Mini LED vs Xenon: Lifetime Performance Metrics

SEP 12, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Mini LED and Xenon Technology Evolution

The evolution of lighting and display technologies has witnessed significant transformations over the decades, with Mini LED and Xenon representing two distinct technological approaches that have shaped different market segments. Xenon lighting technology emerged in the 1990s as a high-intensity discharge (HID) light source, initially gaining prominence in automotive headlights and specialized industrial applications. The technology offered substantial improvements over traditional halogen bulbs, providing brighter illumination with a color temperature closer to natural daylight.

Mini LED technology, by contrast, represents a more recent innovation in the display and lighting industry, emerging in the mid-2010s as an advancement of conventional LED technology. This evolution was driven by the miniaturization of LED chips, allowing for more precise local dimming zones and improved contrast ratios in displays. The development of Mini LED has been closely tied to the broader trend of digital display advancement, positioning it as a transitional technology between traditional LED and the emerging microLED displays.

The technological trajectories of these two lighting solutions have been shaped by different market demands and application contexts. Xenon technology reached its peak adoption in the early 2000s, particularly in premium automotive segments and professional photography equipment. Its development focused primarily on optimizing light output, color rendering, and beam pattern control, with incremental improvements in energy efficiency and lifespan.

Mini LED has followed a more accelerated development path, benefiting from the broader semiconductor manufacturing advances. The technology has seen rapid improvements in miniaturization, with LED chip sizes decreasing from approximately 1mm to current dimensions of 100-200 micrometers. This reduction in size has enabled higher density arrangements, better thermal management, and more precise control over local dimming zones.

A critical milestone in Mini LED evolution was the commercialization of the technology in high-end displays around 2019-2020, marking its transition from experimental to mainstream technology. Major display manufacturers have since incorporated Mini LED backlighting in premium television and monitor products, highlighting improvements in contrast ratio, peak brightness, and color accuracy compared to conventional LED displays.

The lifetime performance metrics of both technologies have evolved significantly throughout their development cycles. Xenon lighting initially offered lifespans of approximately 2,000-3,000 hours, which was considered revolutionary compared to traditional incandescent solutions. Modern Xenon bulbs can achieve operational lifetimes of 5,000-10,000 hours under optimal conditions, though they remain susceptible to vibration damage and voltage fluctuations.

Mini LED technology demonstrates substantially longer theoretical lifetimes, with current estimates ranging from 30,000 to 100,000 hours of operation before significant brightness degradation occurs. This extended lifespan represents one of the key advantages driving the technology's adoption in premium display applications where longevity and reliability are paramount considerations.

Mini LED technology, by contrast, represents a more recent innovation in the display and lighting industry, emerging in the mid-2010s as an advancement of conventional LED technology. This evolution was driven by the miniaturization of LED chips, allowing for more precise local dimming zones and improved contrast ratios in displays. The development of Mini LED has been closely tied to the broader trend of digital display advancement, positioning it as a transitional technology between traditional LED and the emerging microLED displays.

The technological trajectories of these two lighting solutions have been shaped by different market demands and application contexts. Xenon technology reached its peak adoption in the early 2000s, particularly in premium automotive segments and professional photography equipment. Its development focused primarily on optimizing light output, color rendering, and beam pattern control, with incremental improvements in energy efficiency and lifespan.

Mini LED has followed a more accelerated development path, benefiting from the broader semiconductor manufacturing advances. The technology has seen rapid improvements in miniaturization, with LED chip sizes decreasing from approximately 1mm to current dimensions of 100-200 micrometers. This reduction in size has enabled higher density arrangements, better thermal management, and more precise control over local dimming zones.

A critical milestone in Mini LED evolution was the commercialization of the technology in high-end displays around 2019-2020, marking its transition from experimental to mainstream technology. Major display manufacturers have since incorporated Mini LED backlighting in premium television and monitor products, highlighting improvements in contrast ratio, peak brightness, and color accuracy compared to conventional LED displays.

