How Are PID Controllers Applied In Process Control Industries?

SEP 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PID Control Evolution and Objectives

Proportional-Integral-Derivative (PID) control has evolved significantly since its inception in the early 20th century. The first documented implementation of PID control dates back to 1911 when Elmer Sperry developed an automatic ship steering mechanism. However, it was Nicolas Minorsky's theoretical work in 1922 that formalized the mathematical foundation of PID control based on observations of helmsmen steering ships.

The 1930s and 1940s witnessed the transition from mechanical to pneumatic PID controllers, enabling more precise control in industrial settings. Taylor Instrument Companies and Foxboro were among the pioneers in developing commercial pneumatic controllers that gained widespread adoption in process industries. These early controllers relied on mechanical components to perform the proportional, integral, and derivative calculations.

The electronic revolution of the 1950s and 1960s marked another significant milestone in PID control evolution. Electronic controllers offered improved accuracy, reliability, and flexibility compared to their pneumatic counterparts. This period saw the development of analog electronic PID controllers that could handle more complex control scenarios with faster response times.

The digital transformation in the 1970s and 1980s revolutionized PID control implementation. Microprocessors enabled the development of digital PID controllers with unprecedented computational capabilities. This shift allowed for more sophisticated control algorithms, adaptive tuning methods, and integration with emerging distributed control systems (DCS).

Today's PID controllers represent the culmination of over a century of technological advancement. Modern implementations feature auto-tuning capabilities, fuzzy logic integration, model predictive control elements, and seamless integration with industrial IoT platforms. These advanced controllers can self-optimize parameters based on process dynamics and adapt to changing conditions.

