Use Of PID Control In Chemical And Biochemical Engineering Systems

SEP 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PID Control Evolution in Process Engineering

PID control has evolved significantly in process engineering since its inception in the early 20th century. The first formal description of a PID controller was published by Nicolas Minorsky in 1922, based on his observations of helmsmen steering ships. This marked the beginning of systematic control theory application in industrial processes. By the 1930s, pneumatic controllers implementing PID algorithms became commercially available, revolutionizing chemical process control capabilities.

The 1940s and 1950s witnessed the transition from pneumatic to electronic PID controllers, offering improved precision and reliability. This period also saw the development of fundamental tuning methods by Ziegler and Nichols in 1942, providing systematic approaches to controller parameter selection that remain influential today. These methods addressed the previously intuitive nature of controller tuning, establishing mathematical frameworks for optimizing control performance.

The 1960s and 1970s brought significant advancements with the introduction of distributed control systems (DCS), integrating PID control into comprehensive plant management frameworks. This integration allowed for centralized monitoring and adjustment of multiple control loops simultaneously, dramatically improving operational efficiency in complex chemical processes. During this era, academic research also expanded the theoretical understanding of PID control, developing more sophisticated tuning methods and stability analyses.

The digital revolution of the 1980s and 1990s transformed PID implementation through microprocessor-based controllers, enabling advanced features like auto-tuning, gain scheduling, and adaptive control. These innovations addressed the limitations of traditional fixed-parameter PID controllers when dealing with nonlinear chemical processes. Software-based control systems also facilitated the implementation of more complex control strategies while maintaining the familiar PID framework that engineers trusted.

Since 2000, PID control has evolved to incorporate artificial intelligence and machine learning techniques, creating hybrid systems that combine classical control theory with data-driven approaches. Modern chemical engineering applications now feature self-optimizing PID controllers that continuously adjust parameters based on process performance metrics. Additionally, model predictive control (MPC) has emerged as a complementary technology, often working alongside PID controllers in a hierarchical structure.

The most recent developments include cloud-based monitoring and optimization of PID controllers across global manufacturing networks, enabling unprecedented levels of process harmonization and knowledge sharing. Industry 4.0 initiatives have further integrated PID control with IoT sensors and big data analytics, creating more responsive and intelligent process control systems for chemical and biochemical applications.

The 1940s and 1950s witnessed the transition from pneumatic to electronic PID controllers, offering improved precision and reliability. This period also saw the development of fundamental tuning methods by Ziegler and Nichols in 1942, providing systematic approaches to controller parameter selection that remain influential today. These methods addressed the previously intuitive nature of controller tuning, establishing mathematical frameworks for optimizing control performance.

The 1960s and 1970s brought significant advancements with the introduction of distributed control systems (DCS), integrating PID control into comprehensive plant management frameworks. This integration allowed for centralized monitoring and adjustment of multiple control loops simultaneously, dramatically improving operational efficiency in complex chemical processes. During this era, academic research also expanded the theoretical understanding of PID control, developing more sophisticated tuning methods and stability analyses.

The digital revolution of the 1980s and 1990s transformed PID implementation through microprocessor-based controllers, enabling advanced features like auto-tuning, gain scheduling, and adaptive control. These innovations addressed the limitations of traditional fixed-parameter PID controllers when dealing with nonlinear chemical processes. Software-based control systems also facilitated the implementation of more complex control strategies while maintaining the familiar PID framework that engineers trusted.

Since 2000, PID control has evolved to incorporate artificial intelligence and machine learning techniques, creating hybrid systems that combine classical control theory with data-driven approaches. Modern chemical engineering applications now feature self-optimizing PID controllers that continuously adjust parameters based on process performance metrics. Additionally, model predictive control (MPC) has emerged as a complementary technology, often working alongside PID controllers in a hierarchical structure.

