Optimize Mini LED Performance in High-Temperature Zones

SEP 12, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Mini LED Technology Background and Performance Goals

Mini LED technology represents a significant advancement in display technology, bridging the gap between traditional LED backlighting and the more advanced Micro LED displays. Emerging in the mid-2010s, Mini LEDs are semiconductor light sources with dimensions typically ranging from 100 to 200 micrometers, substantially smaller than conventional LEDs but larger than Micro LEDs. This technology has gained substantial traction in premium displays for televisions, monitors, tablets, and automotive applications due to its superior brightness, contrast ratio, and energy efficiency compared to traditional LCD displays.

The evolution of Mini LED technology has been driven by the increasing demand for higher display performance in various applications. Initially developed as an enhancement to conventional LCD backlighting, Mini LEDs have rapidly evolved to address specific market needs for improved local dimming capabilities, higher brightness, and better color accuracy. The technology has seen accelerated adoption since 2019, with major manufacturers incorporating Mini LEDs into their flagship products.

A critical challenge facing Mini LED technology is its performance degradation in high-temperature environments. When operating in elevated temperatures, Mini LEDs experience reduced efficiency, shortened lifespan, color shift, and potential reliability issues. This challenge is particularly pronounced in automotive displays, outdoor signage, and industrial applications where ambient temperatures can fluctuate significantly and reach extreme levels.

The primary technical goals for optimizing Mini LED performance in high-temperature zones include maintaining consistent brightness and color accuracy across varying temperature conditions, extending operational lifespan under thermal stress, and reducing power consumption while managing heat generation. Additionally, there are goals to develop more efficient thermal management solutions specifically designed for the unique characteristics of Mini LED arrays.

Current research aims to achieve thermal stability for Mini LEDs operating in environments up to 85°C without significant performance degradation. This includes maintaining at least 90% of nominal brightness and color accuracy within ±5% of target values across the entire operating temperature range. Another key objective is to extend the useful life of Mini LEDs in high-temperature applications to match or exceed that of conventional displays, targeting at least 50,000 hours of operation without significant degradation.

The technology roadmap for Mini LEDs includes the development of advanced packaging materials with superior thermal conductivity, implementation of intelligent thermal management systems that can dynamically adjust performance parameters based on temperature conditions, and the creation of more temperature-resistant phosphor materials and semiconductor structures to enhance inherent thermal stability at the component level.

The evolution of Mini LED technology has been driven by the increasing demand for higher display performance in various applications. Initially developed as an enhancement to conventional LCD backlighting, Mini LEDs have rapidly evolved to address specific market needs for improved local dimming capabilities, higher brightness, and better color accuracy. The technology has seen accelerated adoption since 2019, with major manufacturers incorporating Mini LEDs into their flagship products.

A critical challenge facing Mini LED technology is its performance degradation in high-temperature environments. When operating in elevated temperatures, Mini LEDs experience reduced efficiency, shortened lifespan, color shift, and potential reliability issues. This challenge is particularly pronounced in automotive displays, outdoor signage, and industrial applications where ambient temperatures can fluctuate significantly and reach extreme levels.

The primary technical goals for optimizing Mini LED performance in high-temperature zones include maintaining consistent brightness and color accuracy across varying temperature conditions, extending operational lifespan under thermal stress, and reducing power consumption while managing heat generation. Additionally, there are goals to develop more efficient thermal management solutions specifically designed for the unique characteristics of Mini LED arrays.

Current research aims to achieve thermal stability for Mini LEDs operating in environments up to 85°C without significant performance degradation. This includes maintaining at least 90% of nominal brightness and color accuracy within ±5% of target values across the entire operating temperature range. Another key objective is to extend the useful life of Mini LEDs in high-temperature applications to match or exceed that of conventional displays, targeting at least 50,000 hours of operation without significant degradation.

The technology roadmap for Mini LEDs includes the development of advanced packaging materials with superior thermal conductivity, implementation of intelligent thermal management systems that can dynamically adjust performance parameters based on temperature conditions, and the creation of more temperature-resistant phosphor materials and semiconductor structures to enhance inherent thermal stability at the component level.

Market Demand Analysis for High-Temperature Mini LED Applications

The global market for high-temperature Mini LED applications is experiencing significant growth, driven by the increasing demand for displays that can operate reliably in extreme environments. Industries such as automotive, aerospace, industrial manufacturing, and outdoor digital signage require display technologies that maintain optimal performance under elevated temperature conditions, often exceeding 85°C. This specialized market segment is projected to grow at a compound annual growth rate of 24.3% through 2028, outpacing the broader Mini LED market.

