How to Enhance Mini LED Heat Dissipation Techniques

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Mini LED Thermal Management Background and Objectives

Mini LED technology has emerged as a revolutionary advancement in display technology, bridging the gap between traditional LED and OLED displays. Since its commercial introduction around 2019, Mini LED has gained significant traction in premium televisions, high-end monitors, and portable devices due to its superior brightness, contrast ratio, and energy efficiency compared to conventional LCD displays. The technology utilizes LED chips sized between 100-200 micrometers, significantly smaller than traditional LEDs but larger than micro LEDs, allowing for more precise local dimming zones and improved backlight control.

The evolution of Mini LED technology has been driven by the increasing demand for higher display quality in consumer electronics, particularly as content consumption shifts toward higher resolution and HDR formats. However, as display manufacturers push for thinner form factors and higher brightness levels, thermal management has become a critical challenge that threatens to limit the technology's potential. Excessive heat not only reduces the lifespan of LED components but also affects color accuracy, brightness uniformity, and overall display performance.

Current thermal management solutions for Mini LED displays often involve traditional approaches such as heat sinks, thermal pads, and passive cooling techniques. These methods, while functional, are increasingly inadequate as pixel densities increase and device profiles become slimmer. The thermal density in modern Mini LED arrays can exceed 50 W/cm², creating hotspots that conventional cooling methods struggle to address effectively.

The primary objective of enhancing Mini LED heat dissipation techniques is to develop more efficient thermal management solutions that can maintain optimal operating temperatures while accommodating the design constraints of modern display products. This includes reducing thermal resistance pathways, implementing advanced materials with superior thermal conductivity, and exploring active cooling methods that can be integrated into slim form factors.

Another critical goal is to achieve uniform heat distribution across the entire display panel, preventing localized hotspots that can lead to differential aging of LED components and subsequent display inconsistencies. This is particularly challenging in applications requiring high brightness levels, such as automotive displays and outdoor signage, where Mini LEDs may operate at maximum power for extended periods.

The technical objectives also extend to developing cost-effective solutions that can be implemented at scale, as thermal management currently represents a significant portion of manufacturing costs for premium Mini LED displays. Finding the optimal balance between thermal performance, manufacturing complexity, and cost will be essential for broader adoption of Mini LED technology across various product categories and price points.

The evolution of Mini LED technology has been driven by the increasing demand for higher display quality in consumer electronics, particularly as content consumption shifts toward higher resolution and HDR formats. However, as display manufacturers push for thinner form factors and higher brightness levels, thermal management has become a critical challenge that threatens to limit the technology's potential. Excessive heat not only reduces the lifespan of LED components but also affects color accuracy, brightness uniformity, and overall display performance.

Current thermal management solutions for Mini LED displays often involve traditional approaches such as heat sinks, thermal pads, and passive cooling techniques. These methods, while functional, are increasingly inadequate as pixel densities increase and device profiles become slimmer. The thermal density in modern Mini LED arrays can exceed 50 W/cm², creating hotspots that conventional cooling methods struggle to address effectively.

The primary objective of enhancing Mini LED heat dissipation techniques is to develop more efficient thermal management solutions that can maintain optimal operating temperatures while accommodating the design constraints of modern display products. This includes reducing thermal resistance pathways, implementing advanced materials with superior thermal conductivity, and exploring active cooling methods that can be integrated into slim form factors.

Another critical goal is to achieve uniform heat distribution across the entire display panel, preventing localized hotspots that can lead to differential aging of LED components and subsequent display inconsistencies. This is particularly challenging in applications requiring high brightness levels, such as automotive displays and outdoor signage, where Mini LEDs may operate at maximum power for extended periods.

The technical objectives also extend to developing cost-effective solutions that can be implemented at scale, as thermal management currently represents a significant portion of manufacturing costs for premium Mini LED displays. Finding the optimal balance between thermal performance, manufacturing complexity, and cost will be essential for broader adoption of Mini LED technology across various product categories and price points.

