Evaluating Mini LED Color Consistency in Production

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Mini LED Technology Background and Objectives

Mini LED technology represents a significant advancement in display technology, bridging the gap between traditional LED backlighting and the more advanced micro LED displays. Emerging in the mid-2010s, Mini LEDs are characterized by their diminutive size, typically ranging from 50 to 200 micrometers, which is substantially smaller than conventional LEDs but larger than micro LEDs. This technology has evolved rapidly over the past decade, driven by increasing demands for higher contrast ratios, improved brightness, and enhanced color accuracy in display applications.

The evolution of Mini LED technology can be traced through several key developmental phases. Initially, research focused on miniaturization techniques and manufacturing processes to produce smaller LED chips efficiently. Subsequently, attention shifted to integration methods for incorporating these tiny light sources into display panels. Recent advancements have centered on addressing color consistency challenges, which remain a critical factor in mass production scenarios.

The primary objective of evaluating Mini LED color consistency in production is to ensure uniform visual performance across display panels. This involves developing robust quality control mechanisms, standardized testing protocols, and innovative calibration techniques. The ultimate goal is to achieve consistent color reproduction that meets or exceeds industry standards while maintaining cost-effective manufacturing processes.

Color consistency in Mini LED displays is particularly challenging due to several factors. The manufacturing variations in semiconductor materials, differences in phosphor coating thickness, and inconsistencies in the driving circuits all contribute to potential color discrepancies. These variations can manifest as noticeable differences in color temperature, brightness, and saturation across different areas of a display or between different production batches.

Current technological trends indicate a growing emphasis on automated optical inspection systems, machine learning-based calibration algorithms, and advanced binning techniques to address these consistency challenges. The industry is moving toward more sophisticated spectral analysis methods and real-time adjustment capabilities to ensure uniform color performance throughout the production process.

The broader implications of achieving consistent color reproduction extend beyond mere technical specifications. As Mini LED technology increasingly penetrates premium display markets including high-end televisions, professional monitors, and automotive displays, color consistency becomes a key differentiator in product quality perception and brand reputation. Furthermore, as virtual reality, augmented reality, and mixed reality applications continue to expand, the demand for precise and consistent color reproduction will only intensify.

The evolution of Mini LED technology can be traced through several key developmental phases. Initially, research focused on miniaturization techniques and manufacturing processes to produce smaller LED chips efficiently. Subsequently, attention shifted to integration methods for incorporating these tiny light sources into display panels. Recent advancements have centered on addressing color consistency challenges, which remain a critical factor in mass production scenarios.

The primary objective of evaluating Mini LED color consistency in production is to ensure uniform visual performance across display panels. This involves developing robust quality control mechanisms, standardized testing protocols, and innovative calibration techniques. The ultimate goal is to achieve consistent color reproduction that meets or exceeds industry standards while maintaining cost-effective manufacturing processes.

Color consistency in Mini LED displays is particularly challenging due to several factors. The manufacturing variations in semiconductor materials, differences in phosphor coating thickness, and inconsistencies in the driving circuits all contribute to potential color discrepancies. These variations can manifest as noticeable differences in color temperature, brightness, and saturation across different areas of a display or between different production batches.

Current technological trends indicate a growing emphasis on automated optical inspection systems, machine learning-based calibration algorithms, and advanced binning techniques to address these consistency challenges. The industry is moving toward more sophisticated spectral analysis methods and real-time adjustment capabilities to ensure uniform color performance throughout the production process.

The broader implications of achieving consistent color reproduction extend beyond mere technical specifications. As Mini LED technology increasingly penetrates premium display markets including high-end televisions, professional monitors, and automotive displays, color consistency becomes a key differentiator in product quality perception and brand reputation. Furthermore, as virtual reality, augmented reality, and mixed reality applications continue to expand, the demand for precise and consistent color reproduction will only intensify.