The lifetime performance metrics of both technologies have evolved significantly throughout their development cycles. Xenon lighting initially offered lifespans of approximately 2,000-3,000 hours, which was considered revolutionary compared to traditional incandescent solutions. Modern Xenon bulbs can achieve operational lifetimes of 5,000-10,000 hours under optimal conditions, though they remain susceptible to vibration damage and voltage fluctuations.

Mini LED technology demonstrates substantially longer theoretical lifetimes, with current estimates ranging from 30,000 to 100,000 hours of operation before significant brightness degradation occurs. This extended lifespan represents one of the key advantages driving the technology's adoption in premium display applications where longevity and reliability are paramount considerations.

Market Demand Analysis for Advanced Lighting Solutions

The lighting solutions market is experiencing a significant shift towards advanced technologies, with Mini LED and Xenon lighting systems emerging as key competitors in various sectors. Current market analysis indicates robust growth in the advanced lighting segment, projected to reach $98 billion by 2027, with a compound annual growth rate of 6.8%. This growth is primarily driven by increasing consumer demand for energy-efficient, long-lasting lighting solutions across automotive, consumer electronics, and commercial applications.

In the automotive sector, premium vehicle manufacturers are increasingly adopting advanced lighting technologies as differentiating features. Market research shows that 72% of luxury vehicle buyers consider advanced lighting systems an important factor in purchasing decisions. The transition from traditional halogen headlights to Xenon systems has been steady over the past decade, while Mini LED technology is now gaining traction for interior lighting and specialized exterior applications.

Consumer electronics represents another significant market segment, with display backlighting applications showing particular promise for Mini LED technology. The demand for high-quality visual experiences in televisions, monitors, and tablets has created a market opportunity valued at approximately $15 billion annually. Consumers are demonstrating willingness to pay premium prices for devices featuring superior display technologies, with 64% of survey respondents indicating improved visual quality as a primary purchase driver.

Commercial and industrial lighting applications constitute a substantial portion of the market demand, with businesses increasingly focused on lifetime performance metrics when evaluating lighting investments. The total cost of ownership, including energy consumption and maintenance requirements, has become a critical decision factor. Market data indicates that facilities managers rank longevity as the second most important consideration after energy efficiency when selecting lighting systems.

Regional market analysis reveals varying adoption patterns, with North America and Europe leading in Xenon technology implementation, while Asian markets show accelerated adoption of Mini LED solutions, particularly in consumer electronics manufacturing hubs. This regional differentiation is creating diverse supply chain dynamics and influencing global pricing structures.

Market forecasts suggest that technologies demonstrating superior lifetime performance metrics will capture increasing market share, with an estimated 38% of buyers willing to pay up to 25% more for lighting solutions that offer documented longevity advantages. This trend is particularly pronounced in commercial applications where maintenance costs represent a significant operational expense.

The sustainability aspect of lighting solutions is also driving market demand, with 57% of corporate buyers now including environmental impact assessments in their procurement processes. Lighting technologies that combine energy efficiency with extended operational lifespans are positioned to capitalize on this growing market segment, creating additional competitive pressure for both Mini LED and Xenon technologies to optimize their lifetime performance metrics.

In the automotive sector, premium vehicle manufacturers are increasingly adopting advanced lighting technologies as differentiating features. Market research shows that 72% of luxury vehicle buyers consider advanced lighting systems an important factor in purchasing decisions. The transition from traditional halogen headlights to Xenon systems has been steady over the past decade, while Mini LED technology is now gaining traction for interior lighting and specialized exterior applications.

Consumer electronics represents another significant market segment, with display backlighting applications showing particular promise for Mini LED technology. The demand for high-quality visual experiences in televisions, monitors, and tablets has created a market opportunity valued at approximately $15 billion annually. Consumers are demonstrating willingness to pay premium prices for devices featuring superior display technologies, with 64% of survey respondents indicating improved visual quality as a primary purchase driver.

Commercial and industrial lighting applications constitute a substantial portion of the market demand, with businesses increasingly focused on lifetime performance metrics when evaluating lighting investments. The total cost of ownership, including energy consumption and maintenance requirements, has become a critical decision factor. Market data indicates that facilities managers rank longevity as the second most important consideration after energy efficiency when selecting lighting systems.

