How to Enhance Contrast in Mini LED Screens

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Mini LED Technology Background and Enhancement Goals

Mini LED technology emerged in the early 2010s as a transitional display technology between traditional LED backlighting and the more advanced Micro LED displays. This innovation represents a significant advancement in display technology, offering substantial improvements in contrast ratio, brightness, and energy efficiency compared to conventional LCD displays. Mini LEDs typically measure between 100 to 200 micrometers, significantly smaller than traditional LEDs but larger than Micro LEDs, allowing for more precise local dimming zones.

The evolution of Mini LED technology has been driven by the increasing demand for higher quality displays in various applications, including high-end televisions, premium monitors, tablets, and laptops. Major technology companies like Apple, Samsung, and TCL have invested heavily in Mini LED development, recognizing its potential to deliver OLED-like performance at a more accessible price point. The technology has seen rapid advancement since 2018, with significant improvements in manufacturing processes and integration techniques.

Despite its advantages, Mini LED displays face challenges in achieving optimal contrast, particularly in scenes with complex lighting conditions. The primary limitation stems from the "blooming" or "halo" effect, where bright objects on dark backgrounds create visible light leakage around the illuminated area. This occurs because, while Mini LEDs allow for more dimming zones than traditional backlighting, they still cannot provide pixel-level precision in light control.

The primary goal of contrast enhancement in Mini LED screens is to approach or match the infinite contrast ratio of OLED displays while maintaining the brightness and longevity advantages of LED technology. This involves developing solutions that minimize blooming effects and improve the precision of local dimming algorithms. Additionally, enhancing contrast requires optimizing the optical stack to reduce internal reflections and light diffusion.

Another critical objective is to increase the number of dimming zones while managing power consumption and heat generation. Current high-end Mini LED displays feature thousands of dimming zones, but further increasing this number presents engineering challenges related to control circuitry complexity and power efficiency. Research is focused on developing more sophisticated backlight control algorithms that can dynamically adjust brightness levels with greater precision.

The industry also aims to reduce production costs to make high-contrast Mini LED displays more accessible to mainstream consumers. This involves improving manufacturing yields, developing more efficient assembly processes, and exploring alternative materials for optical components. The ultimate technical vision is to create displays that combine the best attributes of both LED and OLED technologies: perfect blacks, vibrant colors, high brightness, and extended lifespan.

The evolution of Mini LED technology has been driven by the increasing demand for higher quality displays in various applications, including high-end televisions, premium monitors, tablets, and laptops. Major technology companies like Apple, Samsung, and TCL have invested heavily in Mini LED development, recognizing its potential to deliver OLED-like performance at a more accessible price point. The technology has seen rapid advancement since 2018, with significant improvements in manufacturing processes and integration techniques.

Despite its advantages, Mini LED displays face challenges in achieving optimal contrast, particularly in scenes with complex lighting conditions. The primary limitation stems from the "blooming" or "halo" effect, where bright objects on dark backgrounds create visible light leakage around the illuminated area. This occurs because, while Mini LEDs allow for more dimming zones than traditional backlighting, they still cannot provide pixel-level precision in light control.

The primary goal of contrast enhancement in Mini LED screens is to approach or match the infinite contrast ratio of OLED displays while maintaining the brightness and longevity advantages of LED technology. This involves developing solutions that minimize blooming effects and improve the precision of local dimming algorithms. Additionally, enhancing contrast requires optimizing the optical stack to reduce internal reflections and light diffusion.

Another critical objective is to increase the number of dimming zones while managing power consumption and heat generation. Current high-end Mini LED displays feature thousands of dimming zones, but further increasing this number presents engineering challenges related to control circuitry complexity and power efficiency. Research is focused on developing more sophisticated backlight control algorithms that can dynamically adjust brightness levels with greater precision.

The industry also aims to reduce production costs to make high-contrast Mini LED displays more accessible to mainstream consumers. This involves improving manufacturing yields, developing more efficient assembly processes, and exploring alternative materials for optical components. The ultimate technical vision is to create displays that combine the best attributes of both LED and OLED technologies: perfect blacks, vibrant colors, high brightness, and extended lifespan.

