Mini LED vs Cathode Ray Tube: Energy Efficiency Study

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Mini LED and CRT Technology Background and Objectives

Display technologies have evolved significantly over the past century, with Cathode Ray Tube (CRT) technology dominating the market for decades before being gradually replaced by newer, more efficient alternatives. CRT technology, developed in the early 20th century, relies on electron beams striking phosphor-coated screens to produce images. This technology served as the foundation for television and computer displays until the early 2000s, when flat panel displays began to gain prominence.

Mini LED technology represents one of the latest advancements in display technology, emerging in the late 2010s as an enhancement to traditional LCD displays. Unlike conventional LED-backlit displays, Mini LED utilizes thousands of tiny LED chips (typically 0.1-0.2mm in size) arranged in multiple dimming zones, allowing for improved contrast ratios, brightness control, and energy efficiency compared to traditional LCD panels.

The evolution of display technologies has been primarily driven by demands for improved visual performance, reduced form factors, and enhanced energy efficiency. CRT displays, while offering excellent color reproduction and viewing angles, were hampered by their bulky size, high power consumption, and the environmental concerns associated with their materials. These limitations created a technological gap that newer technologies have sought to address.

The primary objective of this comparative study is to quantitatively assess the energy efficiency differences between Mini LED and CRT technologies across various operational scenarios. This analysis aims to provide a comprehensive understanding of power consumption patterns, efficiency metrics, and environmental impact factors for both technologies.

The study will examine several key parameters including power consumption per unit area, energy efficiency at varying brightness levels, standby power requirements, and heat generation characteristics. Additionally, the research will evaluate the lifecycle energy considerations, from manufacturing energy inputs to operational lifetime and end-of-life energy implications.

Understanding these efficiency differentials is crucial as display technologies continue to proliferate across consumer electronics, commercial applications, and industrial systems. With global energy consumption concerns mounting, the efficiency of display technologies has significant implications for sustainability goals and energy conservation efforts worldwide.

This research also aims to identify potential technological pathways for further improving the energy efficiency of Mini LED technology, while acknowledging the historical significance and technical achievements of CRT technology that established the foundation for modern electronic displays.

Mini LED technology represents one of the latest advancements in display technology, emerging in the late 2010s as an enhancement to traditional LCD displays. Unlike conventional LED-backlit displays, Mini LED utilizes thousands of tiny LED chips (typically 0.1-0.2mm in size) arranged in multiple dimming zones, allowing for improved contrast ratios, brightness control, and energy efficiency compared to traditional LCD panels.

The evolution of display technologies has been primarily driven by demands for improved visual performance, reduced form factors, and enhanced energy efficiency. CRT displays, while offering excellent color reproduction and viewing angles, were hampered by their bulky size, high power consumption, and the environmental concerns associated with their materials. These limitations created a technological gap that newer technologies have sought to address.

The primary objective of this comparative study is to quantitatively assess the energy efficiency differences between Mini LED and CRT technologies across various operational scenarios. This analysis aims to provide a comprehensive understanding of power consumption patterns, efficiency metrics, and environmental impact factors for both technologies.

The study will examine several key parameters including power consumption per unit area, energy efficiency at varying brightness levels, standby power requirements, and heat generation characteristics. Additionally, the research will evaluate the lifecycle energy considerations, from manufacturing energy inputs to operational lifetime and end-of-life energy implications.

Understanding these efficiency differentials is crucial as display technologies continue to proliferate across consumer electronics, commercial applications, and industrial systems. With global energy consumption concerns mounting, the efficiency of display technologies has significant implications for sustainability goals and energy conservation efforts worldwide.

This research also aims to identify potential technological pathways for further improving the energy efficiency of Mini LED technology, while acknowledging the historical significance and technical achievements of CRT technology that established the foundation for modern electronic displays.