Automotive applications represent the largest market segment for high-temperature Mini LED solutions, accounting for approximately 38% of the total demand. The push toward more sophisticated digital cockpits, heads-up displays, and infotainment systems in vehicles has created a substantial need for displays that can withstand the harsh conditions of automotive environments. Temperature fluctuations in vehicles, particularly in regions with extreme climates, necessitate display technologies that maintain brightness, color accuracy, and longevity despite thermal stress.

Industrial manufacturing represents another significant market segment, with demand primarily coming from control panels, human-machine interfaces, and monitoring systems deployed in high-temperature production environments. These applications require displays that can operate continuously in temperatures reaching 105°C while maintaining readability and reliability. The industrial segment currently represents 27% of the high-temperature Mini LED market.

Outdoor digital signage applications are growing rapidly, particularly in regions experiencing extreme weather conditions. These installations must withstand not only high ambient temperatures but also the additional heat generated by direct sunlight exposure. The market for outdoor high-temperature Mini LED displays is growing at 29% annually, driven by increasing digitalization of advertising and information systems in urban environments.

Consumer electronics manufacturers are also showing increased interest in high-temperature Mini LED technology, particularly for devices used in challenging environments. This includes ruggedized tablets, specialized smartphones, and portable monitoring equipment used in field operations. While currently representing only 12% of the market, this segment shows promising growth potential.

Regional analysis indicates that the Asia-Pacific region dominates the high-temperature Mini LED market with 43% share, followed by North America (28%) and Europe (21%). This distribution aligns with the concentration of automotive and electronics manufacturing in these regions. The Middle East is emerging as a growth market due to its extreme climate conditions and increasing investment in outdoor digital infrastructure.

Market research indicates that customers in high-temperature application scenarios prioritize reliability and longevity over initial cost, creating opportunities for premium Mini LED solutions that offer superior thermal management capabilities. The willingness to pay a premium for guaranteed performance in extreme conditions has created a specialized market niche with higher profit margins compared to standard Mini LED applications.

Automotive applications represent the largest market segment for high-temperature Mini LED solutions, accounting for approximately 38% of the total demand. The push toward more sophisticated digital cockpits, heads-up displays, and infotainment systems in vehicles has created a substantial need for displays that can withstand the harsh conditions of automotive environments. Temperature fluctuations in vehicles, particularly in regions with extreme climates, necessitate display technologies that maintain brightness, color accuracy, and longevity despite thermal stress.

Industrial manufacturing represents another significant market segment, with demand primarily coming from control panels, human-machine interfaces, and monitoring systems deployed in high-temperature production environments. These applications require displays that can operate continuously in temperatures reaching 105°C while maintaining readability and reliability. The industrial segment currently represents 27% of the high-temperature Mini LED market.

Outdoor digital signage applications are growing rapidly, particularly in regions experiencing extreme weather conditions. These installations must withstand not only high ambient temperatures but also the additional heat generated by direct sunlight exposure. The market for outdoor high-temperature Mini LED displays is growing at 29% annually, driven by increasing digitalization of advertising and information systems in urban environments.

Consumer electronics manufacturers are also showing increased interest in high-temperature Mini LED technology, particularly for devices used in challenging environments. This includes ruggedized tablets, specialized smartphones, and portable monitoring equipment used in field operations. While currently representing only 12% of the market, this segment shows promising growth potential.

Regional analysis indicates that the Asia-Pacific region dominates the high-temperature Mini LED market with 43% share, followed by North America (28%) and Europe (21%). This distribution aligns with the concentration of automotive and electronics manufacturing in these regions. The Middle East is emerging as a growth market due to its extreme climate conditions and increasing investment in outdoor digital infrastructure.

Market research indicates that customers in high-temperature application scenarios prioritize reliability and longevity over initial cost, creating opportunities for premium Mini LED solutions that offer superior thermal management capabilities. The willingness to pay a premium for guaranteed performance in extreme conditions has created a specialized market niche with higher profit margins compared to standard Mini LED applications.

Current Challenges in High-Temperature Mini LED Performance

Mini LED technology faces significant performance challenges when operating in high-temperature environments, which has become a critical bottleneck for its application in automotive displays, outdoor signage, and industrial equipment. The primary issue is thermal degradation, where elevated temperatures (typically above 85°C) cause substantial reduction in luminous efficacy, with efficiency losses of 15-30% observed at 100°C compared to room temperature operation.

