Optimizing Mini LED Designs for Longer Lifespan

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Mini LED Technology Evolution and Lifespan Goals

Mini LED technology has evolved significantly since its inception in the early 2010s, emerging as a bridge between traditional LED and the more advanced Micro LED technologies. The development trajectory began with conventional LED backlighting systems that suffered from limited local dimming capabilities and relatively short lifespans due to heat management issues. By 2015, the first generation of Mini LEDs appeared, characterized by chip sizes between 100-200 micrometers, offering improved brightness control but still facing considerable thermal challenges that impacted longevity.

The period from 2016 to 2019 marked a critical phase in Mini LED evolution, with manufacturers focusing on reducing chip sizes to below 100 micrometers while simultaneously developing more sophisticated thermal management solutions. This era saw the introduction of advanced packaging techniques that allowed for higher density arrays and better heat dissipation, directly addressing one of the primary factors limiting device lifespan.

By 2020, Mini LED technology had matured sufficiently to enable mass-market adoption in premium displays, with companies like Apple, Samsung, and TCL incorporating the technology into their flagship products. The technical specifications had evolved to include chips typically ranging from 50-100 micrometers, with significantly improved luminous efficiency and reduced power consumption compared to earlier iterations.

Current technical goals for Mini LED lifespan optimization center around achieving operational longevity exceeding 50,000 hours while maintaining consistent brightness and color accuracy throughout the product lifecycle. This represents a substantial improvement over earlier generations that typically degraded noticeably after 30,000 hours of operation. Industry benchmarks now aim for less than 10% brightness degradation after 50,000 hours of use under standard operating conditions.

The technological evolution is increasingly focused on addressing the primary failure mechanisms in Mini LEDs, including junction temperature management, current density optimization, and protection against environmental factors such as humidity and oxidation. Research indicates that for every 10°C reduction in operating temperature, the theoretical lifespan of LEDs can nearly double, making thermal engineering a central focus of current development efforts.

Looking forward, the industry has established ambitious targets for the next generation of Mini LED technology, including operational lifespans approaching 100,000 hours, power efficiency improvements of 30-40% over current designs, and enhanced resistance to color shift over time. These goals are aligned with broader industry trends toward more sustainable, longer-lasting display technologies that reduce electronic waste and improve total cost of ownership for both consumer and commercial applications.

The period from 2016 to 2019 marked a critical phase in Mini LED evolution, with manufacturers focusing on reducing chip sizes to below 100 micrometers while simultaneously developing more sophisticated thermal management solutions. This era saw the introduction of advanced packaging techniques that allowed for higher density arrays and better heat dissipation, directly addressing one of the primary factors limiting device lifespan.

By 2020, Mini LED technology had matured sufficiently to enable mass-market adoption in premium displays, with companies like Apple, Samsung, and TCL incorporating the technology into their flagship products. The technical specifications had evolved to include chips typically ranging from 50-100 micrometers, with significantly improved luminous efficiency and reduced power consumption compared to earlier iterations.

Current technical goals for Mini LED lifespan optimization center around achieving operational longevity exceeding 50,000 hours while maintaining consistent brightness and color accuracy throughout the product lifecycle. This represents a substantial improvement over earlier generations that typically degraded noticeably after 30,000 hours of operation. Industry benchmarks now aim for less than 10% brightness degradation after 50,000 hours of use under standard operating conditions.

The technological evolution is increasingly focused on addressing the primary failure mechanisms in Mini LEDs, including junction temperature management, current density optimization, and protection against environmental factors such as humidity and oxidation. Research indicates that for every 10°C reduction in operating temperature, the theoretical lifespan of LEDs can nearly double, making thermal engineering a central focus of current development efforts.

Looking forward, the industry has established ambitious targets for the next generation of Mini LED technology, including operational lifespans approaching 100,000 hours, power efficiency improvements of 30-40% over current designs, and enhanced resistance to color shift over time. These goals are aligned with broader industry trends toward more sustainable, longer-lasting display technologies that reduce electronic waste and improve total cost of ownership for both consumer and commercial applications.