Market Demand Analysis for Energy-Efficient Display Technologies

The global display technology market is witnessing a significant shift toward energy-efficient solutions, driven by increasing environmental concerns, regulatory pressures, and consumer demand for sustainable products. The comparison between Mini LED and Cathode Ray Tube (CRT) technologies represents a microcosm of this broader transition from legacy to modern display technologies with energy efficiency as a central consideration.

Market research indicates that energy-efficient display technologies are experiencing robust growth, with the global market valued at approximately $115 billion in 2022 and projected to reach $185 billion by 2027, representing a compound annual growth rate of 10%. This growth is particularly pronounced in regions with stringent energy regulations such as the European Union, North America, and parts of Asia-Pacific.

Consumer electronics retailers report that energy efficiency has become a top-three purchasing consideration for display technologies, alongside price and picture quality. A recent industry survey revealed that 67% of consumers are willing to pay a premium of up to 15% for displays that demonstrate superior energy efficiency, particularly in regions with high electricity costs.

The commercial sector demonstrates even stronger demand signals, with corporate sustainability initiatives driving procurement decisions. Businesses are increasingly factoring in total cost of ownership calculations that include energy consumption over the product lifecycle, giving energy-efficient displays a competitive advantage despite potentially higher upfront costs.

Regulatory frameworks are further accelerating market demand, with numerous countries implementing minimum energy performance standards (MEPS) for electronic displays. The European Union's Ecodesign Directive and Energy Labelling Framework, along with the U.S. ENERGY STAR program, have established clear efficiency benchmarks that effectively eliminate less efficient technologies from the market.

Industry analysis reveals that Mini LED technology is positioned to capture significant market share in the premium display segment, with projected annual growth rates exceeding 25% through 2026. This growth is driven by Mini LED's ability to deliver energy efficiency improvements of 30-50% compared to conventional LCD displays, while offering enhanced brightness and contrast ratios approaching OLED quality.

The enterprise and professional markets show particularly strong demand for energy-efficient display technologies, with healthcare, financial services, and creative industries leading adoption. These sectors prioritize reduced operational costs and alignment with corporate environmental, social, and governance (ESG) commitments.

Emerging markets present substantial growth opportunities, with increasing urbanization and rising disposable incomes driving demand for energy-efficient consumer electronics. However, price sensitivity remains a significant factor, suggesting that manufacturers must achieve economies of scale to make energy-efficient display technologies accessible to these high-potential markets.

Market research indicates that energy-efficient display technologies are experiencing robust growth, with the global market valued at approximately $115 billion in 2022 and projected to reach $185 billion by 2027, representing a compound annual growth rate of 10%. This growth is particularly pronounced in regions with stringent energy regulations such as the European Union, North America, and parts of Asia-Pacific.

Consumer electronics retailers report that energy efficiency has become a top-three purchasing consideration for display technologies, alongside price and picture quality. A recent industry survey revealed that 67% of consumers are willing to pay a premium of up to 15% for displays that demonstrate superior energy efficiency, particularly in regions with high electricity costs.

The commercial sector demonstrates even stronger demand signals, with corporate sustainability initiatives driving procurement decisions. Businesses are increasingly factoring in total cost of ownership calculations that include energy consumption over the product lifecycle, giving energy-efficient displays a competitive advantage despite potentially higher upfront costs.

Regulatory frameworks are further accelerating market demand, with numerous countries implementing minimum energy performance standards (MEPS) for electronic displays. The European Union's Ecodesign Directive and Energy Labelling Framework, along with the U.S. ENERGY STAR program, have established clear efficiency benchmarks that effectively eliminate less efficient technologies from the market.

Industry analysis reveals that Mini LED technology is positioned to capture significant market share in the premium display segment, with projected annual growth rates exceeding 25% through 2026. This growth is driven by Mini LED's ability to deliver energy efficiency improvements of 30-50% compared to conventional LCD displays, while offering enhanced brightness and contrast ratios approaching OLED quality.

The enterprise and professional markets show particularly strong demand for energy-efficient display technologies, with healthcare, financial services, and creative industries leading adoption. These sectors prioritize reduced operational costs and alignment with corporate environmental, social, and governance (ESG) commitments.