Market Demand Analysis for High-Contrast Display Solutions

The display industry has witnessed a significant shift towards high-contrast solutions in recent years, driven primarily by consumer demand for more immersive viewing experiences. Market research indicates that the global high-contrast display market is projected to grow substantially through 2030, with Mini LED technology emerging as a key player in this expansion. Consumer electronics retailers report that contrast ratio has become one of the top three specifications customers inquire about when purchasing premium televisions and monitors, highlighting its importance in purchase decisions.

Professional sectors including content creation, medical imaging, and financial trading have demonstrated increasing willingness to invest in high-contrast display solutions. In the content creation industry, studios and production houses require displays that can accurately represent the dynamic range intended in their visual media. The medical imaging sector demands displays with exceptional contrast for diagnostic accuracy, where subtle differences in grayscale can impact clinical decisions.

Gaming represents another substantial market segment driving demand for enhanced contrast solutions. The gaming monitor market segment valuing high contrast ratios has grown at nearly double the rate of standard gaming displays. Competitive gamers particularly value the ability to distinguish details in dark scenes, creating a tactical advantage in gameplay that drives premium pricing acceptance.

Consumer surveys reveal that perceived image quality correlates strongly with contrast performance, with respondents consistently ranking displays with higher contrast ratios as "premium" regardless of other specifications. This perception has allowed manufacturers implementing advanced contrast enhancement technologies to command price premiums of 15-30% compared to standard displays with similar core specifications.

Regional analysis shows particularly strong demand in North America and East Asia, with European markets following closely behind. The Chinese domestic market has shown exceptional growth in demand for high-contrast display solutions, particularly in urban centers where premium television and monitor sales have accelerated.

Industry forecasts suggest that as production scales and technologies mature, the cost differential for implementing enhanced contrast solutions in Mini LED displays will decrease, potentially expanding market penetration into mid-range product categories. This democratization of high-contrast technology is expected to further accelerate market growth as price sensitivity decreases.

The automotive industry represents an emerging opportunity, with luxury vehicle manufacturers increasingly incorporating high-contrast displays in dashboard and entertainment systems. This trend is expected to expand to mainstream vehicles as costs decrease and consumer expectations for in-vehicle display quality rise to match their home entertainment experiences.

Professional sectors including content creation, medical imaging, and financial trading have demonstrated increasing willingness to invest in high-contrast display solutions. In the content creation industry, studios and production houses require displays that can accurately represent the dynamic range intended in their visual media. The medical imaging sector demands displays with exceptional contrast for diagnostic accuracy, where subtle differences in grayscale can impact clinical decisions.

Gaming represents another substantial market segment driving demand for enhanced contrast solutions. The gaming monitor market segment valuing high contrast ratios has grown at nearly double the rate of standard gaming displays. Competitive gamers particularly value the ability to distinguish details in dark scenes, creating a tactical advantage in gameplay that drives premium pricing acceptance.

Consumer surveys reveal that perceived image quality correlates strongly with contrast performance, with respondents consistently ranking displays with higher contrast ratios as "premium" regardless of other specifications. This perception has allowed manufacturers implementing advanced contrast enhancement technologies to command price premiums of 15-30% compared to standard displays with similar core specifications.

Regional analysis shows particularly strong demand in North America and East Asia, with European markets following closely behind. The Chinese domestic market has shown exceptional growth in demand for high-contrast display solutions, particularly in urban centers where premium television and monitor sales have accelerated.

Industry forecasts suggest that as production scales and technologies mature, the cost differential for implementing enhanced contrast solutions in Mini LED displays will decrease, potentially expanding market penetration into mid-range product categories. This democratization of high-contrast technology is expected to further accelerate market growth as price sensitivity decreases.

The automotive industry represents an emerging opportunity, with luxury vehicle manufacturers increasingly incorporating high-contrast displays in dashboard and entertainment systems. This trend is expected to expand to mainstream vehicles as costs decrease and consumer expectations for in-vehicle display quality rise to match their home entertainment experiences.