Market Demand for Durable Display Solutions

The display technology market is witnessing a significant shift towards solutions that offer extended durability and reliability, particularly in the Mini LED segment. Market research indicates that consumers and enterprise clients are increasingly prioritizing longevity in their display investments, with durability becoming a key differentiator in purchase decisions. This trend is especially pronounced in premium market segments where the initial higher cost of Mini LED technology necessitates longer operational lifespans to justify the investment.

Industry surveys reveal that commercial sectors including digital signage, automotive displays, and professional monitors place exceptional emphasis on display longevity, with expected operational lifespans of 50,000+ hours becoming a standard requirement. The healthcare and transportation sectors, where displays operate continuously in critical environments, demonstrate particularly strong demand for displays that maintain consistent performance over extended periods.

Consumer electronics manufacturers report that warranty claims and customer dissatisfaction related to premature display degradation represent significant operational costs. Market analysis shows that brands emphasizing durability in their product messaging can command price premiums of 15-20% over comparable products without such guarantees, indicating strong consumer willingness to pay for reliability.

The environmental sustainability movement is further accelerating demand for longer-lasting display technologies. Regulatory frameworks in major markets are increasingly incorporating electronic waste reduction targets, with the European Union's Circular Economy Action Plan and similar initiatives in Asia-Pacific regions creating market incentives for durable electronic components. Mini LED displays with optimized lifespans directly address these sustainability requirements while reducing total cost of ownership.

Financial analyses demonstrate compelling economic arguments for durable display solutions. In commercial applications, the total cost of ownership calculations strongly favor displays with extended lifespans, even at premium initial price points. For instance, digital signage deployments show ROI improvements of approximately 30% when display lifespan doubles, accounting for installation, maintenance, and replacement costs.

Market forecasts project the premium durable display segment to grow at twice the rate of the overall display market over the next five years. This growth is driven by both consumer and commercial sectors seeking to maximize the value of their technology investments through extended product lifecycles. The Mini LED market specifically is positioned to capture a significant portion of this growth due to its inherent technical advantages in balancing performance with potential longevity.

Industry surveys reveal that commercial sectors including digital signage, automotive displays, and professional monitors place exceptional emphasis on display longevity, with expected operational lifespans of 50,000+ hours becoming a standard requirement. The healthcare and transportation sectors, where displays operate continuously in critical environments, demonstrate particularly strong demand for displays that maintain consistent performance over extended periods.

Consumer electronics manufacturers report that warranty claims and customer dissatisfaction related to premature display degradation represent significant operational costs. Market analysis shows that brands emphasizing durability in their product messaging can command price premiums of 15-20% over comparable products without such guarantees, indicating strong consumer willingness to pay for reliability.

The environmental sustainability movement is further accelerating demand for longer-lasting display technologies. Regulatory frameworks in major markets are increasingly incorporating electronic waste reduction targets, with the European Union's Circular Economy Action Plan and similar initiatives in Asia-Pacific regions creating market incentives for durable electronic components. Mini LED displays with optimized lifespans directly address these sustainability requirements while reducing total cost of ownership.

Financial analyses demonstrate compelling economic arguments for durable display solutions. In commercial applications, the total cost of ownership calculations strongly favor displays with extended lifespans, even at premium initial price points. For instance, digital signage deployments show ROI improvements of approximately 30% when display lifespan doubles, accounting for installation, maintenance, and replacement costs.

Market forecasts project the premium durable display segment to grow at twice the rate of the overall display market over the next five years. This growth is driven by both consumer and commercial sectors seeking to maximize the value of their technology investments through extended product lifecycles. The Mini LED market specifically is positioned to capture a significant portion of this growth due to its inherent technical advantages in balancing performance with potential longevity.

Current Limitations and Challenges in Mini LED Longevity

Despite significant advancements in Mini LED technology, several critical limitations continue to impede the optimization of lifespan in these devices. The primary challenge remains thermal management, as Mini LEDs generate considerable heat during operation that accelerates degradation mechanisms. The miniaturization of LED chips to dimensions below 200 micrometers has intensified this issue, creating thermal hotspots that are difficult to dissipate effectively through conventional cooling methods.

Current packaging technologies present another significant hurdle. The dense arrangement of Mini LEDs requires sophisticated packaging solutions that must simultaneously provide electrical connectivity, thermal conductivity, and protection from environmental factors. Existing packaging materials often demonstrate incompatible thermal expansion coefficients, leading to mechanical stress during thermal cycling that compromises long-term reliability.

