Mini LED vs LCD: Image Quality at USP Comparison

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Mini LED Technology Evolution and Objectives

Mini LED technology represents a significant evolution in display technology, bridging the gap between traditional LCD and OLED displays. The development of Mini LED can be traced back to the early 2010s when manufacturers began exploring ways to enhance LCD performance through improved backlighting systems. This technology emerged as a response to the limitations of conventional LCD displays, particularly in terms of contrast ratio, local dimming capabilities, and color accuracy.

The evolution of Mini LED has been characterized by progressive miniaturization of LED chips used in backlighting. Traditional LCD displays typically utilize LEDs sized at approximately 300-1000 micrometers, whereas Mini LEDs measure between 100-200 micrometers. This reduction in size has enabled manufacturers to pack significantly more LEDs into the same display area, dramatically increasing the number of dimming zones available.

A key milestone in Mini LED development occurred around 2018-2019 when major display manufacturers began commercializing the technology for premium television and monitor segments. The subsequent years witnessed rapid adoption across various product categories, including laptops, tablets, and professional monitors, as production costs decreased and manufacturing processes improved.

The primary technical objective of Mini LED technology is to approach the image quality advantages of OLED displays while maintaining the brightness capabilities and longevity of LCD technology. Specifically, Mini LED aims to deliver superior contrast ratios through enhanced local dimming, with thousands of individually controlled lighting zones compared to the dozens or hundreds found in conventional full-array local dimming LCDs.

Another critical objective is the achievement of deeper black levels, which has traditionally been a weakness of LCD technology. By allowing more precise control over backlight illumination, Mini LED significantly reduces light leakage in dark scenes, resulting in improved perceived contrast and image depth.

Color performance enhancement represents another important goal, with Mini LED technology enabling wider color gamuts and more accurate color reproduction through improved backlighting uniformity and precision. This is particularly valuable for professional applications requiring color-critical work.

The technology also addresses peak brightness capabilities, with Mini LED displays capable of achieving significantly higher brightness levels than OLED alternatives. This provides a distinct advantage for HDR content display and usage in brightly lit environments where screen visibility is paramount.

Looking forward, the technological roadmap for Mini LED includes further miniaturization toward Micro LED technology, increased dimming zone density, improved power efficiency, and cost reduction to enable broader market adoption across mid-range product segments.

The evolution of Mini LED has been characterized by progressive miniaturization of LED chips used in backlighting. Traditional LCD displays typically utilize LEDs sized at approximately 300-1000 micrometers, whereas Mini LEDs measure between 100-200 micrometers. This reduction in size has enabled manufacturers to pack significantly more LEDs into the same display area, dramatically increasing the number of dimming zones available.

A key milestone in Mini LED development occurred around 2018-2019 when major display manufacturers began commercializing the technology for premium television and monitor segments. The subsequent years witnessed rapid adoption across various product categories, including laptops, tablets, and professional monitors, as production costs decreased and manufacturing processes improved.

The primary technical objective of Mini LED technology is to approach the image quality advantages of OLED displays while maintaining the brightness capabilities and longevity of LCD technology. Specifically, Mini LED aims to deliver superior contrast ratios through enhanced local dimming, with thousands of individually controlled lighting zones compared to the dozens or hundreds found in conventional full-array local dimming LCDs.

Another critical objective is the achievement of deeper black levels, which has traditionally been a weakness of LCD technology. By allowing more precise control over backlight illumination, Mini LED significantly reduces light leakage in dark scenes, resulting in improved perceived contrast and image depth.

Color performance enhancement represents another important goal, with Mini LED technology enabling wider color gamuts and more accurate color reproduction through improved backlighting uniformity and precision. This is particularly valuable for professional applications requiring color-critical work.

The technology also addresses peak brightness capabilities, with Mini LED displays capable of achieving significantly higher brightness levels than OLED alternatives. This provides a distinct advantage for HDR content display and usage in brightly lit environments where screen visibility is paramount.

Looking forward, the technological roadmap for Mini LED includes further miniaturization toward Micro LED technology, increased dimming zone density, improved power efficiency, and cost reduction to enable broader market adoption across mid-range product segments.