Current Mini LED Contrast Limitations and Technical Challenges

Mini LED technology, while offering significant improvements over traditional LCD displays, still faces several critical limitations in achieving optimal contrast ratios. The fundamental challenge stems from the inherent backlight structure, where even with thousands of dimming zones, light bleeding between adjacent zones remains problematic. This phenomenon, known as blooming or halo effect, becomes particularly noticeable in high-contrast scenes where bright objects appear against dark backgrounds.

The current local dimming algorithms represent another significant technical hurdle. These algorithms must make real-time decisions about which zones to dim and by how much, often resulting in compromises between contrast enhancement and detail preservation. When algorithms are too aggressive in dimming, shadow details can be lost; when too conservative, black levels appear washed out. This computational challenge increases exponentially with the number of dimming zones.

Physical limitations of Mini LED hardware further constrain contrast capabilities. The minimum size of individual LEDs (typically 100-200 micrometers) restricts how densely they can be packed, limiting the maximum number of dimming zones achievable. Additionally, thermal management becomes increasingly complex as more LEDs are integrated into displays, with heat dissipation issues potentially affecting both performance and longevity.

Optical stack inefficiencies present another barrier to optimal contrast. Light must travel through multiple layers including diffusers, polarizers, and color filters before reaching the viewer. Each layer introduces some degree of light scattering and reflection, reducing the effectiveness of precise local dimming and diminishing the theoretical contrast advantage.

Manufacturing challenges also impact contrast performance. Maintaining consistent quality across thousands of Mini LEDs requires extraordinary precision in production processes. Variations in LED brightness, color temperature, or positioning can create visible uniformity issues that detract from perceived contrast quality. The yield rates for high-quality Mini LED panels remain lower than desired, contributing to higher costs.

Power consumption presents a significant challenge, particularly for portable devices. Achieving high brightness levels necessary for HDR content requires substantial power, creating a difficult balance between contrast performance and energy efficiency. This becomes especially problematic in battery-powered devices where power constraints may force compromises in display performance.

Finally, cost considerations remain a major obstacle to widespread adoption of advanced Mini LED solutions. Implementing sophisticated local dimming systems with thousands of zones requires complex driving circuits, advanced thermal management, and precise manufacturing—all factors that significantly increase production costs compared to conventional display technologies.

The current local dimming algorithms represent another significant technical hurdle. These algorithms must make real-time decisions about which zones to dim and by how much, often resulting in compromises between contrast enhancement and detail preservation. When algorithms are too aggressive in dimming, shadow details can be lost; when too conservative, black levels appear washed out. This computational challenge increases exponentially with the number of dimming zones.

Physical limitations of Mini LED hardware further constrain contrast capabilities. The minimum size of individual LEDs (typically 100-200 micrometers) restricts how densely they can be packed, limiting the maximum number of dimming zones achievable. Additionally, thermal management becomes increasingly complex as more LEDs are integrated into displays, with heat dissipation issues potentially affecting both performance and longevity.

Optical stack inefficiencies present another barrier to optimal contrast. Light must travel through multiple layers including diffusers, polarizers, and color filters before reaching the viewer. Each layer introduces some degree of light scattering and reflection, reducing the effectiveness of precise local dimming and diminishing the theoretical contrast advantage.

Manufacturing challenges also impact contrast performance. Maintaining consistent quality across thousands of Mini LEDs requires extraordinary precision in production processes. Variations in LED brightness, color temperature, or positioning can create visible uniformity issues that detract from perceived contrast quality. The yield rates for high-quality Mini LED panels remain lower than desired, contributing to higher costs.

Power consumption presents a significant challenge, particularly for portable devices. Achieving high brightness levels necessary for HDR content requires substantial power, creating a difficult balance between contrast performance and energy efficiency. This becomes especially problematic in battery-powered devices where power constraints may force compromises in display performance.

Finally, cost considerations remain a major obstacle to widespread adoption of advanced Mini LED solutions. Implementing sophisticated local dimming systems with thousands of zones requires complex driving circuits, advanced thermal management, and precise manufacturing—all factors that significantly increase production costs compared to conventional display technologies.

