Assessing Mini LED Performance in Dynamic Environments

SEP 12, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Mini LED Technology Background and Objectives

Mini LED technology represents a significant advancement in display technology, bridging the gap between traditional LED backlighting and the more advanced Micro LED displays. Emerging in the mid-2010s, Mini LEDs are characterized by their diminutive size, typically ranging from 100 to 200 micrometers, which is substantially smaller than conventional LEDs but larger than Micro LEDs. This technology has evolved from the continuous pursuit of enhanced display performance, particularly in terms of contrast ratio, brightness, and energy efficiency.

The evolution of Mini LED technology has been driven by the increasing demands for superior visual experiences across various applications, from consumer electronics to automotive displays and professional monitors. The trajectory of development has been marked by progressive miniaturization of LED chips, improvements in manufacturing processes, and advancements in control algorithms to manage the increased number of dimming zones.

In dynamic environments, which encompass varying ambient lighting conditions, temperature fluctuations, and diverse usage scenarios, the performance of Mini LED displays faces unique challenges and opportunities. Understanding how Mini LED technology performs under these variable conditions is crucial for optimizing display quality and user experience across different applications.

The primary technical objectives for Mini LED technology in dynamic environments include achieving consistent brightness and color accuracy regardless of ambient conditions, minimizing power consumption while maintaining optimal visual performance, and ensuring reliability and longevity of the display under varying operational stresses. Additionally, there is a focus on reducing the occurrence of blooming effects and enhancing local dimming capabilities to improve contrast in challenging viewing conditions.

Recent advancements in Mini LED technology have focused on increasing the number of dimming zones, improving the uniformity of backlighting, and developing more sophisticated algorithms for local dimming control. These improvements aim to address the specific challenges posed by dynamic environments, such as rapid changes in ambient light or viewing angles.

Looking forward, the technical trajectory for Mini LED displays is oriented towards further miniaturization, increased energy efficiency, and enhanced integration with other display technologies. The goal is to create displays that can automatically adapt to changing environmental conditions while maintaining optimal visual performance and energy efficiency.

As we assess Mini LED performance in dynamic environments, it is essential to consider not only the current capabilities but also the potential for future innovations that could further enhance the adaptability and performance of this technology in diverse and challenging usage scenarios.

The evolution of Mini LED technology has been driven by the increasing demands for superior visual experiences across various applications, from consumer electronics to automotive displays and professional monitors. The trajectory of development has been marked by progressive miniaturization of LED chips, improvements in manufacturing processes, and advancements in control algorithms to manage the increased number of dimming zones.

In dynamic environments, which encompass varying ambient lighting conditions, temperature fluctuations, and diverse usage scenarios, the performance of Mini LED displays faces unique challenges and opportunities. Understanding how Mini LED technology performs under these variable conditions is crucial for optimizing display quality and user experience across different applications.

The primary technical objectives for Mini LED technology in dynamic environments include achieving consistent brightness and color accuracy regardless of ambient conditions, minimizing power consumption while maintaining optimal visual performance, and ensuring reliability and longevity of the display under varying operational stresses. Additionally, there is a focus on reducing the occurrence of blooming effects and enhancing local dimming capabilities to improve contrast in challenging viewing conditions.

Recent advancements in Mini LED technology have focused on increasing the number of dimming zones, improving the uniformity of backlighting, and developing more sophisticated algorithms for local dimming control. These improvements aim to address the specific challenges posed by dynamic environments, such as rapid changes in ambient light or viewing angles.

Looking forward, the technical trajectory for Mini LED displays is oriented towards further miniaturization, increased energy efficiency, and enhanced integration with other display technologies. The goal is to create displays that can automatically adapt to changing environmental conditions while maintaining optimal visual performance and energy efficiency.

As we assess Mini LED performance in dynamic environments, it is essential to consider not only the current capabilities but also the potential for future innovations that could further enhance the adaptability and performance of this technology in diverse and challenging usage scenarios.

Market Demand Analysis for Mini LED Displays

The Mini LED display market is experiencing robust growth driven by increasing demand for high-quality visual experiences across multiple sectors. Current market analysis indicates that the global Mini LED display market is projected to reach approximately 5.3 billion USD by 2025, with a compound annual growth rate of 86.6% from 2020. This exceptional growth trajectory is primarily fueled by the superior performance characteristics of Mini LED technology, particularly in dynamic environments where lighting conditions frequently change.

