How Does A PID Controller Support Automatic Cruise Control In Vehicles?

SEP 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PID Control Technology Background and Objectives

PID control technology has evolved significantly since its inception in the late 19th century, with the first theoretical analysis of a PID controller published by Nicolas Minorsky in 1922. Originally developed for naval vessel steering systems, PID controllers have since become fundamental components in numerous industrial applications due to their reliability, simplicity, and effectiveness. In automotive engineering, PID control technology began gaining prominence in the 1990s with the introduction of early cruise control systems, which initially focused solely on maintaining constant vehicle speed.

The evolution of PID controllers in automotive applications has been marked by continuous refinement in algorithm design, implementation methods, and integration with other vehicle systems. From simple analog circuits to sophisticated digital implementations, PID controllers have become increasingly precise and adaptable. Modern automotive PID controllers benefit from advancements in microprocessor technology, allowing for more complex calculations, adaptive parameter tuning, and integration with vehicle dynamics management systems.

The primary objective of PID control in Automatic Cruise Control (ACC) systems is to maintain a desired vehicle speed with minimal deviation regardless of external disturbances such as road gradients, wind resistance, or varying load conditions. This is achieved through the controller's ability to continuously calculate an error value as the difference between the desired setpoint (target speed) and measured process variable (actual speed), then apply corrections based on proportional, integral, and derivative calculations.

Beyond basic speed maintenance, modern PID-based cruise control systems aim to enhance driving comfort by providing smooth acceleration and deceleration profiles, improve fuel efficiency through optimized throttle control, and increase safety by maintaining consistent vehicle behavior. The technology also serves as a foundation for more advanced driver assistance systems, including adaptive cruise control which incorporates radar or lidar sensors to maintain safe following distances from preceding vehicles.

Current technological trends indicate a movement toward more sophisticated control algorithms that combine traditional PID principles with adaptive and predictive elements. These hybrid approaches allow for better handling of the inherently nonlinear dynamics of vehicle motion and varying road conditions. Research is increasingly focused on self-tuning PID controllers that can automatically adjust their parameters based on driving conditions and vehicle response characteristics.

The ultimate goal for PID control technology in automotive applications is to achieve a perfect balance between performance, comfort, and efficiency while maintaining robust operation across all driving scenarios. This includes seamless integration with emerging autonomous driving technologies, where PID control serves as a critical component in the hierarchical control architecture of self-driving vehicles.

The evolution of PID controllers in automotive applications has been marked by continuous refinement in algorithm design, implementation methods, and integration with other vehicle systems. From simple analog circuits to sophisticated digital implementations, PID controllers have become increasingly precise and adaptable. Modern automotive PID controllers benefit from advancements in microprocessor technology, allowing for more complex calculations, adaptive parameter tuning, and integration with vehicle dynamics management systems.

The primary objective of PID control in Automatic Cruise Control (ACC) systems is to maintain a desired vehicle speed with minimal deviation regardless of external disturbances such as road gradients, wind resistance, or varying load conditions. This is achieved through the controller's ability to continuously calculate an error value as the difference between the desired setpoint (target speed) and measured process variable (actual speed), then apply corrections based on proportional, integral, and derivative calculations.

Beyond basic speed maintenance, modern PID-based cruise control systems aim to enhance driving comfort by providing smooth acceleration and deceleration profiles, improve fuel efficiency through optimized throttle control, and increase safety by maintaining consistent vehicle behavior. The technology also serves as a foundation for more advanced driver assistance systems, including adaptive cruise control which incorporates radar or lidar sensors to maintain safe following distances from preceding vehicles.

Current technological trends indicate a movement toward more sophisticated control algorithms that combine traditional PID principles with adaptive and predictive elements. These hybrid approaches allow for better handling of the inherently nonlinear dynamics of vehicle motion and varying road conditions. Research is increasingly focused on self-tuning PID controllers that can automatically adjust their parameters based on driving conditions and vehicle response characteristics.