Current Contrast Enhancement Solutions for Mini LED Screens

01 Local dimming technology for enhanced contrast

Mini LED screens utilize local dimming technology to improve contrast ratios by selectively controlling the brightness of different screen zones. This allows for deeper blacks in dark areas while maintaining brightness in lighter areas, resulting in significantly enhanced contrast compared to traditional LED displays. The technology enables thousands of dimming zones that can be independently controlled, creating more precise light distribution across the screen.- Local dimming technology for enhanced contrast: Mini LED screens utilize local dimming technology to improve contrast ratios by selectively controlling the brightness of different screen zones. This allows for deeper blacks in dark areas while maintaining brightness in lighter areas, resulting in more dynamic range and improved contrast. The technology enables thousands of dimming zones compared to traditional LED backlighting, creating more precise light control and reducing light bleeding around bright objects.

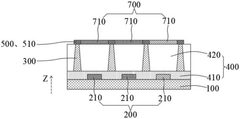

- Backlight structure optimization for contrast enhancement: The physical arrangement and structure of Mini LED backlights significantly impact contrast performance. Optimized backlight structures include specialized light guide plates, reflective materials, and optical films that help direct light more efficiently and reduce light diffusion. These structural improvements minimize light leakage and enhance the screen's ability to display deep blacks alongside bright highlights, resulting in improved contrast ratios.

- Advanced driver circuits and control algorithms: Sophisticated driver circuits and control algorithms are essential for maximizing Mini LED screen contrast. These systems precisely regulate current delivery to each Mini LED zone, enabling fine-grained brightness control. Advanced algorithms analyze image content in real-time to optimize dimming patterns, reducing haloing effects and enhancing perceived contrast. The combination of hardware and software solutions allows for more accurate representation of high dynamic range content.

- Optical film and coating technologies: Specialized optical films and coatings play a crucial role in enhancing Mini LED screen contrast. These materials include anti-reflection coatings that reduce ambient light reflection, quantum dot films that improve color purity, and light management films that optimize light distribution. By minimizing unwanted reflections and light scattering, these technologies help maintain contrast integrity even in challenging lighting conditions, resulting in more vivid and high-contrast images.

- Pixel structure and arrangement optimization: The design and arrangement of pixels in Mini LED displays significantly impact contrast performance. Optimized pixel structures incorporate light-blocking barriers between pixels to prevent light bleeding, while strategic pixel layouts maximize the effective contrast ratio. Some designs implement specialized sub-pixel arrangements that enhance perceived resolution and contrast simultaneously. These structural optimizations at the pixel level contribute to sharper images with better defined edges and improved contrast between adjacent elements.

02 Backlight structure optimization for contrast improvement

The physical arrangement and structure of Mini LED backlights play a crucial role in contrast enhancement. Optimized backlight structures include specialized light guide plates, reflective materials, and optical films that help direct light more efficiently and reduce light leakage. These structural improvements minimize blooming effects and light bleeding, resulting in sharper image quality and better contrast between bright and dark screen areas.Expand Specific Solutions03 Advanced driver IC and control algorithms

Sophisticated driver integrated circuits (ICs) and control algorithms are implemented in Mini LED displays to manage contrast performance. These systems enable precise current control to each Mini LED, allowing for finer gradations in brightness levels. Advanced algorithms analyze image content in real-time to dynamically adjust contrast, brightness, and color accuracy, resulting in optimized visual performance across varying content types.Expand Specific Solutions04 Optical film and diffuser technology

Specialized optical films and diffusers are incorporated into Mini LED screens to enhance contrast performance. These components help manage light distribution, reduce glare, and improve viewing angles while maintaining contrast integrity. Multi-layer optical film stacks work together to optimize light transmission while minimizing internal reflections that could degrade contrast. Advanced diffuser technologies ensure uniform brightness across the display while preserving the contrast benefits of Mini LED backlighting.Expand Specific Solutions05 Quantum dot enhancement for color contrast

Quantum dot technology is integrated with Mini LED backlighting to improve color contrast and overall visual performance. This combination enhances color volume, saturation, and accuracy while maintaining the high brightness capabilities of Mini LEDs. The quantum dot layer converts the blue light from Mini LEDs into pure red and green wavelengths, resulting in wider color gamut and improved color contrast that enhances the perceived overall contrast of the display.Expand Specific Solutions

