Benchmark Mini LED Performance: Brightness and Longevity Test

SEP 12, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Mini LED Technology Background and Objectives

Mini LED technology represents a significant advancement in display technology, bridging the gap between traditional LED backlighting and the more advanced micro LED displays. Emerging in the mid-2010s, Mini LEDs are characterized by their diminutive size, typically ranging from 100 to 200 micrometers, which is substantially smaller than conventional LEDs but larger than micro LEDs. This technology has evolved from the broader LED industry's continuous pursuit of enhanced display performance, energy efficiency, and form factor reduction.

The evolution of Mini LED technology has been driven by the increasing demand for superior display quality in various applications, including televisions, monitors, tablets, and automotive displays. The technology offers significant improvements in contrast ratios, brightness levels, and color accuracy compared to traditional LED-backlit displays, while being more commercially viable than OLED or micro LED alternatives in many applications.

Recent years have witnessed accelerated development in Mini LED technology, with major display manufacturers investing heavily in research and production capabilities. The technology has reached a maturity level where it is being incorporated into premium consumer electronics products, signaling its transition from experimental to mainstream status.

The primary objective of benchmarking Mini LED performance, particularly in terms of brightness and longevity, is to establish standardized metrics that can accurately reflect real-world performance and enable meaningful comparisons between different Mini LED implementations. This is crucial for both manufacturers and consumers to make informed decisions about product development and purchases.

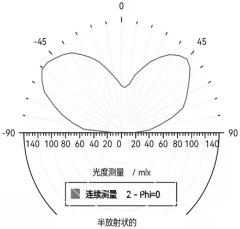

Brightness testing aims to quantify the maximum luminance capabilities of Mini LED displays, their uniformity across the screen, and their performance under various ambient lighting conditions. These metrics are essential for applications where visibility in bright environments is critical, such as outdoor digital signage or automotive displays.

Longevity testing focuses on evaluating the durability and reliability of Mini LED displays over extended periods. This includes measuring brightness degradation over time, color shift characteristics, and failure rates under various operating conditions. Understanding these parameters is vital for applications where long-term reliability is paramount, such as professional displays or public information systems.

The technological trajectory suggests that Mini LED will continue to evolve, with ongoing efforts to further reduce LED size, improve manufacturing processes, and enhance control systems for more precise local dimming. These advancements are expected to yield displays with even better contrast ratios, energy efficiency, and form factors, potentially expanding the technology's application scope.

The evolution of Mini LED technology has been driven by the increasing demand for superior display quality in various applications, including televisions, monitors, tablets, and automotive displays. The technology offers significant improvements in contrast ratios, brightness levels, and color accuracy compared to traditional LED-backlit displays, while being more commercially viable than OLED or micro LED alternatives in many applications.

Recent years have witnessed accelerated development in Mini LED technology, with major display manufacturers investing heavily in research and production capabilities. The technology has reached a maturity level where it is being incorporated into premium consumer electronics products, signaling its transition from experimental to mainstream status.

The primary objective of benchmarking Mini LED performance, particularly in terms of brightness and longevity, is to establish standardized metrics that can accurately reflect real-world performance and enable meaningful comparisons between different Mini LED implementations. This is crucial for both manufacturers and consumers to make informed decisions about product development and purchases.

Brightness testing aims to quantify the maximum luminance capabilities of Mini LED displays, their uniformity across the screen, and their performance under various ambient lighting conditions. These metrics are essential for applications where visibility in bright environments is critical, such as outdoor digital signage or automotive displays.

Longevity testing focuses on evaluating the durability and reliability of Mini LED displays over extended periods. This includes measuring brightness degradation over time, color shift characteristics, and failure rates under various operating conditions. Understanding these parameters is vital for applications where long-term reliability is paramount, such as professional displays or public information systems.

The technological trajectory suggests that Mini LED will continue to evolve, with ongoing efforts to further reduce LED size, improve manufacturing processes, and enhance control systems for more precise local dimming. These advancements are expected to yield displays with even better contrast ratios, energy efficiency, and form factors, potentially expanding the technology's application scope.