The most recent developments include cloud-based monitoring and optimization of PID controllers across global manufacturing networks, enabling unprecedented levels of process harmonization and knowledge sharing. Industry 4.0 initiatives have further integrated PID control with IoT sensors and big data analytics, creating more responsive and intelligent process control systems for chemical and biochemical applications.

Market Demand for Advanced Control Systems

The global market for advanced control systems in chemical and biochemical engineering has experienced significant growth over the past decade, driven primarily by increasing demands for process optimization, energy efficiency, and regulatory compliance. PID (Proportional-Integral-Derivative) control systems, despite being a mature technology, continue to dominate the industrial automation landscape due to their reliability, adaptability, and cost-effectiveness.

Recent market research indicates that the industrial automation market, which includes PID control systems, is projected to reach $296 billion by 2026, with chemical and biochemical sectors accounting for approximately 18% of this value. This growth is particularly pronounced in regions with expanding manufacturing bases such as Asia-Pacific, where investments in chemical processing facilities have increased by nearly 23% since 2018.

The demand for advanced PID control systems is being fueled by several key factors. First, the rising costs of raw materials and energy have compelled chemical and biochemical manufacturers to optimize their processes for maximum efficiency. PID controllers, especially those with adaptive and self-tuning capabilities, offer significant potential for reducing operational costs through precise process control.

Environmental regulations and sustainability initiatives represent another major market driver. Modern emission standards require tighter control of chemical processes, with PID systems playing a crucial role in maintaining parameters within increasingly narrow compliance windows. Companies implementing advanced control systems report average reductions in emissions of 15-20% compared to facilities using outdated control technologies.

The pharmaceutical and biotechnology sectors have emerged as particularly high-growth segments for advanced control systems. The need for precise temperature, pH, and pressure control in bioreactors and fermentation processes has created substantial demand for specialized PID implementations. Market analysis shows that bioprocess control systems are experiencing annual growth rates of 12-14%, significantly outpacing the broader automation market.

Industry 4.0 and digital transformation initiatives are reshaping market expectations for control systems. End-users increasingly demand PID controllers that integrate seamlessly with IoT platforms, offer remote monitoring capabilities, and provide advanced data analytics. This trend has expanded the market beyond traditional hardware to include software and service components, with software solutions for PID optimization growing at 17% annually.

Regional analysis reveals that while North America and Europe represent mature markets with steady demand for replacement and upgrade systems, emerging economies in Asia and Latin America are driving new installation growth. China alone has increased its investment in chemical process automation by 28% over the past five years, creating substantial opportunities for control system providers.

Recent market research indicates that the industrial automation market, which includes PID control systems, is projected to reach $296 billion by 2026, with chemical and biochemical sectors accounting for approximately 18% of this value. This growth is particularly pronounced in regions with expanding manufacturing bases such as Asia-Pacific, where investments in chemical processing facilities have increased by nearly 23% since 2018.

The demand for advanced PID control systems is being fueled by several key factors. First, the rising costs of raw materials and energy have compelled chemical and biochemical manufacturers to optimize their processes for maximum efficiency. PID controllers, especially those with adaptive and self-tuning capabilities, offer significant potential for reducing operational costs through precise process control.

Environmental regulations and sustainability initiatives represent another major market driver. Modern emission standards require tighter control of chemical processes, with PID systems playing a crucial role in maintaining parameters within increasingly narrow compliance windows. Companies implementing advanced control systems report average reductions in emissions of 15-20% compared to facilities using outdated control technologies.

The pharmaceutical and biotechnology sectors have emerged as particularly high-growth segments for advanced control systems. The need for precise temperature, pH, and pressure control in bioreactors and fermentation processes has created substantial demand for specialized PID implementations. Market analysis shows that bioprocess control systems are experiencing annual growth rates of 12-14%, significantly outpacing the broader automation market.

Industry 4.0 and digital transformation initiatives are reshaping market expectations for control systems. End-users increasingly demand PID controllers that integrate seamlessly with IoT platforms, offer remote monitoring capabilities, and provide advanced data analytics. This trend has expanded the market beyond traditional hardware to include software and service components, with software solutions for PID optimization growing at 17% annually.