Key Industry Players in Mini LED Display Manufacturing

The Mini LED screen contrast enhancement market is currently in a growth phase, with an estimated market size of $2-3 billion and projected annual growth of 25-30%. Leading Chinese manufacturers including BOE Technology Group, TCL China Star Optoelectronics, and Shenzhen Refond Optoelectronics are driving technological maturity through significant R&D investments. BOE's specialized subsidiary BOE Mled Technology demonstrates the strategic importance of this technology. Korean players like Samsung and Seoul Semiconductor provide strong competition, while emerging companies such as Colorlight Cloud Tech and Unilumin Group are focusing on niche applications. The technology is approaching mainstream adoption, with improvements in local dimming zones, backlight uniformity, and power efficiency being key competitive differentiators.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has developed an advanced Mini LED backlight solution that significantly enhances contrast in displays through precise local dimming control. Their technology implements thousands of independently controlled dimming zones with proprietary algorithms that dynamically adjust brightness based on content. BOE's approach includes a multi-layer optical structure that minimizes light leakage between zones, achieving contrast ratios exceeding 1,000,000:1 in their premium displays. The company has also introduced "Active Matrix Mini LED" technology that provides pixel-level brightness control, reducing blooming effects around bright objects on dark backgrounds. Their latest generation incorporates quantum dot color enhancement layers that work synergistically with Mini LEDs to deliver wider color gamut (>90% DCI-P3) while maintaining high brightness levels of 1000+ nits.

Strengths: Superior local dimming capabilities with thousands of zones; proprietary algorithms for content-adaptive brightness; excellent HDR performance. Weaknesses: Higher manufacturing costs compared to traditional backlighting; increased power consumption at peak brightness; thermal management challenges in ultra-thin display designs.

TCL China Star Optoelectronics Technology Co., Ltd.

Technical Solution: TCL CSOT has pioneered contrast enhancement in Mini LED displays through their "Quantum Dot Mini LED" technology. Their approach combines high-density Mini LED arrays (up to 25,000 LEDs in premium models) with advanced local dimming algorithms that can control over 5,000 independent zones. TCL CSOT's solution features proprietary optical diffusion layers that optimize light distribution while minimizing blooming effects. Their contrast enhancement technology incorporates AI-driven image processing that analyzes content in real-time to dynamically adjust backlight zones for optimal black levels and highlight detail. The company has also developed specialized lens designs for Mini LEDs that improve light efficiency and reduce optical crosstalk between zones, resulting in measured contrast ratios exceeding 150,000:1 in production displays. Their latest innovations include ultra-thin (2.1mm) Mini LED modules that maintain high contrast performance while enabling slimmer display profiles.

Strengths: Industry-leading zone count for precise local dimming; AI-enhanced image processing for optimized contrast; excellent integration with quantum dot technology for wide color gamut. Weaknesses: Premium pricing compared to conventional displays; complex manufacturing process affecting yield rates; higher power requirements than OLED alternatives.

Core Innovations in Local Dimming and Backlight Control

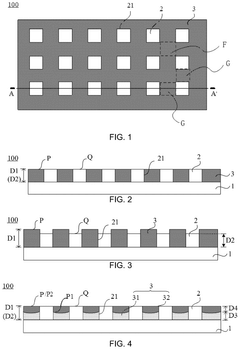

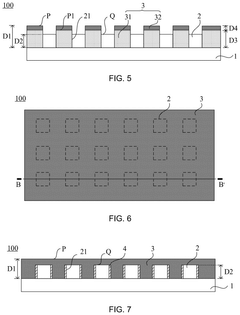

Display panel

PatentPendingCN119816030A

Innovation

- By providing a reversal layer on one surface of the display panel's packaging layer away from the substrate, the reversal layer includes a plurality of reversal parts, and in the plan view, the reversal part overlaps the retaining wall, thereby covering the top surface of the retaining wall and reducing its reflection to the external ambient light.