Market Demand Analysis for High-Resolution Displays

The high-resolution display market has witnessed substantial growth in recent years, driven primarily by increasing consumer demand for superior visual experiences across multiple device categories. Market research indicates that the global high-resolution display market is projected to reach $174 billion by 2027, with a compound annual growth rate exceeding 7.5% from 2022 to 2027. This growth trajectory is particularly evident in premium segments where image quality serves as a critical differentiator.

Consumer preferences have evolved significantly, with surveys revealing that over 65% of smartphone users now consider display quality among their top three purchase decision factors. This represents a marked shift from earlier periods when processing power and camera capabilities dominated consumer priorities. Similar trends are observable in the television and monitor markets, where high-resolution displays have transitioned from luxury features to standard expectations.

The professional sector demonstrates even stronger demand patterns. Design professionals, content creators, and medical imaging specialists increasingly require displays with superior color accuracy, contrast ratios, and resolution. This professional segment is growing at approximately 9% annually, outpacing the consumer market and commanding premium pricing for advanced display technologies.

Regional analysis reveals varying adoption rates and preferences. North American and European markets show stronger preference for premium display technologies with emphasis on color accuracy and contrast, while Asian markets demonstrate higher sensitivity to resolution specifications and brightness capabilities. Emerging markets are experiencing accelerated adoption rates as manufacturing efficiencies drive down costs of high-resolution technologies.

The Mini LED technology is positioned at a critical intersection of these market demands. Unlike traditional LCD displays, Mini LED backlighting offers significantly improved contrast ratios and brightness levels while maintaining cost advantages over OLED alternatives. Market forecasts suggest Mini LED-equipped devices will capture 24% of the premium display market by 2025, representing a substantial opportunity for manufacturers investing in this technology.

Industry surveys indicate that consumers are willing to pay a 15-20% premium for displays with demonstrably superior image quality, particularly when improvements in contrast ratio and color accuracy are visibly apparent. This price tolerance creates a viable commercial pathway for Mini LED technology adoption despite its higher manufacturing costs compared to standard LCD configurations.

The automotive and enterprise sectors represent emerging high-growth opportunities, with in-vehicle displays and commercial signage increasingly demanding the visual performance characteristics that Mini LED technology can deliver. These sectors are projected to contribute significantly to market expansion beyond traditional consumer electronics applications.

Consumer preferences have evolved significantly, with surveys revealing that over 65% of smartphone users now consider display quality among their top three purchase decision factors. This represents a marked shift from earlier periods when processing power and camera capabilities dominated consumer priorities. Similar trends are observable in the television and monitor markets, where high-resolution displays have transitioned from luxury features to standard expectations.

The professional sector demonstrates even stronger demand patterns. Design professionals, content creators, and medical imaging specialists increasingly require displays with superior color accuracy, contrast ratios, and resolution. This professional segment is growing at approximately 9% annually, outpacing the consumer market and commanding premium pricing for advanced display technologies.

Regional analysis reveals varying adoption rates and preferences. North American and European markets show stronger preference for premium display technologies with emphasis on color accuracy and contrast, while Asian markets demonstrate higher sensitivity to resolution specifications and brightness capabilities. Emerging markets are experiencing accelerated adoption rates as manufacturing efficiencies drive down costs of high-resolution technologies.

The Mini LED technology is positioned at a critical intersection of these market demands. Unlike traditional LCD displays, Mini LED backlighting offers significantly improved contrast ratios and brightness levels while maintaining cost advantages over OLED alternatives. Market forecasts suggest Mini LED-equipped devices will capture 24% of the premium display market by 2025, representing a substantial opportunity for manufacturers investing in this technology.

Industry surveys indicate that consumers are willing to pay a 15-20% premium for displays with demonstrably superior image quality, particularly when improvements in contrast ratio and color accuracy are visibly apparent. This price tolerance creates a viable commercial pathway for Mini LED technology adoption despite its higher manufacturing costs compared to standard LCD configurations.

The automotive and enterprise sectors represent emerging high-growth opportunities, with in-vehicle displays and commercial signage increasingly demanding the visual performance characteristics that Mini LED technology can deliver. These sectors are projected to contribute significantly to market expansion beyond traditional consumer electronics applications.