Regional analysis reveals that while North America and Europe represent mature markets with steady demand for replacement and upgrade systems, emerging economies in Asia and Latin America are driving new installation growth. China alone has increased its investment in chemical process automation by 28% over the past five years, creating substantial opportunities for control system providers.

Current Challenges in Chemical Process Control

Despite significant advancements in process control technologies, the chemical and biochemical engineering sectors continue to face substantial challenges in implementing effective PID control systems. One of the primary obstacles remains the inherent nonlinearity of chemical processes, which often renders traditional linear PID controllers inadequate for maintaining optimal performance across varying operating conditions. These nonlinearities arise from complex reaction kinetics, phase transitions, and thermodynamic constraints that characterize chemical systems.

Time delays present another formidable challenge, particularly in large-scale industrial operations where sensor placement may be distant from control points. These delays can destabilize control loops and trigger oscillatory behaviors that compromise product quality and process safety. The situation becomes even more complex in biochemical systems where reaction rates can vary unpredictably due to biological variability and metabolic shifts.

Parameter tuning remains a persistent difficulty in chemical process control. The traditional Ziegler-Nichols method and its derivatives often fail to provide optimal tuning for processes with significant dead time or inverse response characteristics. This has led to increased interest in adaptive and self-tuning PID controllers, though their implementation in safety-critical chemical environments remains cautious due to validation concerns.

Multivariable interactions pose another significant challenge, as chemical processes typically involve numerous interdependent variables. Traditional single-loop PID controllers struggle with these interactions, leading to control conflicts and suboptimal performance. While model predictive control (MPC) offers solutions for such scenarios, many facilities still rely on PID controllers due to their simplicity and reliability, necessitating better approaches to handle loop interactions.

Energy efficiency considerations have emerged as a critical challenge, with increasing pressure to optimize control strategies not only for product quality but also for minimizing energy consumption. This dual optimization problem often creates competing objectives that traditional PID control structures struggle to balance effectively.

Disturbance rejection capabilities remain insufficient in many chemical processes subject to frequent feed composition changes, utility fluctuations, or environmental variations. Enhanced feedforward strategies and disturbance observers have shown promise but require accurate process models that are often difficult to develop and maintain in dynamic production environments.

Finally, the integration of PID control with emerging technologies such as artificial intelligence, digital twins, and Industrial Internet of Things (IIoT) presents both opportunities and challenges. While these technologies offer potential for significant improvements in control performance, they also introduce complexity in implementation, validation, and regulatory compliance that the industry is still working to address.

Time delays present another formidable challenge, particularly in large-scale industrial operations where sensor placement may be distant from control points. These delays can destabilize control loops and trigger oscillatory behaviors that compromise product quality and process safety. The situation becomes even more complex in biochemical systems where reaction rates can vary unpredictably due to biological variability and metabolic shifts.

Parameter tuning remains a persistent difficulty in chemical process control. The traditional Ziegler-Nichols method and its derivatives often fail to provide optimal tuning for processes with significant dead time or inverse response characteristics. This has led to increased interest in adaptive and self-tuning PID controllers, though their implementation in safety-critical chemical environments remains cautious due to validation concerns.

Multivariable interactions pose another significant challenge, as chemical processes typically involve numerous interdependent variables. Traditional single-loop PID controllers struggle with these interactions, leading to control conflicts and suboptimal performance. While model predictive control (MPC) offers solutions for such scenarios, many facilities still rely on PID controllers due to their simplicity and reliability, necessitating better approaches to handle loop interactions.

Energy efficiency considerations have emerged as a critical challenge, with increasing pressure to optimize control strategies not only for product quality but also for minimizing energy consumption. This dual optimization problem often creates competing objectives that traditional PID control structures struggle to balance effectively.

Disturbance rejection capabilities remain insufficient in many chemical processes subject to frequent feed composition changes, utility fluctuations, or environmental variations. Enhanced feedforward strategies and disturbance observers have shown promise but require accurate process models that are often difficult to develop and maintain in dynamic production environments.