Consumer electronics represents the largest market segment for Mini LED displays, with premium televisions and high-end monitors leading adoption. Major manufacturers including Samsung, LG, and TCL have launched flagship Mini LED TV models, responding to consumer demand for enhanced contrast ratios and brightness levels that maintain performance integrity across varying ambient light conditions. The automotive sector has emerged as another significant growth area, with luxury vehicle manufacturers incorporating Mini LED displays in dashboard systems and entertainment consoles that must perform optimally under rapidly changing lighting conditions from day to night driving scenarios.

Professional markets show substantial demand growth, particularly in creative industries where color accuracy under different environmental conditions is critical. Content creation professionals, including video editors, photographers, and graphic designers, require displays that maintain consistent performance regardless of studio lighting variations. This segment values Mini LED's ability to deliver precise color reproduction and minimize the impact of ambient light changes on perceived image quality.

The commercial display sector, encompassing digital signage and large-format displays, represents another expanding market for Mini LED technology. These applications often operate in challenging dynamic environments with fluctuating lighting conditions, from bright outdoor settings to dimly lit indoor spaces. Mini LED's superior brightness capability, reaching up to 1,500 nits in commercial implementations, enables content visibility across these diverse scenarios.

Regional analysis reveals Asia Pacific as the dominant market for Mini LED displays, accounting for approximately 45% of global demand. This regional leadership stems from the concentration of display manufacturing infrastructure and early technology adoption in countries like China, Taiwan, and South Korea. North America follows as the second-largest market, driven by premium consumer electronics demand and professional applications.

Market research indicates that consumers and professional users increasingly prioritize display performance in dynamic environments when making purchasing decisions. A recent industry survey found that 78% of premium display buyers consider consistent performance across different lighting conditions as "very important" or "extremely important" in their decision-making process. This consumer preference aligns perfectly with Mini LED's core performance advantages in variable lighting scenarios.

Consumer electronics represents the largest market segment for Mini LED displays, with premium televisions and high-end monitors leading adoption. Major manufacturers including Samsung, LG, and TCL have launched flagship Mini LED TV models, responding to consumer demand for enhanced contrast ratios and brightness levels that maintain performance integrity across varying ambient light conditions. The automotive sector has emerged as another significant growth area, with luxury vehicle manufacturers incorporating Mini LED displays in dashboard systems and entertainment consoles that must perform optimally under rapidly changing lighting conditions from day to night driving scenarios.

Professional markets show substantial demand growth, particularly in creative industries where color accuracy under different environmental conditions is critical. Content creation professionals, including video editors, photographers, and graphic designers, require displays that maintain consistent performance regardless of studio lighting variations. This segment values Mini LED's ability to deliver precise color reproduction and minimize the impact of ambient light changes on perceived image quality.

The commercial display sector, encompassing digital signage and large-format displays, represents another expanding market for Mini LED technology. These applications often operate in challenging dynamic environments with fluctuating lighting conditions, from bright outdoor settings to dimly lit indoor spaces. Mini LED's superior brightness capability, reaching up to 1,500 nits in commercial implementations, enables content visibility across these diverse scenarios.

Regional analysis reveals Asia Pacific as the dominant market for Mini LED displays, accounting for approximately 45% of global demand. This regional leadership stems from the concentration of display manufacturing infrastructure and early technology adoption in countries like China, Taiwan, and South Korea. North America follows as the second-largest market, driven by premium consumer electronics demand and professional applications.

Market research indicates that consumers and professional users increasingly prioritize display performance in dynamic environments when making purchasing decisions. A recent industry survey found that 78% of premium display buyers consider consistent performance across different lighting conditions as "very important" or "extremely important" in their decision-making process. This consumer preference aligns perfectly with Mini LED's core performance advantages in variable lighting scenarios.

Technical Challenges in Dynamic Environments

Mini LED technology faces significant challenges when operating in dynamic environments, where lighting conditions, temperature, and usage scenarios constantly change. One of the primary technical hurdles is maintaining consistent brightness and color accuracy across varying ambient light conditions. When transitioning between indoor and outdoor environments, Mini LED displays often struggle to adjust their brightness and contrast ratios quickly enough to maintain optimal visibility and color reproduction.

Temperature fluctuations present another substantial challenge for Mini LED performance. The semiconductor materials in Mini LEDs exhibit temperature-dependent behavior, affecting both efficiency and color stability. In cold environments, Mini LEDs may require higher driving voltages, while in hot conditions, they can experience thermal runaway effects that reduce lifespan and reliability. Current thermal management solutions are often inadequate for rapidly changing temperature environments.