Technical Challenges in Mini LED vs LCD Implementation

The implementation of Mini LED technology in displays presents several significant technical challenges when compared to traditional LCD technology. One of the primary difficulties lies in the manufacturing process of Mini LEDs themselves. With sizes typically ranging from 50 to 200 micrometers, these components require extremely precise manufacturing techniques to ensure consistency across thousands of individual LEDs in a single display panel.

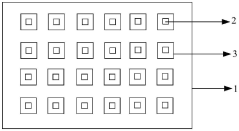

The transfer and placement of Mini LEDs onto the backlight unit demands advanced equipment capable of handling these miniature components with exceptional accuracy. Even minor misalignments can result in visible uniformity issues across the display. This challenge is compounded by the sheer quantity of LEDs required - a high-end Mini LED display may contain tens of thousands of individual light sources that must be precisely positioned.

Thermal management represents another substantial hurdle in Mini LED implementation. Despite their small size, Mini LEDs generate significant heat during operation, particularly when driven at high brightness levels. Without effective thermal dissipation solutions, this can lead to reduced lifespan, color shift, and potential panel damage. Engineers must develop sophisticated heat management systems that maintain optimal operating temperatures without adding excessive bulk to the display.

The driving circuitry for Mini LED backlights introduces additional complexity compared to conventional LCD systems. To achieve the promised advantages in contrast and local dimming, Mini LED displays require sophisticated control systems capable of independently managing thousands of dimming zones. This necessitates more complex circuit designs, increased processing power, and specialized algorithms to prevent artifacts like blooming or haloing around bright objects.

Cost considerations remain a significant barrier to widespread Mini LED adoption. The manufacturing processes involved in producing Mini LEDs at scale, combined with the additional components required for implementation, result in substantially higher production costs compared to traditional LCD technology. This cost differential must be addressed through manufacturing innovations and economies of scale before Mini LED can achieve mainstream market penetration.

Quality control presents unique challenges in Mini LED production. The technology's performance advantages depend on consistent LED behavior across thousands of components. Detecting and replacing defective Mini LEDs during manufacturing requires specialized testing equipment and procedures that add complexity to the production process.

Finally, power efficiency optimization remains an ongoing challenge. While Mini LED backlighting can potentially reduce power consumption through more precise local dimming, the increased number of components and control systems can offset these gains without careful engineering. Balancing brightness capabilities with power efficiency requirements demands sophisticated power management solutions that maximize the technology's energy-saving potential.

The transfer and placement of Mini LEDs onto the backlight unit demands advanced equipment capable of handling these miniature components with exceptional accuracy. Even minor misalignments can result in visible uniformity issues across the display. This challenge is compounded by the sheer quantity of LEDs required - a high-end Mini LED display may contain tens of thousands of individual light sources that must be precisely positioned.

Thermal management represents another substantial hurdle in Mini LED implementation. Despite their small size, Mini LEDs generate significant heat during operation, particularly when driven at high brightness levels. Without effective thermal dissipation solutions, this can lead to reduced lifespan, color shift, and potential panel damage. Engineers must develop sophisticated heat management systems that maintain optimal operating temperatures without adding excessive bulk to the display.

The driving circuitry for Mini LED backlights introduces additional complexity compared to conventional LCD systems. To achieve the promised advantages in contrast and local dimming, Mini LED displays require sophisticated control systems capable of independently managing thousands of dimming zones. This necessitates more complex circuit designs, increased processing power, and specialized algorithms to prevent artifacts like blooming or haloing around bright objects.

Cost considerations remain a significant barrier to widespread Mini LED adoption. The manufacturing processes involved in producing Mini LEDs at scale, combined with the additional components required for implementation, result in substantially higher production costs compared to traditional LCD technology. This cost differential must be addressed through manufacturing innovations and economies of scale before Mini LED can achieve mainstream market penetration.

Quality control presents unique challenges in Mini LED production. The technology's performance advantages depend on consistent LED behavior across thousands of components. Detecting and replacing defective Mini LEDs during manufacturing requires specialized testing equipment and procedures that add complexity to the production process.

Finally, power efficiency optimization remains an ongoing challenge. While Mini LED backlighting can potentially reduce power consumption through more precise local dimming, the increased number of components and control systems can offset these gains without careful engineering. Balancing brightness capabilities with power efficiency requirements demands sophisticated power management solutions that maximize the technology's energy-saving potential.