Market Demand Analysis for Color Consistent Mini LEDs

The global market for Mini LED displays with consistent color performance is experiencing robust growth, driven primarily by increasing demand for high-end consumer electronics and professional display applications. Current market projections indicate that the Mini LED display market will reach approximately $5.3 billion by 2025, with a compound annual growth rate of 86.6% from 2020. Color consistency represents a critical quality parameter within this expanding market, as inconsistent color reproduction significantly diminishes perceived product value and user experience.

Consumer electronics represents the largest market segment demanding color-consistent Mini LEDs, particularly in premium television displays, where manufacturers like Samsung, LG, and TCL have introduced flagship models featuring Mini LED backlighting technology. These high-end displays command premium pricing specifically due to their superior color accuracy, uniformity, and contrast ratios compared to conventional LED-backlit displays.

The professional display market constitutes another significant demand driver, with creative industries including film production, photography, graphic design, and medical imaging requiring displays with exceptional color fidelity. In these applications, color consistency is not merely an aesthetic preference but a functional requirement that directly impacts professional outcomes and decision-making processes.

Automotive displays represent an emerging high-growth segment for color-consistent Mini LEDs. As vehicle manufacturers integrate increasingly sophisticated digital dashboards and infotainment systems, the demand for displays that maintain color accuracy across varying ambient lighting conditions and extended operational lifespans has intensified. Industry analysts project that automotive Mini LED implementation will grow at 92.3% CAGR through 2026.

Regional market analysis reveals that Asia Pacific currently dominates Mini LED production, with Taiwan, China, and South Korea leading manufacturing capacity. However, North America and Europe represent the most demanding markets for color-consistent products, with higher willingness to pay premium prices for superior color performance.

Market research indicates that consumers and professional users are increasingly sophisticated in their evaluation of display quality, with 78% of premium display purchasers citing color consistency as "very important" or "extremely important" in their buying decisions. This represents a significant shift from earlier market conditions where brightness and resolution were the primary purchase drivers.

The competitive landscape shows that manufacturers capable of delivering superior color consistency command price premiums of 15-30% compared to products with standard color performance. This price differential underscores the substantial market value placed on color consistency and explains the intensive industry focus on developing production methodologies that can deliver consistent color performance at scale.

Consumer electronics represents the largest market segment demanding color-consistent Mini LEDs, particularly in premium television displays, where manufacturers like Samsung, LG, and TCL have introduced flagship models featuring Mini LED backlighting technology. These high-end displays command premium pricing specifically due to their superior color accuracy, uniformity, and contrast ratios compared to conventional LED-backlit displays.

The professional display market constitutes another significant demand driver, with creative industries including film production, photography, graphic design, and medical imaging requiring displays with exceptional color fidelity. In these applications, color consistency is not merely an aesthetic preference but a functional requirement that directly impacts professional outcomes and decision-making processes.

Automotive displays represent an emerging high-growth segment for color-consistent Mini LEDs. As vehicle manufacturers integrate increasingly sophisticated digital dashboards and infotainment systems, the demand for displays that maintain color accuracy across varying ambient lighting conditions and extended operational lifespans has intensified. Industry analysts project that automotive Mini LED implementation will grow at 92.3% CAGR through 2026.

Regional market analysis reveals that Asia Pacific currently dominates Mini LED production, with Taiwan, China, and South Korea leading manufacturing capacity. However, North America and Europe represent the most demanding markets for color-consistent products, with higher willingness to pay premium prices for superior color performance.

Market research indicates that consumers and professional users are increasingly sophisticated in their evaluation of display quality, with 78% of premium display purchasers citing color consistency as "very important" or "extremely important" in their buying decisions. This represents a significant shift from earlier market conditions where brightness and resolution were the primary purchase drivers.

The competitive landscape shows that manufacturers capable of delivering superior color consistency command price premiums of 15-30% compared to products with standard color performance. This price differential underscores the substantial market value placed on color consistency and explains the intensive industry focus on developing production methodologies that can deliver consistent color performance at scale.

Technical Challenges in Mini LED Color Consistency

Achieving consistent color performance across Mini LED displays presents significant technical challenges that manufacturers must overcome to ensure product quality. The primary obstacle lies in the inherent variability of LED manufacturing processes, where even minor deviations in semiconductor materials, epitaxial growth conditions, or chip fabrication can result in noticeable color inconsistencies. These variations manifest as differences in wavelength emission, luminous intensity, and color temperature across individual Mini LEDs within the same display panel.

