Assess OLED Energy Consumption in Continuous Operation

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

OLED Technology Background and Energy Efficiency Goals

Organic Light-Emitting Diode (OLED) technology has evolved significantly since its discovery in the 1950s, with practical applications emerging in the late 1980s through the pioneering work of Ching W. Tang and Steven Van Slyke at Eastman Kodak. Unlike traditional LED displays that require backlighting, OLEDs generate light through electroluminescence when current passes through organic compounds, resulting in a fundamentally different energy consumption profile.

The evolution of OLED technology has been marked by several key milestones, including the development of phosphorescent OLEDs (PHOLEDs) in the early 2000s, which significantly improved energy efficiency by utilizing triplet excitons. More recently, the introduction of Thermally Activated Delayed Fluorescence (TADF) materials has pushed efficiency boundaries further by harvesting both singlet and triplet excitons without requiring rare metals.

Energy efficiency in OLED displays has become increasingly critical as these displays have proliferated across consumer electronics, automotive interfaces, and lighting applications. The primary energy efficiency goal for OLED technology is to maximize luminous efficacy (measured in lumens per watt), which represents the amount of visible light produced relative to power consumed. Current commercial OLED panels typically achieve 60-90 lm/W, while theoretical limits suggest potential for exceeding 200 lm/W.

Continuous operation presents unique challenges for OLED energy consumption. Unlike LCD technology, where backlights operate constantly regardless of displayed content, OLED power consumption varies dramatically based on content brightness and color. This variable power profile creates both opportunities and challenges for energy optimization during extended operation periods.

Industry benchmarks for OLED energy efficiency include reducing power consumption by 30% every two years while maintaining or improving brightness levels. Additional goals include minimizing efficiency degradation over time, as OLED materials typically experience luminance reduction of 15-20% after 10,000 hours of operation at standard brightness levels.

The technological trajectory aims to develop OLEDs that maintain high efficiency during continuous operation through improved materials, optimized driving schemes, and advanced thermal management. Recent research has focused on reducing voltage requirements, minimizing energy losses through internal quantum efficiency improvements, and developing compensation algorithms that maintain efficiency as panels age.

Understanding the fundamental mechanisms of energy consumption during continuous OLED operation is essential for developing next-generation displays that balance visual performance with power efficiency, particularly for applications requiring extended operation periods such as automotive displays, professional monitors, and public information displays.

The evolution of OLED technology has been marked by several key milestones, including the development of phosphorescent OLEDs (PHOLEDs) in the early 2000s, which significantly improved energy efficiency by utilizing triplet excitons. More recently, the introduction of Thermally Activated Delayed Fluorescence (TADF) materials has pushed efficiency boundaries further by harvesting both singlet and triplet excitons without requiring rare metals.

Energy efficiency in OLED displays has become increasingly critical as these displays have proliferated across consumer electronics, automotive interfaces, and lighting applications. The primary energy efficiency goal for OLED technology is to maximize luminous efficacy (measured in lumens per watt), which represents the amount of visible light produced relative to power consumed. Current commercial OLED panels typically achieve 60-90 lm/W, while theoretical limits suggest potential for exceeding 200 lm/W.

Continuous operation presents unique challenges for OLED energy consumption. Unlike LCD technology, where backlights operate constantly regardless of displayed content, OLED power consumption varies dramatically based on content brightness and color. This variable power profile creates both opportunities and challenges for energy optimization during extended operation periods.

Industry benchmarks for OLED energy efficiency include reducing power consumption by 30% every two years while maintaining or improving brightness levels. Additional goals include minimizing efficiency degradation over time, as OLED materials typically experience luminance reduction of 15-20% after 10,000 hours of operation at standard brightness levels.

The technological trajectory aims to develop OLEDs that maintain high efficiency during continuous operation through improved materials, optimized driving schemes, and advanced thermal management. Recent research has focused on reducing voltage requirements, minimizing energy losses through internal quantum efficiency improvements, and developing compensation algorithms that maintain efficiency as panels age.