Current Display Solutions Comparison

01 Mini LED backlight technology for improved contrast and brightness

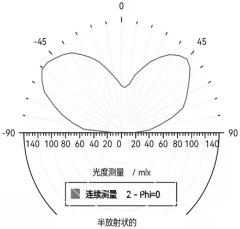

Mini LED backlight technology enhances LCD displays by providing more precise local dimming zones compared to traditional LED backlights. This technology allows for better contrast ratios, higher brightness levels, and improved HDR performance. The smaller size and greater number of LEDs enable more accurate control of light output across different areas of the display, resulting in deeper blacks and brighter highlights.- Mini LED backlight technology for improved contrast and brightness: Mini LED technology uses thousands of tiny LED chips as a backlight source for LCD displays, enabling more precise local dimming zones compared to traditional LED backlighting. This results in significantly improved contrast ratios, deeper blacks, and higher peak brightness levels, enhancing the overall image quality of LCD displays while reducing blooming effects around bright objects.

- Color performance and gamut enhancement in display technologies: Advanced display technologies incorporate improved color management systems and wider color gamuts to enhance image quality. These innovations include quantum dot technology, specialized color filters, and advanced color processing algorithms that enable more accurate color reproduction, higher color saturation, and better color consistency across the display, resulting in more vibrant and lifelike images.

- Display panel structure and optical improvements: Structural and optical enhancements in display panels contribute to superior image quality. These include advanced LCD panel designs with improved pixel structures, optical films that enhance light transmission and viewing angles, and specialized diffusion layers that ensure uniform brightness across the display surface. These improvements result in better clarity, reduced motion blur, and enhanced viewing experiences from multiple angles.

- Power efficiency and thermal management in display systems: Innovative power management and thermal control systems in modern display technologies optimize energy consumption while maintaining high image quality. These systems include adaptive brightness control, intelligent power distribution across dimming zones, and enhanced thermal dissipation designs that prevent performance degradation due to heat. These advancements enable displays to maintain consistent image quality while operating efficiently.

- Image processing algorithms and display drivers: Sophisticated image processing algorithms and display driver technologies enhance the visual output of Mini LED and LCD displays. These include advanced scaling algorithms, motion compensation techniques, HDR processing, and real-time content adaptation. The integration of specialized display processors enables features like dynamic contrast enhancement, noise reduction, and edge enhancement, resulting in clearer, more detailed images with improved motion handling.

02 Color reproduction and gamut enhancement in display technologies

Advanced color management systems in Mini LED and LCD displays enable wider color gamuts and more accurate color reproduction. These technologies incorporate specialized color filters, quantum dot enhancement films, and sophisticated color processing algorithms to achieve more vibrant and true-to-life colors. The improved backlighting from Mini LEDs also contributes to better color volume and consistency across different brightness levels.Expand Specific Solutions03 Display panel structure and optical enhancements

Innovations in panel structure and optical components significantly impact image quality in both Mini LED and LCD displays. These include advanced liquid crystal materials, improved polarizers, anti-reflection coatings, and optical films that enhance light transmission and viewing angles. Specialized diffusion layers help distribute the Mini LED backlight evenly across the display surface, eliminating hotspots and ensuring uniform brightness.Expand Specific Solutions04 Image processing and enhancement algorithms

Sophisticated image processing technologies are employed to maximize the visual quality of Mini LED and LCD displays. These include adaptive contrast enhancement, motion compensation, upscaling algorithms, and noise reduction techniques. Advanced processors analyze content in real-time to optimize brightness, contrast, and color settings for different types of content, resulting in sharper images with better detail preservation in both bright and dark scenes.Expand Specific Solutions05 Power efficiency and thermal management for display quality

Power efficiency and thermal management solutions are critical for maintaining consistent image quality in Mini LED and LCD displays. Advanced power delivery systems ensure stable brightness levels while minimizing energy consumption. Thermal management techniques prevent overheating that could affect color accuracy and panel longevity. Dynamic power adjustment technologies optimize energy usage based on displayed content while preserving visual quality.Expand Specific Solutions