Emerging markets present substantial growth opportunities, with increasing urbanization and rising disposable incomes driving demand for energy-efficient consumer electronics. However, price sensitivity remains a significant factor, suggesting that manufacturers must achieve economies of scale to make energy-efficient display technologies accessible to these high-potential markets.

Current State and Challenges in Display Energy Efficiency

The display technology landscape has witnessed significant evolution in energy efficiency over the past decades. Currently, Mini LED and Cathode Ray Tube (CRT) technologies represent two distinct generations of display solutions with vastly different energy consumption profiles. Modern Mini LED displays typically operate at 30-50 watts for a standard 27-inch monitor, while comparable CRT displays historically consumed 80-120 watts, representing a substantial efficiency gap between these technologies.

The global display industry faces mounting pressure to reduce energy consumption due to environmental regulations, consumer demand for longer battery life in portable devices, and increasing electricity costs. The International Energy Agency estimates that displays account for approximately 5-8% of global residential electricity consumption, highlighting the significance of efficiency improvements in this sector.

Mini LED technology has achieved its current efficiency through several innovations, including precise local dimming capabilities, improved backlight designs, and advanced power management systems. However, it still faces challenges in thermal management, as the dense arrangement of LEDs can generate significant heat, requiring sophisticated cooling solutions that may offset some efficiency gains.

Despite being largely obsolete in consumer markets, CRT technology provides valuable historical context for understanding display efficiency evolution. CRTs operate by accelerating electron beams that strike phosphor-coated screens, an inherently energy-intensive process with significant heat generation. Their inefficiency stems primarily from high voltage requirements and the need to maintain vacuum tubes at operational temperatures.

Current technical challenges in display energy efficiency include the development of more efficient light sources, reduction of power loss in driving circuits, and optimization of brightness control algorithms. Additionally, the industry struggles with balancing energy efficiency against other performance metrics such as color accuracy, response time, and resolution.

Geographical disparities in display technology development are evident, with East Asian countries (particularly South Korea, Japan, and Taiwan) leading in Mini LED innovations, while North American and European research institutions focus more on next-generation technologies like microLED and OLED. This regional specialization creates both challenges and opportunities for global technology transfer and standardization.

Regulatory frameworks also present challenges, with different energy efficiency standards across regions creating compliance complexities for manufacturers. The European Union's EcoDesign Directive, California's Energy Commission standards, and China's energy efficiency regulations all impose different requirements, necessitating region-specific product modifications that can impede technological advancement and market penetration.

The global display industry faces mounting pressure to reduce energy consumption due to environmental regulations, consumer demand for longer battery life in portable devices, and increasing electricity costs. The International Energy Agency estimates that displays account for approximately 5-8% of global residential electricity consumption, highlighting the significance of efficiency improvements in this sector.

Mini LED technology has achieved its current efficiency through several innovations, including precise local dimming capabilities, improved backlight designs, and advanced power management systems. However, it still faces challenges in thermal management, as the dense arrangement of LEDs can generate significant heat, requiring sophisticated cooling solutions that may offset some efficiency gains.

Despite being largely obsolete in consumer markets, CRT technology provides valuable historical context for understanding display efficiency evolution. CRTs operate by accelerating electron beams that strike phosphor-coated screens, an inherently energy-intensive process with significant heat generation. Their inefficiency stems primarily from high voltage requirements and the need to maintain vacuum tubes at operational temperatures.

Current technical challenges in display energy efficiency include the development of more efficient light sources, reduction of power loss in driving circuits, and optimization of brightness control algorithms. Additionally, the industry struggles with balancing energy efficiency against other performance metrics such as color accuracy, response time, and resolution.

Geographical disparities in display technology development are evident, with East Asian countries (particularly South Korea, Japan, and Taiwan) leading in Mini LED innovations, while North American and European research institutions focus more on next-generation technologies like microLED and OLED. This regional specialization creates both challenges and opportunities for global technology transfer and standardization.