Understanding the fundamental mechanisms of energy consumption during continuous OLED operation is essential for developing next-generation displays that balance visual performance with power efficiency, particularly for applications requiring extended operation periods such as automotive displays, professional monitors, and public information displays.

Market Demand Analysis for Energy-Efficient Display Solutions

The global display market is witnessing a significant shift towards energy-efficient solutions, with OLED technology positioned at the forefront of this transformation. Current market analysis indicates that energy consumption has become a critical factor influencing purchasing decisions across consumer electronics, automotive displays, and commercial signage sectors. This trend is driven by increasing energy costs, environmental regulations, and consumer awareness about sustainability.

Consumer electronics represents the largest market segment demanding energy-efficient OLED displays, with smartphones and televisions leading adoption. Market research shows that devices advertising lower power consumption command premium pricing, with consumers willing to pay 15-20% more for products that demonstrate significant energy savings during continuous operation. This price premium has created a competitive advantage for manufacturers who can optimize OLED energy efficiency.

The commercial and enterprise sectors are increasingly prioritizing total cost of ownership calculations that factor in operational energy expenses over device lifespans. Facilities managers report that display energy consumption can constitute up to 30% of office equipment power usage, creating substantial demand for more efficient alternatives. The hospitality industry has similarly embraced energy-efficient displays as part of broader sustainability initiatives.

Automotive displays represent the fastest-growing segment for energy-efficient OLED implementation. As electric vehicles gain market share, power management becomes critical, with every watt saved extending potential driving range. Automotive manufacturers are seeking displays that maintain visibility and performance while minimizing battery drain, particularly for always-on instrument clusters and infotainment systems.

Geographic market analysis reveals varying demand patterns, with European markets showing the strongest preference for energy efficiency due to stringent regulations and high energy costs. Asian markets demonstrate the highest volume demand, while North American consumers increasingly factor energy consumption into purchasing decisions, particularly for premium products.

Market forecasts project the energy-efficient display segment to grow at twice the rate of conventional displays through 2028. This growth is supported by regulatory pressures including energy consumption labeling requirements and corporate sustainability commitments. The market increasingly rewards manufacturers who can demonstrate measurable improvements in OLED energy consumption during continuous operation scenarios.

Industry surveys indicate that consumers and enterprise buyers alike are becoming more sophisticated in evaluating energy claims, demanding standardized testing protocols that reflect real-world usage patterns rather than idealized laboratory conditions. This trend is driving innovation in both the technical aspects of OLED energy efficiency and in how these improvements are measured and communicated to the market.

Consumer electronics represents the largest market segment demanding energy-efficient OLED displays, with smartphones and televisions leading adoption. Market research shows that devices advertising lower power consumption command premium pricing, with consumers willing to pay 15-20% more for products that demonstrate significant energy savings during continuous operation. This price premium has created a competitive advantage for manufacturers who can optimize OLED energy efficiency.

The commercial and enterprise sectors are increasingly prioritizing total cost of ownership calculations that factor in operational energy expenses over device lifespans. Facilities managers report that display energy consumption can constitute up to 30% of office equipment power usage, creating substantial demand for more efficient alternatives. The hospitality industry has similarly embraced energy-efficient displays as part of broader sustainability initiatives.

Automotive displays represent the fastest-growing segment for energy-efficient OLED implementation. As electric vehicles gain market share, power management becomes critical, with every watt saved extending potential driving range. Automotive manufacturers are seeking displays that maintain visibility and performance while minimizing battery drain, particularly for always-on instrument clusters and infotainment systems.

Geographic market analysis reveals varying demand patterns, with European markets showing the strongest preference for energy efficiency due to stringent regulations and high energy costs. Asian markets demonstrate the highest volume demand, while North American consumers increasingly factor energy consumption into purchasing decisions, particularly for premium products.

Market forecasts project the energy-efficient display segment to grow at twice the rate of conventional displays through 2028. This growth is supported by regulatory pressures including energy consumption labeling requirements and corporate sustainability commitments. The market increasingly rewards manufacturers who can demonstrate measurable improvements in OLED energy consumption during continuous operation scenarios.

