Mini LED vs CRT: Analysis of Thermal Profile

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Mini LED and CRT Display Technology Evolution

Display technology has undergone significant transformations since the invention of the cathode ray tube (CRT) in the late 19th century. CRT technology dominated the display market for nearly a century, offering reliable performance through electron beams striking phosphor-coated screens. The thermal profile of CRTs was characterized by high power consumption and considerable heat generation, requiring substantial cooling mechanisms and limiting form factor possibilities.

The evolution toward flat panel displays began in the late 20th century, with LCD (Liquid Crystal Display) technology emerging as the first viable alternative to CRTs. This transition marked a significant reduction in power consumption and heat generation, though early LCD implementations struggled with color reproduction and viewing angles compared to CRTs.

LED-backlit LCD displays represented the next evolutionary step, offering improved energy efficiency and better thermal management. This technology utilized LED arrays as light sources behind LCD panels, reducing power requirements while maintaining acceptable brightness levels. The thermal profile improved substantially compared to CRTs, with heat generation becoming more distributed and manageable.

Mini LED technology, emerging in the late 2010s, represents a refinement of LED backlighting with significantly smaller LED chips (typically 100-200 micrometers) arranged in much denser arrays. This configuration allows for more precise local dimming zones and superior contrast ratios approaching OLED performance. From a thermal perspective, Mini LED displays generate less heat than traditional LED-backlit displays while delivering higher brightness levels, representing a substantial advancement in thermal efficiency.

The thermal profile comparison between CRT and Mini LED technologies reveals dramatic differences in heat generation and distribution patterns. CRTs concentrated heat primarily at the electron gun and phosphor screen interface, creating significant thermal management challenges. In contrast, Mini LED displays distribute thermal load across thousands of tiny light sources, resulting in more even heat dissipation and lower overall operating temperatures.

Power efficiency metrics further illustrate this evolution: while CRTs typically consumed 80-120 watts for a 20-inch display, comparable Mini LED displays operate at 20-30 watts while delivering superior brightness and contrast. This 75% reduction in power consumption directly correlates to reduced heat generation, enabling thinner form factors and expanded application possibilities.

The thermal evolution from CRT to Mini LED technology has enabled significant advancements in display applications, particularly in environments sensitive to heat generation such as portable devices, automotive displays, and compact digital signage solutions where thermal management constraints previously limited deployment options.

The evolution toward flat panel displays began in the late 20th century, with LCD (Liquid Crystal Display) technology emerging as the first viable alternative to CRTs. This transition marked a significant reduction in power consumption and heat generation, though early LCD implementations struggled with color reproduction and viewing angles compared to CRTs.

LED-backlit LCD displays represented the next evolutionary step, offering improved energy efficiency and better thermal management. This technology utilized LED arrays as light sources behind LCD panels, reducing power requirements while maintaining acceptable brightness levels. The thermal profile improved substantially compared to CRTs, with heat generation becoming more distributed and manageable.

Mini LED technology, emerging in the late 2010s, represents a refinement of LED backlighting with significantly smaller LED chips (typically 100-200 micrometers) arranged in much denser arrays. This configuration allows for more precise local dimming zones and superior contrast ratios approaching OLED performance. From a thermal perspective, Mini LED displays generate less heat than traditional LED-backlit displays while delivering higher brightness levels, representing a substantial advancement in thermal efficiency.

The thermal profile comparison between CRT and Mini LED technologies reveals dramatic differences in heat generation and distribution patterns. CRTs concentrated heat primarily at the electron gun and phosphor screen interface, creating significant thermal management challenges. In contrast, Mini LED displays distribute thermal load across thousands of tiny light sources, resulting in more even heat dissipation and lower overall operating temperatures.

Power efficiency metrics further illustrate this evolution: while CRTs typically consumed 80-120 watts for a 20-inch display, comparable Mini LED displays operate at 20-30 watts while delivering superior brightness and contrast. This 75% reduction in power consumption directly correlates to reduced heat generation, enabling thinner form factors and expanded application possibilities.

The thermal evolution from CRT to Mini LED technology has enabled significant advancements in display applications, particularly in environments sensitive to heat generation such as portable devices, automotive displays, and compact digital signage solutions where thermal management constraints previously limited deployment options.