Color shift represents another major challenge, as different LED phosphors respond variably to temperature increases. Red phosphors are particularly susceptible, experiencing greater degradation than blue or green counterparts, resulting in noticeable white point drift and color inconsistency across display panels. This phenomenon becomes more pronounced in applications requiring precise color reproduction.

Reliability and lifespan reduction present long-term concerns, with accelerated aging mechanisms activated at high temperatures. Research indicates that operating Mini LEDs at 20°C above their rated temperature can reduce lifespan by 30-50%. The microscopic bond wire connections and phosphor materials undergo thermal stress, leading to premature failure modes including delamination, cracking, and phosphor degradation.

Thermal management complexity increases substantially in high-density Mini LED arrays. The compact nature of these displays, with pixel pitches often below 1mm, creates significant heat concentration zones. Conventional cooling solutions become inadequate as they add bulk and weight, contradicting the thin profile advantage of Mini LED technology. This challenge is particularly acute in automotive applications where space constraints are severe.

Power efficiency degradation compounds these issues, as Mini LEDs require increased driving current at elevated temperatures to maintain brightness levels, creating a negative feedback loop of higher power consumption generating more heat. This phenomenon is especially problematic in battery-powered devices where energy efficiency is paramount.

Manufacturing consistency presents additional challenges, with high-temperature performance varying significantly between production batches. This variability necessitates complex binning processes and compensation algorithms, increasing production costs and complexity. The industry currently lacks standardized testing protocols specifically designed for high-temperature Mini LED performance evaluation.

Addressing these challenges requires interdisciplinary approaches combining materials science, thermal engineering, and electronic design. Current research focuses on developing temperature-resistant phosphors, advanced thermal interface materials, and more efficient driver ICs capable of temperature-adaptive operation. Without significant breakthroughs in these areas, Mini LED technology will continue to face limitations in high-temperature application scenarios.

Color shift represents another major challenge, as different LED phosphors respond variably to temperature increases. Red phosphors are particularly susceptible, experiencing greater degradation than blue or green counterparts, resulting in noticeable white point drift and color inconsistency across display panels. This phenomenon becomes more pronounced in applications requiring precise color reproduction.

Reliability and lifespan reduction present long-term concerns, with accelerated aging mechanisms activated at high temperatures. Research indicates that operating Mini LEDs at 20°C above their rated temperature can reduce lifespan by 30-50%. The microscopic bond wire connections and phosphor materials undergo thermal stress, leading to premature failure modes including delamination, cracking, and phosphor degradation.

Thermal management complexity increases substantially in high-density Mini LED arrays. The compact nature of these displays, with pixel pitches often below 1mm, creates significant heat concentration zones. Conventional cooling solutions become inadequate as they add bulk and weight, contradicting the thin profile advantage of Mini LED technology. This challenge is particularly acute in automotive applications where space constraints are severe.

Power efficiency degradation compounds these issues, as Mini LEDs require increased driving current at elevated temperatures to maintain brightness levels, creating a negative feedback loop of higher power consumption generating more heat. This phenomenon is especially problematic in battery-powered devices where energy efficiency is paramount.

Manufacturing consistency presents additional challenges, with high-temperature performance varying significantly between production batches. This variability necessitates complex binning processes and compensation algorithms, increasing production costs and complexity. The industry currently lacks standardized testing protocols specifically designed for high-temperature Mini LED performance evaluation.

Addressing these challenges requires interdisciplinary approaches combining materials science, thermal engineering, and electronic design. Current research focuses on developing temperature-resistant phosphors, advanced thermal interface materials, and more efficient driver ICs capable of temperature-adaptive operation. Without significant breakthroughs in these areas, Mini LED technology will continue to face limitations in high-temperature application scenarios.

Existing Thermal Management Solutions for Mini LED

01 Mini LED backlight technology advancements

Mini LED backlight technology has evolved to enhance display performance through improved local dimming capabilities. These advancements include optimized LED arrangement patterns, increased number of dimming zones, and refined control algorithms that significantly improve contrast ratio and reduce blooming effects. The technology enables thinner display profiles while delivering higher brightness levels and more uniform illumination across the screen.- Mini LED backlight technology advancements: Mini LED backlight technology has evolved to enhance display performance through improved local dimming capabilities, higher contrast ratios, and better brightness uniformity. These advancements allow for more precise control of light output across the display panel, resulting in deeper blacks and more vibrant colors. The technology typically employs thousands of miniaturized LED chips arranged in multiple dimming zones to achieve superior HDR performance compared to conventional LED backlighting systems.