The drive current stability represents a persistent technical obstacle. Mini LEDs typically operate at higher current densities than traditional LEDs, which accelerates electron migration and junction degradation. Current crowding effects at the microscale level create uneven current distribution across the device, resulting in localized overheating and premature failure points that significantly reduce overall lifespan.

Material degradation mechanisms continue to challenge researchers. The phosphor materials used for color conversion in Mini LEDs exhibit photochemical and thermal degradation over time, leading to color shift and reduced luminous efficacy. Additionally, encapsulation materials suffer from yellowing and cracking under prolonged exposure to heat and blue light, compromising both optical performance and physical protection.

Manufacturing inconsistencies further exacerbate lifespan variability. The precision required for Mini LED fabrication pushes the limits of current manufacturing capabilities, resulting in microscopic defects that serve as nucleation sites for failure mechanisms. These defects, often undetectable during quality control, manifest as premature failures during operation, creating reliability prediction challenges.

Environmental susceptibility remains problematic, particularly in automotive and outdoor display applications. Mini LEDs demonstrate heightened sensitivity to humidity, temperature fluctuations, and vibration compared to conventional lighting technologies. The ingress of moisture at the microscale level accelerates corrosion of metallic components and degrades semiconductor interfaces, substantially reducing operational lifespan.

Standardization gaps in testing protocols present additional challenges. Current accelerated life testing methodologies developed for conventional LEDs may not accurately predict Mini LED failure modes or lifespan. The industry lacks consensus on appropriate stress conditions and acceleration factors specific to Mini LED technology, hampering meaningful comparison between different design approaches and materials.

Current packaging technologies present another significant hurdle. The dense arrangement of Mini LEDs requires sophisticated packaging solutions that must simultaneously provide electrical connectivity, thermal conductivity, and protection from environmental factors. Existing packaging materials often demonstrate incompatible thermal expansion coefficients, leading to mechanical stress during thermal cycling that compromises long-term reliability.

The drive current stability represents a persistent technical obstacle. Mini LEDs typically operate at higher current densities than traditional LEDs, which accelerates electron migration and junction degradation. Current crowding effects at the microscale level create uneven current distribution across the device, resulting in localized overheating and premature failure points that significantly reduce overall lifespan.

Material degradation mechanisms continue to challenge researchers. The phosphor materials used for color conversion in Mini LEDs exhibit photochemical and thermal degradation over time, leading to color shift and reduced luminous efficacy. Additionally, encapsulation materials suffer from yellowing and cracking under prolonged exposure to heat and blue light, compromising both optical performance and physical protection.

Manufacturing inconsistencies further exacerbate lifespan variability. The precision required for Mini LED fabrication pushes the limits of current manufacturing capabilities, resulting in microscopic defects that serve as nucleation sites for failure mechanisms. These defects, often undetectable during quality control, manifest as premature failures during operation, creating reliability prediction challenges.

Environmental susceptibility remains problematic, particularly in automotive and outdoor display applications. Mini LEDs demonstrate heightened sensitivity to humidity, temperature fluctuations, and vibration compared to conventional lighting technologies. The ingress of moisture at the microscale level accelerates corrosion of metallic components and degrades semiconductor interfaces, substantially reducing operational lifespan.

Standardization gaps in testing protocols present additional challenges. Current accelerated life testing methodologies developed for conventional LEDs may not accurately predict Mini LED failure modes or lifespan. The industry lacks consensus on appropriate stress conditions and acceleration factors specific to Mini LED technology, hampering meaningful comparison between different design approaches and materials.

Current Approaches to Mini LED Lifespan Extension

01 Factors affecting Mini LED lifespan

Various factors can impact the lifespan of Mini LEDs, including operating temperature, driving current, and environmental conditions. Proper thermal management systems can significantly extend the lifespan by preventing overheating. Additionally, controlling the driving current within specified parameters helps prevent premature degradation of the LED components. Environmental factors such as humidity and exposure to contaminants can also affect the long-term performance and durability of Mini LEDs.- Factors affecting Mini LED lifespan: Various factors can impact the lifespan of Mini LEDs, including operating temperature, driving current, and environmental conditions. Proper thermal management and current regulation are critical for extending the operational life of Mini LEDs. Manufacturers implement different design strategies to mitigate heat buildup and prevent premature degradation of the LED components, which can significantly enhance the overall lifespan of Mini LED displays and lighting systems.