Regional market analysis reveals varying adoption patterns, with North America and Europe leading in Xenon technology implementation, while Asian markets show accelerated adoption of Mini LED solutions, particularly in consumer electronics manufacturing hubs. This regional differentiation is creating diverse supply chain dynamics and influencing global pricing structures.

Market forecasts suggest that technologies demonstrating superior lifetime performance metrics will capture increasing market share, with an estimated 38% of buyers willing to pay up to 25% more for lighting solutions that offer documented longevity advantages. This trend is particularly pronounced in commercial applications where maintenance costs represent a significant operational expense.

The sustainability aspect of lighting solutions is also driving market demand, with 57% of corporate buyers now including environmental impact assessments in their procurement processes. Lighting technologies that combine energy efficiency with extended operational lifespans are positioned to capitalize on this growing market segment, creating additional competitive pressure for both Mini LED and Xenon technologies to optimize their lifetime performance metrics.

Current Technical Limitations and Challenges

Despite significant advancements in both Mini LED and Xenon lighting technologies, several technical limitations and challenges persist that impact their lifetime performance metrics. Mini LED technology faces challenges related to thermal management, as the high density of LEDs in compact arrays generates considerable heat that can accelerate degradation if not properly dissipated. This thermal stress directly impacts the phosphor conversion efficiency over time, leading to color shift and reduced luminance output after extended operation periods.

The manufacturing precision required for Mini LED arrays presents another significant challenge. The miniaturization process demands extremely tight tolerances for consistent performance across thousands of individual emitters. Even minor variations in manufacturing can result in uneven aging patterns, creating visible inconsistencies in brightness and color uniformity as the display ages.

For Xenon lighting systems, the primary limitation stems from their fundamental operating principle. The high-voltage arc discharge mechanism creates extreme thermal cycling that gradually deteriorates the electrodes. This deterioration process accelerates with each on-off cycle, making Xenon systems particularly vulnerable in applications requiring frequent switching, despite their impressive initial brightness capabilities.

Power efficiency represents another critical challenge for Xenon technology. The conversion of electrical energy to light involves significant heat generation, with typical efficiency rates of 5-15% compared to Mini LED's 40-60%. This inefficiency not only impacts energy consumption but also contributes to faster degradation of internal components due to thermal stress.

The environmental impact of both technologies presents ongoing challenges. Xenon lamps contain trace amounts of mercury and require specialized disposal procedures, while Mini LED manufacturing involves rare earth elements with complex supply chains and extraction processes that raise sustainability concerns.

Reliability testing methodologies constitute a cross-cutting challenge for both technologies. Current accelerated aging tests may not accurately predict real-world performance, particularly for Mini LED systems where the interaction between thousands of individual emitters creates complex failure patterns that are difficult to model in laboratory conditions.

The cost-performance balance remains problematic, especially for Mini LED technology. While manufacturing costs have decreased, the complex driving circuits and thermal management systems required for optimal lifetime performance add significant expense that must be justified by performance advantages in specific applications.

The manufacturing precision required for Mini LED arrays presents another significant challenge. The miniaturization process demands extremely tight tolerances for consistent performance across thousands of individual emitters. Even minor variations in manufacturing can result in uneven aging patterns, creating visible inconsistencies in brightness and color uniformity as the display ages.

For Xenon lighting systems, the primary limitation stems from their fundamental operating principle. The high-voltage arc discharge mechanism creates extreme thermal cycling that gradually deteriorates the electrodes. This deterioration process accelerates with each on-off cycle, making Xenon systems particularly vulnerable in applications requiring frequent switching, despite their impressive initial brightness capabilities.

Power efficiency represents another critical challenge for Xenon technology. The conversion of electrical energy to light involves significant heat generation, with typical efficiency rates of 5-15% compared to Mini LED's 40-60%. This inefficiency not only impacts energy consumption but also contributes to faster degradation of internal components due to thermal stress.