- Thermal management solutions for Mini LED displays: Effective thermal management is crucial for optimizing Mini LED performance and longevity. Various solutions have been developed to dissipate heat efficiently, including specialized heat sinks, thermal interface materials, and innovative cooling structures. These thermal management systems help maintain consistent brightness levels, prevent color shift, and extend the operational lifespan of Mini LED displays by reducing thermal stress on the LED components and associated circuitry.

- Mini LED driving circuit and power efficiency improvements: Advanced driving circuits for Mini LED displays focus on improving power efficiency while maintaining optimal brightness and color accuracy. These circuits incorporate sophisticated current control mechanisms, voltage regulation systems, and pulse width modulation techniques to precisely manage power delivery to individual LED zones. Innovations in this area have resulted in reduced power consumption, minimized heat generation, and enhanced overall display performance through more precise control of Mini LED arrays.

- Optical enhancement technologies for Mini LED displays: Optical enhancement technologies for Mini LED displays include specialized diffusers, reflectors, and light guide plates that improve light distribution and efficiency. These components help minimize light leakage, enhance brightness uniformity, and optimize viewing angles. Advanced optical films and coatings are also employed to reduce reflections, improve color accuracy, and increase the overall optical efficiency of Mini LED display systems, resulting in superior image quality and reduced power requirements.

- Integration of Mini LED technology in various display applications: Mini LED technology has been successfully integrated into various display applications including televisions, monitors, automotive displays, and portable devices. Each application presents unique challenges and requirements for optimizing Mini LED performance, such as size constraints, power limitations, and environmental considerations. Specialized designs have been developed to address these application-specific needs while maximizing the benefits of Mini LED technology, including enhanced contrast, improved color accuracy, and increased brightness for diverse usage scenarios.

02 Thermal management solutions for Mini LED displays

Effective thermal management is crucial for Mini LED display performance. Various solutions have been developed including specialized heat dissipation structures, thermal interface materials, and cooling systems that prevent performance degradation due to heat accumulation. These thermal solutions help maintain consistent brightness, extend LED lifespan, and ensure stable color performance even during extended operation periods.Expand Specific Solutions03 Mini LED driving circuit and power efficiency improvements

Advanced driving circuits for Mini LED displays focus on power efficiency and precise current control. These circuits incorporate sophisticated pulse width modulation techniques, current compensation algorithms, and voltage regulation systems to deliver consistent brightness while minimizing power consumption. The improved driving architecture enables faster response times and more accurate grayscale rendering while extending battery life in portable applications.Expand Specific Solutions04 Optical enhancement technologies for Mini LED displays

Optical enhancement technologies significantly improve Mini LED display performance through specialized lens designs, reflective structures, and light guide patterns. These optical solutions optimize light extraction efficiency, reduce light leakage, and enhance viewing angles. The integration of quantum dot films and specialized diffusers further improves color gamut coverage and screen uniformity, resulting in more vibrant and accurate color reproduction.Expand Specific Solutions05 Manufacturing processes and yield improvement for Mini LED displays

Advanced manufacturing processes have been developed to improve Mini LED production yield and consistency. These include precision transfer techniques, automated inspection systems, and repair methodologies that address common defects. Innovations in substrate preparation, chip bonding, and encapsulation processes have enabled higher density Mini LED arrays with improved uniformity. These manufacturing advancements have contributed to cost reduction while maintaining high-quality standards.Expand Specific Solutions