The miniaturization of LEDs to dimensions below 100 micrometers introduces additional complexity to color consistency control. As LED size decreases, the impact of edge effects and surface defects becomes proportionally more significant, affecting the quantum efficiency and spectral characteristics of each emitter. This scaling challenge is particularly evident in the blue wavelength spectrum, where minor variations can cascade into visible color shifts across the display.

Binning processes, traditionally used to categorize LEDs by performance parameters, become increasingly difficult with Mini LEDs due to their vast quantities in a single display. While conventional displays might use dozens or hundreds of LEDs, Mini LED backlight systems employ thousands to tens of thousands of emitters, making comprehensive individual testing and sorting economically prohibitive at production scales.

Temperature management presents another critical challenge affecting color consistency. Mini LEDs exhibit temperature-dependent color shift behaviors, with different thermal expansion coefficients across materials potentially causing stress-induced wavelength shifts. The compact arrangement of Mini LEDs creates thermal hotspots that can lead to uneven temperature distribution across the display, resulting in visible color inconsistencies during operation.

The phosphor conversion process used in white-light Mini LEDs introduces additional variables affecting color consistency. Variations in phosphor particle size, distribution, and concentration can cause significant differences in color rendering and white point accuracy. The challenge is compounded by aging effects, as phosphor materials may degrade at different rates depending on their composition and operating conditions.

Current quality control methodologies struggle to efficiently detect and correct color inconsistencies at the production scale required for Mini LED displays. Traditional spectroradiometric measurements are time-consuming and difficult to implement for the millions of Mini LEDs in modern display products. The industry lacks standardized, high-throughput testing protocols specifically designed for Mini LED color evaluation.

Integration challenges further complicate color consistency, as the optical stack design, including light guide plates, diffusers, and color filters, can either mitigate or amplify underlying Mini LED color variations. The interaction between these components creates a complex system where addressing color consistency requires a holistic approach spanning materials science, manufacturing processes, and optical engineering.

The miniaturization of LEDs to dimensions below 100 micrometers introduces additional complexity to color consistency control. As LED size decreases, the impact of edge effects and surface defects becomes proportionally more significant, affecting the quantum efficiency and spectral characteristics of each emitter. This scaling challenge is particularly evident in the blue wavelength spectrum, where minor variations can cascade into visible color shifts across the display.

Binning processes, traditionally used to categorize LEDs by performance parameters, become increasingly difficult with Mini LEDs due to their vast quantities in a single display. While conventional displays might use dozens or hundreds of LEDs, Mini LED backlight systems employ thousands to tens of thousands of emitters, making comprehensive individual testing and sorting economically prohibitive at production scales.

Temperature management presents another critical challenge affecting color consistency. Mini LEDs exhibit temperature-dependent color shift behaviors, with different thermal expansion coefficients across materials potentially causing stress-induced wavelength shifts. The compact arrangement of Mini LEDs creates thermal hotspots that can lead to uneven temperature distribution across the display, resulting in visible color inconsistencies during operation.

The phosphor conversion process used in white-light Mini LEDs introduces additional variables affecting color consistency. Variations in phosphor particle size, distribution, and concentration can cause significant differences in color rendering and white point accuracy. The challenge is compounded by aging effects, as phosphor materials may degrade at different rates depending on their composition and operating conditions.

Current quality control methodologies struggle to efficiently detect and correct color inconsistencies at the production scale required for Mini LED displays. Traditional spectroradiometric measurements are time-consuming and difficult to implement for the millions of Mini LEDs in modern display products. The industry lacks standardized, high-throughput testing protocols specifically designed for Mini LED color evaluation.

Integration challenges further complicate color consistency, as the optical stack design, including light guide plates, diffusers, and color filters, can either mitigate or amplify underlying Mini LED color variations. The interaction between these components creates a complex system where addressing color consistency requires a holistic approach spanning materials science, manufacturing processes, and optical engineering.