Finally, the integration of PID control with emerging technologies such as artificial intelligence, digital twins, and Industrial Internet of Things (IIoT) presents both opportunities and challenges. While these technologies offer potential for significant improvements in control performance, they also introduce complexity in implementation, validation, and regulatory compliance that the industry is still working to address.

Mainstream PID Implementation Strategies

01 PID Control in Automotive Systems

PID (Proportional-Integral-Derivative) control is widely implemented in automotive systems for precise regulation of various vehicle functions. These applications include engine management, fuel injection timing, throttle control, and emissions management. The control algorithms help maintain optimal performance while adapting to changing driving conditions and environmental factors, resulting in improved fuel efficiency and reduced emissions.- PID Control in Industrial Automation: PID (Proportional-Integral-Derivative) controllers are widely used in industrial automation systems for precise control of processes. These controllers calculate an error value as the difference between a measured process variable and a desired setpoint, then apply corrections based on proportional, integral, and derivative terms. This approach enables stable and accurate control in various industrial applications including manufacturing, chemical processing, and power generation systems.

- PID Control in Temperature Regulation Systems: Temperature regulation systems often employ PID control algorithms to maintain precise thermal conditions. The controller continuously monitors temperature deviations from the setpoint and adjusts heating or cooling elements accordingly. The proportional component provides immediate response to temperature changes, the integral component eliminates steady-state errors, and the derivative component improves stability by responding to the rate of temperature change. This approach is particularly valuable in applications requiring tight temperature control.

- Advanced PID Tuning Methods: Various methods have been developed for optimizing PID controller parameters to achieve desired system performance. These tuning techniques include auto-tuning algorithms, adaptive control methods, and model-based approaches that automatically adjust controller parameters based on system response. Advanced tuning methods can significantly improve control performance by reducing overshoot, settling time, and steady-state error while enhancing robustness against disturbances and system variations.

- PID Control in Network and Communication Systems: PID control principles have been adapted for use in network and communication systems to regulate data flow, bandwidth allocation, and quality of service parameters. These controllers monitor network performance metrics and dynamically adjust system parameters to maintain optimal operation under varying conditions. The application of PID control in this domain helps manage network congestion, minimize latency, and ensure reliable data transmission across complex communication infrastructures.

- Hybrid and Modified PID Control Architectures: Researchers have developed various hybrid and modified PID control architectures to overcome limitations of traditional PID controllers. These include fuzzy PID controllers, neural network-enhanced PID systems, and cascaded PID control structures. Such advanced architectures combine the simplicity and reliability of conventional PID control with additional features that improve performance in nonlinear systems, handle time delays more effectively, and provide better disturbance rejection capabilities.

02 PID Control for Industrial Automation

Industrial automation systems utilize PID controllers for maintaining precise control over manufacturing processes. These controllers regulate variables such as temperature, pressure, flow rate, and speed in production environments. Advanced implementations include self-tuning capabilities that automatically adjust control parameters based on system response, improving stability and reducing the need for manual intervention in complex industrial settings.Expand Specific Solutions03 PID Control in Power Systems

Power generation and distribution systems employ PID control for voltage regulation, frequency control, and load balancing. These controllers help maintain grid stability by continuously adjusting power output to match demand fluctuations. Modern implementations incorporate adaptive algorithms that can respond to sudden changes in load conditions while minimizing oscillations in the power supply network.Expand Specific Solutions04 Digital PID Control Implementation

Digital implementations of PID controllers offer enhanced flexibility and performance compared to analog counterparts. These systems utilize microprocessors or specialized hardware to execute control algorithms with high precision. Features include real-time parameter adjustment, complex filtering techniques to reduce noise, and the ability to implement advanced control strategies such as cascaded PID loops or gain scheduling based on operating conditions.Expand Specific Solutions05 PID Control with Adaptive Tuning