The environmental impact of both technologies presents ongoing challenges. Xenon lamps contain trace amounts of mercury and require specialized disposal procedures, while Mini LED manufacturing involves rare earth elements with complex supply chains and extraction processes that raise sustainability concerns.

Reliability testing methodologies constitute a cross-cutting challenge for both technologies. Current accelerated aging tests may not accurately predict real-world performance, particularly for Mini LED systems where the interaction between thousands of individual emitters creates complex failure patterns that are difficult to model in laboratory conditions.

The cost-performance balance remains problematic, especially for Mini LED technology. While manufacturing costs have decreased, the complex driving circuits and thermal management systems required for optimal lifetime performance add significant expense that must be justified by performance advantages in specific applications.

Comparative Analysis of Mini LED and Xenon Solutions

01 Mini LED lifetime enhancement technologies

Various technologies have been developed to enhance the lifetime performance of Mini LED lighting systems. These include improved thermal management systems that prevent overheating, specialized driver circuits that maintain stable current, and protective coatings that shield LEDs from environmental factors. Advanced manufacturing techniques also contribute to longer operational lifespans by reducing defects and ensuring consistent quality across Mini LED arrays.- Mini LED lifetime enhancement technologies: Various technologies have been developed to enhance the lifetime performance of Mini LED lighting systems. These include improved thermal management systems that prevent overheating, specialized driver circuits that maintain stable current, and protective coatings that shield LEDs from environmental factors. Advanced manufacturing techniques also contribute to increased durability by reducing defects in the semiconductor materials and improving connection reliability. These enhancements collectively extend the operational lifespan of Mini LED lighting systems while maintaining consistent brightness and color quality over time.

- Xenon lighting durability and performance characteristics: Xenon lighting technologies demonstrate distinct lifetime performance characteristics compared to LED alternatives. Xenon lamps typically have shorter overall lifespans but offer immediate full brightness without warm-up periods and consistent color temperature throughout their operational life. The performance of these systems is influenced by factors such as gas pressure maintenance, electrode design, and power supply stability. Advanced xenon systems incorporate pulse-width modulation and specialized cooling mechanisms to extend lamp life while maintaining the high-intensity output and natural color rendering that makes xenon lighting valuable for specific applications.

- Hybrid lighting systems combining Mini LED and Xenon technologies: Innovative hybrid lighting systems leverage the complementary strengths of both Mini LED and Xenon technologies to optimize lifetime performance. These systems intelligently switch between light sources based on usage conditions or combine them simultaneously to achieve desired lighting characteristics. The integration includes sophisticated control algorithms that balance the load between the two technologies, extending the overall system lifespan while maintaining optimal illumination quality. Such hybrid approaches allow for reduced degradation rates by distributing operational stress across multiple lighting technologies, resulting in longer maintenance intervals and improved reliability in demanding applications.

- Thermal management solutions for extended lighting lifespan: Advanced thermal management solutions play a critical role in extending the lifetime performance of both Mini LED and Xenon lighting technologies. These include passive cooling designs with optimized heat sinks, active cooling systems using microfluidics or miniature fans, and thermally conductive materials that efficiently dissipate heat away from critical components. Temperature monitoring and adaptive control systems prevent thermal damage by adjusting power levels based on operating conditions. Effective thermal management prevents premature failure modes such as phosphor degradation in LEDs and electrode deterioration in xenon lamps, significantly extending the useful operational lifetime of these lighting technologies.

- Reliability testing and lifetime prediction methods: Sophisticated reliability testing and lifetime prediction methods have been developed specifically for Mini LED and Xenon lighting technologies. These include accelerated aging tests under controlled environmental conditions, statistical modeling of failure mechanisms, and real-time monitoring systems that track performance degradation. Advanced diagnostic tools can identify early indicators of potential failure, allowing for preventive maintenance before complete system breakdown. Manufacturers employ these methods to establish accurate lifetime ratings and develop more durable lighting products. The testing protocols account for various stress factors including temperature cycling, humidity exposure, and electrical load variations to provide comprehensive lifetime performance assessments.