Current Color Consistency Evaluation Methods

01 Color uniformity control in Mini LED displays

Various techniques are employed to ensure color consistency across Mini LED displays. These include precise manufacturing processes, color calibration algorithms, and optical design optimizations that minimize color variations between individual LEDs. These approaches help achieve uniform brightness and color reproduction across the display panel, which is crucial for high-quality visual performance in applications like televisions, monitors, and mobile devices.- Color consistency control in Mini LED displays: Various methods are employed to ensure color consistency in Mini LED displays, including precise manufacturing processes, color calibration techniques, and quality control measures. These approaches help to minimize variations in color output across the display, resulting in more uniform and accurate color reproduction. Advanced algorithms and feedback systems can be implemented to detect and correct color inconsistencies in real-time.

- Packaging techniques for Mini LED color uniformity: Specialized packaging techniques are crucial for maintaining color consistency in Mini LED arrays. These include optimized chip mounting methods, phosphor coating processes, and encapsulation techniques that ensure uniform light emission. Advanced packaging designs can minimize thermal effects on color output and reduce variations in wavelength emission across multiple LEDs, resulting in better overall color consistency.

- Thermal management for color stability: Thermal management systems are implemented to maintain consistent color performance in Mini LED displays. As temperature fluctuations can cause shifts in LED color output, various cooling solutions and heat dissipation structures are employed to ensure stable operating temperatures. These include heat sinks, thermal interface materials, and active cooling systems that help maintain uniform temperature distribution across the LED array.

- Driving circuit design for uniform color output: Specialized driving circuits are designed to deliver precise current control to Mini LEDs, ensuring consistent color output across the display. These circuits can include current compensation mechanisms, feedback systems, and calibration capabilities that adjust for manufacturing variations between individual LEDs. Advanced driving schemes can dynamically adjust power delivery based on real-time monitoring of LED performance to maintain color consistency.

- Material selection and processing for color uniformity: The selection and processing of materials used in Mini LED manufacturing significantly impacts color consistency. This includes the purity of semiconductor materials, phosphor composition, and substrate characteristics. Advanced material processing techniques ensure uniform light emission properties across batches of LEDs. Quality control in material sourcing and processing helps minimize variations in wavelength emission and color temperature.

02 Phosphor and packaging technologies for color consistency

Specialized phosphor materials and advanced packaging technologies are used to enhance color consistency in Mini LEDs. These include precise phosphor deposition methods, uniform phosphor distribution techniques, and innovative package designs that minimize color shift. These technologies help maintain consistent color temperature and spectrum across multiple LEDs, ensuring visual uniformity in the final display product.Expand Specific Solutions03 Thermal management for color stability

Effective thermal management systems are implemented to maintain color consistency in Mini LED displays. As temperature fluctuations can cause color shifts in LEDs, various heat dissipation structures, thermal interface materials, and cooling solutions are employed to regulate operating temperatures. These thermal management approaches help preserve color accuracy and consistency during extended operation periods.Expand Specific Solutions04 Driving circuit and current control methods

Specialized driving circuits and current control methods are developed to ensure consistent color output from Mini LEDs. These include precise current regulation techniques, compensation algorithms for aging effects, and feedback systems that monitor and adjust LED performance in real-time. By maintaining stable electrical characteristics across all LEDs in a display, these approaches help achieve uniform color reproduction.Expand Specific Solutions05 Binning and sorting techniques for LED matching

Advanced binning and sorting techniques are employed during manufacturing to group Mini LEDs with similar color characteristics. This process involves precise measurement of each LED's color coordinates, brightness, and electrical properties, followed by categorization into bins with tightly controlled parameters. By using LEDs from the same or compatible bins in a display, manufacturers can achieve better color consistency across the entire panel.Expand Specific Solutions