Adaptive PID control systems automatically adjust their parameters in response to changing process dynamics. These systems continuously monitor performance metrics and modify control parameters to maintain optimal response characteristics. Techniques include model-based adaptation, rule-based adjustment, and machine learning approaches that improve control performance over time by learning from system behavior patterns and disturbance responses.Expand Specific Solutions

Leading Companies in Process Control Solutions

PID control in chemical and biochemical engineering systems is currently in a mature development phase, with a global market size estimated to exceed $2 billion annually. The competitive landscape features established industrial automation companies like SUPCON Technology and Vertiv Corp. providing comprehensive control solutions, alongside specialized firms such as Beijing Century Longbo Technology focusing on intelligent process optimization. Academic institutions including Northeastern University and Xi'an Jiaotong University contribute significant research advancements. The technology demonstrates high maturity with widespread implementation across chemical processing, pharmaceutical manufacturing, and bioprocessing applications, evidenced by Wuxi Xuelang Shuzhi Technology's industrial internet platforms and Zhejiang Supcon Software's specialized control systems for complex biochemical processes.

SUPCON Technology Co., Ltd.

Technical Solution: SUPCON has developed advanced PID control systems specifically tailored for chemical and biochemical processes. Their solution integrates traditional PID algorithms with adaptive control mechanisms that automatically adjust parameters based on process dynamics. The company's DCS (Distributed Control System) platform incorporates multi-loop PID controllers with anti-windup features and feed-forward capabilities to handle the complex, non-linear characteristics of chemical reactions. SUPCON's technology employs cascade control structures where primary and secondary PID loops work in tandem to maintain critical process variables like temperature, pressure, and concentration within tight specifications. Their systems also feature self-tuning PID algorithms that continuously optimize controller performance during operation, reducing the need for manual intervention and accommodating process changes over time.

Strengths: Highly specialized for chemical industry applications with proven implementation in petrochemical plants and pharmaceutical manufacturing. Their systems demonstrate excellent disturbance rejection and setpoint tracking in highly exothermic reactions. Weaknesses: Higher implementation costs compared to generic control solutions, and requires specialized training for operators to fully utilize advanced features.

Vertiv Corp.

Technical Solution: Vertiv has developed specialized PID control solutions for environmental control systems in critical chemical and biochemical facilities. Their approach focuses on precise temperature and humidity control essential for sensitive biochemical processes and storage. The company's PID implementations feature energy-efficient algorithms that maintain tight environmental parameters while optimizing power consumption in large-scale facilities. Vertiv's control systems incorporate redundant PID loops with automatic failover mechanisms to ensure continuous operation in mission-critical applications like vaccine production and pharmaceutical storage. Their technology includes specialized PID tuning methods that account for the thermal dynamics of different facility configurations and process equipment. Additionally, Vertiv has developed integrated monitoring systems that track PID performance metrics and provide predictive maintenance alerts to prevent control degradation before it impacts process quality.

Strengths: Exceptional reliability with redundant control architectures and proven performance in mission-critical applications. Their systems demonstrate excellent energy efficiency while maintaining precise environmental parameters. Weaknesses: Less specialized for specific chemical reaction control compared to process-focused competitors, and higher initial capital investment requirements.

Key Innovations in Adaptive PID Algorithms

Method and system for autotuning a PID controller on electromechanical actuators using machine learning

PatentWO2023122636A1

Innovation

- A system and method utilizing a neural network-based autotuning system that determines PID gains by estimating load torque and applying these gains to the PID controller, eliminating the need for manual tuning and enabling adaptive control independent of actuator type or application.

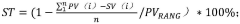

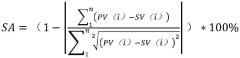

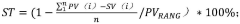

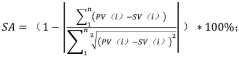

Performance evaluation method and evaluation device for PID (Proportion Integration Differentiation) control loop

PatentPendingCN117192971A

Innovation

- Provide a PID control loop performance evaluation method and device. By obtaining the control loop operation data, health detection of valves and instruments is performed, and based on the parameter performance evaluation of the control loop, the fluctuation amplitude, stability and accuracy scores are calculated, and the weights are set. coefficients, quantitative evaluation results, and push alarm information to optimize loop performance.