Key Industry Players and Competitive Landscape

The Mini LED vs LCD display technology market is currently in a growth phase, with increasing adoption across premium consumer electronics. The market size is expanding rapidly, driven by demand for enhanced image quality and energy efficiency. Technologically, Mini LED represents a significant advancement over traditional LCD, offering improved contrast ratios and brightness while maintaining cost advantages over OLED. Leading players like Samsung Electronics and BOE Technology Group have achieved considerable maturity in Mini LED technology, with Samsung Display particularly advanced in commercialization. Chinese manufacturers including TCL China Star Optoelectronics and Tianma Microelectronics are rapidly closing the technology gap. Companies like Industrial Technology Research Institute and Rayleigh Vision Intelligence are focusing on next-generation innovations, particularly in mass transfer technologies critical for manufacturing efficiency and cost reduction.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has developed an advanced Mini LED backlight solution that integrates with their high-performance LCD panels. Their technology utilizes Mini LEDs with dimensions ranging from 100-200 micrometers, arranged in a sophisticated matrix pattern to create thousands of independently controlled dimming zones. BOE's implementation features their proprietary Active Matrix Driving Technology that enables precise control of each zone with minimal light leakage between adjacent areas. Their panels achieve peak brightness levels of approximately 1,500-2,000 nits while maintaining excellent color performance through quantum dot enhancement layers that expand the color gamut to over 90% of the DCI-P3 standard. BOE's Mini LED displays incorporate specialized optical films and light guide plates to improve light uniformity and reduce the panel thickness to competitive levels. The company has also developed advanced local dimming algorithms that analyze content in real-time to optimize contrast performance, achieving contrast ratios exceeding 100,000:1 in optimal viewing conditions. BOE's latest Mini LED panels feature response times as low as 4ms, addressing traditional LCD motion handling limitations.

Strengths: Excellent brightness capabilities (1,500-2,000 nits) enabling superior HDR performance; significantly improved contrast over conventional LCDs; good color performance with quantum dot enhancement; competitive manufacturing costs through vertical integration. Weaknesses: Fewer dimming zones than some premium competitors; still exhibits noticeable blooming in challenging contrast scenarios; thicker overall panel design compared to OLED; higher power consumption than self-emissive display technologies.

TCL China Star Optoelectronics Technology Co., Ltd.

Technical Solution: TCL CSOT has pioneered Mini LED backlight technology with their proprietary OD Zero™ (Optical Distance Zero) design, which minimizes the distance between the Mini LED backlight layer and the LCD panel. This approach reduces the overall panel thickness while improving light control precision. Their implementation utilizes Mini LEDs with dimensions under 200 micrometers, arranged in matrices of up to 10,000+ individually controlled dimming zones in premium models. TCL CSOT's Mini LED displays incorporate advanced quantum dot color enhancement technology, delivering over 95% coverage of the DCI-P3 color space with improved color volume at high brightness levels. Their panels achieve peak brightness exceeding 2,000 nits while maintaining excellent uniformity through proprietary optical designs and diffuser technologies. TCL CSOT has developed sophisticated local dimming algorithms that analyze content in real-time, dynamically adjusting each zone to minimize blooming effects while preserving highlight detail. Their latest generation panels feature response times as low as 4ms and support refresh rates up to 144Hz, addressing traditional LCD motion handling limitations.

Strengths: Industry-leading OD Zero™ design creating thinner panels than typical Mini LED implementations; excellent peak brightness capabilities (2,000+ nits); high number of dimming zones providing near-OLED contrast in many scenarios; competitive manufacturing costs through vertical integration. Weaknesses: Still exhibits some blooming in challenging high-contrast scenes; higher power consumption than OLED technology; complex manufacturing process affecting yield rates; slightly less uniform black levels compared to self-emissive displays.

Core Technical Innovations in Mini LED Technology

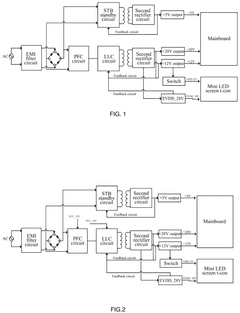

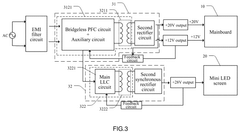

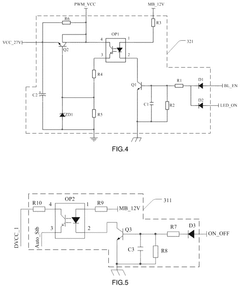

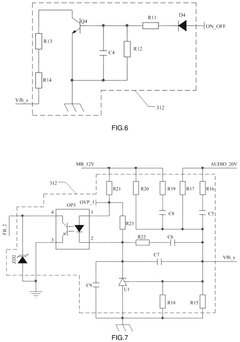

Mini LED driving power supply and mini LED television

PatentActiveUS12131687B2

Innovation

- A Mini-LED driving power supply with a power supply board comprising a first and second conversion module, where the first module outputs +12V and +20V voltages to the mainboard based on a power-on/off signal, and the second module converts high-voltage direct current into +28V for the Mini-LED screen, ensuring independent voltage outputs to prevent interference.