The ultimate goal for PID control technology in automotive applications is to achieve a perfect balance between performance, comfort, and efficiency while maintaining robust operation across all driving scenarios. This includes seamless integration with emerging autonomous driving technologies, where PID control serves as a critical component in the hierarchical control architecture of self-driving vehicles.

Market Analysis of Cruise Control Systems

The global cruise control system market has witnessed substantial growth over the past decade, primarily driven by increasing consumer demand for enhanced driving comfort and safety features. As of 2023, the market size for cruise control systems has reached approximately $20 billion, with projections indicating a compound annual growth rate of 6.8% through 2028. This growth trajectory is supported by the rising integration of advanced driver assistance systems (ADAS) in mid-range and economy vehicles, expanding beyond the premium segment where such technologies were traditionally concentrated.

The market segmentation reveals distinct categories based on technology sophistication. Basic cruise control systems still maintain a significant market share in developing economies, while adaptive cruise control (ACC) systems have become standard in developed markets like North America, Europe, and parts of Asia. The newest segment—predictive cruise control systems utilizing PID controllers with AI enhancements—currently represents the fastest-growing segment with a 12.3% year-over-year increase.

Regional analysis indicates North America leads the market with approximately 35% share, followed by Europe at 30% and Asia-Pacific at 25%. The remaining 10% is distributed across other regions. China has emerged as a particularly dynamic market, with domestic manufacturers rapidly closing the technological gap with established international players.

Consumer adoption patterns demonstrate a clear correlation between fuel efficiency benefits and cruise control system adoption. Studies indicate that vehicles equipped with PID-based cruise control systems achieve 7-10% better fuel economy on highways compared to manual driving. This economic benefit has become a significant marketing point for manufacturers, especially as fuel prices and environmental concerns continue to influence purchasing decisions.

The competitive landscape features traditional automotive suppliers like Bosch, Continental, and Denso dominating with combined market share exceeding 50%. However, technology companies including NVIDIA, Intel (Mobileye), and emerging startups are disrupting the space by introducing software-defined solutions that enhance the capabilities of existing hardware. This shift toward software-centric systems is enabling more sophisticated PID controller implementations that can better handle complex driving scenarios.

Price sensitivity analysis reveals that consumers are increasingly willing to pay premium prices for advanced cruise control systems, with the perceived value of these systems rising as their capabilities expand beyond simple speed maintenance to include features like stop-and-go functionality in traffic and curve adaptation. The average price premium for vehicles equipped with advanced PID-based cruise control systems ranges between $800-1,500 depending on vehicle segment and region.

The market segmentation reveals distinct categories based on technology sophistication. Basic cruise control systems still maintain a significant market share in developing economies, while adaptive cruise control (ACC) systems have become standard in developed markets like North America, Europe, and parts of Asia. The newest segment—predictive cruise control systems utilizing PID controllers with AI enhancements—currently represents the fastest-growing segment with a 12.3% year-over-year increase.

Regional analysis indicates North America leads the market with approximately 35% share, followed by Europe at 30% and Asia-Pacific at 25%. The remaining 10% is distributed across other regions. China has emerged as a particularly dynamic market, with domestic manufacturers rapidly closing the technological gap with established international players.

Consumer adoption patterns demonstrate a clear correlation between fuel efficiency benefits and cruise control system adoption. Studies indicate that vehicles equipped with PID-based cruise control systems achieve 7-10% better fuel economy on highways compared to manual driving. This economic benefit has become a significant marketing point for manufacturers, especially as fuel prices and environmental concerns continue to influence purchasing decisions.

The competitive landscape features traditional automotive suppliers like Bosch, Continental, and Denso dominating with combined market share exceeding 50%. However, technology companies including NVIDIA, Intel (Mobileye), and emerging startups are disrupting the space by introducing software-defined solutions that enhance the capabilities of existing hardware. This shift toward software-centric systems is enabling more sophisticated PID controller implementations that can better handle complex driving scenarios.

Price sensitivity analysis reveals that consumers are increasingly willing to pay premium prices for advanced cruise control systems, with the perceived value of these systems rising as their capabilities expand beyond simple speed maintenance to include features like stop-and-go functionality in traffic and curve adaptation. The average price premium for vehicles equipped with advanced PID-based cruise control systems ranges between $800-1,500 depending on vehicle segment and region.