Power management becomes increasingly complex in dynamic settings. Mini LED displays must balance power consumption with performance requirements that shift based on environmental conditions. The need for adaptive brightness control systems that can respond intelligently to changing environments without compromising visual quality or battery life remains a significant technical obstacle.

Motion-related challenges also impact Mini LED performance in dynamic environments. When used in moving vehicles or handheld devices, Mini LEDs must maintain image stability despite vibration and movement. The response time of Mini LED backlighting systems needs further improvement to eliminate motion blur and artifacts in high-motion scenarios.

Durability concerns emerge when Mini LED displays are subjected to varying environmental stressors. Humidity, dust, and physical impacts can compromise the integrity of Mini LED arrays and their control circuitry. Current encapsulation and protection technologies have not fully addressed these vulnerabilities, particularly in outdoor or industrial applications.

Integration challenges with sensing and adaptive control systems represent another technical barrier. Creating seamless feedback loops between environmental sensors and Mini LED control systems requires sophisticated algorithms and hardware integration that many manufacturers have yet to perfect. The latency between environmental change detection and display adjustment remains too high for truly responsive performance.

Uniformity issues become more pronounced in dynamic environments. As Mini LEDs age at different rates depending on usage patterns and environmental exposure, maintaining consistent performance across the entire display becomes increasingly difficult. Current compensation algorithms struggle to account for all variables in dynamic usage scenarios, resulting in visible non-uniformities over time.

AI-driven adaptive control systems show promise but remain computationally intensive and power-hungry, limiting their practical implementation in many portable Mini LED applications where dynamic environmental adaptation is most needed.

Temperature fluctuations present another substantial challenge for Mini LED performance. The semiconductor materials in Mini LEDs exhibit temperature-dependent behavior, affecting both efficiency and color stability. In cold environments, Mini LEDs may require higher driving voltages, while in hot conditions, they can experience thermal runaway effects that reduce lifespan and reliability. Current thermal management solutions are often inadequate for rapidly changing temperature environments.

Power management becomes increasingly complex in dynamic settings. Mini LED displays must balance power consumption with performance requirements that shift based on environmental conditions. The need for adaptive brightness control systems that can respond intelligently to changing environments without compromising visual quality or battery life remains a significant technical obstacle.

Motion-related challenges also impact Mini LED performance in dynamic environments. When used in moving vehicles or handheld devices, Mini LEDs must maintain image stability despite vibration and movement. The response time of Mini LED backlighting systems needs further improvement to eliminate motion blur and artifacts in high-motion scenarios.

Durability concerns emerge when Mini LED displays are subjected to varying environmental stressors. Humidity, dust, and physical impacts can compromise the integrity of Mini LED arrays and their control circuitry. Current encapsulation and protection technologies have not fully addressed these vulnerabilities, particularly in outdoor or industrial applications.

Integration challenges with sensing and adaptive control systems represent another technical barrier. Creating seamless feedback loops between environmental sensors and Mini LED control systems requires sophisticated algorithms and hardware integration that many manufacturers have yet to perfect. The latency between environmental change detection and display adjustment remains too high for truly responsive performance.

Uniformity issues become more pronounced in dynamic environments. As Mini LEDs age at different rates depending on usage patterns and environmental exposure, maintaining consistent performance across the entire display becomes increasingly difficult. Current compensation algorithms struggle to account for all variables in dynamic usage scenarios, resulting in visible non-uniformities over time.

AI-driven adaptive control systems show promise but remain computationally intensive and power-hungry, limiting their practical implementation in many portable Mini LED applications where dynamic environmental adaptation is most needed.