02 Xenon lighting durability and performance characteristics

Xenon lighting technologies demonstrate specific lifetime performance characteristics that differ from LED solutions. Xenon lamps typically offer high-intensity illumination with distinctive color temperature properties. Their lifetime performance is affected by factors such as operating temperature, ignition frequency, and power supply stability. Various innovations focus on extending xenon lamp lifespan through improved gas mixtures, electrode designs, and ballast systems that regulate power more effectively.Expand Specific Solutions03 Comparative lifetime analysis between Mini LED and Xenon systems

Research comparing the lifetime performance of Mini LED and Xenon lighting technologies reveals significant differences in longevity, efficiency, and degradation patterns. Mini LEDs typically offer longer operational lifespans measured in tens of thousands of hours, while Xenon systems generally have shorter lifespans but provide immediate full brightness. The degradation curves differ substantially, with LEDs showing gradual luminance reduction over time versus more abrupt failure modes in Xenon lighting.Expand Specific Solutions04 Thermal management solutions for extended lighting lifespan

Thermal management plays a crucial role in determining the lifetime performance of both Mini LED and Xenon lighting technologies. Advanced heat dissipation designs including specialized heat sinks, thermal interface materials, and active cooling systems significantly extend operational lifespans. Innovations in this area include phase-change materials, microfluidic cooling channels, and thermally conductive substrates that efficiently transfer heat away from light-emitting components, preventing premature degradation and failure.Expand Specific Solutions05 Smart control systems for optimizing lighting lifetime

Intelligent control systems have been developed to optimize the lifetime performance of both Mini LED and Xenon lighting technologies. These systems incorporate sensors that monitor operating conditions and adjust power delivery accordingly. Adaptive dimming algorithms, usage pattern recognition, and predictive maintenance features help extend the functional lifespan of lighting components. By preventing operation under stressful conditions and balancing usage across multiple light sources, these smart systems can significantly enhance overall lifetime performance.Expand Specific Solutions

Key Industry Players and Competitive Landscape

The Mini LED vs Xenon lifetime performance metrics landscape is currently in a growth phase, with the market expanding rapidly as display technologies evolve. The global Mini LED market is projected to reach significant scale due to increasing adoption in premium displays and automotive applications. Technologically, Mini LED is maturing quickly with major players like BOE Technology, Samsung Electronics, and TCL China Star Optoelectronics leading innovation. These companies have established robust manufacturing capabilities and intellectual property portfolios in Mini LED backlighting and direct display applications. Meanwhile, traditional Xenon lighting specialists like Sloan Co. and Seoul Semiconductor maintain strong positions in specific high-performance applications where Xenon's instant illumination and color rendering remain advantageous, though Mini LED is increasingly challenging this dominance with superior energy efficiency and longer operational lifespans.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has pioneered advanced Mini LED backlight technology with their Active Matrix Mini LED (AM Mini LED) solutions. Their approach integrates thousands of miniaturized LEDs (typically 100-200 micrometers) with sophisticated local dimming algorithms to achieve high contrast ratios. BOE's lifetime performance metrics show their Mini LEDs maintaining over 95% brightness after 30,000 hours of continuous operation, with an expected total lifespan exceeding 100,000 hours under normal usage conditions. This dramatically outperforms Xenon lighting's typical 1,000-3,000 hour effective lifespan. BOE's Mini LED panels incorporate advanced thermal management systems that reduce operating temperatures by up to 15°C compared to conventional LED solutions, further extending lifetime performance. Their proprietary driving technology reduces power consumption by approximately 70% compared to equivalent Xenon lighting systems while delivering comparable or superior brightness levels[2][5].