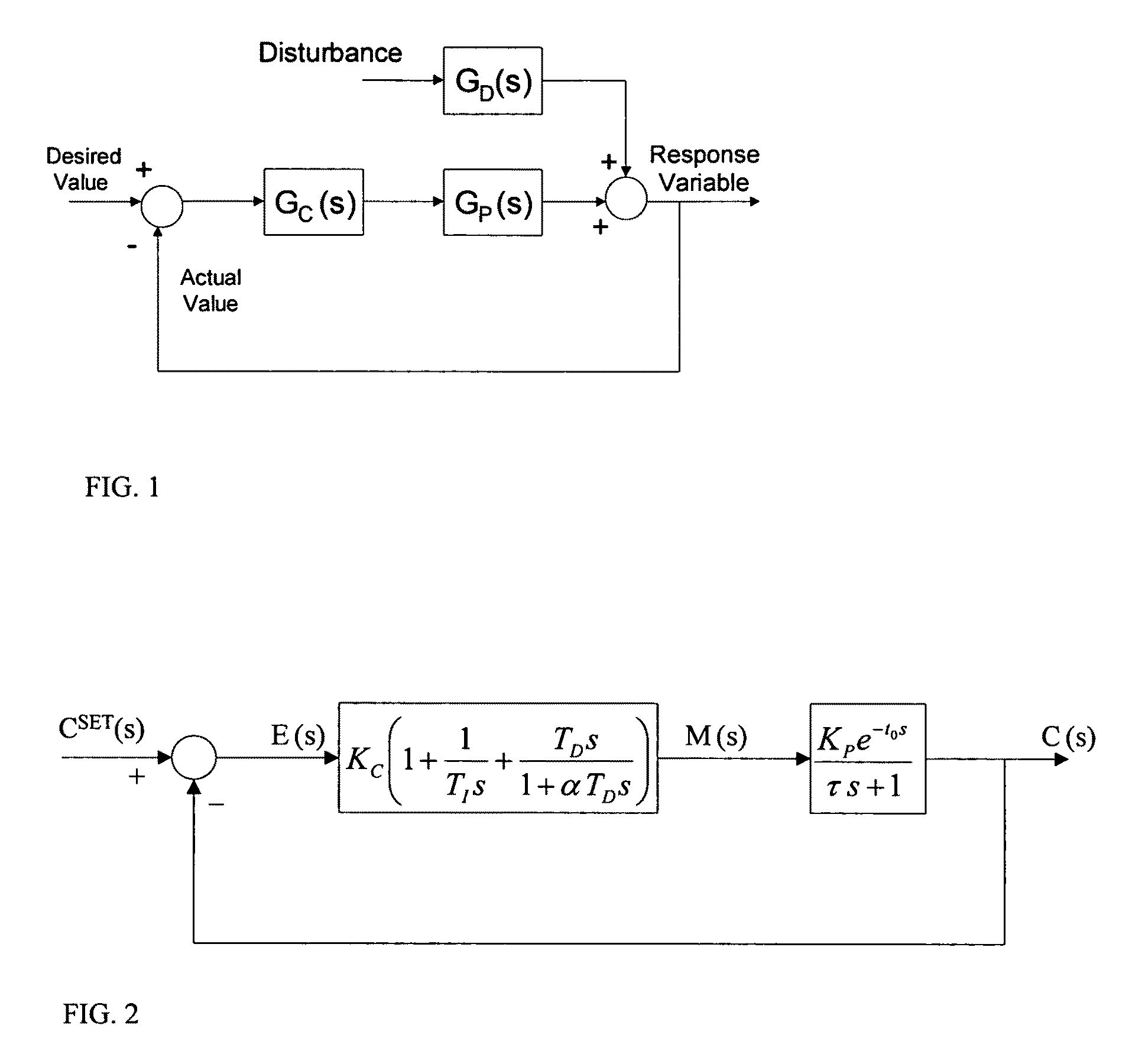

The primary objective of PID control in process industries remains consistent: to maintain a process variable at a desired setpoint with minimal deviation despite disturbances. This fundamental goal drives continuous innovation in PID technology. Specific objectives include minimizing settling time, reducing overshoot, eliminating steady-state errors, and ensuring robust performance across varying operating conditions.

As industries demand higher efficiency, reduced energy consumption, and stricter quality control, PID controllers continue to evolve. Current development focuses on enhancing controller intelligence through machine learning algorithms, improving integration with industrial automation systems, and developing specialized PID variants for specific industry applications. The evolution trajectory suggests future PID controllers will feature increased autonomy, predictive capabilities, and seamless integration with digital twin technologies.

The 1930s and 1940s witnessed the transition from mechanical to pneumatic PID controllers, enabling more precise control in industrial settings. Taylor Instrument Companies and Foxboro were among the pioneers in developing commercial pneumatic controllers that gained widespread adoption in process industries. These early controllers relied on mechanical components to perform the proportional, integral, and derivative calculations.

The electronic revolution of the 1950s and 1960s marked another significant milestone in PID control evolution. Electronic controllers offered improved accuracy, reliability, and flexibility compared to their pneumatic counterparts. This period saw the development of analog electronic PID controllers that could handle more complex control scenarios with faster response times.

The digital transformation in the 1970s and 1980s revolutionized PID control implementation. Microprocessors enabled the development of digital PID controllers with unprecedented computational capabilities. This shift allowed for more sophisticated control algorithms, adaptive tuning methods, and integration with emerging distributed control systems (DCS).

Today's PID controllers represent the culmination of over a century of technological advancement. Modern implementations feature auto-tuning capabilities, fuzzy logic integration, model predictive control elements, and seamless integration with industrial IoT platforms. These advanced controllers can self-optimize parameters based on process dynamics and adapt to changing conditions.

The primary objective of PID control in process industries remains consistent: to maintain a process variable at a desired setpoint with minimal deviation despite disturbances. This fundamental goal drives continuous innovation in PID technology. Specific objectives include minimizing settling time, reducing overshoot, eliminating steady-state errors, and ensuring robust performance across varying operating conditions.

As industries demand higher efficiency, reduced energy consumption, and stricter quality control, PID controllers continue to evolve. Current development focuses on enhancing controller intelligence through machine learning algorithms, improving integration with industrial automation systems, and developing specialized PID variants for specific industry applications. The evolution trajectory suggests future PID controllers will feature increased autonomy, predictive capabilities, and seamless integration with digital twin technologies.

Industrial Process Control Market Analysis

The global industrial process control market has witnessed substantial growth in recent years, reaching approximately $132.6 billion in 2022 and projected to expand at a CAGR of 6.8% through 2030. This growth is primarily driven by increasing automation across manufacturing sectors and the rising demand for efficient production processes that minimize human intervention while maximizing output quality and consistency.

PID controllers represent a significant segment within this market, accounting for roughly 42% of all control systems deployed in industrial settings. Their dominance stems from their versatility, reliability, and cost-effectiveness compared to more complex control solutions. Industries such as oil and gas, chemicals, food and beverage, pharmaceuticals, and power generation are the primary adopters of PID control technology.

Regionally, North America and Europe currently hold the largest market shares at 29% and 27% respectively, owing to their established industrial bases and early adoption of automation technologies. However, the Asia-Pacific region is experiencing the fastest growth rate at 8.2% annually, driven by rapid industrialization in countries like China, India, and South Korea, alongside significant investments in manufacturing infrastructure.

The market landscape is characterized by both established players and emerging specialists. Major automation companies like Siemens, ABB, Honeywell, Emerson, and Yokogawa collectively control approximately 58% of the global market share. These companies offer comprehensive process control solutions that integrate PID controllers within broader distributed control systems (DCS) and programmable logic controller (PLC) platforms.

Customer demand is increasingly shifting toward smart PID controllers with self-tuning capabilities, remote monitoring features, and integration with Industrial Internet of Things (IIoT) platforms. This trend is reflected in the 23% annual growth in sales of advanced PID controllers with connectivity features, compared to just 4% growth for traditional standalone units.