Market Demand Analysis for Enhanced Mini LED Cooling Solutions

The Mini LED display market is experiencing robust growth, driven by increasing demand for high-quality visual experiences across multiple sectors. Current market projections indicate that the global Mini LED market is expected to reach 2.9 billion USD by 2025, with a compound annual growth rate of 86.6% from 2020. This exponential growth underscores the critical need for enhanced thermal management solutions, as heat dissipation remains one of the primary challenges limiting Mini LED technology's full potential.

Consumer electronics represents the largest market segment for Mini LED applications, with premium televisions, high-end monitors, and tablets leading adoption. Apple's integration of Mini LED technology in iPad Pro and MacBook Pro models has significantly raised consumer awareness and expectations. Market research indicates that consumers are willing to pay a premium of 15-20% for displays with superior brightness, contrast, and longevity—all attributes directly impacted by effective heat management.

The automotive industry presents another rapidly expanding market for Mini LED technology, particularly for dashboard displays and infotainment systems. With the automotive display market projected to grow at 8.5% annually through 2026, manufacturers are seeking thermal solutions that can withstand the harsh operating conditions of vehicles while maintaining display performance and longevity.

Commercial and industrial applications constitute a third significant market segment, with digital signage, control room displays, and specialized medical monitors requiring increasingly sophisticated thermal management. In these applications, continuous operation under varying environmental conditions places extreme demands on cooling systems, with operational reliability being paramount.

Market feedback indicates several specific demands driving innovation in Mini LED cooling solutions. First, there is strong pressure for thinner display profiles, with consumer electronics manufacturers targeting overall thickness reductions of 10-15% in next-generation products. This dimensional constraint severely limits traditional cooling approaches and necessitates novel thermal management techniques.

Energy efficiency represents another critical market demand, with both regulatory pressures and consumer preferences driving manufacturers to reduce power consumption. Enhanced thermal management directly contributes to this goal by improving LED efficiency and reducing the need for active cooling systems that consume additional power.

Reliability metrics show that operating temperature directly correlates with Mini LED lifespan, with each 10°C reduction potentially extending operational life by 30-50%. This longevity benefit translates to significant value for end-users in all market segments, creating strong demand for advanced cooling solutions that can maintain optimal operating temperatures under diverse conditions.

Consumer electronics represents the largest market segment for Mini LED applications, with premium televisions, high-end monitors, and tablets leading adoption. Apple's integration of Mini LED technology in iPad Pro and MacBook Pro models has significantly raised consumer awareness and expectations. Market research indicates that consumers are willing to pay a premium of 15-20% for displays with superior brightness, contrast, and longevity—all attributes directly impacted by effective heat management.

The automotive industry presents another rapidly expanding market for Mini LED technology, particularly for dashboard displays and infotainment systems. With the automotive display market projected to grow at 8.5% annually through 2026, manufacturers are seeking thermal solutions that can withstand the harsh operating conditions of vehicles while maintaining display performance and longevity.

Commercial and industrial applications constitute a third significant market segment, with digital signage, control room displays, and specialized medical monitors requiring increasingly sophisticated thermal management. In these applications, continuous operation under varying environmental conditions places extreme demands on cooling systems, with operational reliability being paramount.

Market feedback indicates several specific demands driving innovation in Mini LED cooling solutions. First, there is strong pressure for thinner display profiles, with consumer electronics manufacturers targeting overall thickness reductions of 10-15% in next-generation products. This dimensional constraint severely limits traditional cooling approaches and necessitates novel thermal management techniques.

Energy efficiency represents another critical market demand, with both regulatory pressures and consumer preferences driving manufacturers to reduce power consumption. Enhanced thermal management directly contributes to this goal by improving LED efficiency and reducing the need for active cooling systems that consume additional power.

Reliability metrics show that operating temperature directly correlates with Mini LED lifespan, with each 10°C reduction potentially extending operational life by 30-50%. This longevity benefit translates to significant value for end-users in all market segments, creating strong demand for advanced cooling solutions that can maintain optimal operating temperatures under diverse conditions.

Current Heat Dissipation Challenges in Mini LED Technology

Mini LED technology, while offering significant advantages in display performance, faces substantial thermal management challenges that limit its full potential. The primary issue stems from the high power density of Mini LED arrays, where thousands of miniaturized light-emitting diodes are packed into compact spaces. These densely arranged LEDs generate considerable heat during operation, with thermal loads often exceeding 50-100 W/cm² in high-brightness applications, creating localized hotspots that can reach temperatures above 120°C without proper thermal management.