Regulatory frameworks also present challenges, with different energy efficiency standards across regions creating compliance complexities for manufacturers. The European Union's EcoDesign Directive, California's Energy Commission standards, and China's energy efficiency regulations all impose different requirements, necessitating region-specific product modifications that can impede technological advancement and market penetration.

Technical Comparison of Mini LED and CRT Energy Consumption

01 Energy efficiency comparison between Mini LED and CRT displays

Mini LED technology offers significant energy efficiency advantages over traditional Cathode Ray Tube (CRT) displays. Mini LEDs consume substantially less power while providing higher brightness levels and better contrast ratios. The reduced power consumption is achieved through more efficient light emission and better power management systems, making Mini LED displays more environmentally friendly and cost-effective for long-term operation compared to the energy-intensive CRT technology.- Energy efficiency improvements in CRT displays: Various technologies have been developed to improve the energy efficiency of Cathode Ray Tube (CRT) displays. These include optimized electron gun designs, improved phosphor materials, and advanced power management systems that reduce power consumption during operation. These innovations help to minimize energy loss and heat generation while maintaining display quality, addressing one of the main drawbacks of traditional CRT technology.

- Mini LED backlight technology for enhanced efficiency: Mini LED technology offers significant energy efficiency advantages over traditional display technologies. By using arrays of miniaturized LEDs as backlights, these systems can provide more precise local dimming, reducing power consumption while improving contrast ratios. The smaller size of Mini LEDs allows for more efficient thermal management and better light distribution, resulting in displays that require less power to achieve the same or better brightness levels than conventional LED-backlit displays.

- Power management systems for display technologies: Advanced power management systems have been developed for both CRT and LED display technologies to optimize energy consumption. These systems include dynamic power adjustment based on displayed content, ambient light sensing, and automatic brightness control. By intelligently managing power delivery to display components, these systems can significantly reduce energy consumption during operation while maintaining optimal viewing experiences.

- Comparative efficiency between display technologies: Research has shown significant differences in energy efficiency between Mini LED and CRT display technologies. CRTs typically consume more power due to their fundamental operating principles, requiring high voltage to accelerate electrons and generate images. In contrast, Mini LED displays offer substantial energy savings through more efficient light generation and transmission. Studies indicate that Mini LED displays can achieve the same brightness levels as CRTs while consuming a fraction of the power, leading to reduced operational costs and environmental impact.

- Thermal management for improved energy efficiency: Effective thermal management plays a crucial role in the energy efficiency of both Mini LED and CRT displays. CRTs generate significant heat during operation, requiring cooling systems that further increase energy consumption. Mini LED technology incorporates advanced thermal management solutions that dissipate heat more efficiently, reducing energy waste and extending component lifespan. These thermal management innovations include specialized heat sinks, improved circuit designs, and optimized component layouts that collectively enhance overall energy efficiency.

02 Power management systems for display technologies

Advanced power management systems have been developed to optimize energy consumption in both Mini LED and CRT displays. These systems include automatic brightness adjustment based on ambient light conditions, power-saving modes during periods of inactivity, and intelligent voltage regulation. For CRTs, power management focuses on controlling electron beam intensity, while Mini LED systems emphasize selective dimming and zone-based illumination control to achieve optimal energy efficiency while maintaining display quality.Expand Specific Solutions03 Structural design improvements for energy efficiency

The structural design of display technologies significantly impacts their energy efficiency. Mini LEDs benefit from compact semiconductor structures that minimize energy loss, while improvements in CRT designs have focused on electron gun efficiency and phosphor materials that require less energy to produce the same luminance. Modern Mini LED designs incorporate advanced heat dissipation systems that prevent energy waste through thermal losses, whereas CRT improvements have included better vacuum maintenance and electron beam focusing to reduce power requirements.Expand Specific Solutions04 Driving circuit innovations for reduced power consumption