- Lifespan enhancement technologies: Advanced technologies have been developed to enhance Mini LED lifespan, including improved phosphor materials, optimized chip structures, and specialized encapsulation methods. These innovations help to reduce degradation mechanisms such as color shift and luminance decay over time. Some solutions incorporate intelligent driving systems that adjust power delivery based on usage patterns and environmental conditions, thereby preserving the LED's performance characteristics throughout its operational life.

- Reliability testing and lifespan prediction: Manufacturers employ various reliability testing methodologies to predict and verify the lifespan of Mini LEDs. These include accelerated aging tests, temperature cycling, and humidity stress testing. Advanced statistical models and algorithms are used to analyze test data and project the expected useful life of Mini LED components under different operating conditions. This information helps in establishing warranty periods and performance guarantees for Mini LED-based products.

- Comparative lifespan against other display technologies: Mini LEDs generally offer superior lifespan compared to many competing display technologies. When properly designed and operated, Mini LED displays can maintain acceptable brightness and color accuracy for tens of thousands of hours. This extended operational life makes them particularly suitable for applications requiring long-term reliability, such as digital signage, automotive displays, and premium consumer electronics. The technology's durability provides a competitive advantage in terms of total cost of ownership over the product lifecycle.

- Power management for extended lifespan: Effective power management strategies play a crucial role in extending Mini LED lifespan. Intelligent dimming algorithms, voltage regulation systems, and adaptive brightness controls help to minimize stress on the LED components. Some advanced designs incorporate power cycling protocols that periodically rest certain LED segments to distribute wear more evenly across the display. These power management techniques not only extend the useful life of Mini LED displays but also improve energy efficiency during operation.

02 Lifespan enhancement technologies

Advanced technologies have been developed to enhance Mini LED lifespan, including improved phosphor materials, optimized chip structures, and protective packaging. These technologies aim to reduce degradation mechanisms such as color shift and luminance decay over time. Some innovations focus on specialized encapsulation materials that protect the LED from moisture and oxidation, while others involve novel heat dissipation structures that maintain optimal operating temperatures, resulting in significantly extended operational lifetimes.Expand Specific Solutions03 Lifespan testing and prediction methods

Various methodologies have been developed for testing and predicting the lifespan of Mini LEDs. These include accelerated aging tests under controlled conditions, statistical modeling of degradation patterns, and real-time monitoring systems. Advanced algorithms can analyze performance data to predict remaining useful life, allowing for preventive maintenance before failure. Some testing protocols involve subjecting the LEDs to extreme conditions to identify potential failure modes and establish more accurate lifespan estimates under normal operating conditions.Expand Specific Solutions04 Power management for extended lifespan

Effective power management systems play a crucial role in extending Mini LED lifespan. These include intelligent driving circuits that adjust current based on operating conditions, pulse width modulation techniques that reduce thermal stress, and voltage regulation systems that prevent electrical overstress. Some advanced power management solutions incorporate feedback mechanisms that monitor LED performance in real-time and make adjustments to optimize both performance and longevity, balancing brightness requirements with lifespan considerations.Expand Specific Solutions05 Comparative lifespan between display technologies