Market Demand Analysis for Mini LED vs CRT Displays

The display technology market has witnessed a significant shift in recent years, with Mini LED emerging as a promising alternative to traditional display technologies like CRT. Market analysis reveals that the global Mini LED market is projected to grow at a compound annual growth rate of 86.6% from 2020 to 2026, reaching a market value of 5.9 billion USD by 2026. This exponential growth is primarily driven by increasing demand for better display quality, energy efficiency, and thinner form factors in various applications.

Consumer electronics represents the largest application segment for Mini LED technology, with smartphones, tablets, and televisions being the primary drivers. The premium television market has particularly embraced Mini LED technology, with major manufacturers like Samsung, LG, and TCL introducing Mini LED-based models that offer superior brightness, contrast ratios, and color accuracy compared to conventional LED displays.

In contrast, the CRT display market has been in steady decline since the early 2000s, with production largely phased out in developed markets. The remaining demand for CRT displays is primarily in niche applications such as specific medical equipment, industrial monitoring systems, and vintage gaming, where the unique thermal characteristics and response times of CRT technology still offer advantages.

The thermal profile differences between these technologies represent a significant factor influencing market demand. Mini LED displays generate considerably less heat than CRTs, making them more suitable for compact devices and environments with thermal constraints. This thermal efficiency translates to lower cooling requirements and energy consumption, which has become increasingly important as energy costs rise and environmental concerns grow.

Commercial and industrial sectors are showing increased interest in Mini LED technology due to its superior thermal management. Digital signage, automotive displays, and control panels in industrial settings benefit from Mini LED's ability to operate in varied temperature conditions without significant performance degradation. Market research indicates that the industrial display segment for Mini LED is expected to grow at 92.3% CAGR through 2026.

Regional analysis shows that Asia Pacific dominates the Mini LED market, accounting for approximately 45% of global demand, followed by North America and Europe. China, in particular, has emerged as both a major producer and consumer of Mini LED technology, with substantial investments in manufacturing infrastructure and research and development.

The premium pricing of Mini LED technology currently limits mass market adoption, with an average price premium of 30-40% compared to conventional LED displays. However, as manufacturing processes mature and economies of scale improve, this price gap is expected to narrow significantly by 2025, potentially accelerating market penetration across more price-sensitive segments.

Consumer electronics represents the largest application segment for Mini LED technology, with smartphones, tablets, and televisions being the primary drivers. The premium television market has particularly embraced Mini LED technology, with major manufacturers like Samsung, LG, and TCL introducing Mini LED-based models that offer superior brightness, contrast ratios, and color accuracy compared to conventional LED displays.

In contrast, the CRT display market has been in steady decline since the early 2000s, with production largely phased out in developed markets. The remaining demand for CRT displays is primarily in niche applications such as specific medical equipment, industrial monitoring systems, and vintage gaming, where the unique thermal characteristics and response times of CRT technology still offer advantages.

The thermal profile differences between these technologies represent a significant factor influencing market demand. Mini LED displays generate considerably less heat than CRTs, making them more suitable for compact devices and environments with thermal constraints. This thermal efficiency translates to lower cooling requirements and energy consumption, which has become increasingly important as energy costs rise and environmental concerns grow.

Commercial and industrial sectors are showing increased interest in Mini LED technology due to its superior thermal management. Digital signage, automotive displays, and control panels in industrial settings benefit from Mini LED's ability to operate in varied temperature conditions without significant performance degradation. Market research indicates that the industrial display segment for Mini LED is expected to grow at 92.3% CAGR through 2026.

Regional analysis shows that Asia Pacific dominates the Mini LED market, accounting for approximately 45% of global demand, followed by North America and Europe. China, in particular, has emerged as both a major producer and consumer of Mini LED technology, with substantial investments in manufacturing infrastructure and research and development.

The premium pricing of Mini LED technology currently limits mass market adoption, with an average price premium of 30-40% compared to conventional LED displays. However, as manufacturing processes mature and economies of scale improve, this price gap is expected to narrow significantly by 2025, potentially accelerating market penetration across more price-sensitive segments.