Current Performance Assessment Methodologies

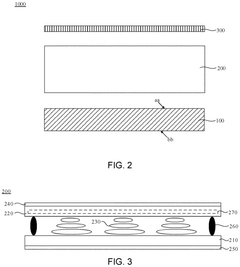

01 Mini LED Backlight Technology

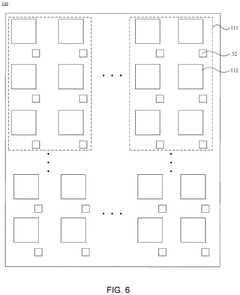

Mini LED backlight technology involves using thousands of tiny LEDs as the backlight source for displays, offering improved contrast ratios, brightness, and energy efficiency compared to traditional LED backlighting. This technology allows for more precise local dimming zones, resulting in deeper blacks and better HDR performance in display applications such as TVs, monitors, and automotive displays.- Mini LED display technology and structure: Mini LED technology involves the use of miniaturized LED chips in display panels, offering improved brightness, contrast ratio, and color accuracy compared to traditional LED displays. The structure typically includes arrays of small LED chips, usually less than 200 micrometers in size, arranged in a matrix formation. These displays utilize local dimming zones to enhance contrast and provide better black levels, making them suitable for high-end televisions, monitors, and other display applications.

- Thermal management in Mini LED displays: Effective thermal management is crucial for Mini LED performance as heat generation can impact both efficiency and lifespan. Various thermal dissipation techniques are employed, including specialized heat sinks, thermal interface materials, and optimized circuit designs. Advanced cooling systems help maintain optimal operating temperatures, preventing thermal degradation of the LEDs and ensuring consistent brightness and color output over time.

- Backlight control and local dimming technology: Mini LED backlighting systems employ sophisticated control mechanisms to manage thousands of individual LEDs. Local dimming technology allows for precise control of different zones in the display, enabling high dynamic range (HDR) content with deeper blacks and brighter highlights. Advanced algorithms optimize the dimming patterns to reduce blooming effects and improve overall contrast ratio, resulting in more vivid and realistic image quality.

- Manufacturing processes and yield improvement: Manufacturing Mini LEDs presents unique challenges due to their small size and high density. Advanced production techniques include precision transfer methods, automated assembly processes, and specialized testing procedures to ensure quality and consistency. Yield improvement strategies focus on reducing defects during chip production, enhancing placement accuracy, and implementing effective quality control measures to lower production costs while maintaining performance standards.

- Power efficiency and driving circuits: Mini LED displays require sophisticated driving circuits to efficiently power thousands of individual LEDs while maintaining uniform brightness. Power management systems optimize energy consumption through pulse-width modulation techniques and intelligent brightness control algorithms. Advanced driver ICs enable precise current control to each Mini LED, ensuring consistent performance across the display while minimizing power consumption, making them more energy-efficient than traditional display technologies.

02 Mini LED Display Manufacturing Processes

Advanced manufacturing processes for Mini LED displays include innovative assembly methods, substrate technologies, and bonding techniques that improve production efficiency and yield rates. These processes address challenges such as precise placement of thousands of tiny LED chips, thermal management, and uniform light distribution, enabling mass production of high-quality Mini LED displays at competitive costs.Expand Specific Solutions03 Mini LED Driving Circuits and Control Systems

Specialized driving circuits and control systems for Mini LED displays manage the power delivery and precise control of thousands of individual LED zones. These systems include advanced pulse width modulation techniques, current regulation methods, and intelligent dimming algorithms that optimize power consumption while maintaining display quality and preventing issues such as flickering or uneven brightness.Expand Specific Solutions04 Mini LED Optical Enhancement Technologies

Optical enhancement technologies for Mini LED displays include specialized diffusers, reflectors, and light guide plates that improve light uniformity and efficiency. These components help minimize optical crosstalk between adjacent Mini LEDs, enhance viewing angles, and optimize the overall light output, resulting in displays with better brightness, color accuracy, and reduced power consumption.Expand Specific Solutions05 Mini LED Applications in Various Devices

Mini LED technology is being implemented across various devices including high-end televisions, gaming monitors, laptops, tablets, automotive displays, and professional monitors. Each application leverages Mini LED's advantages such as high brightness, improved contrast ratios, and energy efficiency while addressing specific requirements for form factor, power consumption, and display performance characteristics suited to different use cases.Expand Specific Solutions