Research has shown that Mini LEDs generally offer longer lifespans compared to conventional LED technologies and other display technologies like OLED. This extended lifespan is attributed to lower operating temperatures, more efficient light emission, and improved manufacturing processes. Studies indicate that properly designed Mini LED displays can maintain acceptable brightness levels for 50,000 to 100,000 hours of operation, significantly outperforming many alternative display technologies in long-term durability and consistent performance over time.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The Mini LED market is currently in a growth phase, with increasing adoption across display technologies due to its advantages in lifespan optimization. The global market size is expanding rapidly, projected to reach significant value as major players invest in research and development. Technologically, Mini LED sits between conventional LED and emerging MicroLED, with varying maturity levels among competitors. Companies like BOE Technology, Samsung Electronics, and LG Innotek lead with advanced manufacturing capabilities, while specialized players such as APT Electronics, Foshan NationStar, and Xiamen Changelight focus on component optimization. Chinese manufacturers including HKC, TCL's Wuhan China Star, and Dongguan Zhongjing are rapidly advancing their technical capabilities, competing with established international players like OSRAM, Philips, and Sharp in developing longer-lasting Mini LED solutions.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has pioneered a comprehensive Mini LED lifespan optimization approach centered around their Active Matrix Mini LED (AM-Mini LED) technology. This solution incorporates specialized chip-scale packaging techniques that improve heat dissipation by approximately 30% compared to traditional packages. BOE implements multi-layer thermal interface materials between the LED substrate and heat sink, creating more efficient thermal pathways. Their proprietary current distribution network ensures uniform current delivery across thousands of Mini LEDs, preventing hotspots and current crowding that typically accelerate degradation. BOE's solution also includes advanced phosphor formulations with reduced thermal quenching effects, maintaining consistent light output over extended periods. Additionally, they've developed specialized driving ICs that implement adaptive current modulation based on real-time temperature monitoring, automatically reducing power when thermal thresholds are approached.

Strengths: Highly scalable manufacturing process suitable for various display sizes, excellent thermal management integration, and compatibility with flexible display applications. Weaknesses: Relatively higher cost structure compared to some competitors, and more complex driving circuitry requirements that can impact yield rates.

OSRAM GmbH

Technical Solution: OSRAM has developed a sophisticated Mini LED lifespan optimization solution called "DuraLED" that addresses multiple degradation mechanisms. Their approach begins with specialized epitaxial structures featuring optimized quantum barriers that reduce electron overflow and associated degradation. OSRAM implements advanced thermal interface materials that improve heat transfer efficiency by approximately 35% compared to conventional solutions. Their Mini LEDs incorporate proprietary phosphor formulations with reduced thermal quenching effects, maintaining consistent color performance over extended operational periods. OSRAM's solution features precision-engineered current distribution networks that ensure uniform current density across the LED array, preventing localized overheating. Additionally, they've developed intelligent driving algorithms that continuously monitor junction temperatures and adjust current levels accordingly, implementing predictive aging models that optimize performance throughout the product lifecycle. OSRAM's package design incorporates specialized reflective materials that maintain high efficiency while minimizing phosphor degradation from back-reflected light.

Strengths: Exceptional thermal management capabilities, industry-leading materials science expertise, and comprehensive approach addressing multiple degradation mechanisms simultaneously. Weaknesses: Higher initial implementation costs and more complex manufacturing requirements compared to standard LED solutions.

Key Patents and Innovations in Mini LED Durability

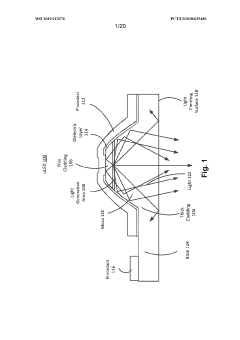

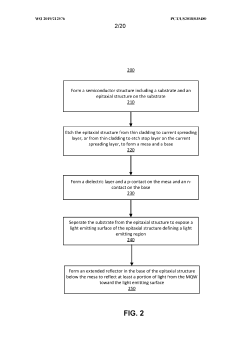

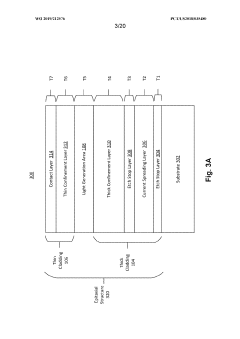

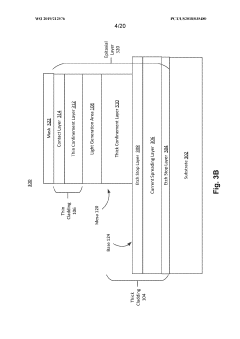

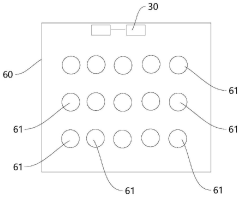

Micron-sized light emitting diode designs

PatentWO2019212576A1

Innovation

- The design includes an epitaxial structure with a base and mesa, featuring a current spreading layer, thick and thin confinement layers, and a reflective contact to collimate and direct light emitted from a light generation area, such as a multi-quantum well, to enhance light extraction efficiency by reflecting and directing lateral light back to the emitting surface.