The microscale dimensions of Mini LEDs (typically 50-200 micrometers) severely restrict conventional cooling approaches. Traditional heat sinks and thermal interface materials designed for larger LED packages become inefficient at this scale, as the thermal pathways are constrained by the miniaturized architecture. This limitation is particularly problematic in ultra-thin display designs where space for thermal solutions is extremely limited, often less than 1mm in total thickness.

Another significant challenge is the non-uniform heat distribution across Mini LED arrays. The thermal gradient between active and inactive zones can exceed 30°C during dynamic content display, causing differential thermal expansion that stresses interconnects and substrates. This thermal cycling accelerates degradation mechanisms and can lead to premature failure through mechanisms such as solder fatigue and delamination of thermal interface materials.

The thermal resistance at material interfaces presents a critical bottleneck in heat dissipation pathways. Each boundary between different materials in the Mini LED package stack—from the semiconductor junction to the heat sink—introduces thermal resistance that impedes efficient heat transfer. Current thermal interface materials often fail to maintain performance over time, with thermal conductivity degradation of 20-30% observed after extended thermal cycling.

Power efficiency limitations further exacerbate thermal challenges. Despite improvements, Mini LEDs still convert only 30-40% of input power to light, with the remainder dissipated as heat. This inefficiency becomes particularly problematic in battery-powered devices where thermal management must be balanced against power consumption constraints.

Manufacturing inconsistencies also contribute to thermal management difficulties. Variations in die-attach quality can create unpredictable thermal pathways, with thermal resistance variations of up to 15% observed between supposedly identical units. These inconsistencies complicate thermal design and necessitate conservative thermal margins that limit performance potential.

Environmental factors introduce additional complexities, as ambient temperature fluctuations can significantly impact thermal management effectiveness. Systems designed for optimal performance at room temperature may experience thermal runaway under elevated ambient conditions, necessitating dynamic thermal management approaches that add complexity and cost.

The microscale dimensions of Mini LEDs (typically 50-200 micrometers) severely restrict conventional cooling approaches. Traditional heat sinks and thermal interface materials designed for larger LED packages become inefficient at this scale, as the thermal pathways are constrained by the miniaturized architecture. This limitation is particularly problematic in ultra-thin display designs where space for thermal solutions is extremely limited, often less than 1mm in total thickness.

Another significant challenge is the non-uniform heat distribution across Mini LED arrays. The thermal gradient between active and inactive zones can exceed 30°C during dynamic content display, causing differential thermal expansion that stresses interconnects and substrates. This thermal cycling accelerates degradation mechanisms and can lead to premature failure through mechanisms such as solder fatigue and delamination of thermal interface materials.

The thermal resistance at material interfaces presents a critical bottleneck in heat dissipation pathways. Each boundary between different materials in the Mini LED package stack—from the semiconductor junction to the heat sink—introduces thermal resistance that impedes efficient heat transfer. Current thermal interface materials often fail to maintain performance over time, with thermal conductivity degradation of 20-30% observed after extended thermal cycling.

Power efficiency limitations further exacerbate thermal challenges. Despite improvements, Mini LEDs still convert only 30-40% of input power to light, with the remainder dissipated as heat. This inefficiency becomes particularly problematic in battery-powered devices where thermal management must be balanced against power consumption constraints.

Manufacturing inconsistencies also contribute to thermal management difficulties. Variations in die-attach quality can create unpredictable thermal pathways, with thermal resistance variations of up to 15% observed between supposedly identical units. These inconsistencies complicate thermal design and necessitate conservative thermal margins that limit performance potential.

Environmental factors introduce additional complexities, as ambient temperature fluctuations can significantly impact thermal management effectiveness. Systems designed for optimal performance at room temperature may experience thermal runaway under elevated ambient conditions, necessitating dynamic thermal management approaches that add complexity and cost.