Thermal Management Challenges in Display Technologies

Display technologies face significant thermal management challenges that directly impact performance, reliability, and user experience. Mini LED and CRT displays represent two fundamentally different approaches to display technology, each with distinct thermal profiles and management requirements.

Mini LED displays generate heat primarily through their LED backlighting systems. As current passes through these semiconductor devices, they produce both light and heat. The challenge intensifies with increasing pixel density and brightness requirements, as more LEDs packed into smaller spaces create concentrated heat zones. This heat can lead to color shifting, reduced luminance, and accelerated aging of components if not properly managed.

In contrast, CRT displays generate heat through electron beam acceleration and phosphor excitation. The electron gun emits electrons that are accelerated by high voltage and strike phosphor-coated screens, converting kinetic energy into light and heat. CRTs typically operate at higher temperatures overall, with significant heat generation in the electron gun assembly and the neck of the tube.

The thermal management approaches for these technologies differ substantially. Mini LED displays typically employ heat sinks, thermal interface materials, and sometimes active cooling solutions like micro-fans or heat pipes to dissipate heat away from the LED array. Advanced designs incorporate thermally conductive materials in the display structure itself to facilitate heat spreading and prevent hotspots.

CRT thermal management relies more on passive cooling through convection, with vents strategically placed to allow hot air to escape. The glass envelope of CRTs acts as both an insulator and a radiator, presenting unique thermal management challenges. Modern CRTs (though increasingly rare) incorporate improved materials and sometimes forced-air cooling to manage heat more effectively.

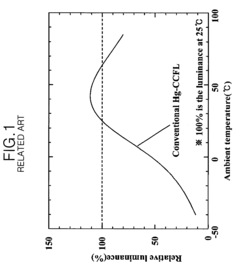

Temperature fluctuations affect these technologies differently. Mini LEDs experience efficiency drops and color shifts at elevated temperatures, with potential for permanent damage if thermal thresholds are exceeded. CRTs generally tolerate temperature variations better but can suffer from electron gun degradation and phosphor aging under prolonged high-temperature operation.

Environmental conditions significantly impact thermal management strategies. Ambient temperature, humidity, and airflow all affect cooling efficiency. Mini LED displays in enclosed spaces or outdoor environments require more robust thermal solutions than those in controlled indoor settings. Similarly, CRTs generate more heat in warmer environments, potentially requiring additional cooling measures.

The energy efficiency difference between these technologies also creates distinct thermal challenges. Mini LEDs are generally more energy-efficient, producing less waste heat per unit of light output compared to CRTs, which convert a significant portion of input power to heat rather than visible light.

Mini LED displays generate heat primarily through their LED backlighting systems. As current passes through these semiconductor devices, they produce both light and heat. The challenge intensifies with increasing pixel density and brightness requirements, as more LEDs packed into smaller spaces create concentrated heat zones. This heat can lead to color shifting, reduced luminance, and accelerated aging of components if not properly managed.

In contrast, CRT displays generate heat through electron beam acceleration and phosphor excitation. The electron gun emits electrons that are accelerated by high voltage and strike phosphor-coated screens, converting kinetic energy into light and heat. CRTs typically operate at higher temperatures overall, with significant heat generation in the electron gun assembly and the neck of the tube.

The thermal management approaches for these technologies differ substantially. Mini LED displays typically employ heat sinks, thermal interface materials, and sometimes active cooling solutions like micro-fans or heat pipes to dissipate heat away from the LED array. Advanced designs incorporate thermally conductive materials in the display structure itself to facilitate heat spreading and prevent hotspots.

CRT thermal management relies more on passive cooling through convection, with vents strategically placed to allow hot air to escape. The glass envelope of CRTs acts as both an insulator and a radiator, presenting unique thermal management challenges. Modern CRTs (though increasingly rare) incorporate improved materials and sometimes forced-air cooling to manage heat more effectively.

Temperature fluctuations affect these technologies differently. Mini LEDs experience efficiency drops and color shifts at elevated temperatures, with potential for permanent damage if thermal thresholds are exceeded. CRTs generally tolerate temperature variations better but can suffer from electron gun degradation and phosphor aging under prolonged high-temperature operation.