Key Industry Players in Mini LED Manufacturing

Mini LED technology is currently in the growth phase of its industry lifecycle, characterized by increasing adoption in high-end displays. The global market is expanding rapidly, projected to reach significant scale as manufacturers address color consistency challenges in production. Technologically, Mini LED sits between conventional LED and more advanced Micro LED, with varying maturity levels among key players. Companies like BOE Technology, TCL China Star, and Shenzhen Refond Optoelectronics have made substantial progress in color uniformity control, while APT Electronics and Jufei Optoelectronics are advancing inspection technologies. Emerging players such as Magicray and Xiamen University research teams are developing innovative solutions for color consistency evaluation, indicating a competitive landscape with both established manufacturers and specialized technology providers.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has developed a comprehensive Mini LED color consistency evaluation system that integrates multiple advanced technologies. Their approach combines spectroradiometric measurement with AI-powered color calibration algorithms to ensure uniform color performance across large display panels. The system employs a high-precision optical probe array that can simultaneously measure thousands of Mini LED zones, creating detailed color mapping profiles. BOE's proprietary "Active Matrix Compensation" technology dynamically adjusts individual LED current based on real-time feedback, compensating for inherent variations in LED characteristics. Their production line implements a multi-stage binning process where LEDs are sorted according to wavelength, luminance, and forward voltage with tolerances as tight as ±1nm for wavelength and ±3% for luminance. This ensures consistent visual performance across the entire display surface even after extended operation periods.

Strengths: Industry-leading measurement precision with proprietary compensation algorithms that adapt to LED aging. Comprehensive binning system that minimizes initial variations. Weaknesses: The complex calibration system increases production costs and time, potentially limiting throughput in mass production scenarios.

Shenzhen Absen Optoelectronic Co., Ltd.

Technical Solution: Absen has developed a specialized "Color Uniformity Management System" (CUMS) for Mini LED production that focuses on maintaining color consistency across large-format displays and video walls. Their approach incorporates a calibrated camera array system that captures high-resolution images of operational displays to create detailed color distribution maps. Absen's proprietary "Pixel-by-Pixel Calibration" technology individually adjusts each Mini LED's output parameters to achieve uniform visual performance. Their production evaluation process includes a unique "accelerated aging test" where panels undergo controlled stress testing to predict and compensate for color shift over time. The company employs a sophisticated binning strategy with up to 16 wavelength categories and 12 brightness levels to ensure tight color matching between adjacent modules. Absen's system also incorporates environmental sensors that allow displays to automatically adjust color parameters based on ambient lighting conditions, maintaining perceived color consistency across varying installation environments.

Strengths: Specialized expertise in large-format displays with excellent module-to-module consistency. Advanced aging prediction algorithms that compensate for long-term color drift. Weaknesses: System optimized primarily for commercial display applications rather than consumer electronics, potentially limiting applicability in some market segments.

Critical Patents and Research in Color Measurement

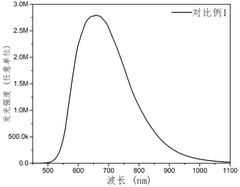

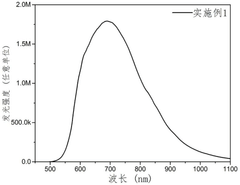

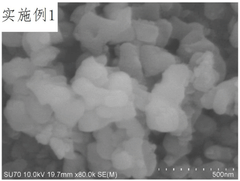

Method for obtaining nanoscale nitride fluorescent material

PatentPendingCN119736086A

Innovation

- Using non-stoichiometric raw materials and oxalic acid solution sonication method, nano-scale nitride fluorescent materials with a median D50 particle size of 80 nm to 100 nm were prepared under high temperature sintering and grinding.

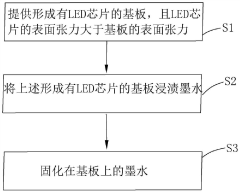

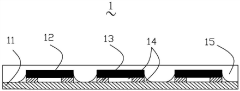

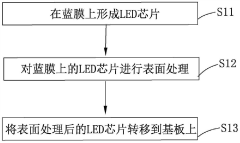

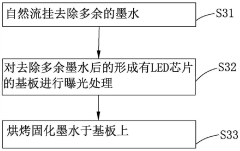

Method for improving consistency of ink color displayed by mini-LED

PatentPendingCN114023206A

Innovation

- By surface treatment of the LED chip to increase its tension so that its surface tension is greater than the surface tension of the substrate, specific ink dipping and curing methods are used to use the tension difference to improve the efficiency of the ink adhering to the substrate and reduce the need for contrast to rely on toner , thereby reducing the calorific value.