Key Industry Players in Mini LED Manufacturing

The Mini LED performance optimization in high-temperature environments represents a growing technological challenge within a rapidly maturing market. Currently, the industry is transitioning from early adoption to mainstream implementation, with the global Mini LED market expected to reach significant growth in the coming years. Leading players like BOE Technology, TCL China Star, and HKC Corp are investing heavily in thermal management solutions for Mini LED displays, while companies such as Lumileds, Advanced Optoelectronic Technology, and Dialight focus on component-level innovations. The competitive landscape is characterized by increasing collaboration between display manufacturers and LED specialists, with Asian companies (particularly Chinese firms like BOE and Tianma Microelectronics) dominating production capacity while Western companies like Gentex and LG Electronics focus on specialized applications requiring high-temperature resilience.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has developed an advanced thermal management system for Mini LED displays that incorporates multiple cooling technologies. Their solution uses a combination of graphene heat dissipation layers and micro-channel liquid cooling systems specifically designed for high-temperature environments. The company's proprietary "CoolSense" technology integrates thermally conductive materials directly into the LED backplane, creating efficient heat pathways away from the light-emitting components. BOE has also implemented adaptive brightness control algorithms that dynamically adjust power consumption based on thermal feedback, preventing performance degradation in elevated temperatures. Their latest Mini LED panels feature redesigned driver ICs with improved thermal efficiency, reducing heat generation at the source while maintaining optimal brightness levels[1][3]. The company has reported a 30% improvement in thermal efficiency compared to conventional Mini LED designs.

Strengths: Industry-leading thermal management integration, comprehensive approach combining hardware and software solutions, and significant market presence in display manufacturing. Weaknesses: Higher production costs compared to traditional LCD technologies, and the cooling systems add complexity to the manufacturing process, potentially affecting yield rates.

TCL China Star Optoelectronics Technology Co., Ltd.

Technical Solution: TCL CSOT has pioneered a high-temperature resistant Mini LED solution called "ThermaLED" specifically engineered for harsh environmental conditions. Their approach focuses on material innovation, utilizing specialized phosphor compositions that maintain color consistency and luminous efficacy even at elevated temperatures up to 85°C. The company has developed a proprietary thermal interface material (TIM) that creates superior thermal conductivity between the LED chips and heat sinks. TCL's solution incorporates a multi-layer PCB design with embedded thermal vias that efficiently channel heat away from critical components[2]. Additionally, they've implemented an intelligent thermal management system that continuously monitors temperature across the display panel and adjusts power delivery to individual zones to prevent hotspots. Their latest generation of Mini LEDs features optimized chip architecture with reduced thermal resistance, allowing for more efficient heat dissipation while maintaining high brightness levels of over 1000 nits even in high-temperature environments.

Strengths: Superior material science approach with specialized phosphors for high-temperature applications, comprehensive thermal management system, and strong integration with their display manufacturing ecosystem. Weaknesses: Higher initial cost compared to conventional LED solutions, and the specialized materials may have limited availability, potentially affecting production scaling.

Core Patents in High-Temperature Mini LED Technology

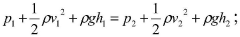

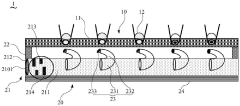

Heat dissipation mechanism, backlight module and display device

PatentPendingCN117028951A

Innovation

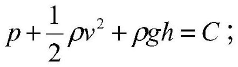

- A heat dissipation mechanism is used, including a ventilation component, a support component and a ventilation duct. A ventilation cavity is formed inside the ventilation component. Ventilation openings and connection holes are provided on the side of the ventilation component. The support component is used to form a gap between the light panel and the ventilation component. , the ventilation duct passes through the connecting hole to form an arc structure to introduce cold air, utilizes air multiplication and Bernoulli fluid mechanics principles to achieve efficient heat dissipation, and controls the opening and closing of the ventilation duct through a solenoid valve to achieve zoned heat dissipation.

Method for controlling backlight unit, display panel and display device

PatentWO2022147951A1

Innovation

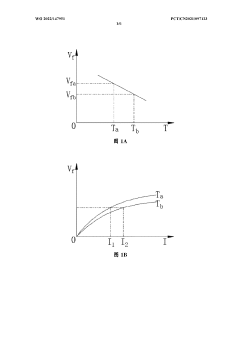

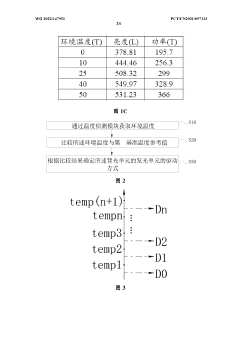

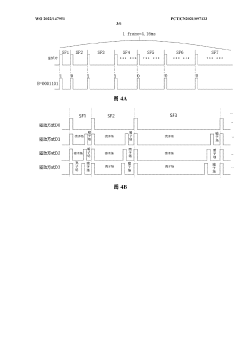

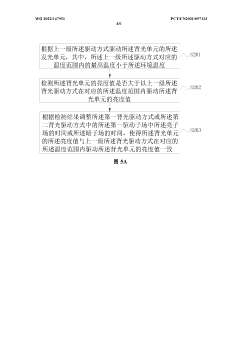

- Obtain the ambient temperature through the temperature detection module, compare it with the benchmark temperature reference value, adjust the driving mode of the backlight unit, including constant voltage driving and non-equimolecular field driving mode, and adjust the time of the bright subfield and dark subfield to maintain consistent brightness.