Current PID Implementation Challenges in Vehicles

Despite the widespread adoption of PID controllers in automotive cruise control systems, several significant implementation challenges persist in modern vehicles. The fundamental issue lies in the inherent non-linearity of vehicle dynamics, which contrasts with the linear control approach of traditional PID systems. Vehicle performance varies substantially across different operating conditions—engine efficiency fluctuates with temperature, aerodynamic drag increases exponentially with speed, and road gradient introduces unpredictable disturbances. These variables create a complex control environment that basic PID implementations struggle to address effectively.

Parameter tuning represents another major challenge for automotive engineers. The optimal PID gains (proportional, integral, and derivative coefficients) differ significantly based on vehicle weight, engine specifications, transmission characteristics, and even tire conditions. This necessitates extensive calibration processes during development, often requiring compromise settings that perform adequately across various conditions rather than optimally in specific scenarios.

Environmental factors further complicate PID implementation. Sudden headwinds, changing road surfaces, and varying inclines can introduce disturbances that cause traditional PID controllers to exhibit undesirable behaviors such as overshooting target speeds or responding sluggishly to changes. These limitations become particularly pronounced in stop-and-go traffic situations where the control system must frequently transition between acceleration and deceleration.

Sensor quality and data processing limitations also present significant hurdles. PID controllers rely on accurate speed measurements, but vehicle speed sensors can introduce noise, latency, or measurement errors. The sampling rate of the control system may be insufficient for rapid response in certain driving scenarios, while computational constraints in automotive ECUs may limit the complexity of implementable control algorithms.

Integration challenges arise when PID cruise control must work harmoniously with other vehicle systems. Modern vehicles incorporate numerous control systems including stability control, traction control, and collision avoidance systems. Ensuring these systems operate cohesively without conflicting control actions requires sophisticated arbitration mechanisms that can compromise PID performance.

Lastly, user experience considerations create additional implementation challenges. Drivers expect cruise control systems to behave predictably and comfortably across diverse conditions. Achieving the right balance between responsive speed maintenance and smooth, gradual acceleration/deceleration profiles requires careful tuning beyond mere speed accuracy. This human-centered design requirement often necessitates modifications to textbook PID implementations, introducing additional complexity to the control system architecture.

Parameter tuning represents another major challenge for automotive engineers. The optimal PID gains (proportional, integral, and derivative coefficients) differ significantly based on vehicle weight, engine specifications, transmission characteristics, and even tire conditions. This necessitates extensive calibration processes during development, often requiring compromise settings that perform adequately across various conditions rather than optimally in specific scenarios.

Environmental factors further complicate PID implementation. Sudden headwinds, changing road surfaces, and varying inclines can introduce disturbances that cause traditional PID controllers to exhibit undesirable behaviors such as overshooting target speeds or responding sluggishly to changes. These limitations become particularly pronounced in stop-and-go traffic situations where the control system must frequently transition between acceleration and deceleration.

Sensor quality and data processing limitations also present significant hurdles. PID controllers rely on accurate speed measurements, but vehicle speed sensors can introduce noise, latency, or measurement errors. The sampling rate of the control system may be insufficient for rapid response in certain driving scenarios, while computational constraints in automotive ECUs may limit the complexity of implementable control algorithms.

Integration challenges arise when PID cruise control must work harmoniously with other vehicle systems. Modern vehicles incorporate numerous control systems including stability control, traction control, and collision avoidance systems. Ensuring these systems operate cohesively without conflicting control actions requires sophisticated arbitration mechanisms that can compromise PID performance.

Lastly, user experience considerations create additional implementation challenges. Drivers expect cruise control systems to behave predictably and comfortably across diverse conditions. Achieving the right balance between responsive speed maintenance and smooth, gradual acceleration/deceleration profiles requires careful tuning beyond mere speed accuracy. This human-centered design requirement often necessitates modifications to textbook PID implementations, introducing additional complexity to the control system architecture.