Environmental conditions significantly impact thermal management strategies. Ambient temperature, humidity, and airflow all affect cooling efficiency. Mini LED displays in enclosed spaces or outdoor environments require more robust thermal solutions than those in controlled indoor settings. Similarly, CRTs generate more heat in warmer environments, potentially requiring additional cooling measures.

The energy efficiency difference between these technologies also creates distinct thermal challenges. Mini LEDs are generally more energy-efficient, producing less waste heat per unit of light output compared to CRTs, which convert a significant portion of input power to heat rather than visible light.

Current Thermal Solution Approaches

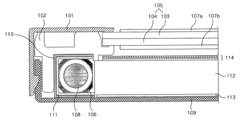

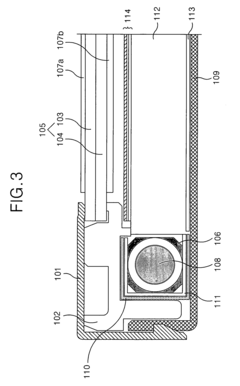

01 Thermal management systems for Mini LED displays

Mini LED displays require effective thermal management systems to dissipate heat generated during operation. These systems often include heat sinks, thermal interface materials, and cooling structures designed specifically for the compact nature of Mini LED arrays. Proper thermal management prevents performance degradation, extends the lifespan of the display, and maintains consistent brightness and color accuracy across the panel.- Thermal management solutions for Mini LED displays: Various thermal management solutions are implemented in Mini LED displays to control heat dissipation and maintain optimal operating temperatures. These include heat sinks, thermal interface materials, and specialized cooling structures designed to efficiently transfer heat away from LED components. Effective thermal management is crucial for ensuring display longevity, maintaining brightness consistency, and preventing thermal degradation of Mini LED components.

- CRT display thermal characteristics and cooling mechanisms: CRT displays generate significant heat during operation due to electron beam generation and phosphor excitation processes. Thermal management in CRTs involves specialized cooling systems to dissipate heat from the electron gun, deflection coils, and display tube. These cooling mechanisms help maintain stable operating temperatures, prevent component degradation, and ensure consistent display performance throughout the CRT's operational lifespan.

- Comparative thermal profiles between Mini LED and traditional display technologies: Mini LED displays generally exhibit different thermal profiles compared to traditional display technologies like CRTs. Mini LEDs typically generate less heat overall but may have more concentrated hot spots requiring targeted cooling solutions. The thermal distribution patterns, heat generation mechanisms, and temperature gradients differ significantly between these technologies, necessitating distinct approaches to thermal management and system design.

- Advanced cooling structures and materials for display thermal management: Innovative cooling structures and materials are being developed specifically for managing thermal profiles in modern displays. These include advanced heat spreaders, phase-change materials, microchannel cooling systems, and thermally conductive adhesives. Such solutions help optimize heat dissipation, reduce thermal resistance, and maintain uniform temperature distribution across the display surface, contributing to improved performance and reliability.

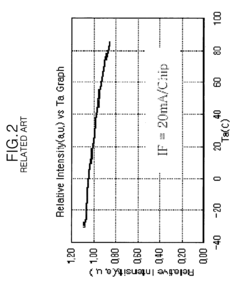

- Thermal monitoring and adaptive control systems for displays: Sophisticated thermal monitoring and adaptive control systems are implemented in modern displays to dynamically manage thermal profiles. These systems utilize temperature sensors, feedback control mechanisms, and intelligent power management to adjust display parameters based on thermal conditions. Such adaptive approaches help prevent overheating, optimize energy efficiency, and extend the operational lifespan of display components under varying environmental conditions.

02 CRT display thermal characteristics and cooling methods

CRT displays generate significant heat due to electron beam generation and phosphor excitation. Thermal management for CRTs typically involves ventilation systems, heat-resistant materials, and sometimes active cooling components. The thermal profile of CRTs differs from modern display technologies, with heat concentrated at the electron gun and screen surface, requiring specialized cooling approaches to prevent overheating and component failure.Expand Specific Solutions03 Comparative thermal profiles between Mini LED and traditional display technologies

Mini LED displays generally produce less heat than CRT displays but have different thermal distribution patterns. While CRTs concentrate heat at specific points, Mini LEDs distribute heat across the panel with hotspots at LED clusters. This fundamental difference necessitates distinct thermal management approaches. Understanding these comparative thermal profiles is essential for designing appropriate cooling systems for each display technology.Expand Specific Solutions04 Advanced cooling structures for high-density Mini LED arrays