Industry surveys indicate that consumers and enterprise buyers alike are becoming more sophisticated in evaluating energy claims, demanding standardized testing protocols that reflect real-world usage patterns rather than idealized laboratory conditions. This trend is driving innovation in both the technical aspects of OLED energy efficiency and in how these improvements are measured and communicated to the market.

Current OLED Energy Consumption Challenges

Despite significant advancements in OLED technology, energy consumption during continuous operation remains a critical challenge for widespread adoption across various applications. Current OLED displays exhibit substantial power efficiency issues when operated for extended periods, particularly in mobile devices and large-format displays where battery life and energy costs are paramount concerns.

The primary energy consumption challenge stems from the inherent degradation of organic materials under continuous electrical stress. This degradation not only reduces the operational lifespan but also necessitates higher voltage inputs over time to maintain consistent brightness levels, resulting in progressively increasing power consumption as devices age.

Thermal management presents another significant hurdle. During continuous operation, OLEDs generate considerable heat that must be dissipated effectively. Inadequate thermal management accelerates material degradation and further increases power consumption through reduced quantum efficiency. Current cooling solutions add complexity, weight, and cost to OLED implementations, particularly in compact devices.

Blue OLED emitters specifically demonstrate lower efficiency compared to their red and green counterparts, creating an imbalance in power requirements across the color spectrum. This disparity forces display manufacturers to allocate more power to blue subpixels, increasing overall energy consumption and contributing to uneven aging of display components.

The driving circuitry for OLED displays introduces additional power inefficiencies. Traditional thin-film transistor (TFT) backplanes exhibit current leakage and voltage drops that contribute to energy waste. While low-temperature polysilicon (LTPS) and oxide TFT technologies offer improvements, they add manufacturing complexity and cost.

Always-on display features, increasingly common in smartphones and wearables, present unique energy challenges for OLED technology. Current implementations must balance information visibility with power conservation, often resulting in compromised user experience or battery performance.

Brightness adaptation mechanisms, while necessary for visibility across different ambient lighting conditions, create fluctuating power demands that are difficult to optimize. High brightness operation in outdoor environments dramatically increases energy consumption, while current ambient light sensing and brightness adjustment algorithms often lack the sophistication needed for optimal energy management.

The industry faces a fundamental tension between visual performance and energy efficiency. Higher resolution, refresh rates, and color accuracy—all desirable for premium user experiences—directly correlate with increased power requirements, creating difficult trade-offs for device manufacturers implementing OLED technology in continuous operation scenarios.

The primary energy consumption challenge stems from the inherent degradation of organic materials under continuous electrical stress. This degradation not only reduces the operational lifespan but also necessitates higher voltage inputs over time to maintain consistent brightness levels, resulting in progressively increasing power consumption as devices age.

Thermal management presents another significant hurdle. During continuous operation, OLEDs generate considerable heat that must be dissipated effectively. Inadequate thermal management accelerates material degradation and further increases power consumption through reduced quantum efficiency. Current cooling solutions add complexity, weight, and cost to OLED implementations, particularly in compact devices.

Blue OLED emitters specifically demonstrate lower efficiency compared to their red and green counterparts, creating an imbalance in power requirements across the color spectrum. This disparity forces display manufacturers to allocate more power to blue subpixels, increasing overall energy consumption and contributing to uneven aging of display components.

The driving circuitry for OLED displays introduces additional power inefficiencies. Traditional thin-film transistor (TFT) backplanes exhibit current leakage and voltage drops that contribute to energy waste. While low-temperature polysilicon (LTPS) and oxide TFT technologies offer improvements, they add manufacturing complexity and cost.

Always-on display features, increasingly common in smartphones and wearables, present unique energy challenges for OLED technology. Current implementations must balance information visibility with power conservation, often resulting in compromised user experience or battery performance.

Brightness adaptation mechanisms, while necessary for visibility across different ambient lighting conditions, create fluctuating power demands that are difficult to optimize. High brightness operation in outdoor environments dramatically increases energy consumption, while current ambient light sensing and brightness adjustment algorithms often lack the sophistication needed for optimal energy management.