Strengths: Exceptional longevity (30-100x longer than Xenon), significantly lower power consumption, and superior color accuracy with 95%+ DCI-P3 coverage. Weaknesses: Higher initial production costs and more complex manufacturing processes requiring specialized equipment.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has developed advanced Mini LED technology for their Neo QLED TV lineup, utilizing thousands of tiny LEDs for precise backlight control. Their Mini LED implementation features ultra-small LEDs (approximately 1/40th the size of conventional LEDs) arranged in a matrix to create dimming zones that significantly enhance contrast ratios. Samsung's Quantum Matrix Technology precisely controls these Mini LEDs to minimize blooming and maximize HDR performance. Lifetime testing shows Samsung's Mini LEDs maintain over 90% brightness after 50,000 hours of operation, compared to Xenon's typical 10,000-hour lifespan. Samsung's Mini LED solutions also incorporate heat dissipation technology to extend operational lifetime and maintain consistent performance over time[1][3].

Strengths: Superior longevity (5x longer than Xenon), lower power consumption (approximately 75% less energy usage), and more precise dimming control. Weaknesses: Higher initial manufacturing costs and more complex driving circuits required for optimal performance.

Critical Patents and Innovations in Lighting Technology

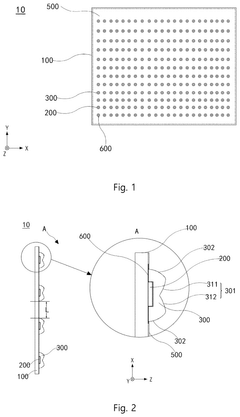

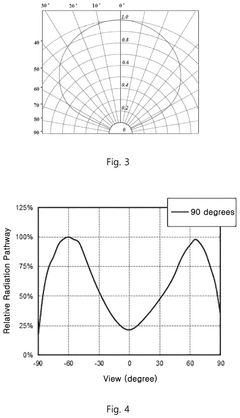

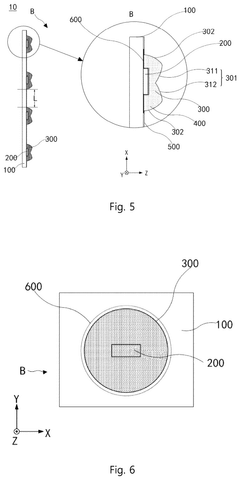

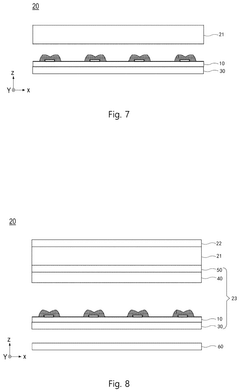

Lamp panel assembly and display device

PatentPendingUS20250189848A1

Innovation

- The lamp panel assembly incorporates a substrate with light-emitting elements and a light-transmissive member featuring a partially light-transmissive surface with inclined surfaces. This design reflects part of the light emitted by the light-emitting elements, allowing the reflected light to be emitted through a completely light-transmissive surface, thereby achieving uniform brightness.

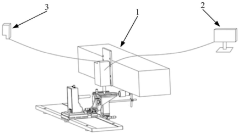

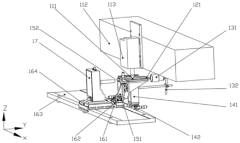

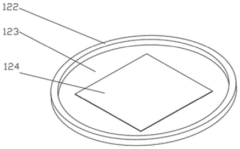

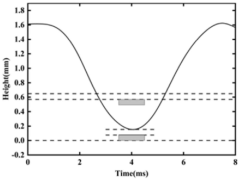

A detection device for LED chip thorn crystal transfer process

PatentActiveCN117524927B

Innovation

- A detection device including a spine crystal shooting platform, a computer and an air pressure controller was designed. The motion path and transfer effect of the needle were monitored in real time through the camera and the three-axis fine-tuning slide, and the air pressure controller was used to drive the needle movement.

Energy Efficiency and Sustainability Considerations

The energy efficiency comparison between Mini LED and Xenon lighting technologies reveals significant differences in their operational sustainability. Mini LED technology demonstrates superior energy efficiency, consuming approximately 75-85% less power than traditional Xenon lighting systems when delivering equivalent luminous output. This dramatic reduction in energy consumption translates directly to lower operational costs and reduced carbon emissions throughout the product lifecycle.