Material Science Advancements for High-Temperature Applications

Recent advancements in material science have opened new frontiers for Mini LED technology in high-temperature environments. Traditional semiconductor materials used in Mini LEDs, such as gallium nitride (GaN) and indium gallium nitride (InGaN), face significant challenges when operating at elevated temperatures, including reduced luminous efficiency, color shift, and accelerated degradation. These limitations have prompted intensive research into novel materials and composite structures specifically engineered for thermal resilience.

Silicon carbide (SiC) substrates have emerged as a promising alternative to traditional sapphire substrates, offering superior thermal conductivity—approximately three times higher than sapphire—which facilitates more efficient heat dissipation. This property is particularly valuable in automotive displays and outdoor signage applications where ambient temperatures can exceed 85°C.

Aluminum nitride (AlN) represents another breakthrough material, with a thermal conductivity of up to 320 W/m·K compared to GaN's 130 W/m·K. Research published in Advanced Materials (2022) demonstrated that AlN-based buffer layers can reduce thermal boundary resistance by up to 40%, significantly enhancing thermal management in high-power Mini LED arrays.

Quantum dot enhancement films (QDEF) incorporating thermally stable perovskite materials have shown remarkable color stability at temperatures up to 120°C. These advanced materials maintain quantum yield above 80% even after 1000 hours of operation at elevated temperatures, compared to conventional QDs that typically degrade to below 50% efficiency under similar conditions.

Carbon-based materials, particularly graphene and carbon nanotubes, are being integrated into Mini LED packaging to create thermally conductive pathways. A single-layer graphene heat spreader can reduce the junction temperature by up to 15°C under high-power operation, as demonstrated in research from Seoul National University.

Ceramic-polymer composite encapsulants represent another significant advancement, replacing traditional silicone materials that suffer from yellowing and degradation at high temperatures. These composites maintain optical transparency while providing thermal stability up to 200°C, extending the operational lifetime of Mini LEDs in extreme environments.

High-temperature phosphors based on rare-earth doped nitrides and oxynitrides have been developed to maintain consistent color conversion efficiency across wide temperature ranges. These materials exhibit less than 10% reduction in quantum efficiency when operating between -40°C and 150°C, addressing a critical challenge in maintaining color consistency in variable temperature conditions.

Silicon carbide (SiC) substrates have emerged as a promising alternative to traditional sapphire substrates, offering superior thermal conductivity—approximately three times higher than sapphire—which facilitates more efficient heat dissipation. This property is particularly valuable in automotive displays and outdoor signage applications where ambient temperatures can exceed 85°C.

Aluminum nitride (AlN) represents another breakthrough material, with a thermal conductivity of up to 320 W/m·K compared to GaN's 130 W/m·K. Research published in Advanced Materials (2022) demonstrated that AlN-based buffer layers can reduce thermal boundary resistance by up to 40%, significantly enhancing thermal management in high-power Mini LED arrays.

Quantum dot enhancement films (QDEF) incorporating thermally stable perovskite materials have shown remarkable color stability at temperatures up to 120°C. These advanced materials maintain quantum yield above 80% even after 1000 hours of operation at elevated temperatures, compared to conventional QDs that typically degrade to below 50% efficiency under similar conditions.

Carbon-based materials, particularly graphene and carbon nanotubes, are being integrated into Mini LED packaging to create thermally conductive pathways. A single-layer graphene heat spreader can reduce the junction temperature by up to 15°C under high-power operation, as demonstrated in research from Seoul National University.

Ceramic-polymer composite encapsulants represent another significant advancement, replacing traditional silicone materials that suffer from yellowing and degradation at high temperatures. These composites maintain optical transparency while providing thermal stability up to 200°C, extending the operational lifetime of Mini LEDs in extreme environments.

High-temperature phosphors based on rare-earth doped nitrides and oxynitrides have been developed to maintain consistent color conversion efficiency across wide temperature ranges. These materials exhibit less than 10% reduction in quantum efficiency when operating between -40°C and 150°C, addressing a critical challenge in maintaining color consistency in variable temperature conditions.