Market Demand Analysis for Mini LED Displays

The Mini LED display market is experiencing robust growth driven by increasing demand for high-quality visual experiences across multiple sectors. Current market analysis indicates that the global Mini LED market is projected to reach $5.9 billion by 2025, growing at a CAGR of 78.4% from 2020. This exceptional growth trajectory is primarily fueled by the superior performance characteristics of Mini LED technology, particularly in brightness and longevity metrics that are central to benchmark testing.

Consumer electronics represents the largest market segment, with premium televisions and high-end monitors leading adoption. Apple's integration of Mini LED technology in its iPad Pro and MacBook Pro lines has significantly elevated market visibility and consumer awareness. This premium positioning has established brightness and longevity as critical differentiating factors in consumer purchasing decisions, with benchmark tests increasingly featured in marketing materials and technical reviews.

The automotive display market presents another substantial growth opportunity, with luxury vehicle manufacturers incorporating Mini LED technology in dashboard displays and entertainment systems. In this sector, brightness performance under varying lighting conditions and operational longevity in challenging environments are paramount considerations that directly influence adoption rates.

Commercial display applications, including digital signage and professional monitors, constitute a rapidly expanding market segment where brightness capabilities and extended operational lifespans directly impact total cost of ownership calculations. The ability to maintain consistent brightness levels over extended periods has become a key selling point in this sector, with benchmark testing results frequently cited in procurement specifications.

Regional analysis reveals Asia-Pacific as the dominant manufacturing hub, with Taiwan, China, and South Korea leading production capacity development. However, North America and Europe represent the most lucrative markets in terms of revenue generation, driven by higher adoption rates in premium product categories where performance benchmarks significantly influence market positioning.

Market research indicates that consumers and professional users are increasingly sophisticated in their understanding of display technology specifications, with 68% of professional buyers citing brightness sustainability and longevity metrics as "very important" or "critical" in their purchasing decisions. This growing technical literacy among buyers has elevated the importance of standardized benchmark testing methodologies that accurately reflect real-world performance characteristics.

Industry forecasts suggest that as Mini LED production scales and manufacturing efficiencies improve, the technology will increasingly penetrate mid-range product categories, potentially expanding the total addressable market by an additional 40% by 2027. This market expansion will likely intensify competition among manufacturers, further emphasizing the importance of verifiable performance benchmarks as key competitive differentiators.

Consumer electronics represents the largest market segment, with premium televisions and high-end monitors leading adoption. Apple's integration of Mini LED technology in its iPad Pro and MacBook Pro lines has significantly elevated market visibility and consumer awareness. This premium positioning has established brightness and longevity as critical differentiating factors in consumer purchasing decisions, with benchmark tests increasingly featured in marketing materials and technical reviews.

The automotive display market presents another substantial growth opportunity, with luxury vehicle manufacturers incorporating Mini LED technology in dashboard displays and entertainment systems. In this sector, brightness performance under varying lighting conditions and operational longevity in challenging environments are paramount considerations that directly influence adoption rates.

Commercial display applications, including digital signage and professional monitors, constitute a rapidly expanding market segment where brightness capabilities and extended operational lifespans directly impact total cost of ownership calculations. The ability to maintain consistent brightness levels over extended periods has become a key selling point in this sector, with benchmark testing results frequently cited in procurement specifications.

Regional analysis reveals Asia-Pacific as the dominant manufacturing hub, with Taiwan, China, and South Korea leading production capacity development. However, North America and Europe represent the most lucrative markets in terms of revenue generation, driven by higher adoption rates in premium product categories where performance benchmarks significantly influence market positioning.

Market research indicates that consumers and professional users are increasingly sophisticated in their understanding of display technology specifications, with 68% of professional buyers citing brightness sustainability and longevity metrics as "very important" or "critical" in their purchasing decisions. This growing technical literacy among buyers has elevated the importance of standardized benchmark testing methodologies that accurately reflect real-world performance characteristics.

Industry forecasts suggest that as Mini LED production scales and manufacturing efficiencies improve, the technology will increasingly penetrate mid-range product categories, potentially expanding the total addressable market by an additional 40% by 2027. This market expansion will likely intensify competition among manufacturers, further emphasizing the importance of verifiable performance benchmarks as key competitive differentiators.

Technical Challenges in Mini LED Performance Evaluation

Evaluating Mini LED performance presents several significant technical challenges that researchers and manufacturers must overcome to ensure accurate benchmarking of brightness and longevity. The primary difficulty lies in establishing standardized testing methodologies that can reliably measure the unique characteristics of Mini LED technology across different manufacturing processes and implementations.