Key market challenges include the technical expertise required for optimal PID implementation and tuning, competition from advanced control methodologies like model predictive control (MPC) in complex applications, and cybersecurity concerns as control systems become more connected. Despite these challenges, the fundamental reliability and proven performance of PID control continue to ensure its central role in industrial process control applications across diverse manufacturing sectors.

PID controllers represent a significant segment within this market, accounting for roughly 42% of all control systems deployed in industrial settings. Their dominance stems from their versatility, reliability, and cost-effectiveness compared to more complex control solutions. Industries such as oil and gas, chemicals, food and beverage, pharmaceuticals, and power generation are the primary adopters of PID control technology.

Regionally, North America and Europe currently hold the largest market shares at 29% and 27% respectively, owing to their established industrial bases and early adoption of automation technologies. However, the Asia-Pacific region is experiencing the fastest growth rate at 8.2% annually, driven by rapid industrialization in countries like China, India, and South Korea, alongside significant investments in manufacturing infrastructure.

The market landscape is characterized by both established players and emerging specialists. Major automation companies like Siemens, ABB, Honeywell, Emerson, and Yokogawa collectively control approximately 58% of the global market share. These companies offer comprehensive process control solutions that integrate PID controllers within broader distributed control systems (DCS) and programmable logic controller (PLC) platforms.

Customer demand is increasingly shifting toward smart PID controllers with self-tuning capabilities, remote monitoring features, and integration with Industrial Internet of Things (IIoT) platforms. This trend is reflected in the 23% annual growth in sales of advanced PID controllers with connectivity features, compared to just 4% growth for traditional standalone units.

Key market challenges include the technical expertise required for optimal PID implementation and tuning, competition from advanced control methodologies like model predictive control (MPC) in complex applications, and cybersecurity concerns as control systems become more connected. Despite these challenges, the fundamental reliability and proven performance of PID control continue to ensure its central role in industrial process control applications across diverse manufacturing sectors.

Current PID Implementation Challenges

Despite the widespread adoption of PID controllers in process industries, several significant implementation challenges persist. One of the most fundamental issues is controller tuning, which remains a complex task requiring considerable expertise. Many facilities struggle with finding optimal PID parameters (proportional, integral, and derivative gains) that balance responsiveness with stability across varying operating conditions. This challenge is exacerbated in processes with nonlinear dynamics, where a single set of PID parameters may perform adequately in one operating region but poorly in others.

Process interactions present another substantial hurdle in PID implementation. In complex industrial systems with multiple interacting control loops, adjustments in one loop can significantly impact others, creating cascading effects that are difficult to predict and manage. This interaction often leads to reduced overall system performance and stability issues that conventional single-loop PID controllers cannot adequately address.

Time delays, inherent in many industrial processes, pose particular difficulties for PID control. When process dead time exceeds a certain threshold relative to the process time constant, traditional PID algorithms become increasingly ineffective. Industries dealing with transport delays, thermal processes, or chemical reactions frequently encounter this limitation, forcing compromises between control performance and stability.

The digital implementation of PID controllers introduces its own set of challenges. Discretization effects, sampling rate selection, and anti-windup mechanisms must be carefully considered. Many legacy systems utilize simplified PID algorithms that lack advanced features like derivative filtering or setpoint weighting, limiting their effectiveness in demanding applications.

Adaptation to changing process conditions represents a persistent challenge. Traditional fixed-parameter PID controllers often struggle when process dynamics change due to equipment aging, fouling, catalyst deactivation, or intentional operating point shifts. Without adaptive mechanisms, controllers require frequent retuning, increasing maintenance costs and operational disruptions.

Measurement noise and disturbances further complicate PID implementation. Derivative action, while valuable for anticipating process changes, amplifies high-frequency noise in measurement signals. This necessitates careful filtering approaches that balance noise rejection against control responsiveness, a balance many implementations fail to achieve optimally.

Finally, there exists a significant knowledge gap in many industrial settings. As experienced control engineers retire, organizations often lose critical expertise in PID implementation and troubleshooting. Modern automated tuning tools, while helpful, cannot fully replace deep understanding of process dynamics and control theory, leading to suboptimal implementations and missed opportunities for performance improvement.

Process interactions present another substantial hurdle in PID implementation. In complex industrial systems with multiple interacting control loops, adjustments in one loop can significantly impact others, creating cascading effects that are difficult to predict and manage. This interaction often leads to reduced overall system performance and stability issues that conventional single-loop PID controllers cannot adequately address.

Time delays, inherent in many industrial processes, pose particular difficulties for PID control. When process dead time exceeds a certain threshold relative to the process time constant, traditional PID algorithms become increasingly ineffective. Industries dealing with transport delays, thermal processes, or chemical reactions frequently encounter this limitation, forcing compromises between control performance and stability.