Quality Control Standards and Specifications

Quality control standards for Mini LED production must be rigorously defined to ensure color consistency across displays. The International Commission on Illumination (CIE) color space standards serve as the foundation for Mini LED quality assessment, with specific focus on the CIE 1931 and CIE 1976 color spaces that provide mathematical frameworks for quantifying color differences. Industry leaders typically require color variation to remain within a 3-step MacAdam ellipse, representing the just-noticeable difference threshold for human perception.

JEDEC standards specifically address semiconductor component reliability, while the Video Electronics Standards Association (VESA) has developed DisplayHDR True Black certification that includes color accuracy requirements particularly relevant for Mini LED displays. These standards typically specify maximum allowable deviation in chromaticity coordinates (Δu'v' < 0.004), color temperature tolerance (±200K), and gamma curve compliance (2.2±0.2).

Manufacturing specifications for Mini LED color consistency include binning requirements that categorize LEDs based on luminance (±5% tolerance), dominant wavelength (±1nm for blue/green, ±2nm for red), and forward voltage (±0.1V). Advanced production lines implement automated optical inspection systems calibrated to detect deviations exceeding 97% confidence intervals from reference standards.

Quality assurance protocols mandate sampling rates of 3-5% of production volume with increased inspection frequency during production ramp-up phases. Statistical Process Control (SPC) methodologies, particularly Cpk values exceeding 1.33, are required to demonstrate process capability for color consistency. Manufacturers must maintain detailed documentation of measurement conditions, including ambient temperature (23°C±2°C) and humidity (45%±10% RH).

Incoming component specifications require LED suppliers to provide detailed spectral power distribution data and bin sorting information. Assembly specifications mandate precise current regulation (±1% tolerance) to maintain consistent driving conditions. Final product acceptance criteria typically specify ΔCIE94 values below 2.0 across the display surface and maximum luminance variation of ±10% at multiple measurement points.

Industry certification bodies like TÜV and UL have established verification protocols for Mini LED displays that include color uniformity assessments under various viewing angles (±45° horizontal, ±30° vertical). These specifications are increasingly harmonized with energy efficiency standards such as Energy Star, which incorporate color quality metrics alongside power consumption requirements.

JEDEC standards specifically address semiconductor component reliability, while the Video Electronics Standards Association (VESA) has developed DisplayHDR True Black certification that includes color accuracy requirements particularly relevant for Mini LED displays. These standards typically specify maximum allowable deviation in chromaticity coordinates (Δu'v' < 0.004), color temperature tolerance (±200K), and gamma curve compliance (2.2±0.2).

Manufacturing specifications for Mini LED color consistency include binning requirements that categorize LEDs based on luminance (±5% tolerance), dominant wavelength (±1nm for blue/green, ±2nm for red), and forward voltage (±0.1V). Advanced production lines implement automated optical inspection systems calibrated to detect deviations exceeding 97% confidence intervals from reference standards.

Quality assurance protocols mandate sampling rates of 3-5% of production volume with increased inspection frequency during production ramp-up phases. Statistical Process Control (SPC) methodologies, particularly Cpk values exceeding 1.33, are required to demonstrate process capability for color consistency. Manufacturers must maintain detailed documentation of measurement conditions, including ambient temperature (23°C±2°C) and humidity (45%±10% RH).

Incoming component specifications require LED suppliers to provide detailed spectral power distribution data and bin sorting information. Assembly specifications mandate precise current regulation (±1% tolerance) to maintain consistent driving conditions. Final product acceptance criteria typically specify ΔCIE94 values below 2.0 across the display surface and maximum luminance variation of ±10% at multiple measurement points.