Current Heat Dissipation Approaches for Mini LED Displays

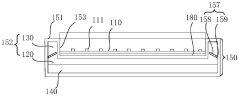

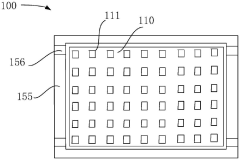

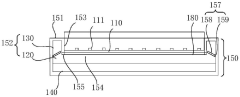

01 Heat sink structures for Mini LED devices

Various heat sink structures can be integrated into Mini LED devices to enhance thermal dissipation. These structures include metal heat sinks, fins, and specialized thermal conductive materials that efficiently transfer heat away from the LED chips. The design of these heat sinks often incorporates increased surface area to maximize heat dissipation efficiency while maintaining compact form factors suitable for Mini LED applications.- Heat dissipation structures for Mini LED displays: Various structural designs are employed in Mini LED displays to enhance heat dissipation efficiency. These include specialized heat sinks, thermal pads, and integrated cooling components that are directly attached to the LED modules. The designs focus on maximizing the contact area between heat-generating components and cooling elements, allowing for more efficient thermal transfer and preventing overheating of the display.

- Thermal management using heat conductive materials: Heat conductive materials play a crucial role in Mini LED thermal management. These materials include high thermal conductivity metals like aluminum and copper, specialized thermal interface materials, and thermally conductive adhesives. These materials create efficient thermal pathways from the LED chips to external heat dissipation structures, significantly improving the overall cooling performance of Mini LED displays.

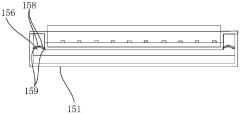

- Active cooling solutions for Mini LED applications: Active cooling technologies are implemented in high-performance Mini LED displays to manage thermal loads. These solutions include miniaturized fans, liquid cooling systems, and thermoelectric coolers that actively remove heat from the LED modules. Active cooling is particularly important in high-brightness applications where passive cooling alone may be insufficient to maintain optimal operating temperatures.

- Integrated circuit and substrate design for thermal management: Advanced circuit and substrate designs are developed specifically for Mini LED thermal management. These include multi-layer PCB designs with embedded thermal vias, specialized substrate materials with high thermal conductivity, and optimized circuit layouts that distribute heat more evenly. The integration of thermal management features directly into the circuit design helps to address heat dissipation at the source.

- Modular and package-level thermal solutions: Package-level thermal management solutions focus on addressing heat dissipation at the LED module or package level. These include specialized LED packaging with integrated heat spreaders, modular heat sink designs that can be customized for different applications, and thermal management systems that consider the entire display assembly. These solutions provide comprehensive thermal management while maintaining the compact form factor required for Mini LED applications.

02 Thermal interface materials and substrates

Specialized thermal interface materials and substrates are employed to improve heat transfer from Mini LED chips to heat dissipation components. These materials include high thermal conductivity ceramics, metal core PCBs, and composite materials designed to minimize thermal resistance. The selection of appropriate substrate materials with optimal thermal properties is crucial for effective heat management in compact Mini LED designs.Expand Specific Solutions03 Active cooling solutions for Mini LED displays

Active cooling technologies are implemented in Mini LED displays to manage thermal loads under high-brightness operations. These solutions include miniaturized fans, liquid cooling systems, and thermoelectric coolers that actively remove heat from critical components. Active cooling approaches are particularly important for high-density Mini LED arrays where passive cooling alone may be insufficient to maintain optimal operating temperatures.Expand Specific Solutions04 Integrated thermal management systems

Comprehensive thermal management systems for Mini LED applications integrate multiple cooling strategies including heat pipes, vapor chambers, and specialized thermal channels. These systems are designed to efficiently distribute and dissipate heat throughout the device, preventing hotspots and ensuring uniform temperature distribution. The integration of these thermal management components is optimized to maintain the slim profile required for modern Mini LED display applications.Expand Specific Solutions05 Structural design optimizations for heat dissipation

Innovative structural designs enhance heat dissipation in Mini LED devices through optimized component arrangement, airflow channels, and thermal path engineering. These designs include specialized housing structures with thermal vents, strategic placement of components to facilitate natural convection, and the use of thermally conductive enclosures. The structural optimizations focus on maximizing heat transfer efficiency while maintaining the compact form factor and aesthetic requirements of Mini LED applications.Expand Specific Solutions