The digital implementation of PID controllers introduces its own set of challenges. Discretization effects, sampling rate selection, and anti-windup mechanisms must be carefully considered. Many legacy systems utilize simplified PID algorithms that lack advanced features like derivative filtering or setpoint weighting, limiting their effectiveness in demanding applications.

Adaptation to changing process conditions represents a persistent challenge. Traditional fixed-parameter PID controllers often struggle when process dynamics change due to equipment aging, fouling, catalyst deactivation, or intentional operating point shifts. Without adaptive mechanisms, controllers require frequent retuning, increasing maintenance costs and operational disruptions.

Measurement noise and disturbances further complicate PID implementation. Derivative action, while valuable for anticipating process changes, amplifies high-frequency noise in measurement signals. This necessitates careful filtering approaches that balance noise rejection against control responsiveness, a balance many implementations fail to achieve optimally.

Finally, there exists a significant knowledge gap in many industrial settings. As experienced control engineers retire, organizations often lose critical expertise in PID implementation and troubleshooting. Modern automated tuning tools, while helpful, cannot fully replace deep understanding of process dynamics and control theory, leading to suboptimal implementations and missed opportunities for performance improvement.

Modern PID Control Architectures and Methods

01 PID Controller Design and Tuning Methods

Various methods for designing and tuning PID controllers to achieve optimal performance in control systems. These methods include automatic tuning algorithms, adaptive control techniques, and optimization approaches that adjust the proportional, integral, and derivative parameters based on system response characteristics. Advanced tuning methods help in minimizing overshoot, reducing settling time, and improving overall system stability across different operating conditions.- PID controller design and tuning methods: Various methods for designing and tuning PID controllers to achieve optimal performance in control systems. These methods include automatic tuning algorithms, adaptive control techniques, and optimization approaches that adjust the proportional, integral, and derivative parameters to meet specific performance criteria such as minimizing overshoot, settling time, or steady-state error.

- Applications of PID controllers in industrial processes: Implementation of PID controllers in various industrial applications including manufacturing, chemical processing, and automation systems. These controllers are used to regulate process variables such as temperature, pressure, flow rate, and level in industrial settings, providing stable and reliable control for critical operations.

- Advanced PID control strategies: Enhanced PID control strategies that go beyond traditional implementations, including cascaded PID structures, fuzzy logic integration, neural network-based PID controllers, and model predictive control approaches that incorporate PID elements. These advanced strategies provide improved performance for complex systems with nonlinearities, time delays, or multivariable interactions.

- Digital implementation of PID controllers: Methods and systems for implementing PID controllers in digital environments, including microprocessor-based designs, FPGA implementations, and software-based control systems. These digital implementations offer advantages such as flexibility in parameter adjustment, integration with other digital systems, and advanced features like auto-tuning and adaptive control.

- PID controllers with self-learning capabilities: Self-learning and adaptive PID control systems that can automatically adjust their parameters based on system performance and changing conditions. These controllers incorporate machine learning algorithms, neural networks, or other artificial intelligence techniques to optimize control performance over time without human intervention, making them suitable for complex or time-varying processes.

02 PID Controllers in Industrial Automation

Implementation of PID controllers in industrial automation systems for process control and manufacturing applications. These controllers are used to regulate temperature, pressure, flow, and other process variables in industrial settings. The integration of PID control with industrial automation systems enables precise control of manufacturing processes, improving product quality, consistency, and production efficiency while reducing waste and energy consumption.Expand Specific Solutions03 Advanced PID Control Algorithms

Development of advanced PID control algorithms that extend beyond traditional PID functionality. These include fuzzy logic PID controllers, neural network-based PID systems, and hybrid control strategies that combine PID with other control techniques. Advanced algorithms provide improved performance for complex, nonlinear systems and can adapt to changing process dynamics or disturbances, offering more robust control solutions than conventional PID approaches.Expand Specific Solutions04 Digital Implementation of PID Controllers

Methods and systems for implementing PID controllers in digital platforms, including microcontrollers, programmable logic controllers (PLCs), and embedded systems. Digital implementation enables features such as auto-tuning, gain scheduling, and anti-windup protection. These digital PID controllers offer advantages in terms of flexibility, precision, and integration capabilities with modern industrial communication networks and IoT systems.Expand Specific Solutions05 PID Controllers for Specific Applications

Specialized PID control solutions designed for specific applications such as HVAC systems, motor control, power electronics, and medical devices. These application-specific controllers incorporate features tailored to the unique requirements of each domain, including specialized filtering techniques, disturbance rejection mechanisms, and safety features. The controllers are optimized for the particular dynamics and constraints of their target applications.Expand Specific Solutions

Leading PID Controller Manufacturers and Integrators

PID controllers in process control industries are currently in a mature market phase, with an estimated global market size of $2-3 billion and steady annual growth of 4-5%. The technology has reached high maturity with established implementation standards across various sectors. Leading players include Honeywell International, ABB Group, and Emerson's Fisher-Rosemount Systems, who dominate with comprehensive control solutions. Regional competitors like SUPCON Technology and Nanjing Sciyon are gaining market share through specialized applications. Innovation is now focused on integration with AI and IoT, as demonstrated by emerging players like Luffy AI and Spiro Control, who are developing adaptive PID systems that optimize performance through machine learning algorithms for Industry 4.0 applications.