The industry faces a fundamental tension between visual performance and energy efficiency. Higher resolution, refresh rates, and color accuracy—all desirable for premium user experiences—directly correlate with increased power requirements, creating difficult trade-offs for device manufacturers implementing OLED technology in continuous operation scenarios.

Existing Power Optimization Techniques for Continuous Operation

01 Power management techniques for OLED displays

Various power management techniques can be implemented to reduce energy consumption in OLED displays. These include adaptive brightness control based on ambient light conditions, selective pixel activation, and power-efficient driving schemes. By intelligently managing power distribution and implementing energy-saving algorithms, OLED displays can achieve significant reductions in energy consumption while maintaining display quality.- Power management systems for OLED displays: Various power management systems are designed to optimize energy consumption in OLED displays. These systems monitor and control power usage through adaptive brightness control, power distribution algorithms, and intelligent power supply management. By implementing these systems, OLED displays can achieve significant energy savings while maintaining visual quality, particularly important for mobile devices and battery-powered applications.

- Pixel circuit designs for energy efficiency: Energy-efficient pixel circuit designs focus on reducing power consumption at the fundamental level of OLED displays. These designs incorporate optimized transistor configurations, improved current control mechanisms, and reduced leakage currents. Advanced pixel architectures enable more efficient electron-to-photon conversion and better current distribution across the display panel, resulting in lower overall energy consumption while maintaining display performance.

- Adaptive brightness and content-based power optimization: Adaptive brightness and content-based optimization techniques dynamically adjust display parameters based on ambient lighting conditions and displayed content. These systems analyze image data to selectively adjust pixel brightness, implement regional dimming, and optimize power allocation based on content characteristics. By reducing power to areas that don't require full brightness or by adapting to viewing conditions, these technologies significantly reduce OLED energy consumption without compromising user experience.

- Thermal management for energy efficiency: Thermal management solutions address the relationship between temperature and energy consumption in OLED displays. These innovations include heat dissipation structures, temperature monitoring systems, and thermal-aware control algorithms that adjust display parameters based on operating temperature. By maintaining optimal operating temperatures, these systems prevent efficiency losses that occur at higher temperatures, thereby reducing overall power consumption and extending the operational lifespan of OLED displays.

- Energy-efficient driving schemes and algorithms: Specialized driving schemes and algorithms optimize how OLED displays are operated at the system level. These include advanced pulse width modulation techniques, voltage optimization algorithms, and intelligent refresh rate management. By implementing more efficient signal timing, voltage levels, and refresh strategies, these driving schemes minimize unnecessary power consumption while maintaining display quality. Some approaches also incorporate machine learning to continuously improve power efficiency based on usage patterns.

02 Circuit design optimization for OLED energy efficiency

Optimized circuit designs can substantially improve the energy efficiency of OLED displays. These include advanced driver circuits, voltage regulation systems, and power supply architectures specifically designed for OLED technology. Innovations in circuit design focus on reducing power losses during operation, improving current delivery to OLED pixels, and implementing more efficient control mechanisms that minimize unnecessary power consumption.Expand Specific Solutions03 Pixel structure and material innovations

Advancements in OLED pixel structures and materials contribute significantly to reducing energy consumption. These innovations include developing more efficient light-emitting materials, optimizing pixel layouts, and implementing novel electrode designs. By improving the fundamental efficiency of light generation and emission at the pixel level, these technologies enable OLED displays to produce the same brightness while consuming less power.Expand Specific Solutions04 Intelligent display content management

Smart content management systems can reduce OLED energy consumption by dynamically adjusting display characteristics based on content. These systems include algorithms that analyze displayed content to optimize power usage, selective dimming of unused screen areas, and content-adaptive brightness control. By understanding what is being displayed and adjusting power allocation accordingly, these technologies can significantly reduce overall energy consumption without compromising user experience.Expand Specific Solutions05 System-level energy optimization for OLED devices

