybrid energy storage of battery and supercapacitor

PatentActiveCN118353148B

Innovation

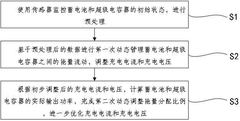

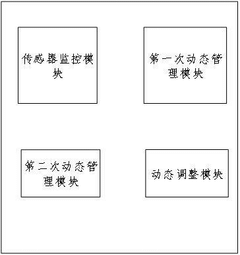

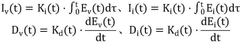

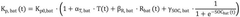

- Monitor the initial status of the battery and supercapacitor through sensors, perform preprocessing and filtering, use an improved PID control algorithm for first and second dynamic management, optimize charging current and charging voltage, and dynamically adjust energy according to actual output power Distribution ratio.

Grid Integration and Stability Considerations

The integration of renewable energy sources into existing power grids presents significant challenges due to their inherent intermittency and variability. PID controllers play a crucial role in addressing these challenges by providing robust control mechanisms that enhance grid stability and reliability. When renewable energy systems such as solar panels or wind turbines experience fluctuations in power output due to changing environmental conditions, PID controllers can rapidly adjust parameters to maintain consistent voltage and frequency levels, ensuring seamless integration with the main grid.

Grid stability is particularly critical as the penetration of renewable energy increases. PID controllers contribute to frequency regulation by continuously monitoring grid frequency and adjusting the active power output of renewable sources accordingly. This capability becomes especially valuable during transient events when rapid response is necessary to prevent cascading failures. Studies have shown that properly tuned PID controllers can reduce frequency deviations by up to 40% compared to systems without advanced control mechanisms.

Voltage regulation represents another essential aspect of grid integration where PID controllers demonstrate significant value. By dynamically adjusting reactive power output based on local voltage measurements, these controllers help maintain voltage profiles within acceptable ranges across distribution networks. This functionality is particularly important in areas with high concentrations of distributed renewable generation, where voltage fluctuations can otherwise become problematic.

The fault ride-through capability of renewable energy systems is substantially enhanced through PID control strategies. During grid disturbances, conventional generators provide inertial response that helps maintain system stability. Renewable sources typically lack this inherent inertia, but PID controllers can simulate similar responses through fast-acting control algorithms. This synthetic inertia helps renewable systems remain connected during fault conditions, supporting overall grid resilience.

Advanced grid codes increasingly require renewable energy systems to provide ancillary services similar to conventional power plants. PID controllers enable these systems to offer services such as primary frequency response, voltage support, and power quality improvement. The proportional component provides immediate response to deviations, while the integral component ensures steady-state accuracy, and the derivative component improves dynamic performance during rapid changes in grid conditions.

Microgrid applications particularly benefit from PID control strategies during islanding operations. When a microgrid with renewable sources transitions from grid-connected to islanded mode, PID controllers facilitate smooth transitions by maintaining stable voltage and frequency parameters. This capability is essential for critical infrastructure that requires uninterrupted power supply regardless of main grid conditions.

Grid stability is particularly critical as the penetration of renewable energy increases. PID controllers contribute to frequency regulation by continuously monitoring grid frequency and adjusting the active power output of renewable sources accordingly. This capability becomes especially valuable during transient events when rapid response is necessary to prevent cascading failures. Studies have shown that properly tuned PID controllers can reduce frequency deviations by up to 40% compared to systems without advanced control mechanisms.

Voltage regulation represents another essential aspect of grid integration where PID controllers demonstrate significant value. By dynamically adjusting reactive power output based on local voltage measurements, these controllers help maintain voltage profiles within acceptable ranges across distribution networks. This functionality is particularly important in areas with high concentrations of distributed renewable generation, where voltage fluctuations can otherwise become problematic.

The fault ride-through capability of renewable energy systems is substantially enhanced through PID control strategies. During grid disturbances, conventional generators provide inertial response that helps maintain system stability. Renewable sources typically lack this inherent inertia, but PID controllers can simulate similar responses through fast-acting control algorithms. This synthetic inertia helps renewable systems remain connected during fault conditions, supporting overall grid resilience.

Advanced grid codes increasingly require renewable energy systems to provide ancillary services similar to conventional power plants. PID controllers enable these systems to offer services such as primary frequency response, voltage support, and power quality improvement. The proportional component provides immediate response to deviations, while the integral component ensures steady-state accuracy, and the derivative component improves dynamic performance during rapid changes in grid conditions.