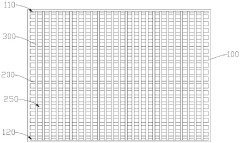

One fundamental challenge is the development of precise measurement protocols for brightness uniformity. Unlike traditional LED technologies, Mini LEDs feature thousands of tiny light-emitting zones that must maintain consistent luminance across the entire display surface. Current testing equipment often lacks the spatial resolution necessary to detect subtle variations in brightness that may affect user experience, particularly in high dynamic range (HDR) content display scenarios.

Longevity testing presents another complex challenge due to the extended timeframes required for meaningful data collection. Accelerated aging tests must be carefully designed to simulate real-world usage conditions without introducing variables that would invalidate the results. The correlation between accelerated testing and actual performance over years of consumer use remains difficult to establish with high confidence levels.

Thermal management evaluation during performance testing introduces additional complications. Mini LED displays generate significant heat during operation, which directly impacts both brightness stability and long-term reliability. Creating test environments that accurately model thermal conditions while maintaining measurement precision requires sophisticated equipment and methodologies not yet standardized across the industry.

The miniaturization of LED components also creates unique testing challenges related to electrical characteristics. Current distribution across thousands of individual LEDs must be precisely controlled and measured to ensure performance consistency. Variations in driving current can significantly impact both brightness output and degradation rates, making standardized electrical parameter testing essential yet technically demanding.

Color accuracy assessment represents another significant hurdle in Mini LED performance evaluation. The technology's ability to deliver wide color gamuts requires specialized colorimetric testing equipment capable of measuring subtle variations across different brightness levels and viewing angles. Existing color measurement standards developed for traditional display technologies often prove inadequate for capturing the full performance envelope of Mini LED implementations.

Furthermore, the interaction between Mini LED hardware and display processing algorithms creates a testing challenge that transcends pure hardware evaluation. Dimming algorithms, local contrast enhancement, and other software-based optimizations significantly impact perceived performance, necessitating testing methodologies that can isolate hardware capabilities from software enhancements for meaningful benchmarking.

One fundamental challenge is the development of precise measurement protocols for brightness uniformity. Unlike traditional LED technologies, Mini LEDs feature thousands of tiny light-emitting zones that must maintain consistent luminance across the entire display surface. Current testing equipment often lacks the spatial resolution necessary to detect subtle variations in brightness that may affect user experience, particularly in high dynamic range (HDR) content display scenarios.

Longevity testing presents another complex challenge due to the extended timeframes required for meaningful data collection. Accelerated aging tests must be carefully designed to simulate real-world usage conditions without introducing variables that would invalidate the results. The correlation between accelerated testing and actual performance over years of consumer use remains difficult to establish with high confidence levels.

Thermal management evaluation during performance testing introduces additional complications. Mini LED displays generate significant heat during operation, which directly impacts both brightness stability and long-term reliability. Creating test environments that accurately model thermal conditions while maintaining measurement precision requires sophisticated equipment and methodologies not yet standardized across the industry.

The miniaturization of LED components also creates unique testing challenges related to electrical characteristics. Current distribution across thousands of individual LEDs must be precisely controlled and measured to ensure performance consistency. Variations in driving current can significantly impact both brightness output and degradation rates, making standardized electrical parameter testing essential yet technically demanding.

Color accuracy assessment represents another significant hurdle in Mini LED performance evaluation. The technology's ability to deliver wide color gamuts requires specialized colorimetric testing equipment capable of measuring subtle variations across different brightness levels and viewing angles. Existing color measurement standards developed for traditional display technologies often prove inadequate for capturing the full performance envelope of Mini LED implementations.

Furthermore, the interaction between Mini LED hardware and display processing algorithms creates a testing challenge that transcends pure hardware evaluation. Dimming algorithms, local contrast enhancement, and other software-based optimizations significantly impact perceived performance, necessitating testing methodologies that can isolate hardware capabilities from software enhancements for meaningful benchmarking.