Current PID-based Cruise Control Solutions

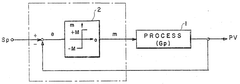

01 PID parameter tuning for improved control accuracy

Proper tuning of PID controller parameters (proportional, integral, and derivative) is crucial for achieving high control accuracy. Various methods and algorithms can be employed to optimize these parameters based on the specific requirements of the control system. Adaptive tuning techniques can automatically adjust parameters in response to changing conditions, ensuring consistent control accuracy across different operating scenarios.- PID parameter tuning for improved control accuracy: Proper tuning of PID controller parameters (proportional, integral, and derivative) is essential for achieving high control accuracy. Various methods and algorithms can be employed to optimize these parameters based on system requirements. Adaptive tuning techniques can automatically adjust parameters in response to changing conditions, while manual tuning approaches rely on established methods like Ziegler-Nichols. Optimized parameter selection helps minimize overshoot, reduce settling time, and improve steady-state accuracy in control systems.

- Advanced PID control algorithms for precision applications: Enhanced PID control algorithms incorporate additional features beyond traditional PID control to achieve higher accuracy. These include fuzzy logic integration, neural network adaptation, and model predictive control elements. Such advanced algorithms can better handle nonlinearities, disturbances, and time delays in complex systems. They often employ real-time optimization techniques to continuously adjust control strategies based on system performance metrics, resulting in significantly improved control accuracy for demanding applications.

- Disturbance rejection and compensation techniques: Effective disturbance rejection is crucial for maintaining control accuracy in PID systems. Various compensation techniques can be implemented to mitigate the effects of external disturbances, system nonlinearities, and parameter variations. Feed-forward compensation anticipates disturbances based on measurable variables, while observer-based methods estimate and counteract unmeasurable disturbances. Anti-windup mechanisms prevent integral term saturation during large disturbances, ensuring faster recovery and improved control accuracy under varying operating conditions.

- Digital implementation and sampling considerations: The digital implementation of PID controllers significantly impacts control accuracy. Proper selection of sampling rate, quantization resolution, and numerical algorithms is essential for high-precision control. Higher sampling rates generally improve accuracy but increase computational demands, while appropriate anti-aliasing filters prevent high-frequency noise from affecting control performance. Discretization methods for converting continuous-time designs to discrete implementations must be carefully selected to preserve control characteristics and maintain stability across the operating range.

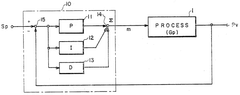

- Hybrid and cascaded control structures: Hybrid and cascaded control structures combine multiple control loops or different control strategies to achieve superior accuracy. Cascaded PID configurations use nested control loops where the output of one controller becomes the setpoint for another, allowing for more precise control of complex processes with multiple dynamics. Hybrid approaches integrate PID with other control methodologies such as state feedback or sliding mode control. These architectures can effectively handle systems with multiple time constants or conflicting control objectives, resulting in enhanced overall control accuracy.

02 Advanced PID control architectures

Enhanced PID control architectures, such as cascaded PID controllers, fuzzy PID controllers, and neural network-based PID controllers, can significantly improve control accuracy. These advanced structures can better handle system nonlinearities, disturbances, and time delays that traditional PID controllers struggle with, resulting in more precise control performance across a wider range of operating conditions.Expand Specific Solutions03 Disturbance rejection techniques

Implementing effective disturbance rejection techniques in PID control systems can substantially enhance control accuracy. These techniques include feed-forward compensation, disturbance observers, and anti-windup mechanisms that prevent integral term saturation. By actively compensating for external disturbances and internal system variations, these methods maintain precise control even under challenging conditions.Expand Specific Solutions04 Digital implementation and sampling optimization

Digital implementation considerations, including sampling rate optimization, discretization methods, and computational efficiency, significantly impact PID controller accuracy. Proper selection of sampling frequency relative to system dynamics, implementation of anti-aliasing filters, and efficient numerical algorithms can minimize quantization errors and improve overall control precision in digital PID systems.Expand Specific Solutions05 Self-tuning and adaptive PID control