Key Industry Players and Competitive Landscape

The Mini LED market is currently in a growth phase, with increasing adoption in dynamic environments due to superior performance characteristics. The global market size is projected to expand significantly, driven by applications in high-end displays and automotive sectors. Technologically, companies are at varying maturity levels: BOE Technology, TCL's China Star, and LG Display lead with advanced production capabilities, while Jade Bird Display and Wolfspeed focus on specialized innovations. Hisense, Skyworth, and Changhong are rapidly advancing their Mini LED implementations for consumer electronics. Research institutions like Southeast University and KAIST are contributing breakthrough technologies, pushing performance boundaries in challenging environments. The competitive landscape shows Asian manufacturers dominating production scale while Western companies excel in specialized applications.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has developed an advanced Mini LED backlight technology specifically designed for dynamic environments, featuring their Active Matrix Mini LED (AM Mini LED) solution. This technology incorporates thousands of individually controlled mini LED zones with sizes below 200 micrometers, enabling precise local dimming capabilities. BOE's solution includes proprietary algorithms that dynamically adjust brightness and contrast based on ambient light conditions, ensuring optimal visibility across varying environments from bright outdoor settings to dark rooms. Their Dynamic Environment Compensation System (DECS) uses integrated light sensors to detect environmental changes and automatically calibrate display parameters in real-time. BOE has also implemented thermal management solutions to maintain consistent performance under temperature fluctuations, with specialized heat dissipation materials that prevent brightness degradation during extended operation in challenging environments.

Strengths: Superior local dimming capabilities with thousands of dimming zones providing excellent HDR performance; advanced real-time environmental adaptation algorithms; robust thermal management system for consistent performance. Weaknesses: Higher manufacturing costs compared to traditional LED solutions; increased power consumption requirements; complex control systems requiring sophisticated drivers.

Sichuan Changhong Electric Co., Ltd.

Technical Solution: Changhong has developed an innovative Mini LED solution called "AdaptiveVision" specifically designed for performance stability in dynamic environments. Their technology features a multi-layer mini LED architecture with specialized optical films that reduce glare and maintain contrast regardless of ambient light conditions. Changhong's solution incorporates their "Environmental Response System" (ERS) which utilizes an array of sensors to detect changes in ambient light, temperature, and viewing angle, automatically adjusting backlight parameters to maintain optimal image quality. Their mini LED implementation includes over 20,000 individual LED units organized into approximately 1,500 independently controlled dimming zones, enabling precise local contrast management. Changhong has also developed proprietary driving algorithms that predict and compensate for LED performance variations caused by temperature fluctuations, ensuring consistent brightness and color accuracy across operating conditions ranging from 0°C to 45°C. Their solution includes specialized heat dissipation structures that maintain thermal stability even during extended high-brightness operation in enclosed spaces.

Strengths: Excellent anti-glare performance in variable lighting conditions; sophisticated environmental sensing and adaptation capabilities; good thermal management for consistent long-term performance. Weaknesses: Slightly lower peak brightness compared to premium competitors; more limited dimming zone count than top-tier solutions; higher power consumption in maximum brightness modes.

Core Technical Innovations in Mini LED

Light-emitting substrate, backlight module, and display device

PatentPendingEP4443485A1

Innovation

- The light-emitting substrate design includes a back plate with light-emitting regions and a bonding electrode group, where the impedance between the first bonding electrode and adjacent electrodes is increased by varying the distance and adding empty spaces or redundant electrodes, ensuring that the current flow is reduced to prevent observable luminance, thereby enhancing picture quality.

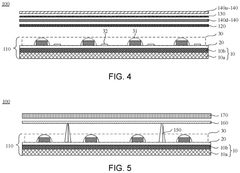

Micron-sized light emitting diode designs

PatentWO2019212576A1

Innovation

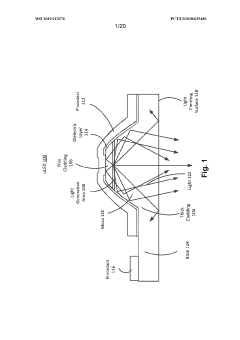

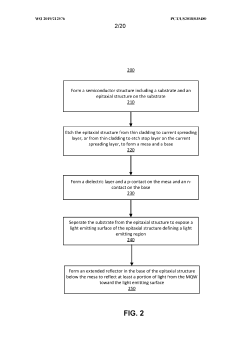

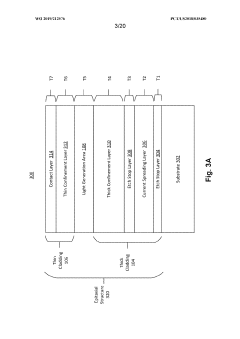

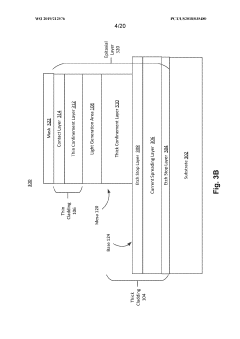

- The design includes an epitaxial structure with a base and mesa, featuring a current spreading layer, thick and thin confinement layers, and a reflective contact to collimate and direct light emitted from a light generation area, such as a multi-quantum well, to enhance light extraction efficiency by reflecting and directing lateral light back to the emitting surface.