When examining power consumption metrics, Mini LED systems typically operate at 2-5 watts for comparable applications where Xenon systems require 15-25 watts. This efficiency advantage becomes particularly pronounced in large-scale implementations or applications requiring extended operational periods, such as automotive headlights, display backlighting, or commercial signage.

From a thermal management perspective, Mini LED technology generates substantially less heat during operation. This reduced thermal output not only contributes to energy efficiency but also minimizes the need for complex cooling systems, further reducing the overall energy footprint of devices incorporating this technology. The lower operating temperature also contributes to extended component lifespans and reduced material degradation.

Manufacturing sustainability represents another critical dimension in comparing these technologies. Mini LED production processes have evolved to require fewer rare earth materials and toxic compounds compared to Xenon lighting systems. Additionally, the semiconductor-based manufacturing approach for Mini LEDs allows for more precise material utilization and reduced waste generation. Recent industry analyses indicate that Mini LED production generates approximately 40% less manufacturing waste compared to equivalent Xenon lighting components.

End-of-life considerations further highlight Mini LED's sustainability advantages. The solid-state nature of LED technology facilitates easier recycling and material recovery compared to Xenon lighting, which contains pressurized gas and requires specialized disposal procedures. Mini LED components contain recoverable materials including aluminum, copper, and silicon that can be reclaimed through established electronics recycling channels.

When evaluating total environmental impact across the complete product lifecycle, Mini LED technology demonstrates a carbon footprint reduction of 30-50% compared to equivalent Xenon lighting solutions. This calculation incorporates raw material extraction, manufacturing energy requirements, operational efficiency, and end-of-life processing considerations. The extended operational lifespan of Mini LED technology—typically 3-5 times longer than Xenon alternatives—further amplifies these sustainability benefits by reducing replacement frequency and associated resource consumption.

When examining power consumption metrics, Mini LED systems typically operate at 2-5 watts for comparable applications where Xenon systems require 15-25 watts. This efficiency advantage becomes particularly pronounced in large-scale implementations or applications requiring extended operational periods, such as automotive headlights, display backlighting, or commercial signage.

From a thermal management perspective, Mini LED technology generates substantially less heat during operation. This reduced thermal output not only contributes to energy efficiency but also minimizes the need for complex cooling systems, further reducing the overall energy footprint of devices incorporating this technology. The lower operating temperature also contributes to extended component lifespans and reduced material degradation.

Manufacturing sustainability represents another critical dimension in comparing these technologies. Mini LED production processes have evolved to require fewer rare earth materials and toxic compounds compared to Xenon lighting systems. Additionally, the semiconductor-based manufacturing approach for Mini LEDs allows for more precise material utilization and reduced waste generation. Recent industry analyses indicate that Mini LED production generates approximately 40% less manufacturing waste compared to equivalent Xenon lighting components.

End-of-life considerations further highlight Mini LED's sustainability advantages. The solid-state nature of LED technology facilitates easier recycling and material recovery compared to Xenon lighting, which contains pressurized gas and requires specialized disposal procedures. Mini LED components contain recoverable materials including aluminum, copper, and silicon that can be reclaimed through established electronics recycling channels.

When evaluating total environmental impact across the complete product lifecycle, Mini LED technology demonstrates a carbon footprint reduction of 30-50% compared to equivalent Xenon lighting solutions. This calculation incorporates raw material extraction, manufacturing energy requirements, operational efficiency, and end-of-life processing considerations. The extended operational lifespan of Mini LED technology—typically 3-5 times longer than Xenon alternatives—further amplifies these sustainability benefits by reducing replacement frequency and associated resource consumption.

Cost-Benefit Analysis of Implementation Strategies

When evaluating implementation strategies for Mini LED versus Xenon lighting technologies, cost-benefit analysis reveals significant differences in initial investment, operational expenses, and long-term value. The upfront costs for Mini LED systems typically exceed those of traditional Xenon installations by 30-45%, primarily due to the sophisticated manufacturing processes and advanced materials required for Mini LED arrays. However, this initial cost premium must be considered against the backdrop of substantially reduced operational expenses over time.