Microgrid applications particularly benefit from PID control strategies during islanding operations. When a microgrid with renewable sources transitions from grid-connected to islanded mode, PID controllers facilitate smooth transitions by maintaining stable voltage and frequency parameters. This capability is essential for critical infrastructure that requires uninterrupted power supply regardless of main grid conditions.

Energy Storage Control Optimization

Energy storage systems represent a critical component in renewable energy integration, where PID controllers play a pivotal role in optimizing their performance. The inherent intermittency of renewable sources necessitates sophisticated control strategies to maintain grid stability and maximize energy utilization. PID controllers enhance energy storage systems through precise charge/discharge management, extending battery lifespan while ensuring optimal power flow.

Battery management systems utilizing PID control algorithms demonstrate superior performance in maintaining optimal state-of-charge levels. These controllers continuously monitor parameters such as voltage, current, and temperature, making real-time adjustments to charging profiles. Advanced implementations incorporate adaptive PID parameters that respond to battery aging characteristics, significantly improving cycle life by 15-30% compared to conventional methods.

For grid-scale applications, cascaded PID control architectures enable multi-objective optimization across various storage technologies. Hybrid storage systems combining batteries with supercapacitors or flywheels benefit particularly from this approach, where each storage medium requires distinct control parameters. The outer loop typically manages energy distribution while inner loops handle rapid power fluctuations, creating a hierarchical control structure that addresses both short and long-term energy management goals.

Machine learning-enhanced PID controllers represent the cutting edge in storage optimization, where reinforcement learning algorithms continuously refine control parameters based on operational data. These systems have demonstrated energy efficiency improvements of up to 12% in field tests, particularly in microgrids with high renewable penetration. The self-tuning capability proves especially valuable in environments with seasonal variations in renewable generation patterns.

Economic optimization has become increasingly integrated with technical control objectives, where PID controllers incorporate electricity pricing signals to determine optimal charge/discharge timing. Time-of-use arbitrage strategies implemented through modified PID algorithms have shown potential for 8-15% cost reductions in commercial installations. The controller's ability to balance immediate grid services with long-term storage efficiency creates significant economic value beyond traditional technical performance metrics.

Thermal management of storage systems represents another critical application area, where PID controllers maintain optimal operating temperatures across battery arrays. Temperature uniformity directly impacts system longevity, with advanced thermal control strategies reducing degradation rates by up to 25% in high-temperature environments. Multi-variable PID implementations coordinate cooling systems with charge rates to prevent thermal runaway while maximizing available capacity.

Battery management systems utilizing PID control algorithms demonstrate superior performance in maintaining optimal state-of-charge levels. These controllers continuously monitor parameters such as voltage, current, and temperature, making real-time adjustments to charging profiles. Advanced implementations incorporate adaptive PID parameters that respond to battery aging characteristics, significantly improving cycle life by 15-30% compared to conventional methods.

For grid-scale applications, cascaded PID control architectures enable multi-objective optimization across various storage technologies. Hybrid storage systems combining batteries with supercapacitors or flywheels benefit particularly from this approach, where each storage medium requires distinct control parameters. The outer loop typically manages energy distribution while inner loops handle rapid power fluctuations, creating a hierarchical control structure that addresses both short and long-term energy management goals.

Machine learning-enhanced PID controllers represent the cutting edge in storage optimization, where reinforcement learning algorithms continuously refine control parameters based on operational data. These systems have demonstrated energy efficiency improvements of up to 12% in field tests, particularly in microgrids with high renewable penetration. The self-tuning capability proves especially valuable in environments with seasonal variations in renewable generation patterns.

Economic optimization has become increasingly integrated with technical control objectives, where PID controllers incorporate electricity pricing signals to determine optimal charge/discharge timing. Time-of-use arbitrage strategies implemented through modified PID algorithms have shown potential for 8-15% cost reductions in commercial installations. The controller's ability to balance immediate grid services with long-term storage efficiency creates significant economic value beyond traditional technical performance metrics.

Thermal management of storage systems represents another critical application area, where PID controllers maintain optimal operating temperatures across battery arrays. Temperature uniformity directly impacts system longevity, with advanced thermal control strategies reducing degradation rates by up to 25% in high-temperature environments. Multi-variable PID implementations coordinate cooling systems with charge rates to prevent thermal runaway while maximizing available capacity.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!