Industry certification bodies like TÜV and UL have established verification protocols for Mini LED displays that include color uniformity assessments under various viewing angles (±45° horizontal, ±30° vertical). These specifications are increasingly harmonized with energy efficiency standards such as Energy Star, which incorporate color quality metrics alongside power consumption requirements.

Production Yield Optimization Strategies

Optimizing production yield for Mini LED displays requires a systematic approach to address color consistency challenges. The implementation of Statistical Process Control (SPC) methodologies has proven effective in identifying process variations that impact color uniformity. By establishing control limits for key parameters such as wavelength, luminance, and chromaticity coordinates, manufacturers can detect deviations early and make timely adjustments. Real-time monitoring systems equipped with machine vision technology enable continuous assessment of color performance metrics during production, significantly reducing the occurrence of out-of-specification panels.

Advanced binning strategies represent another critical optimization approach. Traditional binning methods based solely on wavelength ranges have evolved into multi-dimensional classification systems that consider luminance, color temperature, and spatial uniformity simultaneously. This comprehensive binning methodology, when coupled with intelligent matching algorithms, ensures that LEDs with complementary characteristics are grouped together, minimizing perceptible color variations across the display surface.

Adaptive manufacturing processes have demonstrated substantial yield improvements in Mini LED production. These systems utilize closed-loop feedback mechanisms that automatically adjust process parameters based on real-time measurement data. For instance, when color drift is detected during production, parameters such as phosphor deposition thickness or current driving conditions can be dynamically modified to maintain consistency. Manufacturers implementing these adaptive systems have reported yield improvements of 15-22% compared to traditional fixed-parameter approaches.

Material qualification and supplier management constitute fundamental elements of yield optimization. Establishing rigorous incoming quality control procedures for critical materials such as phosphors, substrates, and encapsulants helps prevent downstream color consistency issues. Leading manufacturers have implemented supplier certification programs that include regular audits and statistical monitoring of key material properties affecting color performance. These programs typically require suppliers to demonstrate process capability indices (Cpk) exceeding 1.33 for color-critical parameters.

Equipment calibration and maintenance protocols significantly impact color consistency in Mini LED production. Regular spectroradiometer calibration, standardized measurement conditions, and cross-equipment correlation procedures ensure measurement system reliability. Preventive maintenance schedules for critical equipment such as phosphor deposition systems and testing stations help maintain process stability. Companies implementing comprehensive equipment management systems report reduced color variation and up to 30% fewer production interruptions related to measurement discrepancies.

Advanced binning strategies represent another critical optimization approach. Traditional binning methods based solely on wavelength ranges have evolved into multi-dimensional classification systems that consider luminance, color temperature, and spatial uniformity simultaneously. This comprehensive binning methodology, when coupled with intelligent matching algorithms, ensures that LEDs with complementary characteristics are grouped together, minimizing perceptible color variations across the display surface.

Adaptive manufacturing processes have demonstrated substantial yield improvements in Mini LED production. These systems utilize closed-loop feedback mechanisms that automatically adjust process parameters based on real-time measurement data. For instance, when color drift is detected during production, parameters such as phosphor deposition thickness or current driving conditions can be dynamically modified to maintain consistency. Manufacturers implementing these adaptive systems have reported yield improvements of 15-22% compared to traditional fixed-parameter approaches.

Material qualification and supplier management constitute fundamental elements of yield optimization. Establishing rigorous incoming quality control procedures for critical materials such as phosphors, substrates, and encapsulants helps prevent downstream color consistency issues. Leading manufacturers have implemented supplier certification programs that include regular audits and statistical monitoring of key material properties affecting color performance. These programs typically require suppliers to demonstrate process capability indices (Cpk) exceeding 1.33 for color-critical parameters.

Equipment calibration and maintenance protocols significantly impact color consistency in Mini LED production. Regular spectroradiometer calibration, standardized measurement conditions, and cross-equipment correlation procedures ensure measurement system reliability. Preventive maintenance schedules for critical equipment such as phosphor deposition systems and testing stations help maintain process stability. Companies implementing comprehensive equipment management systems report reduced color variation and up to 30% fewer production interruptions related to measurement discrepancies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!