SUPCON Technology Co., Ltd.

Technical Solution: SUPCON Technology implements PID control through their SUPMAX distributed control system, which features multiple PID algorithm variants optimized for different process characteristics. Their controllers incorporate adaptive tuning mechanisms that automatically adjust PID parameters based on process response patterns, maintaining optimal performance as conditions change. SUPCON has developed specialized PID implementations for challenging applications in petrochemical and power generation industries, including their multi-variable decoupling PID that minimizes interactions between related control loops. Their PID controllers feature advanced anti-windup strategies that maintain control stability during output saturation conditions while preserving responsiveness when constraints are removed. SUPCON's approach includes intelligent gain scheduling that automatically selects appropriate PID parameters based on operating conditions, improving performance across varying process states. Their latest innovations include model-based PID that incorporates simplified process models to improve disturbance rejection while maintaining robustness against model uncertainties.

Strengths: Cost-effective implementation for large-scale systems; strong performance in challenging process environments; excellent localized support in Asian markets. Weaknesses: Less global presence compared to Western competitors; documentation and interfaces primarily optimized for Chinese market; fewer third-party integration options compared to more established platforms.

Fisher-Rosemount Systems, Inc.

Technical Solution: Fisher-Rosemount Systems (part of Emerson) implements PID control through their DeltaV and Ovation distributed control systems, featuring proprietary PID algorithms optimized for process industries. Their PID implementation includes advanced features such as dynamic reset limiting that prevents integral windup while maintaining aggressive tuning. Fisher-Rosemount's controllers incorporate fuzzy logic-based gain scheduling that automatically adjusts controller parameters based on process conditions, improving performance across varying operating points. Their InSight PID tuning software uses pattern recognition to identify process dynamics and recommend optimal PID parameters, reducing commissioning time by up to 60% compared to manual tuning methods. The company has developed specialized PID variants for challenging applications, including their Lambda tuning methodology that balances responsiveness with robustness for processes with significant deadtime. Fisher-Rosemount's controllers also feature unique disturbance rejection algorithms that can identify and compensate for measured disturbances before they significantly impact the controlled variable.

Strengths: Exceptional disturbance rejection capabilities; intuitive operator interfaces that simplify monitoring and intervention; comprehensive diagnostics that identify control issues early. Weaknesses: Proprietary architecture can limit integration with third-party systems; higher licensing costs for advanced features; requires specialized training for configuration optimization.

Key PID Tuning Algorithms and Patents

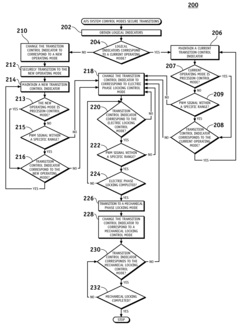

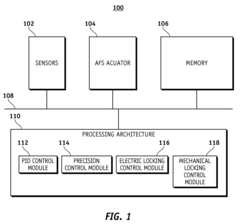

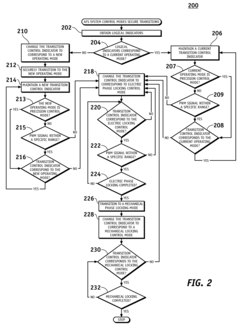

Secure Control Mode Transition Methods for an Active Front Steer System

PatentInactiveUS20080208410A1

Innovation

- A system and method that maintains a transition control indicator value to monitor and secure transitions between control modes, preventing unwanted transitions by using logical indicators and memory fault models to ensure safe mode changes, particularly restricting electric phase locking to mechanical locking and preventing transitions from PID to precision control.