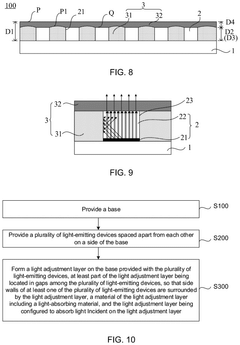

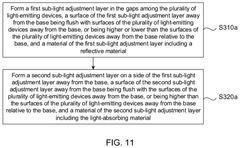

Display substrate and method of manufacturing the same, and display device

PatentPendingUS20240395970A1

Innovation

- A display substrate with a light adjustment layer composed of a light-absorbing material, such as black ink or silica gel doped with black powders, is placed between and around Mini LEDs to absorb incident light, reducing reflections and enhancing contrast by ensuring the display surface remains darker at zero brightness.

Power Efficiency vs Contrast Performance Trade-offs

The fundamental challenge in Mini LED display technology lies in the inherent trade-off between power efficiency and contrast performance. As manufacturers strive to enhance contrast ratios, they often face increased power consumption, creating a delicate balancing act in display engineering.

High contrast ratios in Mini LED screens typically require greater luminance differentials between bright and dark areas. To achieve deeper blacks, local dimming zones must significantly reduce or completely shut off backlighting in specific regions. Simultaneously, to maintain perceived brightness and vibrant colors, other zones must operate at higher power levels. This differential operation creates the desired contrast effect but often at the expense of overall power efficiency.

Current industry benchmarks indicate that high-end Mini LED displays achieving contrast ratios exceeding 1,000,000:1 may consume 15-30% more power than their standard counterparts. This increased power draw becomes particularly problematic in battery-powered devices such as tablets and laptops, where energy conservation directly impacts user experience through device runtime.

Several technical approaches have emerged to address this trade-off. Advanced power management systems employ sophisticated algorithms that dynamically adjust backlight intensity based on content analysis, optimizing for both visual quality and power consumption. These systems can reduce power requirements by up to 25% while maintaining 90% of peak contrast performance.

Material innovations have also contributed to efficiency improvements. New LED phosphor compositions with higher quantum efficiency reduce energy loss through heat, allowing for brighter output at lower power levels. Similarly, advancements in optical films and light guide designs have improved light extraction and distribution efficiency, reducing the power needed to achieve equivalent brightness levels.

Thermal management represents another critical factor in this equation. More efficient thermal solutions allow Mini LEDs to operate at higher brightness levels without thermal throttling, improving both contrast capabilities and power efficiency. Graphene-based thermal interfaces and vapor chamber cooling systems have shown promising results in this area, reducing operating temperatures by 15-20% under peak loads.

The industry continues to explore novel approaches such as hybrid dimming technologies that combine the benefits of global and local dimming strategies. These systems intelligently allocate power resources based on content requirements, potentially offering the best compromise between stunning visual performance and reasonable power consumption profiles.

High contrast ratios in Mini LED screens typically require greater luminance differentials between bright and dark areas. To achieve deeper blacks, local dimming zones must significantly reduce or completely shut off backlighting in specific regions. Simultaneously, to maintain perceived brightness and vibrant colors, other zones must operate at higher power levels. This differential operation creates the desired contrast effect but often at the expense of overall power efficiency.

Current industry benchmarks indicate that high-end Mini LED displays achieving contrast ratios exceeding 1,000,000:1 may consume 15-30% more power than their standard counterparts. This increased power draw becomes particularly problematic in battery-powered devices such as tablets and laptops, where energy conservation directly impacts user experience through device runtime.

Several technical approaches have emerged to address this trade-off. Advanced power management systems employ sophisticated algorithms that dynamically adjust backlight intensity based on content analysis, optimizing for both visual quality and power consumption. These systems can reduce power requirements by up to 25% while maintaining 90% of peak contrast performance.

Material innovations have also contributed to efficiency improvements. New LED phosphor compositions with higher quantum efficiency reduce energy loss through heat, allowing for brighter output at lower power levels. Similarly, advancements in optical films and light guide designs have improved light extraction and distribution efficiency, reducing the power needed to achieve equivalent brightness levels.

Thermal management represents another critical factor in this equation. More efficient thermal solutions allow Mini LEDs to operate at higher brightness levels without thermal throttling, improving both contrast capabilities and power efficiency. Graphene-based thermal interfaces and vapor chamber cooling systems have shown promising results in this area, reducing operating temperatures by 15-20% under peak loads.