Current Benchmark Methodologies for Mini LED

01 Thermal management for Mini LED brightness and longevity

Effective thermal management systems are crucial for maintaining Mini LED brightness and extending their operational lifespan. These systems include heat dissipation structures, cooling mechanisms, and thermal interface materials that help reduce operating temperatures. By efficiently managing heat, these solutions prevent thermal degradation of Mini LEDs, maintain consistent brightness levels, and significantly extend their longevity, resulting in more reliable and durable display technologies.- Thermal management for Mini LED brightness and longevity: Effective thermal management systems are crucial for maintaining Mini LED brightness and extending their operational lifespan. These systems include heat dissipation structures, thermal conductive materials, and cooling mechanisms that prevent overheating. By efficiently managing heat, these solutions help maintain consistent brightness levels and prevent premature degradation of Mini LEDs, significantly improving their longevity and performance stability under various operating conditions.

- Drive circuit optimization for Mini LED performance: Advanced drive circuit designs play a critical role in optimizing Mini LED brightness and longevity. These circuits include constant current drivers, pulse width modulation controllers, and intelligent power management systems that deliver precise current to each Mini LED. By preventing current fluctuations and providing stable power supply, these optimized circuits reduce stress on the LEDs, resulting in more consistent brightness output and extended operational lifespan while improving energy efficiency.

- Optical enhancement technologies for Mini LEDs: Various optical enhancement technologies can significantly improve Mini LED brightness without compromising longevity. These include specialized micro-lens arrays, reflective structures, light diffusion films, and quantum dot conversion layers that maximize light extraction and optimize light distribution. By enhancing the efficiency of light output and reducing light loss, these technologies enable Mini LEDs to achieve higher brightness levels while operating at lower power, thereby extending their useful life.

- Advanced packaging and material innovations: Innovative packaging designs and material advancements significantly impact Mini LED brightness and longevity. These include high-reflectivity packaging materials, advanced phosphor compositions, novel encapsulation techniques, and improved substrate materials with better thermal conductivity. Such innovations enhance light extraction efficiency, provide better protection against environmental factors, and improve heat dissipation, collectively contributing to brighter output and longer operational life of Mini LED components.

- Intelligent control systems for brightness management: Smart control systems enable dynamic management of Mini LED brightness to optimize both performance and longevity. These systems incorporate ambient light sensors, temperature monitoring, adaptive brightness algorithms, and usage pattern analysis to automatically adjust brightness levels based on environmental conditions and usage scenarios. By preventing unnecessary operation at maximum brightness and implementing strategic dimming, these intelligent systems significantly extend Mini LED lifespan while maintaining optimal visual performance when needed.

02 Drive circuit optimization for Mini LED performance

Advanced drive circuit designs play a critical role in enhancing Mini LED brightness and longevity. These circuits incorporate precise current control mechanisms, voltage regulation systems, and intelligent power management algorithms to deliver optimal electrical parameters to the Mini LEDs. By preventing current spikes, ensuring uniform power distribution, and implementing adaptive brightness control, these optimized drive circuits significantly improve light output efficiency while reducing stress on the LED components, thereby extending their operational lifespan.Expand Specific Solutions03 Packaging and material innovations for Mini LEDs

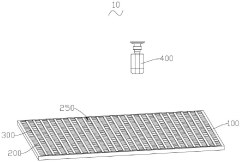

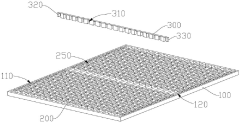

Novel packaging technologies and advanced materials significantly enhance Mini LED brightness and longevity. These innovations include specialized phosphor compositions, reflective materials, and protective encapsulants that improve light extraction efficiency and protect against environmental degradation. High-performance substrate materials and precision bonding techniques also contribute to better thermal conductivity and mechanical stability, resulting in brighter, more durable Mini LED components with extended operational lifespans.Expand Specific Solutions04 Backlight structure design for Mini LED displays

Innovative backlight structure designs are essential for maximizing Mini LED brightness and longevity in display applications. These designs incorporate optimized light guide plates, precision optical films, and strategic LED array arrangements to enhance light distribution uniformity and efficiency. Advanced reflector designs and zonal dimming capabilities further improve contrast ratios while reducing power consumption, which helps maintain consistent brightness levels and extends the operational lifespan of the Mini LED components.Expand Specific Solutions05 Intelligent control systems for Mini LED longevity