Leading Manufacturers and Suppliers in Mini LED Thermal Solutions

The Mini LED heat dissipation technology market is currently in a growth phase, with an estimated market size of $2-3 billion and projected annual growth of 15-20%. Major display manufacturers including BOE Technology, TCL China Star, HKC, and Hon Hai Precision (Foxconn) are leading technological advancements in this space. The competitive landscape shows varying levels of technical maturity, with companies like Samsung, Sharp, and BOE demonstrating more advanced thermal management solutions through their patented technologies. Industrial Technology Research Institute and specialized LED manufacturers such as Epistar and Harvatek are contributing significant R&D innovations, particularly in substrate materials and thermal interface designs that enhance heat dissipation efficiency while maintaining display performance.

Hon Hai Precision Industry Co., Ltd.

Technical Solution: Hon Hai (Foxconn) has developed a comprehensive Mini LED heat dissipation solution centered around their "Thermal Matrix Architecture." This system employs a combination of micro heat pipes and specialized aluminum-silicon composite heat sinks that offer 40% better thermal conductivity than traditional materials. Their approach includes strategic placement of thermal vias beneath Mini LED arrays to create direct heat dissipation channels. Foxconn has also pioneered an advanced liquid metal thermal interface material specifically formulated for Mini LED applications, which demonstrates 5-8°C lower operating temperatures compared to conventional thermal pastes. The company integrates active cooling elements in their high-brightness display solutions, using miniaturized fans with optimized airflow patterns to enhance convection cooling without increasing device thickness significantly.

Strengths: Comprehensive thermal management approach combining passive and active cooling; advanced materials research with proprietary thermal interface compounds; manufacturing scale advantages for cost-effective implementation. Weaknesses: Active cooling components may introduce reliability concerns over time; higher power consumption in solutions utilizing active cooling elements.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has developed an advanced thermal management system for Mini LED displays that incorporates a multi-layer heat dissipation structure. Their solution utilizes a combination of graphite sheets and vapor chambers to efficiently transfer heat away from the Mini LED chips. The company has implemented a patented "Heat Bridge" technology that creates direct thermal pathways from the LED junction to the heat sink, reducing thermal resistance by approximately 30%. BOE's approach also includes specialized thermal interface materials (TIMs) with high thermal conductivity (>8 W/m·K) to maximize heat transfer between components. Their latest Mini LED backlight units feature optimized circuit designs that distribute heat more evenly across the panel, preventing hotspots and extending the lifespan of the display.

Strengths: Superior thermal efficiency with their multi-layer approach; proprietary "Heat Bridge" technology provides excellent thermal pathways; comprehensive solution addressing both materials and design aspects. Weaknesses: Higher manufacturing complexity may increase production costs; requires precise assembly processes to maintain thermal performance.

Key Thermal Management Patents and Technical Innovations

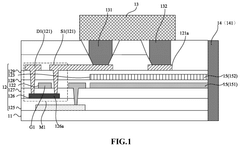

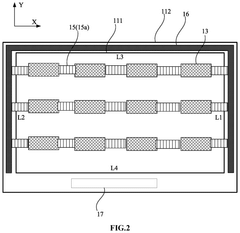

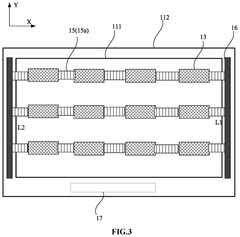

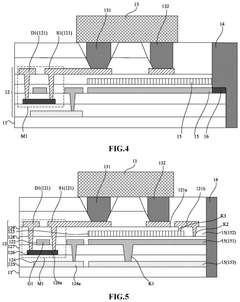

Backlight module and display device

PatentPendingCN117452700A

Innovation

- Design a backlight module that uses a thermal conductive layer and a heat dissipation structure. It utilizes the vaporization and liquefaction cycle of coolant between different air pressure layers to achieve continuous and stable heat dissipation through high and low pressure differences. The coolant vaporizes at low pressure and liquefies at high pressure to form Heat dissipation cycle to improve heat dissipation capacity.