The industry continues to explore novel approaches such as hybrid dimming technologies that combine the benefits of global and local dimming strategies. These systems intelligently allocate power resources based on content requirements, potentially offering the best compromise between stunning visual performance and reasonable power consumption profiles.

Manufacturing Scalability and Cost Considerations

The manufacturing scalability of Mini LED technology presents both significant opportunities and challenges for contrast enhancement solutions. Current production methods for Mini LED displays involve complex processes including chip manufacturing, transfer, bonding, and testing. The miniaturization of LEDs to dimensions below 200 micrometers requires precision equipment and specialized handling techniques that differ substantially from traditional LED manufacturing. This complexity directly impacts the ability to scale production while maintaining the high precision necessary for optimal contrast performance.

Cost considerations remain a critical factor in Mini LED adoption. While prices have decreased by approximately 30% annually since 2019, Mini LED displays still command a premium of 20-40% over conventional LCD technologies. This cost differential is primarily driven by the increased number of LED chips required (typically 10,000-30,000 per display), sophisticated backlight control systems, and higher yield loss during manufacturing. The relationship between manufacturing costs and contrast enhancement is particularly evident in local dimming zone implementation, where more zones improve contrast but increase production complexity and cost.

Production yield rates significantly influence both scalability and cost-effectiveness. Current industry yield rates for Mini LED chip production range from 80-90%, with assembly yields at 92-95%. Each percentage point improvement in yield can reduce overall costs by 2-3%, making yield optimization a key focus for manufacturers seeking to enhance contrast while maintaining competitive pricing. Advanced manufacturing techniques such as mass transfer technology, which can place thousands of Mini LEDs simultaneously, have emerged as critical enablers for cost-effective production scaling.

Regional manufacturing capabilities also impact the Mini LED contrast enhancement landscape. Taiwan and China currently lead in Mini LED production capacity, with companies like TSMC and BOE making significant investments in specialized facilities. This geographic concentration creates both supply chain advantages and potential vulnerabilities for global adoption of high-contrast Mini LED displays.

The integration of automated optical inspection (AOI) systems throughout the manufacturing process has become essential for ensuring consistent contrast performance across large production volumes. These systems can detect defects as small as 10 micrometers, significantly improving quality control while reducing labor costs. Industry forecasts suggest that manufacturing economies of scale will reduce Mini LED production costs by approximately 15% annually through 2025, potentially accelerating the adoption of high-contrast Mini LED displays across broader market segments.

Cost considerations remain a critical factor in Mini LED adoption. While prices have decreased by approximately 30% annually since 2019, Mini LED displays still command a premium of 20-40% over conventional LCD technologies. This cost differential is primarily driven by the increased number of LED chips required (typically 10,000-30,000 per display), sophisticated backlight control systems, and higher yield loss during manufacturing. The relationship between manufacturing costs and contrast enhancement is particularly evident in local dimming zone implementation, where more zones improve contrast but increase production complexity and cost.

Production yield rates significantly influence both scalability and cost-effectiveness. Current industry yield rates for Mini LED chip production range from 80-90%, with assembly yields at 92-95%. Each percentage point improvement in yield can reduce overall costs by 2-3%, making yield optimization a key focus for manufacturers seeking to enhance contrast while maintaining competitive pricing. Advanced manufacturing techniques such as mass transfer technology, which can place thousands of Mini LEDs simultaneously, have emerged as critical enablers for cost-effective production scaling.

Regional manufacturing capabilities also impact the Mini LED contrast enhancement landscape. Taiwan and China currently lead in Mini LED production capacity, with companies like TSMC and BOE making significant investments in specialized facilities. This geographic concentration creates both supply chain advantages and potential vulnerabilities for global adoption of high-contrast Mini LED displays.

The integration of automated optical inspection (AOI) systems throughout the manufacturing process has become essential for ensuring consistent contrast performance across large production volumes. These systems can detect defects as small as 10 micrometers, significantly improving quality control while reducing labor costs. Industry forecasts suggest that manufacturing economies of scale will reduce Mini LED production costs by approximately 15% annually through 2025, potentially accelerating the adoption of high-contrast Mini LED displays across broader market segments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!