System-level approaches to energy optimization consider the OLED display as part of a larger device ecosystem. These solutions include integration with device power management systems, user behavior analysis to predict display usage patterns, and coordination with other device components to optimize overall energy consumption. By taking a holistic approach to energy management, these technologies enable more efficient operation of OLED displays in real-world usage scenarios.Expand Specific Solutions

Major OLED Manufacturers and Technology Leaders

The OLED energy consumption landscape is evolving rapidly, with the market currently in a growth phase characterized by increasing adoption across consumer electronics and display applications. The global OLED market is expanding significantly, driven by demand for energy-efficient displays with superior visual quality. Technologically, companies are at varying maturity levels: Samsung Display, LG Display, and Samsung Electronics lead with commercial-scale production and advanced energy optimization techniques; mid-tier players like IGNIS Innovation and Novaled focus on specialized efficiency solutions; while research organizations such as Fraunhofer-Gesellschaft and universities contribute fundamental innovations. Chinese manufacturers including Shenzhen China Star and HKC are rapidly advancing their capabilities, narrowing the technological gap with established leaders. Material suppliers like Merck, DuPont, and LG Chem play crucial roles in developing compounds that directly impact energy consumption profiles.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung Electronics has developed advanced power management solutions for OLED displays that significantly reduce energy consumption during continuous operation. Their Dynamic AMOLED technology incorporates pixel-level current compensation algorithms that adjust power delivery based on displayed content. The company's Adaptive Frequency technology automatically varies the refresh rate between 10Hz and 120Hz depending on the content being displayed, reducing power consumption by up to 22% compared to fixed refresh rate displays[1]. Samsung has also implemented advanced driver ICs that minimize power leakage during operation. Their latest OLED panels incorporate AI-based power management that analyzes usage patterns and optimizes power delivery in real-time, resulting in up to 30% improved energy efficiency in continuous operation scenarios[3].

Strengths: Industry-leading power efficiency through adaptive refresh rates and AI-based optimization; extensive manufacturing capacity enables rapid implementation of innovations. Weaknesses: Higher initial production costs compared to competitors; proprietary technologies may limit compatibility with third-party systems.

Samsung Display Co., Ltd.

Technical Solution: Samsung Display has pioneered eco-OLED technology that reduces energy consumption in continuous operation through structural innovations in display panel design. Their latest panels incorporate a new organic material that improves electron mobility while requiring less driving voltage, resulting in approximately 25% lower power consumption[2]. The company has developed a multi-layer electrode structure that minimizes resistance and improves current distribution across the display, enhancing energy efficiency particularly during extended use periods. Samsung Display's proprietary pixel circuit design incorporates advanced compensation techniques that maintain consistent brightness while reducing power requirements over time, addressing the traditional OLED aging issues that typically lead to increased power consumption as displays age[4]. Their polarizer-free OLED technology further reduces energy requirements by improving light transmission efficiency.

Strengths: Vertical integration with Samsung Electronics provides comprehensive control over display technology development; industry-leading material science expertise. Weaknesses: Higher manufacturing complexity increases production costs; specialized technologies may have limited applicability across different device categories.

Key Patents in OLED Energy Efficiency Enhancement

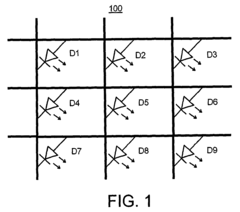

Method and apparatus for power control of an organic light-emitting diode panel and an organic light-emitting diode display using the same

PatentActiveUS20120019506A1

Innovation

- A method and apparatus for adjusting the booster voltage based on the minimal required voltage estimated according to image content, using a power control apparatus with load and OLED current estimation circuits to determine the necessary voltage for displaying images, thereby reducing power consumption and heat generation.