Self-tuning and adaptive PID control strategies automatically adjust controller parameters in response to changing process dynamics or operating conditions. These approaches use real-time system identification, performance monitoring, and optimization algorithms to continuously refine control parameters, ensuring optimal accuracy despite system variations, aging components, or environmental changes.Expand Specific Solutions

Major Automotive and Control Systems Manufacturers

The PID controller market for automatic cruise control is in a mature growth phase, with established players like Bosch, Siemens, and Honeywell dominating the global landscape. The market size is expanding steadily due to increasing adoption of advanced driver assistance systems, projected to reach significant growth as autonomous vehicle technologies evolve. Technologically, the field shows high maturity with companies like GM Global Technology, BYD, and Great Wall Motor implementing sophisticated PID control algorithms in their production vehicles. Chinese manufacturers including Chery Automobile and FAW are rapidly advancing their capabilities, while academic institutions like Southwest Jiaotong University and Southeast University contribute to theoretical innovations. The ecosystem demonstrates a balanced mix of traditional automotive suppliers and emerging technology-focused enterprises collaborating to enhance control precision and reliability.

GM Global Technology Operations LLC

Technical Solution: GM's PID controller implementation for Adaptive Cruise Control (ACC) utilizes a sophisticated multi-layered approach. Their system employs a cascaded PID control architecture where an outer loop controller manages vehicle spacing based on radar-detected lead vehicle distance, while an inner loop controller handles throttle and brake actuation. GM has enhanced traditional PID with predictive modeling that anticipates lead vehicle behavior based on historical movement patterns. Their implementation includes gain scheduling techniques that dynamically adjust PID parameters based on driving conditions, vehicle speed, and road grade. GM's system also incorporates a specialized anti-windup mechanism to prevent integral term saturation during rapid changes in traffic conditions. The controller interfaces with the vehicle's powertrain control module and electronic brake control module through a high-speed CAN network, allowing for precise throttle modulation and smooth brake application with response times under 100ms.

Strengths: Superior integration with GM's vehicle architecture providing seamless operation across diverse powertrain configurations; robust performance in varied weather conditions due to adaptive gain scheduling. Weaknesses: System complexity requires significant computational resources; calibration process is highly vehicle-specific requiring extensive testing for each model implementation.

Knorr-Bremse GmbH

Technical Solution: Knorr-Bremse's PID-based Adaptive Cruise Control solution integrates with their comprehensive commercial vehicle braking systems. Their approach utilizes a distributed control architecture where the PID controller forms the core of their ACC module but works in conjunction with their Electronic Braking System (EBS). The system employs a sophisticated sensor fusion algorithm combining radar, camera, and vehicle dynamics data to establish precise vehicle-to-vehicle distance control. Their implementation features variable time-gap settings (typically 1.0-2.5 seconds) that adjust based on driver preference and vehicle speed. Knorr-Bremse's PID controller incorporates specialized damping coefficients to prevent oscillatory behavior during rapid deceleration events. The system includes proprietary "smooth approach" algorithms that modify PID response characteristics when approaching stopped vehicles, gradually reducing speed to enhance passenger comfort. Their commercial vehicle implementation also accounts for vehicle mass variations, automatically adjusting controller parameters based on load sensors to maintain consistent performance regardless of cargo weight.

Strengths: Exceptional integration with commercial vehicle braking systems; specialized algorithms for heavy vehicle dynamics; robust performance under varying load conditions. Weaknesses: Higher system cost compared to passenger vehicle implementations; requires more extensive calibration for different vehicle configurations and load distributions.

Key PID Algorithm Innovations for Vehicle Speed Control

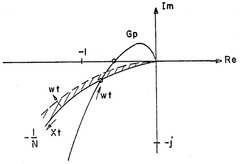

Method of determining PID parameters and an automatic tuning controller using the method

PatentInactiveUS4754391A

Innovation

- A method that monitors a limit cycle generated in a process by inserting a nonlinear element into the PID controller's proportional operation portion and connecting the integral operation portion in parallel, allowing for continuous process control and determination of optimum PID parameters without disrupting normal operation.