Thermal Management Solutions for Mini LED Displays

Thermal management represents a critical challenge in Mini LED display technology, particularly when operating in dynamic environments where temperature fluctuations can significantly impact performance. The thermal characteristics of Mini LED displays stem from their fundamental operating principle, where thousands of miniaturized LED chips generate both light and heat in concentrated areas. Without proper thermal management, these displays face issues including color shift, reduced lifespan, efficiency degradation, and potential physical damage to components.

Current thermal management solutions for Mini LED displays employ multi-layered approaches. Advanced heat sink designs utilizing aluminum, copper, or graphite materials provide primary passive cooling. These are engineered with optimized fin structures and surface treatments to maximize heat dissipation efficiency while maintaining the slim profile demanded by modern display applications.

Active cooling mechanisms supplement passive solutions in high-brightness applications. Micro-fans and specialized thermal electric coolers (TECs) are strategically integrated into display assemblies to create controlled airflow patterns. Some premium implementations incorporate phase-change materials (PCMs) that absorb excess heat during peak operation and release it gradually during lower-intensity usage periods.

Thermal interface materials (TIMs) play a crucial role in the thermal management stack. Advanced silicone-based compounds, graphite sheets, and metal-infused adhesives are precisely applied between Mini LED arrays and heat dissipation components to minimize thermal resistance at junction points. The latest developments include nano-material enhanced TIMs that offer superior thermal conductivity while maintaining electrical isolation properties.

Sophisticated thermal simulation and real-time monitoring systems have become essential components of comprehensive thermal management solutions. Computational fluid dynamics (CFD) modeling allows engineers to predict hotspot formation and optimize cooling system designs before physical prototyping. Meanwhile, embedded temperature sensors and microcontrollers enable dynamic brightness adjustment based on thermal conditions, preventing overheating during extended operation in challenging environments.

Environmental adaptation features represent the cutting edge of Mini LED thermal management. These systems analyze ambient conditions and viewing requirements to automatically adjust power distribution across the display. During high-temperature external conditions, intelligent power management algorithms redistribute electrical load to prevent localized overheating while maintaining visual quality. This adaptive approach extends component lifespan while ensuring consistent performance across varying environmental conditions.

The integration of these thermal management solutions must balance cooling efficiency with constraints including weight, thickness, power consumption, and manufacturing complexity. The most effective implementations combine multiple approaches tailored to specific display applications and expected operating environments.

Current thermal management solutions for Mini LED displays employ multi-layered approaches. Advanced heat sink designs utilizing aluminum, copper, or graphite materials provide primary passive cooling. These are engineered with optimized fin structures and surface treatments to maximize heat dissipation efficiency while maintaining the slim profile demanded by modern display applications.

Active cooling mechanisms supplement passive solutions in high-brightness applications. Micro-fans and specialized thermal electric coolers (TECs) are strategically integrated into display assemblies to create controlled airflow patterns. Some premium implementations incorporate phase-change materials (PCMs) that absorb excess heat during peak operation and release it gradually during lower-intensity usage periods.

Thermal interface materials (TIMs) play a crucial role in the thermal management stack. Advanced silicone-based compounds, graphite sheets, and metal-infused adhesives are precisely applied between Mini LED arrays and heat dissipation components to minimize thermal resistance at junction points. The latest developments include nano-material enhanced TIMs that offer superior thermal conductivity while maintaining electrical isolation properties.

Sophisticated thermal simulation and real-time monitoring systems have become essential components of comprehensive thermal management solutions. Computational fluid dynamics (CFD) modeling allows engineers to predict hotspot formation and optimize cooling system designs before physical prototyping. Meanwhile, embedded temperature sensors and microcontrollers enable dynamic brightness adjustment based on thermal conditions, preventing overheating during extended operation in challenging environments.

Environmental adaptation features represent the cutting edge of Mini LED thermal management. These systems analyze ambient conditions and viewing requirements to automatically adjust power distribution across the display. During high-temperature external conditions, intelligent power management algorithms redistribute electrical load to prevent localized overheating while maintaining visual quality. This adaptive approach extends component lifespan while ensuring consistent performance across varying environmental conditions.