Regulatory Compliance in Process Control

Regulatory compliance in process control systems utilizing PID controllers has become increasingly stringent across chemical and biochemical engineering applications. The FDA's 21 CFR Part 11 establishes comprehensive requirements for electronic records and signatures, directly impacting automated control systems in pharmaceutical manufacturing. These regulations mandate validation protocols, audit trails, and system security measures to ensure data integrity throughout the production process where PID controllers are implemented.

Similarly, the European Medicines Agency (EMA) has established Good Manufacturing Practice (GMP) guidelines that specifically address process control systems. These guidelines require thorough documentation of control parameters, calibration procedures, and system performance verification—all critical aspects when implementing PID control strategies in biochemical processes.

Environmental protection agencies worldwide have instituted regulations governing emissions and waste management that significantly influence process control design. The EPA's Clean Air Act and Clean Water Act in the United States necessitate precise control of reaction conditions and effluent treatment processes, often achieved through sophisticated PID control implementations with strict monitoring requirements.

OSHA and equivalent international safety organizations have developed standards specifically addressing hazardous process control, including requirements for redundant control systems, fail-safe mechanisms, and emergency shutdown procedures. These safety regulations directly impact PID controller design, requiring consideration of control loop reliability and response characteristics during abnormal operating conditions.

The International Society of Automation (ISA) has developed the ISA-88 and ISA-95 standards, which provide frameworks for batch process control and enterprise-control system integration. These standards have been widely adopted and often serve as compliance benchmarks for implementing PID control in regulated industries. They establish standardized approaches to control system documentation, validation, and lifecycle management.

Emerging regulations concerning cybersecurity, such as IEC 62443, are increasingly relevant as process control systems become more interconnected. These standards mandate security assessments, access controls, and intrusion detection capabilities for industrial control systems, adding another layer of compliance requirements to PID implementations in modern chemical and biochemical facilities.

Compliance with these regulations requires comprehensive validation protocols for PID control systems, including Installation Qualification (IQ), Operational Qualification (OQ), and Performance Qualification (PQ) documentation. These validation procedures must demonstrate that control systems consistently operate within specified parameters and can reliably maintain critical process conditions.

Similarly, the European Medicines Agency (EMA) has established Good Manufacturing Practice (GMP) guidelines that specifically address process control systems. These guidelines require thorough documentation of control parameters, calibration procedures, and system performance verification—all critical aspects when implementing PID control strategies in biochemical processes.

Environmental protection agencies worldwide have instituted regulations governing emissions and waste management that significantly influence process control design. The EPA's Clean Air Act and Clean Water Act in the United States necessitate precise control of reaction conditions and effluent treatment processes, often achieved through sophisticated PID control implementations with strict monitoring requirements.

OSHA and equivalent international safety organizations have developed standards specifically addressing hazardous process control, including requirements for redundant control systems, fail-safe mechanisms, and emergency shutdown procedures. These safety regulations directly impact PID controller design, requiring consideration of control loop reliability and response characteristics during abnormal operating conditions.

The International Society of Automation (ISA) has developed the ISA-88 and ISA-95 standards, which provide frameworks for batch process control and enterprise-control system integration. These standards have been widely adopted and often serve as compliance benchmarks for implementing PID control in regulated industries. They establish standardized approaches to control system documentation, validation, and lifecycle management.

Emerging regulations concerning cybersecurity, such as IEC 62443, are increasingly relevant as process control systems become more interconnected. These standards mandate security assessments, access controls, and intrusion detection capabilities for industrial control systems, adding another layer of compliance requirements to PID implementations in modern chemical and biochemical facilities.