Safety Standards and Compliance Requirements

The implementation of PID controllers in Automatic Cruise Control (ACC) systems must adhere to stringent safety standards and compliance requirements to ensure passenger safety and regulatory approval. The ISO 26262 standard, specifically designed for road vehicle functional safety, provides a comprehensive framework for developing safety-critical automotive systems including ACC. This standard requires manufacturers to conduct thorough hazard analysis and risk assessment (HARA) to identify potential failure modes of PID-controlled systems and implement appropriate safety measures.

Federal Motor Vehicle Safety Standards (FMVSS) in the United States and similar regulations in other regions mandate specific performance criteria for ACC systems. These include requirements for system response time, control accuracy, and fail-safe mechanisms. PID controllers must be calibrated to ensure that vehicle acceleration and deceleration rates remain within comfortable and safe limits, typically not exceeding 0.3g for normal operation to prevent passenger discomfort or potential hazards.

The UN ECE Regulation No. 79 for steering equipment and Regulation No. 13-H for braking systems also apply to ACC implementations, particularly for systems that integrate with steering or braking functions. These regulations specify minimum performance requirements and testing protocols that directly impact PID controller design and tuning parameters.

Manufacturers must implement robust fault detection and management systems to monitor PID controller performance continuously. This includes watchdog timers to detect controller malfunctions, sensor validation algorithms to identify faulty inputs, and graceful degradation strategies that maintain basic functionality even when components fail. The system must provide clear notifications to drivers when ACC functionality is compromised or unavailable.

Electromagnetic compatibility (EMC) standards such as ISO 11452 are particularly relevant for electronic control systems like PID controllers. These standards ensure that the controller functions correctly in the presence of electromagnetic interference and does not itself generate interference that could affect other vehicle systems.

Software development for PID controllers must follow ASPICE (Automotive SPICE) or similar quality management standards to ensure systematic development processes. This includes requirements traceability, verification and validation procedures, and comprehensive documentation. The MISRA C guidelines are commonly applied to ensure code reliability and safety in embedded automotive applications like PID controllers.

Cybersecurity considerations have become increasingly important with the rise of connected vehicles. Standards like ISO/SAE 21434 address cybersecurity engineering for road vehicles, requiring manufacturers to implement measures that protect ACC systems from unauthorized access or manipulation that could compromise the PID controller's operation.

Federal Motor Vehicle Safety Standards (FMVSS) in the United States and similar regulations in other regions mandate specific performance criteria for ACC systems. These include requirements for system response time, control accuracy, and fail-safe mechanisms. PID controllers must be calibrated to ensure that vehicle acceleration and deceleration rates remain within comfortable and safe limits, typically not exceeding 0.3g for normal operation to prevent passenger discomfort or potential hazards.

The UN ECE Regulation No. 79 for steering equipment and Regulation No. 13-H for braking systems also apply to ACC implementations, particularly for systems that integrate with steering or braking functions. These regulations specify minimum performance requirements and testing protocols that directly impact PID controller design and tuning parameters.

Manufacturers must implement robust fault detection and management systems to monitor PID controller performance continuously. This includes watchdog timers to detect controller malfunctions, sensor validation algorithms to identify faulty inputs, and graceful degradation strategies that maintain basic functionality even when components fail. The system must provide clear notifications to drivers when ACC functionality is compromised or unavailable.

Electromagnetic compatibility (EMC) standards such as ISO 11452 are particularly relevant for electronic control systems like PID controllers. These standards ensure that the controller functions correctly in the presence of electromagnetic interference and does not itself generate interference that could affect other vehicle systems.

Software development for PID controllers must follow ASPICE (Automotive SPICE) or similar quality management standards to ensure systematic development processes. This includes requirements traceability, verification and validation procedures, and comprehensive documentation. The MISRA C guidelines are commonly applied to ensure code reliability and safety in embedded automotive applications like PID controllers.