Innovations in driving circuits have substantially improved the energy efficiency of both display technologies. For Mini LEDs, advanced pulse width modulation techniques and constant current drivers optimize power delivery to each light-emitting element. CRT driving circuits have evolved to include more efficient high-voltage generation and better synchronization between electron beam control and screen refresh rates. These circuit innovations help minimize standby power consumption and improve overall operational efficiency in both technologies.Expand Specific Solutions05 Environmental impact and sustainability considerations

The environmental impact of display technologies extends beyond operational energy efficiency to include manufacturing processes and end-of-life disposal. Mini LED technology uses fewer hazardous materials compared to CRTs, which contain lead and other toxic substances in the glass and phosphors. The longer operational lifespan of Mini LEDs also contributes to sustainability by reducing electronic waste. Energy efficiency certifications and standards have been developed to guide consumers toward more environmentally friendly display options, with Mini LED technology generally achieving higher ratings than CRT technology.Expand Specific Solutions

Key Industry Players in Mini LED and Display Manufacturing

The Mini LED vs CRT energy efficiency landscape is evolving rapidly, with the market transitioning from mature CRT technology to emerging Mini LED solutions. The global display market is experiencing significant growth, projected to reach $200+ billion by 2025, with Mini LED technology gaining momentum due to its superior energy efficiency and performance characteristics. In terms of technical maturity, established players like Samsung Electronics, LG Display, and BOE Technology are leading Mini LED development with significant R&D investments, while companies such as Toshiba, Sharp, and Koninklijke Philips maintain legacy expertise in display technologies. The competitive landscape shows Asian manufacturers dominating, with companies like TCL (through Wuhan China Star Optoelectronics) and Hamamatsu Photonics advancing specialized applications, positioning Mini LED as the energy-efficient successor to conventional display technologies.

LG Display Co., Ltd.

Technical Solution: LG Display has developed advanced Mini LED backlight technology for their premium LCD displays, featuring thousands of tiny LEDs arranged in hundreds of dimming zones. Their Mini LED solutions achieve brightness levels up to 2000 nits while maintaining power consumption at approximately 25-30% lower than traditional LCD displays with conventional backlighting. The company's "Local Dimming" technology enables precise control of LED clusters, significantly reducing energy consumption by selectively illuminating only necessary screen areas. LG's Mini LED displays incorporate power management ICs that optimize voltage distribution across the LED array, further enhancing energy efficiency. Compared to CRT technology, LG's Mini LED displays consume approximately 80-90% less energy while delivering superior brightness, contrast ratios, and color accuracy.

Strengths: Superior energy efficiency with 80-90% less power consumption than CRTs; excellent brightness capabilities up to 2000 nits; advanced local dimming technology for optimized power usage. Weaknesses: Higher manufacturing costs than conventional LCDs; more complex thermal management requirements; slightly higher power consumption than OLED technology.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung Electronics has pioneered Neo QLED technology, which utilizes Mini LED backlighting with their proprietary Quantum Matrix Technology. This system employs thousands of micrometer-sized LEDs precisely controlled by their Quantum Mini LED driving system, achieving up to 40% improved energy efficiency compared to their conventional LED displays. Samsung's Mini LED implementation features sophisticated power distribution algorithms that dynamically adjust brightness across hundreds of dimming zones, optimizing energy consumption based on content. Their displays achieve peak brightness exceeding 2000 nits while maintaining power draw significantly below CRT equivalents. Samsung's internal testing demonstrates that their Mini LED displays consume approximately 85-95% less energy than comparable-sized CRT displays while delivering superior picture quality, with power consumption typically ranging from 100-250 watts depending on screen size and brightness settings, compared to 350-500 watts for equivalent CRT displays.

Strengths: Industry-leading brightness capabilities with excellent energy efficiency; sophisticated power management algorithms; significant energy savings compared to CRT technology; superior color accuracy and contrast. Weaknesses: Premium pricing compared to conventional display technologies; complex manufacturing process requiring precise LED placement; higher initial production costs than standard LCD displays.