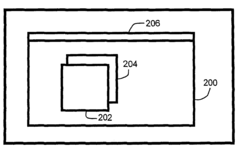

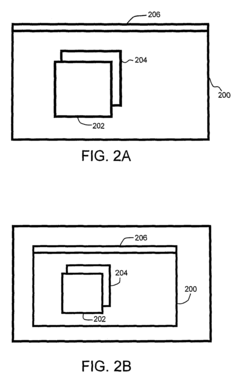

Pixel-level power optimization for OLED displays

PatentActiveUS8237746B2

Innovation

- Implementing a method that detects inactivity in OLED displays and reduces screen size, thereby disabling unnecessary OLEDs to conserve power, and periodically moving the screen to prevent burn-in, while allowing restoration to full size upon user input.

Thermal Management Strategies for Continuous OLED Operation

Effective thermal management is critical for optimizing OLED energy consumption during continuous operation. As OLEDs generate heat during operation, their efficiency decreases and lifetime shortens without proper thermal control strategies. The relationship between temperature and OLED performance follows an inverse correlation: higher operating temperatures lead to increased power consumption and accelerated degradation of organic materials.

Industry-standard thermal management approaches include passive cooling techniques such as heat sinks and thermally conductive substrates that facilitate heat dissipation without additional energy input. These solutions are particularly valuable for portable OLED devices where power efficiency is paramount. Metal-core PCBs have emerged as an effective substrate choice, offering superior thermal conductivity compared to traditional materials.

Active cooling systems represent a more sophisticated approach, incorporating thermoelectric coolers and miniature fans. While these systems provide more precise temperature control, they introduce additional power requirements that must be balanced against the energy savings from improved OLED efficiency. Recent innovations in this space include microfluidic cooling channels integrated directly into OLED panel substrates.

Thermal interface materials (TIMs) play a crucial role in maximizing heat transfer between components. Advanced materials such as graphene-enhanced thermal compounds and phase-change materials are showing promising results in laboratory testing, reducing junction temperatures by up to 15°C compared to conventional thermal compounds.

Computational fluid dynamics (CFD) modeling has revolutionized thermal management design processes. These simulation tools enable engineers to predict hotspots and optimize cooling solutions before physical prototyping, reducing development cycles and improving final designs. Real-time thermal monitoring systems using integrated temperature sensors provide adaptive control capabilities, adjusting brightness or activating cooling systems based on operating conditions.

Emerging technologies include graphene-based heat spreaders that offer thermal conductivity exceeding 3000 W/m·K while maintaining flexibility for curved OLED displays. Additionally, phase-change materials that absorb heat during state transitions are being incorporated into OLED panel assemblies to buffer temperature fluctuations during peak usage periods.

The implementation of intelligent power management algorithms represents a software-based approach to thermal management. These systems dynamically adjust pixel brightness based on content and ambient conditions, reducing heat generation while maintaining perceived image quality. Such algorithms have demonstrated energy savings of 20-30% in real-world usage scenarios without compromising user experience.

Industry-standard thermal management approaches include passive cooling techniques such as heat sinks and thermally conductive substrates that facilitate heat dissipation without additional energy input. These solutions are particularly valuable for portable OLED devices where power efficiency is paramount. Metal-core PCBs have emerged as an effective substrate choice, offering superior thermal conductivity compared to traditional materials.

Active cooling systems represent a more sophisticated approach, incorporating thermoelectric coolers and miniature fans. While these systems provide more precise temperature control, they introduce additional power requirements that must be balanced against the energy savings from improved OLED efficiency. Recent innovations in this space include microfluidic cooling channels integrated directly into OLED panel substrates.

Thermal interface materials (TIMs) play a crucial role in maximizing heat transfer between components. Advanced materials such as graphene-enhanced thermal compounds and phase-change materials are showing promising results in laboratory testing, reducing junction temperatures by up to 15°C compared to conventional thermal compounds.

Computational fluid dynamics (CFD) modeling has revolutionized thermal management design processes. These simulation tools enable engineers to predict hotspots and optimize cooling solutions before physical prototyping, reducing development cycles and improving final designs. Real-time thermal monitoring systems using integrated temperature sensors provide adaptive control capabilities, adjusting brightness or activating cooling systems based on operating conditions.