MiniLED structure capable of improving light emitting uniformity

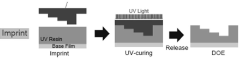

PatentActiveCN220753466U

Innovation

- A rectangular ink frame is made on the substrate and connected to the LED light chip. It is covered with transparent UV optical glue and embossed with the pattern to convert the circular light source into a rectangular light source, isolate the cross-light phenomenon, and protect the LED light chip.

Manufacturing Process Comparison

The manufacturing processes of Mini LED and traditional LCD technologies represent a significant divergence in production complexity, cost structures, and yield rates. Traditional LCD manufacturing has been refined over decades, utilizing mature processes that involve assembling liquid crystal layers between glass substrates with color filters and polarizers. This established manufacturing ecosystem benefits from economies of scale, standardized equipment, and optimized supply chains that contribute to relatively lower production costs.

In contrast, Mini LED backlight technology introduces additional manufacturing challenges due to the miniaturization of LED chips to dimensions typically between 50-200 micrometers. This miniaturization requires precision equipment for handling and placement of thousands of tiny LED chips with extremely tight tolerances. The transfer process from the LED wafer to the backlight unit demands advanced pick-and-place machinery with high accuracy capabilities.

The yield management for Mini LED production presents particular challenges. While traditional LCD manufacturing typically achieves mature yield rates exceeding 90%, Mini LED production currently experiences lower yields, especially during the initial ramp-up phases. The primary yield challenges occur during the chip transfer process and in maintaining consistent performance across thousands of individual LED units within a single display panel.

Production scaling also differs significantly between these technologies. LCD manufacturing benefits from highly automated production lines optimized for high-volume output. Mini LED manufacturing, while increasingly automated, still requires more specialized equipment and quality control processes to manage the complexity of precisely placing thousands of miniaturized light sources.

Cost structures reflect these manufacturing differences. Traditional LCD production costs are dominated by materials (approximately 70-75%), with labor and equipment depreciation accounting for the remainder. Mini LED manufacturing shifts this balance, with higher equipment investment requirements and increased quality control costs representing a larger percentage of the total production expense.

Recent advancements in manufacturing techniques, particularly in mass transfer technologies, are gradually reducing the production cost gap between Mini LED and traditional LCD. Innovations such as simultaneous multi-chip transfer methods and improved testing protocols have enhanced production efficiency for Mini LED displays, though they still command a premium manufacturing cost of approximately 30-40% over comparable LCD panels without Mini LED backlighting.

In contrast, Mini LED backlight technology introduces additional manufacturing challenges due to the miniaturization of LED chips to dimensions typically between 50-200 micrometers. This miniaturization requires precision equipment for handling and placement of thousands of tiny LED chips with extremely tight tolerances. The transfer process from the LED wafer to the backlight unit demands advanced pick-and-place machinery with high accuracy capabilities.

The yield management for Mini LED production presents particular challenges. While traditional LCD manufacturing typically achieves mature yield rates exceeding 90%, Mini LED production currently experiences lower yields, especially during the initial ramp-up phases. The primary yield challenges occur during the chip transfer process and in maintaining consistent performance across thousands of individual LED units within a single display panel.

Production scaling also differs significantly between these technologies. LCD manufacturing benefits from highly automated production lines optimized for high-volume output. Mini LED manufacturing, while increasingly automated, still requires more specialized equipment and quality control processes to manage the complexity of precisely placing thousands of miniaturized light sources.

Cost structures reflect these manufacturing differences. Traditional LCD production costs are dominated by materials (approximately 70-75%), with labor and equipment depreciation accounting for the remainder. Mini LED manufacturing shifts this balance, with higher equipment investment requirements and increased quality control costs representing a larger percentage of the total production expense.