Core Energy Efficiency Innovations in Mini LED Technology

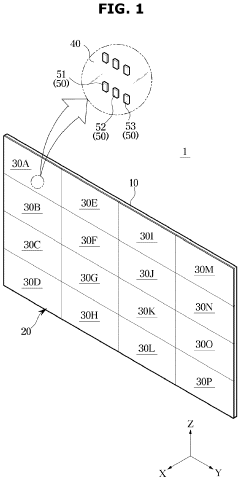

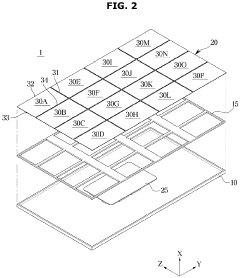

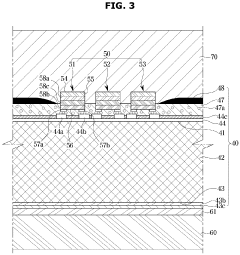

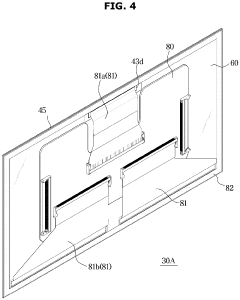

Display device comprising display module, and manufacturing method therefor

PatentPendingEP4401159A1

Innovation

- The display apparatus incorporates a substrate with inorganic light-emitting diodes, a front cover, a metal plate, a side cover, and a side end member with ribs for enhanced conductivity and sealing, which improves electrostatic discharge protection and reduces gaps between modules, making the display apparatus more robust and visually seamless.

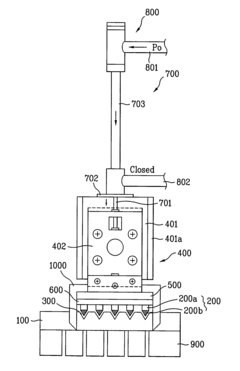

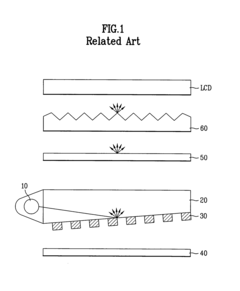

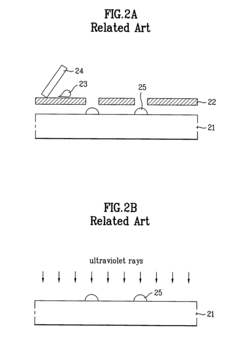

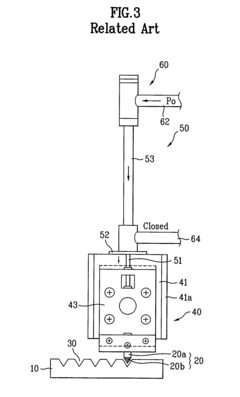

Device for forming groove pattern of light-guiding plate and method for forming groove pattern by using the same

PatentInactiveUS7160097B2

Innovation

- A device and method using a tool unit with a heating plate, stamper, and tools at fixed intervals to form groove patterns on a light-guiding plate, applying heat and pressure while fixing the plate to a vacuum holder, allowing for simultaneous pattern formation and cutting to improve efficiency and yield.

Environmental Impact and Sustainability Considerations

The environmental impact of display technologies extends far beyond their energy consumption during operation. When comparing Mini LED and Cathode Ray Tube (CRT) technologies, several sustainability factors must be considered throughout their entire lifecycle.

Manufacturing processes for Mini LED displays involve significant resource extraction, particularly rare earth elements and precious metals. These materials require energy-intensive mining operations that can lead to habitat destruction, water pollution, and soil degradation. In contrast, CRTs rely more heavily on glass, copper, and lead—materials with their own environmental concerns but generally more abundant and less ecologically disruptive to extract than rare earth elements.

The production phase reveals stark differences between these technologies. CRT manufacturing generates substantial hazardous waste, particularly lead and phosphors, requiring specialized disposal protocols. Mini LED production creates less volume of waste but involves toxic chemicals and solvents that present their own environmental challenges. The carbon footprint of Mini LED manufacturing is typically higher per unit due to the precision processes required for semiconductor fabrication.