Cybersecurity considerations have become increasingly important with the rise of connected vehicles. Standards like ISO/SAE 21434 address cybersecurity engineering for road vehicles, requiring manufacturers to implement measures that protect ACC systems from unauthorized access or manipulation that could compromise the PID controller's operation.

Human-Machine Interface Considerations

The human-machine interface (HMI) in automatic cruise control systems represents a critical junction where PID controller functionality meets driver experience. Effective interface design must balance information transparency with cognitive load management, ensuring drivers remain informed without becoming overwhelmed by technical details.

Vehicle manufacturers have developed various approaches to communicate PID-controlled cruise status to drivers. Most modern implementations utilize multi-modal feedback systems, combining visual displays (typically in instrument clusters or heads-up displays) with haptic and auditory signals. These interfaces commonly display the target speed, current speed, following distance, and system status indicators that reflect the PID controller's operational state.

The challenge lies in translating complex PID operations into intuitive driver feedback. When the proportional component responds to speed deviations, the interface must provide immediate visual confirmation of adjustment initiation. The integral component's accumulative error correction should be represented through gradual interface changes that avoid alarming the driver while still communicating system activity. Derivative component actions, which anticipate future errors, can be particularly challenging to represent in user interfaces without creating driver confusion.

Research indicates that drivers prefer interfaces that provide clear indications of when the PID controller is making significant adjustments, particularly during rapid deceleration events. Studies by automotive human factors researchers have shown that providing anticipatory cues about upcoming controller actions improves driver trust and reduces intervention frequency.

Customization capabilities represent another important consideration, as driver preferences for control responsiveness vary significantly. Advanced interfaces now allow drivers to select between comfort-oriented or performance-oriented PID tuning parameters, effectively adjusting the controller's behavior to match individual driving styles without requiring technical understanding of PID mechanics.

The transition between manual and automatic control presents particular HMI challenges. Interfaces must clearly communicate engagement status and control authority boundaries. This becomes especially important in adaptive cruise control systems where the PID controller dynamically adjusts target speeds based on traffic conditions, potentially creating confusion about system intentions without proper interface design.

As vehicles move toward higher automation levels, HMI considerations for PID-based cruise control continue to evolve. Future interfaces will likely incorporate predictive displays that visualize the controller's planned actions before execution, further improving the transparency of these complex control systems while maintaining an intuitive user experience.

Vehicle manufacturers have developed various approaches to communicate PID-controlled cruise status to drivers. Most modern implementations utilize multi-modal feedback systems, combining visual displays (typically in instrument clusters or heads-up displays) with haptic and auditory signals. These interfaces commonly display the target speed, current speed, following distance, and system status indicators that reflect the PID controller's operational state.

The challenge lies in translating complex PID operations into intuitive driver feedback. When the proportional component responds to speed deviations, the interface must provide immediate visual confirmation of adjustment initiation. The integral component's accumulative error correction should be represented through gradual interface changes that avoid alarming the driver while still communicating system activity. Derivative component actions, which anticipate future errors, can be particularly challenging to represent in user interfaces without creating driver confusion.

Research indicates that drivers prefer interfaces that provide clear indications of when the PID controller is making significant adjustments, particularly during rapid deceleration events. Studies by automotive human factors researchers have shown that providing anticipatory cues about upcoming controller actions improves driver trust and reduces intervention frequency.

Customization capabilities represent another important consideration, as driver preferences for control responsiveness vary significantly. Advanced interfaces now allow drivers to select between comfort-oriented or performance-oriented PID tuning parameters, effectively adjusting the controller's behavior to match individual driving styles without requiring technical understanding of PID mechanics.

The transition between manual and automatic control presents particular HMI challenges. Interfaces must clearly communicate engagement status and control authority boundaries. This becomes especially important in adaptive cruise control systems where the PID controller dynamically adjusts target speeds based on traffic conditions, potentially creating confusion about system intentions without proper interface design.

As vehicles move toward higher automation levels, HMI considerations for PID-based cruise control continue to evolve. Future interfaces will likely incorporate predictive displays that visualize the controller's planned actions before execution, further improving the transparency of these complex control systems while maintaining an intuitive user experience.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!