Environmental Impact and Sustainability Considerations

The environmental impact of Mini LED technology in high-temperature zones extends beyond mere performance considerations to encompass broader sustainability implications. Manufacturing processes for Mini LEDs involve various materials including gallium nitride, indium, and rare earth elements, which require significant energy for extraction and processing. When optimizing these displays for high-temperature environments, additional materials such as specialized heat-resistant compounds and thermal management systems further increase the environmental footprint.

Energy consumption represents a critical environmental factor in high-temperature applications. Mini LEDs operating in elevated temperature conditions typically require more power for cooling systems, which contradicts global energy efficiency goals. However, compared to traditional lighting technologies, optimized Mini LEDs still offer substantial energy savings of 30-50% over their lifecycle, even in challenging thermal environments. This efficiency advantage translates to reduced carbon emissions when viewed from a holistic perspective.

Waste management presents another significant environmental challenge. The complex composition of Mini LED components, particularly those designed for thermal resilience, complicates end-of-life recycling processes. Current recycling rates for advanced display technologies remain below 20% globally, with heat-resistant variants potentially presenting even greater recovery challenges due to their specialized material compositions.

Sustainable design approaches for high-temperature Mini LEDs are emerging as industry priorities. These include designing for disassembly, reducing hazardous substance content, and implementing modular components that facilitate repairs rather than complete replacements. Some manufacturers have begun implementing bio-based heat-resistant polymers and recycled metals in non-critical components, reducing virgin material requirements by up to 15% in next-generation designs.

Water usage in manufacturing processes represents another environmental concern, particularly as many semiconductor fabrication facilities operate in water-stressed regions. Production of high-temperature resistant Mini LEDs typically requires 1.5-2 times more ultrapure water than standard variants due to additional processing steps and more stringent cleaning requirements. Industry leaders have begun implementing closed-loop water recycling systems, achieving water reuse rates of 80-90% in advanced facilities.

Carbon footprint considerations extend throughout the supply chain, from raw material extraction to manufacturing and transportation. Life cycle assessments indicate that optimizing Mini LEDs for high-temperature performance can increase manufacturing-phase emissions by 15-25%, though these increases may be offset by longer operational lifespans and reduced replacement frequency in challenging environments. Several manufacturers have committed to carbon-neutral production by 2030, implementing renewable energy and carbon offset programs specifically targeting their high-performance display divisions.

Energy consumption represents a critical environmental factor in high-temperature applications. Mini LEDs operating in elevated temperature conditions typically require more power for cooling systems, which contradicts global energy efficiency goals. However, compared to traditional lighting technologies, optimized Mini LEDs still offer substantial energy savings of 30-50% over their lifecycle, even in challenging thermal environments. This efficiency advantage translates to reduced carbon emissions when viewed from a holistic perspective.

Waste management presents another significant environmental challenge. The complex composition of Mini LED components, particularly those designed for thermal resilience, complicates end-of-life recycling processes. Current recycling rates for advanced display technologies remain below 20% globally, with heat-resistant variants potentially presenting even greater recovery challenges due to their specialized material compositions.

Sustainable design approaches for high-temperature Mini LEDs are emerging as industry priorities. These include designing for disassembly, reducing hazardous substance content, and implementing modular components that facilitate repairs rather than complete replacements. Some manufacturers have begun implementing bio-based heat-resistant polymers and recycled metals in non-critical components, reducing virgin material requirements by up to 15% in next-generation designs.

Water usage in manufacturing processes represents another environmental concern, particularly as many semiconductor fabrication facilities operate in water-stressed regions. Production of high-temperature resistant Mini LEDs typically requires 1.5-2 times more ultrapure water than standard variants due to additional processing steps and more stringent cleaning requirements. Industry leaders have begun implementing closed-loop water recycling systems, achieving water reuse rates of 80-90% in advanced facilities.

Carbon footprint considerations extend throughout the supply chain, from raw material extraction to manufacturing and transportation. Life cycle assessments indicate that optimizing Mini LEDs for high-temperature performance can increase manufacturing-phase emissions by 15-25%, though these increases may be offset by longer operational lifespans and reduced replacement frequency in challenging environments. Several manufacturers have committed to carbon-neutral production by 2030, implementing renewable energy and carbon offset programs specifically targeting their high-performance display divisions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!