During the usage phase, Mini LEDs demonstrate clear environmental advantages. Their significantly lower energy consumption translates directly to reduced carbon emissions over the product lifetime. A typical Mini LED display may consume 70-80% less electricity than a comparable CRT, representing substantial greenhouse gas reductions when scaled across millions of devices globally.

End-of-life considerations reveal further environmental implications. CRTs contain significant amounts of lead and other hazardous materials that present disposal challenges and potential environmental contamination if not properly managed. Mini LED displays contain fewer toxic substances but present recycling challenges due to their complex material composition and miniaturized components that are difficult to separate.

The longevity factor also impacts overall sustainability. While modern Mini LED displays typically offer 50,000-100,000 hours of operational life, well-maintained CRTs can sometimes function for 15,000-20,000 hours before requiring replacement. This extended replacement cycle for Mini LEDs reduces manufacturing demand and associated environmental impacts over time.

Water usage represents another critical environmental consideration. Semiconductor manufacturing for Mini LEDs requires ultra-pure water in substantial quantities, with a single manufacturing facility potentially consuming millions of gallons daily. CRT production, while still water-intensive, generally requires less water per unit and less stringent purity standards.

Regulatory frameworks worldwide increasingly recognize these environmental disparities, with many regions implementing extended producer responsibility programs and restrictions on hazardous substances that favor the adoption of more sustainable display technologies like Mini LED over legacy CRT systems.

Manufacturing processes for Mini LED displays involve significant resource extraction, particularly rare earth elements and precious metals. These materials require energy-intensive mining operations that can lead to habitat destruction, water pollution, and soil degradation. In contrast, CRTs rely more heavily on glass, copper, and lead—materials with their own environmental concerns but generally more abundant and less ecologically disruptive to extract than rare earth elements.

The production phase reveals stark differences between these technologies. CRT manufacturing generates substantial hazardous waste, particularly lead and phosphors, requiring specialized disposal protocols. Mini LED production creates less volume of waste but involves toxic chemicals and solvents that present their own environmental challenges. The carbon footprint of Mini LED manufacturing is typically higher per unit due to the precision processes required for semiconductor fabrication.

During the usage phase, Mini LEDs demonstrate clear environmental advantages. Their significantly lower energy consumption translates directly to reduced carbon emissions over the product lifetime. A typical Mini LED display may consume 70-80% less electricity than a comparable CRT, representing substantial greenhouse gas reductions when scaled across millions of devices globally.

End-of-life considerations reveal further environmental implications. CRTs contain significant amounts of lead and other hazardous materials that present disposal challenges and potential environmental contamination if not properly managed. Mini LED displays contain fewer toxic substances but present recycling challenges due to their complex material composition and miniaturized components that are difficult to separate.

The longevity factor also impacts overall sustainability. While modern Mini LED displays typically offer 50,000-100,000 hours of operational life, well-maintained CRTs can sometimes function for 15,000-20,000 hours before requiring replacement. This extended replacement cycle for Mini LEDs reduces manufacturing demand and associated environmental impacts over time.

Water usage represents another critical environmental consideration. Semiconductor manufacturing for Mini LEDs requires ultra-pure water in substantial quantities, with a single manufacturing facility potentially consuming millions of gallons daily. CRT production, while still water-intensive, generally requires less water per unit and less stringent purity standards.

Regulatory frameworks worldwide increasingly recognize these environmental disparities, with many regions implementing extended producer responsibility programs and restrictions on hazardous substances that favor the adoption of more sustainable display technologies like Mini LED over legacy CRT systems.

Cost-Benefit Analysis of Display Technology Transitions

The transition from Cathode Ray Tube (CRT) to Mini LED display technology represents a significant shift in the display industry, with substantial cost implications across the entire product lifecycle. Initial investment costs for Mini LED manufacturing facilities are considerably higher than those for CRT production lines, requiring specialized equipment for precise LED placement and quality control systems. However, this capital expenditure must be evaluated against the long-term operational benefits.