The integration of these thermal management solutions must balance cooling efficiency with constraints including weight, thickness, power consumption, and manufacturing complexity. The most effective implementations combine multiple approaches tailored to specific display applications and expected operating environments.

Power Efficiency Optimization Strategies

Power efficiency remains a critical challenge in Mini LED display technology, particularly when operating in dynamic environments where lighting conditions, content types, and usage patterns constantly change. Optimizing power consumption while maintaining display performance requires a multi-faceted approach that addresses both hardware and software components of the display system.

The fundamental power efficiency strategy for Mini LED displays involves implementing advanced local dimming algorithms. These algorithms dynamically adjust the backlight zones based on content analysis, significantly reducing power consumption in darker scenes while maintaining brightness in highlighted areas. Recent advancements in machine learning-based dimming algorithms have shown up to 30% improvement in power efficiency compared to conventional methods, with minimal impact on perceived image quality.

Adaptive refresh rate technologies represent another crucial optimization pathway. By dynamically adjusting the display's refresh rate according to content requirements—lowering it for static content and increasing it for motion-intensive scenes—power consumption can be reduced by 15-25% in typical usage scenarios. This approach is particularly effective in battery-powered devices operating in variable environmental conditions.

Thermal management innovations play a vital role in maintaining power efficiency across different ambient temperatures. Mini LED displays generate considerable heat during operation, which can increase power consumption and reduce component lifespan. Advanced thermal dissipation materials and intelligent thermal throttling systems help maintain optimal operating temperatures, ensuring consistent power efficiency even in challenging thermal environments.

Driver circuit optimization represents a significant opportunity for power savings. High-efficiency LED drivers with reduced voltage drop and improved current regulation can decrease power losses by up to 20%. Additionally, implementing dynamic voltage scaling that adjusts driver voltage based on brightness requirements further enhances efficiency in variable lighting conditions.

Content-aware brightness adaptation systems analyze both displayed content and ambient lighting conditions to automatically adjust display parameters. These systems leverage ambient light sensors and image processing algorithms to maintain optimal visibility while minimizing power consumption. Studies indicate that such systems can reduce power usage by 25-40% compared to fixed-brightness displays, particularly in environments with fluctuating lighting conditions.

Integration of power management ICs specifically designed for Mini LED applications enables precise control over power distribution across the display. These specialized ICs implement sophisticated power gating techniques that selectively deactivate unused portions of the display driver circuitry, resulting in substantial power savings during partial-screen usage scenarios common in many applications.

The fundamental power efficiency strategy for Mini LED displays involves implementing advanced local dimming algorithms. These algorithms dynamically adjust the backlight zones based on content analysis, significantly reducing power consumption in darker scenes while maintaining brightness in highlighted areas. Recent advancements in machine learning-based dimming algorithms have shown up to 30% improvement in power efficiency compared to conventional methods, with minimal impact on perceived image quality.

Adaptive refresh rate technologies represent another crucial optimization pathway. By dynamically adjusting the display's refresh rate according to content requirements—lowering it for static content and increasing it for motion-intensive scenes—power consumption can be reduced by 15-25% in typical usage scenarios. This approach is particularly effective in battery-powered devices operating in variable environmental conditions.

Thermal management innovations play a vital role in maintaining power efficiency across different ambient temperatures. Mini LED displays generate considerable heat during operation, which can increase power consumption and reduce component lifespan. Advanced thermal dissipation materials and intelligent thermal throttling systems help maintain optimal operating temperatures, ensuring consistent power efficiency even in challenging thermal environments.

Driver circuit optimization represents a significant opportunity for power savings. High-efficiency LED drivers with reduced voltage drop and improved current regulation can decrease power losses by up to 20%. Additionally, implementing dynamic voltage scaling that adjusts driver voltage based on brightness requirements further enhances efficiency in variable lighting conditions.

Content-aware brightness adaptation systems analyze both displayed content and ambient lighting conditions to automatically adjust display parameters. These systems leverage ambient light sensors and image processing algorithms to maintain optimal visibility while minimizing power consumption. Studies indicate that such systems can reduce power usage by 25-40% compared to fixed-brightness displays, particularly in environments with fluctuating lighting conditions.

Integration of power management ICs specifically designed for Mini LED applications enables precise control over power distribution across the display. These specialized ICs implement sophisticated power gating techniques that selectively deactivate unused portions of the display driver circuitry, resulting in substantial power savings during partial-screen usage scenarios common in many applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!