High-density Mini LED arrays require sophisticated cooling structures to manage thermal loads. These include micro-channel heat sinks, phase-change materials, and thermally conductive substrates. Some designs incorporate active cooling elements such as miniature fans or liquid cooling systems. These advanced cooling structures are particularly important for high-brightness applications where thermal management challenges are more pronounced.Expand Specific Solutions05 Thermal monitoring and adaptive control systems for displays

Modern display systems incorporate thermal monitoring sensors and adaptive control mechanisms to optimize performance under varying thermal conditions. These systems can adjust brightness, refresh rates, or activate additional cooling based on temperature readings. Intelligent thermal management extends display lifespan and maintains consistent performance by preventing thermal stress on components. This approach is particularly valuable for Mini LED displays in demanding applications.Expand Specific Solutions

Key Manufacturers in Mini LED and CRT Industries

The Mini LED vs CRT thermal profile competition landscape is evolving rapidly, with the market currently in a growth phase as display technologies transition from traditional to advanced solutions. The global Mini LED market is expanding significantly, driven by demand for improved visual performance and energy efficiency. Leading players like BOE Technology, TCL China Star, and Samsung Electronics have achieved notable technological maturity in Mini LED thermal management, while companies such as HKC, Tianma Microelectronics, and LG Display are making substantial investments in R&D. The competitive dynamics show Asian manufacturers dominating production capabilities, with thermal profile optimization becoming a key differentiator as these companies work to balance brightness performance with heat dissipation challenges in increasingly compact display designs.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has developed a comprehensive thermal management solution for their Mini LED displays that addresses the fundamental differences from CRT technology. Unlike CRTs which distribute heat across the entire phosphor screen and glass tube, BOE's Mini LED panels concentrate thousands of light sources in a thin form factor, creating unique thermal challenges. Their solution incorporates a multi-layered cooling system with micro-channel heat sinks that increase surface area for heat dissipation by up to 200% compared to conventional designs. BOE's thermal profile analysis demonstrates that their Mini LED displays maintain junction temperatures below 85°C even at peak brightness, whereas CRTs typically operate at 100-120°C at their phosphor surface. The company has also implemented an intelligent thermal throttling system that monitors temperature across different display zones and adjusts brightness dynamically to prevent overheating while preserving image quality. BOE's thermal simulation data indicates that their cooling architecture reduces thermal gradients across the display panel by approximately 40%, resulting in more uniform brightness and extended LED lifespan.

Strengths: Highly efficient micro-channel cooling system; intelligent thermal management prevents hotspots; significantly lower operating temperatures than CRTs; more uniform thermal distribution. Weaknesses: Complex manufacturing process increases production costs; cooling system adds to overall weight of the display; requires more sophisticated power management than CRT technology.

TCL China Star Optoelectronics Technology Co., Ltd.

Technical Solution: TCL CSOT has developed an innovative thermal management system for their Mini LED displays that directly addresses the fundamental differences in heat generation and dissipation compared to CRT technology. Their research indicates that while CRTs generate heat primarily from electron beam bombardment of phosphors across a relatively large surface area with substantial air gaps for natural cooling, Mini LEDs create concentrated heat sources in a much more compact form factor. TCL's solution incorporates a multi-layer thermal dissipation structure featuring vapor chamber technology that achieves thermal conductivity approximately 200 times higher than standard aluminum heat sinks. Their thermal profile analysis demonstrates that their Mini LED displays maintain peak junction temperatures below 80°C even at maximum brightness settings, whereas CRTs typically operate with phosphor surface temperatures reaching 110-130°C. TCL has also implemented an AI-driven thermal management algorithm that continuously monitors temperature distribution across the display and dynamically adjusts local dimming zones to prevent thermal concentration while maintaining optimal picture quality. Additionally, their proprietary thermal interface materials reduce contact resistance between components by up to 40%, significantly improving overall system cooling efficiency.