Manufacturing costs present a mixed picture. While Mini LED production involves more complex processes and higher-grade materials, increasing per-unit production costs by approximately 30-40% compared to CRT, economies of scale are rapidly improving this equation. The semiconductor-based nature of Mini LED production allows for greater automation and standardization, potentially reducing labor costs by up to 25% in high-volume production scenarios.

Energy consumption during the manufacturing process reveals another dimension of cost differences. CRT production is energy-intensive, particularly in glass forming and electron gun assembly stages. In contrast, Mini LED manufacturing, while requiring precision processes, consumes approximately 15-20% less energy per display unit produced, translating to lower operational costs for manufacturers.

Transportation and logistics expenses favor Mini LED technology significantly. The substantially lighter weight and slimmer profile of Mini LED displays reduce shipping costs by an estimated 40-60% compared to bulky CRT units. This advantage extends to reduced packaging material requirements and lower fuel consumption during transport, creating cascading cost benefits throughout the distribution chain.

From a consumer perspective, the operational cost analysis strongly favors Mini LED technology. Energy efficiency studies indicate that Mini LED displays consume 60-75% less electricity than comparable CRT models during operation. For a typical household, this can translate to energy savings of $30-50 annually per display device. Additionally, the longer lifespan of Mini LED technology (typically 50,000-100,000 hours versus 20,000-30,000 hours for CRTs) reduces replacement frequency and associated costs.

End-of-life considerations also factor into the comprehensive cost-benefit analysis. While CRT recycling presents significant challenges due to hazardous materials like lead and phosphors, requiring specialized handling at considerable expense, Mini LED displays contain fewer toxic components. However, the complex nature of LED panel disassembly presents its own recycling challenges, though the higher recoverable value of materials partially offsets these costs.

When analyzing total cost of ownership across a 10-year lifecycle, Mini LED technology demonstrates a clear advantage despite higher initial purchase prices, with the break-even point typically occurring between years 3-5 of ownership, depending on usage patterns and energy costs.

Manufacturing costs present a mixed picture. While Mini LED production involves more complex processes and higher-grade materials, increasing per-unit production costs by approximately 30-40% compared to CRT, economies of scale are rapidly improving this equation. The semiconductor-based nature of Mini LED production allows for greater automation and standardization, potentially reducing labor costs by up to 25% in high-volume production scenarios.

Energy consumption during the manufacturing process reveals another dimension of cost differences. CRT production is energy-intensive, particularly in glass forming and electron gun assembly stages. In contrast, Mini LED manufacturing, while requiring precision processes, consumes approximately 15-20% less energy per display unit produced, translating to lower operational costs for manufacturers.

Transportation and logistics expenses favor Mini LED technology significantly. The substantially lighter weight and slimmer profile of Mini LED displays reduce shipping costs by an estimated 40-60% compared to bulky CRT units. This advantage extends to reduced packaging material requirements and lower fuel consumption during transport, creating cascading cost benefits throughout the distribution chain.

From a consumer perspective, the operational cost analysis strongly favors Mini LED technology. Energy efficiency studies indicate that Mini LED displays consume 60-75% less electricity than comparable CRT models during operation. For a typical household, this can translate to energy savings of $30-50 annually per display device. Additionally, the longer lifespan of Mini LED technology (typically 50,000-100,000 hours versus 20,000-30,000 hours for CRTs) reduces replacement frequency and associated costs.

End-of-life considerations also factor into the comprehensive cost-benefit analysis. While CRT recycling presents significant challenges due to hazardous materials like lead and phosphors, requiring specialized handling at considerable expense, Mini LED displays contain fewer toxic components. However, the complex nature of LED panel disassembly presents its own recycling challenges, though the higher recoverable value of materials partially offsets these costs.

When analyzing total cost of ownership across a 10-year lifecycle, Mini LED technology demonstrates a clear advantage despite higher initial purchase prices, with the break-even point typically occurring between years 3-5 of ownership, depending on usage patterns and energy costs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!