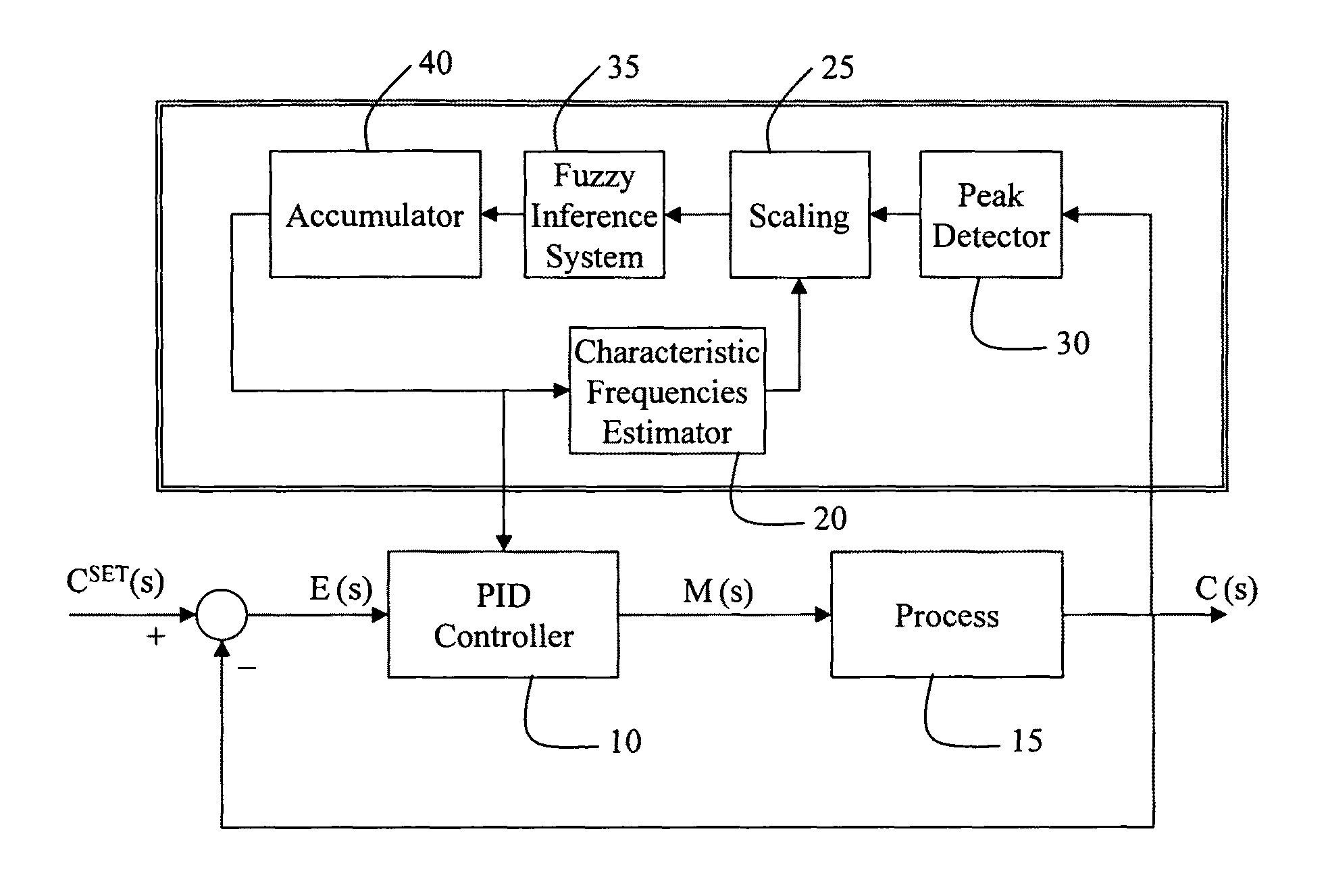

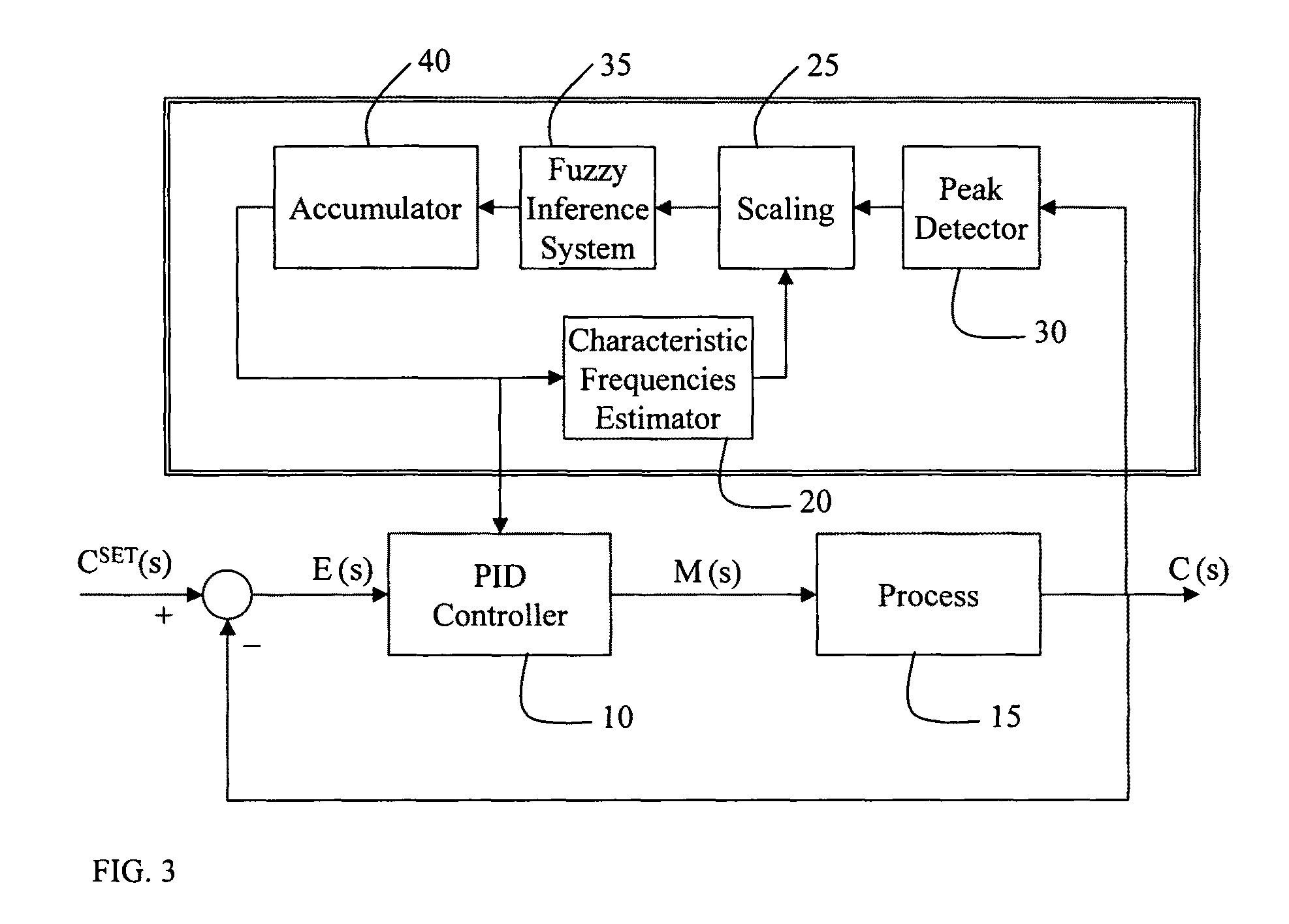

System and method to avoid oscillatory behavior in proportional-integral-derivative (PID) controllers by using fuzzy inference and modified/active damping

PatentInactiveUS7809668B1

Innovation

- A fuzzy-based supervision module that analyzes frequency oscillations and adjusts PID controller tuning parameters using a Fuzzy Inference System to identify and mitigate the leading cause of oscillatory behavior, thereby preventing unstable responses.

Industry-Specific PID Applications

PID controllers have been widely implemented across diverse industrial sectors, each adapting the technology to meet specific operational requirements. In the oil and gas industry, PID controllers regulate critical parameters in refining processes, including temperature control in distillation columns, pressure management in hydrocracking units, and flow control in pipeline transportation systems. These applications ensure product quality while maintaining safe operating conditions in potentially hazardous environments.

The chemical manufacturing sector relies heavily on PID control for precise reaction management. Controllers maintain optimal temperature profiles in batch reactors, regulate pH levels in neutralization processes, and control pressure in polymerization reactions. The ability to maintain tight control over these variables directly impacts product quality, yield, and production efficiency.

Food and beverage processing industries implement PID controllers to ensure product consistency and safety. Temperature control in pasteurization, pressure regulation in fermentation processes, and precise flow control in mixing operations all benefit from PID technology. These applications must meet strict regulatory requirements while maintaining production efficiency.

In pharmaceutical manufacturing, where precision is paramount, PID controllers manage critical parameters in bioreactors, lyophilization processes, and tablet coating operations. The controllers must maintain extremely tight tolerances to ensure product efficacy and compliance with stringent regulatory standards.

Power generation facilities utilize PID control for boiler management, turbine speed regulation, and emissions control systems. These applications must respond to varying load demands while maintaining optimal efficiency and adhering to environmental regulations. The controllers often operate in cascade configurations to handle the complex interdependencies between process variables.

Water and wastewater treatment plants employ PID controllers for chemical dosing, flow regulation, and pressure management throughout treatment processes. These applications must adapt to varying input conditions while consistently meeting output quality standards.

Paper and pulp manufacturing relies on PID control for consistency management, temperature regulation in digesters, and pressure control in bleaching processes. The technology helps balance product quality requirements with energy efficiency goals in these energy-intensive operations.

The chemical manufacturing sector relies heavily on PID control for precise reaction management. Controllers maintain optimal temperature profiles in batch reactors, regulate pH levels in neutralization processes, and control pressure in polymerization reactions. The ability to maintain tight control over these variables directly impacts product quality, yield, and production efficiency.