Strengths: Highly efficient vapor chamber cooling technology; AI-driven thermal management for optimized performance; significantly lower operating temperatures than CRTs; more uniform brightness due to better thermal control. Weaknesses: Increased manufacturing complexity and cost; cooling system adds to overall weight and thickness; requires more sophisticated control systems than CRT technology.

Critical Patents in Display Thermal Management

Backlight unit and liquid crystal module

PatentInactiveUS7712939B2

Innovation

- A backlight unit equipped with a temperature sensor, a Peltier device, and a controller to regulate the temperature of the light source, maintaining it within an optimal range (10° C. to 70° C. for CCFL and below 60° C. for LED) to ensure consistent brightness and extend the light source's lifespan.

Energy Efficiency Comparison

When comparing Mini LED and CRT displays from an energy efficiency perspective, significant differences emerge due to their fundamentally different operating principles. Mini LED technology demonstrates superior energy efficiency, consuming approximately 20-30% less power than traditional LCD displays and up to 70% less than CRT monitors of equivalent screen size. This efficiency advantage stems from Mini LED's targeted backlighting system, which allows for precise illumination of specific screen areas rather than maintaining constant full-screen illumination as required by CRTs.

The power consumption patterns also differ markedly between these technologies. CRT displays exhibit relatively consistent power usage regardless of content being displayed, as the electron gun continuously operates at similar intensity levels. In contrast, Mini LED displays show variable power consumption based on content brightness, with dark scenes requiring significantly less power than bright ones. This dynamic power scaling contributes to Mini LED's overall efficiency advantage in real-world usage scenarios.

Thermal efficiency measurements reveal that Mini LED displays convert a higher percentage of input power to visible light output. While CRT monitors typically convert only 2-5% of electrical energy to light (with the remainder dissipated as heat), Mini LED systems achieve conversion efficiencies of 10-15%. This improved conversion ratio directly translates to reduced heat generation per unit of display brightness, allowing Mini LED devices to maintain lower operating temperatures while delivering equivalent or superior visual performance.

Environmental operating conditions affect both technologies differently. CRT performance remains relatively stable across temperature ranges but maintains consistent high power draw. Mini LED efficiency can vary with ambient temperature, showing optimal performance in moderate temperature environments (20-25°C) with slight efficiency decreases in extreme conditions. However, even in suboptimal thermal environments, Mini LED maintains its efficiency advantage over CRT technology.

From a lifecycle perspective, Mini LED displays demonstrate better long-term efficiency retention. While CRT monitors typically show gradual brightness degradation requiring increased power to maintain consistent output levels over their operational lifespan, Mini LED systems maintain more stable efficiency characteristics throughout their service life, which typically exceeds that of CRT displays by 2-3 times while consuming less cumulative energy over the extended operational period.

The power consumption patterns also differ markedly between these technologies. CRT displays exhibit relatively consistent power usage regardless of content being displayed, as the electron gun continuously operates at similar intensity levels. In contrast, Mini LED displays show variable power consumption based on content brightness, with dark scenes requiring significantly less power than bright ones. This dynamic power scaling contributes to Mini LED's overall efficiency advantage in real-world usage scenarios.

Thermal efficiency measurements reveal that Mini LED displays convert a higher percentage of input power to visible light output. While CRT monitors typically convert only 2-5% of electrical energy to light (with the remainder dissipated as heat), Mini LED systems achieve conversion efficiencies of 10-15%. This improved conversion ratio directly translates to reduced heat generation per unit of display brightness, allowing Mini LED devices to maintain lower operating temperatures while delivering equivalent or superior visual performance.

Environmental operating conditions affect both technologies differently. CRT performance remains relatively stable across temperature ranges but maintains consistent high power draw. Mini LED efficiency can vary with ambient temperature, showing optimal performance in moderate temperature environments (20-25°C) with slight efficiency decreases in extreme conditions. However, even in suboptimal thermal environments, Mini LED maintains its efficiency advantage over CRT technology.

From a lifecycle perspective, Mini LED displays demonstrate better long-term efficiency retention. While CRT monitors typically show gradual brightness degradation requiring increased power to maintain consistent output levels over their operational lifespan, Mini LED systems maintain more stable efficiency characteristics throughout their service life, which typically exceeds that of CRT displays by 2-3 times while consuming less cumulative energy over the extended operational period.