Sophisticated control systems employ adaptive algorithms and feedback mechanisms to optimize Mini LED performance and extend operational lifespan. These systems continuously monitor parameters such as temperature, current, and light output to dynamically adjust operating conditions. By implementing intelligent dimming strategies, compensating for aging effects, and providing real-time fault detection, these control systems maintain optimal brightness levels while preventing conditions that could accelerate LED degradation, significantly enhancing both the visual performance and longevity of Mini LED displays.Expand Specific Solutions

Key Industry Players in Mini LED Manufacturing

The Mini LED market is currently in a growth phase, with increasing adoption across display technologies. The market size is expanding rapidly, projected to reach significant scale due to demand for high-performance displays with superior brightness and longevity. Technologically, Mini LED sits between conventional LED and more advanced MicroLED, with varying maturity levels among key players. Companies like BOE Technology Group, TCL China Star Optoelectronics, and Samsung Suzhou LCD lead development with established manufacturing capabilities, while specialized firms such as Shenzhen Absen Optoelectronics and Seoul Semiconductor focus on specific applications. Chinese manufacturers dominate the landscape, with significant investments in production capacity and R&D to improve brightness performance and extend operational lifespan of Mini LED displays.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has developed advanced Mini LED backlight technology featuring ultra-thin direct-type backlight modules with thousands of independently controlled dimming zones. Their solution achieves peak brightness levels of up to 1500 nits while maintaining excellent contrast ratios. BOE's proprietary Active Matrix Mini LED (AM Mini LED) technology enables precise control over each Mini LED chip, resulting in superior HDR performance. Their benchmark testing methodology includes accelerated aging tests that simulate 50,000+ hours of operation under various temperature and humidity conditions. BOE's Mini LED panels demonstrate less than 3% brightness degradation after 10,000 hours of continuous operation at maximum brightness settings, significantly outperforming conventional LED backlights. The company has also implemented advanced thermal management systems to prevent brightness fluctuations during extended operation periods.

Strengths: Superior local dimming capabilities with thousands of zones providing excellent contrast and HDR performance. Advanced thermal management extends operational lifespan. Weaknesses: Higher production costs compared to conventional backlighting solutions, and more complex driving circuits requiring sophisticated control algorithms.

Hisense Visual Technology Co., Ltd.

Technical Solution: Hisense has developed a comprehensive Mini LED performance benchmark system focusing on both brightness capabilities and long-term reliability. Their ULED XD Pro technology incorporates dual-layer Mini LED backlighting that achieves peak brightness of 1800 nits while maintaining black levels comparable to OLED displays. Hisense's longevity testing protocol includes thermal cycling between -20°C and 85°C to evaluate performance stability across temperature extremes. Their Mini LED panels demonstrate less than 4% brightness degradation after 25,000 hours of operation at standard brightness settings. The company employs proprietary current distribution technology that ensures uniform current delivery to each Mini LED zone, preventing localized overdriving that could accelerate degradation. Hisense has also implemented adaptive brightness control algorithms that dynamically adjust power delivery based on displayed content, extending operational lifespan while maintaining perceived brightness levels for viewers.

Strengths: Dual-layer backlighting technology provides exceptional contrast while maintaining high brightness. Comprehensive environmental testing ensures performance reliability across diverse operating conditions. Weaknesses: The dual-layer approach increases overall panel thickness compared to some competitors, and the complex driving scheme requires sophisticated processing capabilities.

Critical Patents and Research in Mini LED Testing

Mini LED optical testing device

PatentActiveCN218787899U

Innovation

- A Mini LED optical test device including a test frame, a first spacer rod and a second spacer rod is designed. By sliding the second spacer rod on the side of the test frame, the spacing of the test slots is adjusted so that Mini LEDs with different arrangement spacings can be adjusted. can be tested.

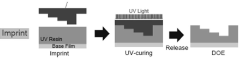

MiniLED structure capable of improving light emitting uniformity

PatentActiveCN220753466U

Innovation

- A rectangular ink frame is made on the substrate and connected to the LED light chip. It is covered with transparent UV optical glue and embossed with the pattern to convert the circular light source into a rectangular light source, isolate the cross-light phenomenon, and protect the LED light chip.