Emerging technologies include graphene-based heat spreaders that offer thermal conductivity exceeding 3000 W/m·K while maintaining flexibility for curved OLED displays. Additionally, phase-change materials that absorb heat during state transitions are being incorporated into OLED panel assemblies to buffer temperature fluctuations during peak usage periods.

The implementation of intelligent power management algorithms represents a software-based approach to thermal management. These systems dynamically adjust pixel brightness based on content and ambient conditions, reducing heat generation while maintaining perceived image quality. Such algorithms have demonstrated energy savings of 20-30% in real-world usage scenarios without compromising user experience.

Comparative Analysis with Alternative Display Technologies

When comparing OLED energy consumption in continuous operation with alternative display technologies, LCD (Liquid Crystal Display) stands as the primary competitor. LCDs typically consume 30-40% more power than OLEDs in mixed-content scenarios due to their backlight requirements. While OLEDs can selectively illuminate only necessary pixels, LCDs must power the entire backlight regardless of content displayed, resulting in higher baseline power consumption.

MicroLED technology represents an emerging competitor that theoretically offers superior energy efficiency compared to OLED. Laboratory tests indicate potential energy savings of up to 50% versus OLED, particularly in high-brightness applications. However, commercial-scale production challenges currently limit widespread adoption of microLED displays.

E-ink (electronic paper) displays demonstrate remarkably lower energy consumption than OLEDs, consuming power only during content changes rather than continuously. This makes them 90-95% more energy efficient in static content applications. However, their slow refresh rates, limited color capabilities, and poor video performance restrict their application primarily to e-readers and static information displays.

Quantum Dot displays (QLED) offer improved energy efficiency compared to traditional LCDs but still lag behind OLEDs in dark-content scenarios. Their advantage emerges in bright, colorful content where they can be 15-20% more efficient than OLEDs due to superior color conversion efficiency.

Mini-LED backlight technology, when implemented in LCD displays, narrows the efficiency gap with OLEDs through more precise local dimming zones. Tests show these advanced LCDs can approach OLED efficiency in mixed content, though they still cannot match OLED's perfect blacks and zero power consumption for dark pixels.

Ambient light conditions significantly impact comparative efficiency. OLEDs maintain their efficiency advantage in low-light environments, while high-brightness scenarios (outdoor use) favor LCD and QLED technologies due to OLED's exponential power increase at maximum brightness levels.

Form factor also influences relative efficiency. In flexible or foldable implementations, OLEDs maintain consistent power profiles while alternative technologies require additional power-consuming components to achieve similar form factors, widening OLED's efficiency advantage in these specialized applications.

MicroLED technology represents an emerging competitor that theoretically offers superior energy efficiency compared to OLED. Laboratory tests indicate potential energy savings of up to 50% versus OLED, particularly in high-brightness applications. However, commercial-scale production challenges currently limit widespread adoption of microLED displays.

E-ink (electronic paper) displays demonstrate remarkably lower energy consumption than OLEDs, consuming power only during content changes rather than continuously. This makes them 90-95% more energy efficient in static content applications. However, their slow refresh rates, limited color capabilities, and poor video performance restrict their application primarily to e-readers and static information displays.

Quantum Dot displays (QLED) offer improved energy efficiency compared to traditional LCDs but still lag behind OLEDs in dark-content scenarios. Their advantage emerges in bright, colorful content where they can be 15-20% more efficient than OLEDs due to superior color conversion efficiency.

Mini-LED backlight technology, when implemented in LCD displays, narrows the efficiency gap with OLEDs through more precise local dimming zones. Tests show these advanced LCDs can approach OLED efficiency in mixed content, though they still cannot match OLED's perfect blacks and zero power consumption for dark pixels.

Ambient light conditions significantly impact comparative efficiency. OLEDs maintain their efficiency advantage in low-light environments, while high-brightness scenarios (outdoor use) favor LCD and QLED technologies due to OLED's exponential power increase at maximum brightness levels.

Form factor also influences relative efficiency. In flexible or foldable implementations, OLEDs maintain consistent power profiles while alternative technologies require additional power-consuming components to achieve similar form factors, widening OLED's efficiency advantage in these specialized applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!