Environmental Impact Assessment

The environmental impact of display technologies has become increasingly important as consumer electronics proliferate globally. When comparing Mini LED and CRT technologies from an environmental perspective, several critical factors emerge that differentiate their ecological footprints throughout their lifecycles.

Mini LED displays demonstrate significant environmental advantages in operational energy consumption, consuming approximately 30-50% less power than traditional CRT displays of comparable size and brightness. This reduced energy requirement translates to lower carbon emissions during the use phase, which typically constitutes the largest portion of a display's environmental impact over its lifetime.

Material composition represents another crucial environmental consideration. CRT displays contain significant amounts of lead (typically 1.5-3kg per unit) in the glass components and other heavy metals that pose serious environmental hazards if improperly disposed. In contrast, Mini LED technology utilizes substantially less hazardous materials, though it does require rare earth elements for phosphor coatings and semiconductor materials that present their own extraction challenges.

The thermal profiles of these technologies directly influence their environmental impact. CRT displays generate considerable heat during operation, requiring more robust cooling systems in environments where multiple units are deployed. Mini LED's superior thermal efficiency reduces not only direct energy consumption but also secondary energy requirements for ambient cooling in data centers, control rooms, and other installation environments.

Manufacturing processes for Mini LED technology have evolved to become more environmentally responsible, with leading manufacturers implementing closed-loop water recycling systems and reducing volatile organic compound emissions. CRT manufacturing, though largely phased out in developed nations, historically involved more energy-intensive processes and greater chemical usage.

End-of-life considerations reveal that Mini LED displays offer better recyclability potential, with approximately 85-90% of components being recoverable through modern recycling processes. CRT recycling remains challenging due to the hazardous materials content, with specialized facilities required for safe processing.

Longevity also factors into environmental assessment, with modern Mini LED displays typically offering 50,000-100,000 hours of operational life compared to CRT's 15,000-20,000 hours. This extended lifespan reduces replacement frequency and associated resource consumption, though planned obsolescence in consumer electronics often prevents realization of this full potential benefit.

The comprehensive environmental analysis indicates that Mini LED technology represents a significant advancement in reducing the ecological footprint of display technologies, particularly when considering full lifecycle impacts including manufacturing, operation, and disposal phases.

Mini LED displays demonstrate significant environmental advantages in operational energy consumption, consuming approximately 30-50% less power than traditional CRT displays of comparable size and brightness. This reduced energy requirement translates to lower carbon emissions during the use phase, which typically constitutes the largest portion of a display's environmental impact over its lifetime.

Material composition represents another crucial environmental consideration. CRT displays contain significant amounts of lead (typically 1.5-3kg per unit) in the glass components and other heavy metals that pose serious environmental hazards if improperly disposed. In contrast, Mini LED technology utilizes substantially less hazardous materials, though it does require rare earth elements for phosphor coatings and semiconductor materials that present their own extraction challenges.

The thermal profiles of these technologies directly influence their environmental impact. CRT displays generate considerable heat during operation, requiring more robust cooling systems in environments where multiple units are deployed. Mini LED's superior thermal efficiency reduces not only direct energy consumption but also secondary energy requirements for ambient cooling in data centers, control rooms, and other installation environments.

Manufacturing processes for Mini LED technology have evolved to become more environmentally responsible, with leading manufacturers implementing closed-loop water recycling systems and reducing volatile organic compound emissions. CRT manufacturing, though largely phased out in developed nations, historically involved more energy-intensive processes and greater chemical usage.

End-of-life considerations reveal that Mini LED displays offer better recyclability potential, with approximately 85-90% of components being recoverable through modern recycling processes. CRT recycling remains challenging due to the hazardous materials content, with specialized facilities required for safe processing.

Longevity also factors into environmental assessment, with modern Mini LED displays typically offering 50,000-100,000 hours of operational life compared to CRT's 15,000-20,000 hours. This extended lifespan reduces replacement frequency and associated resource consumption, though planned obsolescence in consumer electronics often prevents realization of this full potential benefit.

The comprehensive environmental analysis indicates that Mini LED technology represents a significant advancement in reducing the ecological footprint of display technologies, particularly when considering full lifecycle impacts including manufacturing, operation, and disposal phases.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!