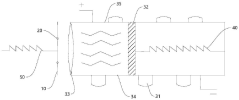

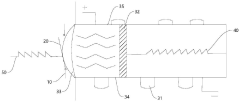

Driving circuit, backlight module and display device

PatentPendingCN117809578A

Innovation

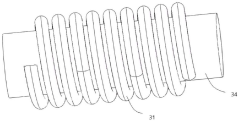

- A driving circuit is designed, including a circuit loop, a control switch and a protection mechanism. By setting up a protection mechanism, when the current of the circuit loop is greater than or equal to the preset value, the protection mechanism drives the control switch to disconnect the circuit loop to prevent excessive current. Damage to the light panel. The protection mechanism can be composed of magnetic induction coils, magnetic parts, flexible parts and reset parts, and uses magnetic fields and mechanical structures to achieve automatic circuit breaking and reset.

Thermal Management Strategies for Mini LED Displays

Effective thermal management is critical for extending the lifespan of Mini LED displays. As these displays pack thousands of miniaturized light-emitting diodes into compact spaces, they generate significant heat during operation. Without proper thermal management, this heat accumulation accelerates LED degradation, reduces brightness, alters color consistency, and ultimately shortens the display's operational life.

The primary thermal management approaches for Mini LED displays include passive and active cooling strategies. Passive solutions utilize materials with high thermal conductivity, such as aluminum or copper heat sinks, to dissipate heat away from sensitive components. These materials create efficient thermal pathways that draw heat from the LEDs and distribute it across larger surface areas for dissipation.

Advanced thermal interface materials (TIMs) play a crucial role in optimizing heat transfer between components. Modern TIMs include phase-change materials, graphite sheets, and metal-infused polymers that conform to surface irregularities, minimizing thermal resistance at component interfaces. These materials significantly improve thermal conductivity while maintaining electrical isolation where necessary.

Active cooling mechanisms supplement passive approaches in high-brightness applications. Micro-fans, thermoelectric coolers, and liquid cooling systems actively remove heat from critical areas. Particularly innovative are vapor chamber cooling solutions that utilize phase-change principles to transport heat rapidly away from LED clusters, maintaining more uniform temperature distribution across the display panel.

Thermal simulation and modeling have become essential design tools for Mini LED manufacturers. Computational fluid dynamics (CFD) simulations enable engineers to identify potential hotspots before physical prototyping, optimizing component placement and thermal pathway design. These simulations account for various operating conditions, helping create robust thermal management systems that perform reliably across diverse environments.

Emerging approaches include integration of microfluidic channels directly into display substrates, allowing coolant to circulate closer to heat sources. Additionally, advanced thermal management algorithms dynamically adjust brightness levels based on temperature sensors, preventing thermal runaway conditions while maximizing performance within safe operating parameters.

The implementation of zone-specific thermal management, where cooling solutions are tailored to different display regions based on their heat generation profiles, represents another optimization frontier. This targeted approach ensures efficient resource allocation while maintaining optimal operating temperatures throughout the display, significantly extending Mini LED lifespan while reducing overall power consumption.

The primary thermal management approaches for Mini LED displays include passive and active cooling strategies. Passive solutions utilize materials with high thermal conductivity, such as aluminum or copper heat sinks, to dissipate heat away from sensitive components. These materials create efficient thermal pathways that draw heat from the LEDs and distribute it across larger surface areas for dissipation.

Advanced thermal interface materials (TIMs) play a crucial role in optimizing heat transfer between components. Modern TIMs include phase-change materials, graphite sheets, and metal-infused polymers that conform to surface irregularities, minimizing thermal resistance at component interfaces. These materials significantly improve thermal conductivity while maintaining electrical isolation where necessary.

Active cooling mechanisms supplement passive approaches in high-brightness applications. Micro-fans, thermoelectric coolers, and liquid cooling systems actively remove heat from critical areas. Particularly innovative are vapor chamber cooling solutions that utilize phase-change principles to transport heat rapidly away from LED clusters, maintaining more uniform temperature distribution across the display panel.

Thermal simulation and modeling have become essential design tools for Mini LED manufacturers. Computational fluid dynamics (CFD) simulations enable engineers to identify potential hotspots before physical prototyping, optimizing component placement and thermal pathway design. These simulations account for various operating conditions, helping create robust thermal management systems that perform reliably across diverse environments.