Food and beverage processing industries implement PID controllers to ensure product consistency and safety. Temperature control in pasteurization, pressure regulation in fermentation processes, and precise flow control in mixing operations all benefit from PID technology. These applications must meet strict regulatory requirements while maintaining production efficiency.

In pharmaceutical manufacturing, where precision is paramount, PID controllers manage critical parameters in bioreactors, lyophilization processes, and tablet coating operations. The controllers must maintain extremely tight tolerances to ensure product efficacy and compliance with stringent regulatory standards.

Power generation facilities utilize PID control for boiler management, turbine speed regulation, and emissions control systems. These applications must respond to varying load demands while maintaining optimal efficiency and adhering to environmental regulations. The controllers often operate in cascade configurations to handle the complex interdependencies between process variables.

Water and wastewater treatment plants employ PID controllers for chemical dosing, flow regulation, and pressure management throughout treatment processes. These applications must adapt to varying input conditions while consistently meeting output quality standards.

Paper and pulp manufacturing relies on PID control for consistency management, temperature regulation in digesters, and pressure control in bleaching processes. The technology helps balance product quality requirements with energy efficiency goals in these energy-intensive operations.

Cybersecurity Considerations in Industrial Control Systems

The integration of PID controllers in industrial control systems has created a complex cybersecurity landscape that demands careful consideration. As these controllers become increasingly networked and connected to enterprise systems, they present expanded attack surfaces for malicious actors. Traditional industrial control systems were designed with operational reliability rather than security as the primary concern, often utilizing legacy protocols lacking encryption or authentication mechanisms.

Security vulnerabilities in PID control systems can manifest through multiple vectors. Unauthorized access to controller parameters could allow attackers to manipulate setpoints, causing process instability or equipment damage. Man-in-the-middle attacks might intercept and alter control signals between sensors, controllers, and actuators, potentially leading to catastrophic failures in critical infrastructure.

Risk assessment frameworks specific to industrial control environments must consider both the likelihood of cyber intrusions and their potential physical consequences. Unlike conventional IT systems, attacks on process control infrastructure can result in tangible, real-world impacts including production losses, equipment damage, environmental incidents, or even human safety risks.

Defense-in-depth strategies have emerged as best practices for securing PID controller implementations. These include network segmentation to isolate control systems from business networks, implementation of demilitarized zones (DMZs), and strict firewall configurations to regulate traffic flows. Regular security audits and vulnerability assessments should be conducted to identify potential weaknesses before they can be exploited.

Secure-by-design principles are increasingly being incorporated into modern PID controller deployments. This includes encrypted communications between system components, robust authentication mechanisms, and comprehensive logging capabilities to detect anomalous behavior. Vendors are developing controllers with enhanced security features, though legacy systems remain problematic.

Incident response planning must account for the unique challenges of industrial environments. Response teams require specialized knowledge of both cybersecurity and process control principles to effectively mitigate attacks without causing further operational disruption. Tabletop exercises and simulations can help organizations prepare for security incidents affecting their control systems.

Regulatory frameworks like IEC 62443, NIST SP 800-82, and industry-specific standards provide guidance for securing industrial control systems. Compliance with these standards is becoming increasingly important as regulatory scrutiny of critical infrastructure security intensifies across global markets.

Security vulnerabilities in PID control systems can manifest through multiple vectors. Unauthorized access to controller parameters could allow attackers to manipulate setpoints, causing process instability or equipment damage. Man-in-the-middle attacks might intercept and alter control signals between sensors, controllers, and actuators, potentially leading to catastrophic failures in critical infrastructure.

Risk assessment frameworks specific to industrial control environments must consider both the likelihood of cyber intrusions and their potential physical consequences. Unlike conventional IT systems, attacks on process control infrastructure can result in tangible, real-world impacts including production losses, equipment damage, environmental incidents, or even human safety risks.

Defense-in-depth strategies have emerged as best practices for securing PID controller implementations. These include network segmentation to isolate control systems from business networks, implementation of demilitarized zones (DMZs), and strict firewall configurations to regulate traffic flows. Regular security audits and vulnerability assessments should be conducted to identify potential weaknesses before they can be exploited.

Secure-by-design principles are increasingly being incorporated into modern PID controller deployments. This includes encrypted communications between system components, robust authentication mechanisms, and comprehensive logging capabilities to detect anomalous behavior. Vendors are developing controllers with enhanced security features, though legacy systems remain problematic.

Incident response planning must account for the unique challenges of industrial environments. Response teams require specialized knowledge of both cybersecurity and process control principles to effectively mitigate attacks without causing further operational disruption. Tabletop exercises and simulations can help organizations prepare for security incidents affecting their control systems.

Regulatory frameworks like IEC 62443, NIST SP 800-82, and industry-specific standards provide guidance for securing industrial control systems. Compliance with these standards is becoming increasingly important as regulatory scrutiny of critical infrastructure security intensifies across global markets.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!