Display panel and display device with enhanced thermal conductivity

PatentActiveUS12107079B2

Innovation

- Incorporating a thermally conductive adhesive and multiple layers of thermally conductive metal on the substrate, which extend to the edges of the display panel, creating a metal heat conduction path for efficient heat dissipation, thereby connecting with the thermally conductive adhesive to radiate heat externally.

Material Science Advancements for Thermal Conductivity

Recent advancements in material science have significantly contributed to enhancing thermal conductivity in Mini LED applications. Traditional thermal management materials like aluminum and copper, while effective, have reached their practical limits for increasingly miniaturized LED displays. The emergence of novel composite materials represents a breakthrough in this domain. Carbon-based materials, particularly graphene and carbon nanotubes, exhibit thermal conductivity values exceeding 2000 W/mK, substantially outperforming conventional metals.

Engineered ceramic compounds have also shown promising results in laboratory settings. Aluminum nitride (AlN) and boron nitride (BN) ceramics demonstrate exceptional thermal properties while maintaining electrical insulation characteristics critical for LED applications. These materials can be integrated into thermal interface materials (TIMs) that reduce contact resistance between heat sources and heat sinks, addressing a major bottleneck in thermal management systems.

Nano-engineered polymers represent another frontier in thermal management materials. By incorporating high thermal conductivity nanoparticles into polymer matrices, researchers have developed flexible thermal interface materials with conductivity values approaching 10 W/mK, a significant improvement over traditional polymer-based solutions. These materials offer the dual advantage of conformability and enhanced heat transfer, making them ideal for complex Mini LED module geometries.

Metal matrix composites (MMCs) combining aluminum or copper with ceramic reinforcements have demonstrated up to 50% improvement in thermal conductivity compared to pure metals. These composites maintain the processability of metals while approaching the thermal performance of more exotic materials, offering a practical middle-ground solution for mass production scenarios.

Phase change materials (PCMs) incorporated into thermal management systems provide additional benefits through their latent heat absorption capabilities. These materials can temporarily absorb heat during peak operation periods, effectively dampening thermal spikes that could otherwise damage sensitive Mini LED components. Recent developments in microencapsulation techniques have addressed previous concerns regarding PCM containment and cycle stability.

Diamond-based thermal materials represent the cutting edge of thermal conductivity research, with theoretical values exceeding 2200 W/mK. While cost prohibitive for widespread application, synthetic diamond films and diamond-loaded composites are finding niche applications in high-performance Mini LED systems where thermal management requirements are particularly demanding.

Engineered ceramic compounds have also shown promising results in laboratory settings. Aluminum nitride (AlN) and boron nitride (BN) ceramics demonstrate exceptional thermal properties while maintaining electrical insulation characteristics critical for LED applications. These materials can be integrated into thermal interface materials (TIMs) that reduce contact resistance between heat sources and heat sinks, addressing a major bottleneck in thermal management systems.

Nano-engineered polymers represent another frontier in thermal management materials. By incorporating high thermal conductivity nanoparticles into polymer matrices, researchers have developed flexible thermal interface materials with conductivity values approaching 10 W/mK, a significant improvement over traditional polymer-based solutions. These materials offer the dual advantage of conformability and enhanced heat transfer, making them ideal for complex Mini LED module geometries.

Metal matrix composites (MMCs) combining aluminum or copper with ceramic reinforcements have demonstrated up to 50% improvement in thermal conductivity compared to pure metals. These composites maintain the processability of metals while approaching the thermal performance of more exotic materials, offering a practical middle-ground solution for mass production scenarios.

Phase change materials (PCMs) incorporated into thermal management systems provide additional benefits through their latent heat absorption capabilities. These materials can temporarily absorb heat during peak operation periods, effectively dampening thermal spikes that could otherwise damage sensitive Mini LED components. Recent developments in microencapsulation techniques have addressed previous concerns regarding PCM containment and cycle stability.

Diamond-based thermal materials represent the cutting edge of thermal conductivity research, with theoretical values exceeding 2200 W/mK. While cost prohibitive for widespread application, synthetic diamond films and diamond-loaded composites are finding niche applications in high-performance Mini LED systems where thermal management requirements are particularly demanding.