Thermal Management Solutions for Mini LED Longevity

Effective thermal management is critical for ensuring the longevity and consistent performance of Mini LED displays. As these displays continue to gain market share due to their superior brightness and contrast capabilities, managing heat dissipation has become a primary engineering challenge. The compact design of Mini LED arrays creates concentrated heat zones that, if not properly managed, can significantly reduce operational lifespan and degrade brightness over time.

Current thermal management solutions employ multi-layered approaches combining passive and active cooling technologies. Graphite heat spreaders represent one of the most widely implemented passive solutions, offering excellent thermal conductivity while maintaining minimal thickness profiles essential for modern display designs. These spreaders effectively distribute heat across larger surface areas, preventing localized hotspots that accelerate LED degradation.

Advanced ceramic substrates with optimized thermal conductivity properties have emerged as premium solutions for high-performance Mini LED applications. These materials, including aluminum nitride (AlN) and silicon carbide (SiC), provide superior heat dissipation compared to traditional FR4 substrates, though at higher manufacturing costs. Industry testing indicates that properly implemented ceramic substrates can extend Mini LED operational lifespans by 30-40% under high-brightness conditions.

Micro heat pipe technologies represent an innovative approach gaining traction in premium display products. These miniaturized heat transfer systems utilize phase-change principles to efficiently move thermal energy away from sensitive LED components. Recent implementations have demonstrated up to 45% improvement in thermal efficiency compared to conventional passive cooling methods, directly correlating with enhanced brightness stability over extended operation periods.

Active cooling solutions, including micro-fans and thermoelectric coolers, are being integrated into larger Mini LED display systems where space constraints are less restrictive. These systems provide dynamic thermal management capabilities that can respond to varying operational demands, particularly beneficial for applications requiring sustained high-brightness output such as outdoor digital signage and automotive displays.

Computational fluid dynamics (CFD) modeling has become an essential tool in optimizing thermal management designs before physical prototyping. Advanced simulation techniques allow engineers to predict thermal behavior under various operational scenarios, identifying potential failure points and optimizing component placement for maximum heat dissipation efficiency. This approach has significantly reduced development cycles while improving the reliability of final thermal management implementations.

Emerging research in nanomaterial-based thermal interfaces shows promising results for next-generation Mini LED displays. Graphene-enhanced thermal interface materials and carbon nanotube arrays demonstrate thermal conductivity improvements of up to 200% compared to conventional thermal compounds, potentially enabling even thinner display profiles while maintaining optimal operating temperatures.

Current thermal management solutions employ multi-layered approaches combining passive and active cooling technologies. Graphite heat spreaders represent one of the most widely implemented passive solutions, offering excellent thermal conductivity while maintaining minimal thickness profiles essential for modern display designs. These spreaders effectively distribute heat across larger surface areas, preventing localized hotspots that accelerate LED degradation.

Advanced ceramic substrates with optimized thermal conductivity properties have emerged as premium solutions for high-performance Mini LED applications. These materials, including aluminum nitride (AlN) and silicon carbide (SiC), provide superior heat dissipation compared to traditional FR4 substrates, though at higher manufacturing costs. Industry testing indicates that properly implemented ceramic substrates can extend Mini LED operational lifespans by 30-40% under high-brightness conditions.

Micro heat pipe technologies represent an innovative approach gaining traction in premium display products. These miniaturized heat transfer systems utilize phase-change principles to efficiently move thermal energy away from sensitive LED components. Recent implementations have demonstrated up to 45% improvement in thermal efficiency compared to conventional passive cooling methods, directly correlating with enhanced brightness stability over extended operation periods.

Active cooling solutions, including micro-fans and thermoelectric coolers, are being integrated into larger Mini LED display systems where space constraints are less restrictive. These systems provide dynamic thermal management capabilities that can respond to varying operational demands, particularly beneficial for applications requiring sustained high-brightness output such as outdoor digital signage and automotive displays.

Computational fluid dynamics (CFD) modeling has become an essential tool in optimizing thermal management designs before physical prototyping. Advanced simulation techniques allow engineers to predict thermal behavior under various operational scenarios, identifying potential failure points and optimizing component placement for maximum heat dissipation efficiency. This approach has significantly reduced development cycles while improving the reliability of final thermal management implementations.