Emerging approaches include integration of microfluidic channels directly into display substrates, allowing coolant to circulate closer to heat sources. Additionally, advanced thermal management algorithms dynamically adjust brightness levels based on temperature sensors, preventing thermal runaway conditions while maximizing performance within safe operating parameters.

The implementation of zone-specific thermal management, where cooling solutions are tailored to different display regions based on their heat generation profiles, represents another optimization frontier. This targeted approach ensures efficient resource allocation while maintaining optimal operating temperatures throughout the display, significantly extending Mini LED lifespan while reducing overall power consumption.

Environmental Impact and Sustainability Considerations

The environmental impact of Mini LED technology extends beyond energy efficiency to encompass the entire lifecycle of these components. Mini LED designs optimized for longer lifespan directly contribute to sustainability by reducing electronic waste generation. With conventional LED displays requiring replacement every 3-5 years, extending Mini LED lifespan to 7-10 years could potentially decrease e-waste volume by 40-50% in this product category.

Material selection plays a crucial role in both environmental impact and longevity. Traditional LED manufacturing relies heavily on rare earth elements like gallium, indium, and phosphor compounds. Sustainable Mini LED design approaches include reducing rare earth content by 15-30% through advanced epitaxial structures and exploring alternative materials with lower environmental footprints. Recent research indicates that gallium nitride on silicon (GaN-on-Si) technology can reduce manufacturing resource intensity while maintaining performance characteristics.

Manufacturing processes for Mini LEDs present significant environmental challenges, particularly in energy consumption and chemical usage. Advanced facilities implementing energy-efficient production techniques have demonstrated potential reductions of 25-35% in carbon emissions compared to standard manufacturing. Water recycling systems in Mini LED production can reclaim up to 80% of process water, addressing a critical environmental concern in semiconductor manufacturing.

Heat management solutions in Mini LED designs impact both lifespan and environmental footprint. Passive cooling technologies that eliminate the need for energy-consuming fans can reduce operational energy requirements by 10-15% over the product lifetime. Thermally efficient designs that distribute heat more effectively not only extend component lifespan but also reduce the thermal load on surrounding systems, creating cascading energy benefits.

End-of-life considerations must be integrated into Mini LED design optimization. Modular approaches that allow for component replacement rather than complete system disposal can extend functional product life by 30-50%. Additionally, designing for disassembly enables more effective material recovery, with potential recycling rates increasing from current industry averages of 20-30% to theoretical maximums of 75-85% for properly designed systems. These circular economy principles represent a significant opportunity to reduce the environmental impact of display technologies.

Material selection plays a crucial role in both environmental impact and longevity. Traditional LED manufacturing relies heavily on rare earth elements like gallium, indium, and phosphor compounds. Sustainable Mini LED design approaches include reducing rare earth content by 15-30% through advanced epitaxial structures and exploring alternative materials with lower environmental footprints. Recent research indicates that gallium nitride on silicon (GaN-on-Si) technology can reduce manufacturing resource intensity while maintaining performance characteristics.

Manufacturing processes for Mini LEDs present significant environmental challenges, particularly in energy consumption and chemical usage. Advanced facilities implementing energy-efficient production techniques have demonstrated potential reductions of 25-35% in carbon emissions compared to standard manufacturing. Water recycling systems in Mini LED production can reclaim up to 80% of process water, addressing a critical environmental concern in semiconductor manufacturing.

Heat management solutions in Mini LED designs impact both lifespan and environmental footprint. Passive cooling technologies that eliminate the need for energy-consuming fans can reduce operational energy requirements by 10-15% over the product lifetime. Thermally efficient designs that distribute heat more effectively not only extend component lifespan but also reduce the thermal load on surrounding systems, creating cascading energy benefits.

End-of-life considerations must be integrated into Mini LED design optimization. Modular approaches that allow for component replacement rather than complete system disposal can extend functional product life by 30-50%. Additionally, designing for disassembly enables more effective material recovery, with potential recycling rates increasing from current industry averages of 20-30% to theoretical maximums of 75-85% for properly designed systems. These circular economy principles represent a significant opportunity to reduce the environmental impact of display technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!