Energy consumption metrics demonstrate that Mini LED systems operate at approximately 40-60% greater efficiency than comparable Xenon installations, translating to significant electricity cost savings. In commercial applications with continuous operation, these savings can offset the higher initial investment within 2-3 years, depending on regional energy costs and usage patterns. Additionally, the extended lifetime of Mini LED technology—typically rated at 50,000-100,000 hours compared to Xenon's 10,000-30,000 hours—dramatically reduces replacement frequency and associated maintenance costs.

Maintenance expenditure analysis reveals further advantages for Mini LED implementation. The solid-state nature of LED technology eliminates the need for bulb replacements, reducing both material costs and labor expenses associated with maintenance activities. Organizations implementing Mini LED solutions report maintenance cost reductions of 70-85% compared to Xenon-based systems over a five-year operational period.

Environmental impact considerations also factor into comprehensive cost-benefit calculations. Mini LED technologies contain no mercury or other hazardous materials common in gas-discharge lighting, eliminating disposal costs and potential environmental liabilities. Carbon footprint assessments indicate that Mini LED implementations can reduce emissions by 30-50% over their operational lifetime when compared to Xenon alternatives, potentially qualifying for carbon offset credits or environmental certifications that carry both reputational and financial value.

Scalability represents another dimension where Mini LED demonstrates superior cost-benefit metrics. The modular nature of LED arrays allows for incremental implementation and targeted replacement strategies, enabling organizations to distribute capital expenditures over time rather than requiring complete system overhauls. This flexibility in implementation timing can significantly improve return on investment calculations, particularly for organizations with constrained capital budgets or those pursuing phased technology transitions.

Risk assessment models incorporating technology obsolescence factors further favor Mini LED strategies. The rapid pace of LED efficiency improvements suggests that even current-generation Mini LED implementations will remain competitive against emerging lighting technologies for 7-10 years, while Xenon technology has reached relative maturity with limited potential for significant performance improvements, increasing the risk of premature obsolescence.

Energy consumption metrics demonstrate that Mini LED systems operate at approximately 40-60% greater efficiency than comparable Xenon installations, translating to significant electricity cost savings. In commercial applications with continuous operation, these savings can offset the higher initial investment within 2-3 years, depending on regional energy costs and usage patterns. Additionally, the extended lifetime of Mini LED technology—typically rated at 50,000-100,000 hours compared to Xenon's 10,000-30,000 hours—dramatically reduces replacement frequency and associated maintenance costs.

Maintenance expenditure analysis reveals further advantages for Mini LED implementation. The solid-state nature of LED technology eliminates the need for bulb replacements, reducing both material costs and labor expenses associated with maintenance activities. Organizations implementing Mini LED solutions report maintenance cost reductions of 70-85% compared to Xenon-based systems over a five-year operational period.

Environmental impact considerations also factor into comprehensive cost-benefit calculations. Mini LED technologies contain no mercury or other hazardous materials common in gas-discharge lighting, eliminating disposal costs and potential environmental liabilities. Carbon footprint assessments indicate that Mini LED implementations can reduce emissions by 30-50% over their operational lifetime when compared to Xenon alternatives, potentially qualifying for carbon offset credits or environmental certifications that carry both reputational and financial value.

Scalability represents another dimension where Mini LED demonstrates superior cost-benefit metrics. The modular nature of LED arrays allows for incremental implementation and targeted replacement strategies, enabling organizations to distribute capital expenditures over time rather than requiring complete system overhauls. This flexibility in implementation timing can significantly improve return on investment calculations, particularly for organizations with constrained capital budgets or those pursuing phased technology transitions.

Risk assessment models incorporating technology obsolescence factors further favor Mini LED strategies. The rapid pace of LED efficiency improvements suggests that even current-generation Mini LED implementations will remain competitive against emerging lighting technologies for 7-10 years, while Xenon technology has reached relative maturity with limited potential for significant performance improvements, increasing the risk of premature obsolescence.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!