Emerging research in nanomaterial-based thermal interfaces shows promising results for next-generation Mini LED displays. Graphene-enhanced thermal interface materials and carbon nanotube arrays demonstrate thermal conductivity improvements of up to 200% compared to conventional thermal compounds, potentially enabling even thinner display profiles while maintaining optimal operating temperatures.

Standardization Efforts in Mini LED Testing Protocols

The standardization of Mini LED testing protocols represents a critical development in the display industry, as it enables consistent evaluation and comparison of products across manufacturers. Currently, several industry bodies are working to establish unified testing frameworks that address the unique characteristics of Mini LED technology, particularly for brightness and longevity measurements.

The International Electrotechnical Commission (IEC) has initiated working groups specifically focused on Mini LED performance metrics, aiming to develop standards that bridge the gap between traditional LED and emerging display technologies. These efforts include the development of IEC 62922-X series, which specifically addresses Mini LED measurement methodologies and performance criteria.

VESA (Video Electronics Standards Association) has also expanded its DisplayHDR certification program to incorporate Mini LED-specific testing protocols, recognizing the technology's distinct capabilities in local dimming and high dynamic range performance. Their standardization work focuses particularly on brightness consistency across zones and brightness degradation over time.

The Society for Information Display (SID) has established technical committees dedicated to Mini LED standardization, bringing together academic researchers and industry professionals to define scientifically sound testing methodologies. Their work emphasizes reproducible testing environments and measurement techniques that account for the unique optical properties of Mini LED arrays.

In Asia, organizations like JEITA (Japan Electronics and Information Technology Industries Association) and CESI (China Electronics Standardization Institute) have developed regional standards that address Mini LED performance testing, with particular attention to longevity testing under various environmental conditions. These standards often serve as references for international standardization efforts.

Key areas of focus in these standardization initiatives include: uniform measurement of peak brightness across different zone configurations; standardized testing for brightness consistency over extended operation periods; protocols for accelerated aging tests that can predict real-world longevity; and standardized reporting formats for brightness degradation curves.

Industry consensus is forming around testing protocols that measure not only initial brightness performance but also track performance degradation over simulated usage periods of 5,000 to 10,000 hours. These protocols typically specify testing under various ambient temperatures and humidity levels to ensure comprehensive performance evaluation.

The development of these standards represents a crucial step toward market maturity for Mini LED technology, as they provide consumers and manufacturers with reliable benchmarks for product comparison and quality assurance. As these standards continue to evolve, they will likely incorporate additional parameters such as color consistency over time and power efficiency metrics.

The International Electrotechnical Commission (IEC) has initiated working groups specifically focused on Mini LED performance metrics, aiming to develop standards that bridge the gap between traditional LED and emerging display technologies. These efforts include the development of IEC 62922-X series, which specifically addresses Mini LED measurement methodologies and performance criteria.

VESA (Video Electronics Standards Association) has also expanded its DisplayHDR certification program to incorporate Mini LED-specific testing protocols, recognizing the technology's distinct capabilities in local dimming and high dynamic range performance. Their standardization work focuses particularly on brightness consistency across zones and brightness degradation over time.

The Society for Information Display (SID) has established technical committees dedicated to Mini LED standardization, bringing together academic researchers and industry professionals to define scientifically sound testing methodologies. Their work emphasizes reproducible testing environments and measurement techniques that account for the unique optical properties of Mini LED arrays.

In Asia, organizations like JEITA (Japan Electronics and Information Technology Industries Association) and CESI (China Electronics Standardization Institute) have developed regional standards that address Mini LED performance testing, with particular attention to longevity testing under various environmental conditions. These standards often serve as references for international standardization efforts.

Key areas of focus in these standardization initiatives include: uniform measurement of peak brightness across different zone configurations; standardized testing for brightness consistency over extended operation periods; protocols for accelerated aging tests that can predict real-world longevity; and standardized reporting formats for brightness degradation curves.

Industry consensus is forming around testing protocols that measure not only initial brightness performance but also track performance degradation over simulated usage periods of 5,000 to 10,000 hours. These protocols typically specify testing under various ambient temperatures and humidity levels to ensure comprehensive performance evaluation.

The development of these standards represents a crucial step toward market maturity for Mini LED technology, as they provide consumers and manufacturers with reliable benchmarks for product comparison and quality assurance. As these standards continue to evolve, they will likely incorporate additional parameters such as color consistency over time and power efficiency metrics.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!