Recent advancements in manufacturing techniques, particularly in mass transfer technologies, are gradually reducing the production cost gap between Mini LED and traditional LCD. Innovations such as simultaneous multi-chip transfer methods and improved testing protocols have enhanced production efficiency for Mini LED displays, though they still command a premium manufacturing cost of approximately 30-40% over comparable LCD panels without Mini LED backlighting.

Energy Efficiency and Environmental Impact

Energy efficiency has emerged as a critical differentiator between Mini LED and traditional LCD display technologies. Mini LED backlight systems demonstrate significantly improved power efficiency compared to conventional LCD displays, primarily due to their more precise local dimming capabilities. This targeted illumination approach allows Mini LED displays to activate only necessary zones, reducing overall power consumption by up to 30% compared to standard LCD panels of equivalent brightness and resolution.

The enhanced energy efficiency of Mini LED technology translates directly into reduced environmental impact throughout the product lifecycle. Manufacturing processes for Mini LED displays have evolved to require fewer rare earth materials than traditional LCD production, with some manufacturers reporting up to 20% reduction in critical mineral usage. This decreased dependence on scarce resources contributes to more sustainable supply chains and reduced extraction impacts.

Heat generation represents another important environmental consideration where Mini LED displays demonstrate superior performance. The localized lighting approach of Mini LED technology generates less waste heat during operation compared to conventional LCD displays that require constant, uniform backlighting. This reduced thermal output not only extends component lifespan but also decreases cooling requirements in devices, creating a cascade of energy savings beyond the display itself.

Carbon footprint assessments conducted by independent environmental research firms indicate that Mini LED displays typically produce 15-25% less carbon emissions over their operational lifetime compared to equivalent LCD panels. This reduction stems from both decreased energy consumption and the extended service life of Mini LED displays, which typically maintain optimal brightness levels for 20-30% longer than conventional LCDs before requiring replacement.

From a disposal perspective, Mini LED technology presents both advantages and challenges. The increased durability and longevity of Mini LED displays reduce replacement frequency, thereby decreasing electronic waste generation. However, the complex arrangement of thousands of miniaturized LEDs creates new recycling challenges that the industry is actively addressing through specialized recovery processes and design modifications aimed at improving end-of-life disassembly.

Regulatory frameworks worldwide are increasingly recognizing the environmental benefits of more efficient display technologies. Several major markets have introduced energy efficiency standards and environmental certifications that favor Mini LED technology over conventional LCD displays, creating market incentives that accelerate adoption while further driving innovation in sustainable display manufacturing practices.

The enhanced energy efficiency of Mini LED technology translates directly into reduced environmental impact throughout the product lifecycle. Manufacturing processes for Mini LED displays have evolved to require fewer rare earth materials than traditional LCD production, with some manufacturers reporting up to 20% reduction in critical mineral usage. This decreased dependence on scarce resources contributes to more sustainable supply chains and reduced extraction impacts.

Heat generation represents another important environmental consideration where Mini LED displays demonstrate superior performance. The localized lighting approach of Mini LED technology generates less waste heat during operation compared to conventional LCD displays that require constant, uniform backlighting. This reduced thermal output not only extends component lifespan but also decreases cooling requirements in devices, creating a cascade of energy savings beyond the display itself.

Carbon footprint assessments conducted by independent environmental research firms indicate that Mini LED displays typically produce 15-25% less carbon emissions over their operational lifetime compared to equivalent LCD panels. This reduction stems from both decreased energy consumption and the extended service life of Mini LED displays, which typically maintain optimal brightness levels for 20-30% longer than conventional LCDs before requiring replacement.

From a disposal perspective, Mini LED technology presents both advantages and challenges. The increased durability and longevity of Mini LED displays reduce replacement frequency, thereby decreasing electronic waste generation. However, the complex arrangement of thousands of miniaturized LEDs creates new recycling challenges that the industry is actively addressing through specialized recovery processes and design modifications aimed at improving end-of-life disassembly.

Regulatory frameworks worldwide are increasingly recognizing the environmental benefits of more efficient display technologies. Several major markets have introduced energy efficiency standards and environmental certifications that favor Mini LED technology over conventional LCD displays, creating market incentives that accelerate adoption while further driving innovation in sustainable display manufacturing practices.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!