Compliance with these regulations requires comprehensive validation protocols for PID control systems, including Installation Qualification (IQ), Operational Qualification (OQ), and Performance Qualification (PQ) documentation. These validation procedures must demonstrate that control systems consistently operate within specified parameters and can reliably maintain critical process conditions.

Energy Efficiency Through Optimized PID Systems

Energy efficiency has become a critical concern in chemical and biochemical engineering systems, with PID control systems offering significant opportunities for optimization. Traditional PID implementations often operate at suboptimal energy consumption levels, creating substantial operational costs and environmental impacts across industrial processes. Recent studies indicate that properly tuned PID controllers can reduce energy consumption by 15-30% compared to poorly tuned or manual control systems.

The energy efficiency optimization of PID systems can be approached through several complementary strategies. Advanced tuning methodologies, including model-based and adaptive tuning algorithms, enable more precise control that minimizes overshoot and settling time—factors that directly contribute to energy waste. Implementation of cascade control structures allows for more responsive management of energy-intensive processes, particularly in reactor temperature control and distillation column operations.

Auto-tuning PID controllers with energy efficiency parameters have demonstrated remarkable results in industrial applications. A 2022 case study in a pharmaceutical fermentation process showed that implementing energy-optimized PID control reduced steam consumption by 22% while maintaining product quality specifications. Similar implementations in continuous chemical processes have yielded electricity savings between 10-18% compared to conventional control approaches.

The integration of predictive elements into PID frameworks represents another frontier in energy optimization. By anticipating process disturbances and load changes, these systems can proactively adjust control parameters to minimize energy spikes and maintain steady-state operation. This approach has proven particularly valuable in batch processes where thermal cycling traditionally consumes significant energy resources.

Real-time energy monitoring coupled with PID performance metrics creates opportunities for continuous improvement. Modern digital control systems can track energy consumption per unit of production, allowing engineers to identify inefficiencies and implement targeted optimizations. The correlation between control loop performance indices and energy utilization provides actionable insights for sustainable process operation.

Emerging research focuses on multi-objective optimization algorithms that balance product quality, throughput, and energy efficiency simultaneously. These approaches recognize the complex trade-offs inherent in process control and seek to establish operating parameters that satisfy all critical constraints while minimizing resource consumption. The development of specialized performance indices that explicitly incorporate energy metrics represents a promising direction for future PID implementation in sustainable chemical engineering.

The energy efficiency optimization of PID systems can be approached through several complementary strategies. Advanced tuning methodologies, including model-based and adaptive tuning algorithms, enable more precise control that minimizes overshoot and settling time—factors that directly contribute to energy waste. Implementation of cascade control structures allows for more responsive management of energy-intensive processes, particularly in reactor temperature control and distillation column operations.

Auto-tuning PID controllers with energy efficiency parameters have demonstrated remarkable results in industrial applications. A 2022 case study in a pharmaceutical fermentation process showed that implementing energy-optimized PID control reduced steam consumption by 22% while maintaining product quality specifications. Similar implementations in continuous chemical processes have yielded electricity savings between 10-18% compared to conventional control approaches.

The integration of predictive elements into PID frameworks represents another frontier in energy optimization. By anticipating process disturbances and load changes, these systems can proactively adjust control parameters to minimize energy spikes and maintain steady-state operation. This approach has proven particularly valuable in batch processes where thermal cycling traditionally consumes significant energy resources.

Real-time energy monitoring coupled with PID performance metrics creates opportunities for continuous improvement. Modern digital control systems can track energy consumption per unit of production, allowing engineers to identify inefficiencies and implement targeted optimizations. The correlation between control loop performance indices and energy utilization provides actionable insights for sustainable process operation.

Emerging research focuses on multi-objective optimization algorithms that balance product quality, throughput, and energy efficiency simultaneously. These approaches recognize the complex trade-offs inherent in process control and seek to establish operating parameters that satisfy all critical constraints while minimizing resource consumption. The development of specialized performance indices that explicitly incorporate energy metrics represents a promising direction for future PID implementation in sustainable chemical engineering.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!