Environmental Impact and Sustainability Considerations

The environmental impact of Mini LED heat dissipation techniques represents a critical consideration in the sustainable development of display technologies. As manufacturers scale up production of Mini LED displays, the materials and processes used for thermal management carry significant ecological implications. Traditional heat dissipation solutions often rely on metals like aluminum and copper, which require energy-intensive mining and processing operations that contribute to carbon emissions and habitat disruption.

Water consumption in the manufacturing of heat dissipation components presents another environmental challenge. The production of thermal interface materials, heat sinks, and cooling systems typically demands substantial water resources, potentially straining local ecosystems in manufacturing regions. Additionally, chemical treatments used to enhance thermal conductivity may introduce toxic substances into the environment if not properly managed.

Energy efficiency during the operational lifetime of Mini LED displays directly correlates with heat dissipation effectiveness. More efficient thermal management reduces power consumption, thereby decreasing the carbon footprint associated with device operation. This relationship underscores the importance of developing heat dissipation techniques that not only enhance performance but also optimize energy utilization throughout the product lifecycle.

The end-of-life considerations for Mini LED thermal management systems present recycling challenges. Complex composite materials used in advanced thermal solutions may be difficult to separate and recycle, potentially contributing to electronic waste issues. Designing heat dissipation components with recyclability in mind becomes increasingly important as environmental regulations tighten globally.

Emerging sustainable approaches include the development of bio-based thermal interface materials derived from renewable resources. These alternatives aim to replace petroleum-based compounds while maintaining or improving thermal performance. Similarly, research into passive cooling designs that reduce or eliminate the need for energy-consuming active cooling components offers promising pathways toward more environmentally friendly Mini LED displays.

Carbon footprint reduction strategies for heat dissipation technologies include localized supply chains, energy-efficient manufacturing processes, and materials with lower embodied energy. Some manufacturers have begun implementing life cycle assessment methodologies to quantify and minimize the environmental impact of their thermal management solutions throughout the product development process.

Regulatory compliance regarding hazardous substances also shapes the development of Mini LED heat dissipation techniques. Global frameworks such as RoHS and REACH restrict the use of certain chemicals, driving innovation toward environmentally safer alternatives for thermal management components and encouraging the industry to adopt greener practices in thermal solution design and implementation.

Water consumption in the manufacturing of heat dissipation components presents another environmental challenge. The production of thermal interface materials, heat sinks, and cooling systems typically demands substantial water resources, potentially straining local ecosystems in manufacturing regions. Additionally, chemical treatments used to enhance thermal conductivity may introduce toxic substances into the environment if not properly managed.

Energy efficiency during the operational lifetime of Mini LED displays directly correlates with heat dissipation effectiveness. More efficient thermal management reduces power consumption, thereby decreasing the carbon footprint associated with device operation. This relationship underscores the importance of developing heat dissipation techniques that not only enhance performance but also optimize energy utilization throughout the product lifecycle.

The end-of-life considerations for Mini LED thermal management systems present recycling challenges. Complex composite materials used in advanced thermal solutions may be difficult to separate and recycle, potentially contributing to electronic waste issues. Designing heat dissipation components with recyclability in mind becomes increasingly important as environmental regulations tighten globally.

Emerging sustainable approaches include the development of bio-based thermal interface materials derived from renewable resources. These alternatives aim to replace petroleum-based compounds while maintaining or improving thermal performance. Similarly, research into passive cooling designs that reduce or eliminate the need for energy-consuming active cooling components offers promising pathways toward more environmentally friendly Mini LED displays.

Carbon footprint reduction strategies for heat dissipation technologies include localized supply chains, energy-efficient manufacturing processes, and materials with lower embodied energy. Some manufacturers have begun implementing life cycle assessment methodologies to quantify and minimize the environmental impact of their thermal management solutions throughout the product development process.

Regulatory compliance regarding hazardous substances also shapes the development of Mini LED heat dissipation techniques. Global frameworks such as RoHS and REACH restrict the use of certain chemicals, driving innovation toward environmentally safer alternatives for thermal management components and encouraging the industry to adopt greener practices in thermal solution design and implementation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!