Mini LED vs AMOLED: Comparing Color Depth

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Display Technology Evolution and Objectives

Display technology has undergone remarkable evolution since the introduction of cathode ray tubes (CRTs) in the early 20th century. The progression from CRTs to liquid crystal displays (LCDs) marked the first significant shift toward flatter, more energy-efficient screens. This evolution continued with the development of plasma display panels (PDPs), which offered improved contrast ratios and viewing angles but suffered from high power consumption and screen burn-in issues.

The 2000s witnessed the emergence of organic light-emitting diode (OLED) technology, revolutionizing display capabilities with self-emissive pixels that eliminated the need for backlighting. This innovation enabled thinner form factors, perfect blacks, and enhanced color reproduction. AMOLED (Active Matrix OLED) further refined this technology by incorporating a thin-film transistor (TFT) backplane for improved control over individual pixels.

More recently, Mini LED technology has emerged as a significant advancement in LCD backlighting. By utilizing thousands of tiny LEDs (typically 0.1-0.2mm) arranged in multiple dimming zones, Mini LED displays achieve improved contrast ratios and brightness levels that approach OLED quality while maintaining LCD's advantages in longevity and resistance to burn-in.

The technical objectives in display development have consistently centered around several key parameters: color accuracy, contrast ratio, brightness, power efficiency, viewing angles, and response time. Color depth specifically refers to the number of distinct colors a display can produce, typically measured in bits per channel. While early displays were limited to 6-bit color (64 shades per RGB channel), modern premium displays aim for 10-bit or even 12-bit color depth, representing billions of possible colors.

In comparing Mini LED and AMOLED technologies specifically regarding color depth, the industry aims to achieve displays capable of reproducing the full spectrum of human visual perception. The technical goal is to develop displays that can accurately represent standardized color spaces such as DCI-P3 (used in digital cinema) and Rec. 2020 (ultra-high-definition television standard), which require precise color reproduction across a wide gamut.

The evolution trajectory suggests a convergence of technologies, with each addressing the other's weaknesses. Future display technology objectives include achieving quantum dot color conversion efficiency in OLED (QD-OLED), improving Mini LED local dimming algorithms, reducing power consumption while maintaining peak brightness, and developing more sustainable manufacturing processes with reduced environmental impact.

The 2000s witnessed the emergence of organic light-emitting diode (OLED) technology, revolutionizing display capabilities with self-emissive pixels that eliminated the need for backlighting. This innovation enabled thinner form factors, perfect blacks, and enhanced color reproduction. AMOLED (Active Matrix OLED) further refined this technology by incorporating a thin-film transistor (TFT) backplane for improved control over individual pixels.

More recently, Mini LED technology has emerged as a significant advancement in LCD backlighting. By utilizing thousands of tiny LEDs (typically 0.1-0.2mm) arranged in multiple dimming zones, Mini LED displays achieve improved contrast ratios and brightness levels that approach OLED quality while maintaining LCD's advantages in longevity and resistance to burn-in.

The technical objectives in display development have consistently centered around several key parameters: color accuracy, contrast ratio, brightness, power efficiency, viewing angles, and response time. Color depth specifically refers to the number of distinct colors a display can produce, typically measured in bits per channel. While early displays were limited to 6-bit color (64 shades per RGB channel), modern premium displays aim for 10-bit or even 12-bit color depth, representing billions of possible colors.

In comparing Mini LED and AMOLED technologies specifically regarding color depth, the industry aims to achieve displays capable of reproducing the full spectrum of human visual perception. The technical goal is to develop displays that can accurately represent standardized color spaces such as DCI-P3 (used in digital cinema) and Rec. 2020 (ultra-high-definition television standard), which require precise color reproduction across a wide gamut.

The evolution trajectory suggests a convergence of technologies, with each addressing the other's weaknesses. Future display technology objectives include achieving quantum dot color conversion efficiency in OLED (QD-OLED), improving Mini LED local dimming algorithms, reducing power consumption while maintaining peak brightness, and developing more sustainable manufacturing processes with reduced environmental impact.

Market Analysis for High Color Depth Displays

The high color depth display market is experiencing robust growth driven by increasing consumer demand for premium visual experiences across multiple device categories. Currently valued at approximately $25 billion globally, this segment is projected to grow at a CAGR of 15.7% through 2028, with particularly strong momentum in the smartphone, premium television, and professional monitor sectors.

Consumer electronics represents the largest application segment, accounting for nearly 65% of the high color depth display market. Within this category, smartphones dominate with over 1.5 billion units shipped annually, where color accuracy and depth have become critical differentiating factors for premium devices. The professional market segment, including design, photography, and video production, though smaller in volume, commands higher margins with displays priced 3-4 times higher than consumer equivalents.

Regionally, East Asia continues to lead market consumption and production, with China, South Korea, and Japan collectively representing 58% of global market share. North America and Europe follow at 22% and 17% respectively, with both regions showing increased demand for professional-grade displays with superior color reproduction capabilities.

The Mini LED and AMOLED technologies are positioned at different price-performance points in the market. AMOLED displays currently command a premium price position, with an average 30% higher cost than comparable Mini LED solutions. However, this gap is narrowing as Mini LED manufacturing scales and AMOLED production efficiencies improve.

Market research indicates that consumers increasingly recognize and value color depth as a purchase criterion, with 72% of premium smartphone buyers and 68% of high-end television purchasers citing color accuracy as "very important" or "extremely important" in recent surveys. This represents a significant shift from five years ago when only 45% of consumers prioritized this feature.

Industry forecasts suggest that by 2025, displays capable of reproducing over 1 billion colors will become standard in mid-range devices, while premium segments will push toward 10-bit and 12-bit color depth capabilities. This trend is accelerating the competition between Mini LED and AMOLED technologies, with manufacturers investing heavily in R&D to maximize color performance while optimizing production costs.

The enterprise and commercial sectors are emerging as significant growth drivers, with digital signage, automotive displays, and medical imaging applications increasingly requiring higher color accuracy. These B2B segments are projected to grow at 18.3% annually through 2027, outpacing the consumer market and potentially reshaping technology investment priorities for display manufacturers.

Consumer electronics represents the largest application segment, accounting for nearly 65% of the high color depth display market. Within this category, smartphones dominate with over 1.5 billion units shipped annually, where color accuracy and depth have become critical differentiating factors for premium devices. The professional market segment, including design, photography, and video production, though smaller in volume, commands higher margins with displays priced 3-4 times higher than consumer equivalents.

Regionally, East Asia continues to lead market consumption and production, with China, South Korea, and Japan collectively representing 58% of global market share. North America and Europe follow at 22% and 17% respectively, with both regions showing increased demand for professional-grade displays with superior color reproduction capabilities.

The Mini LED and AMOLED technologies are positioned at different price-performance points in the market. AMOLED displays currently command a premium price position, with an average 30% higher cost than comparable Mini LED solutions. However, this gap is narrowing as Mini LED manufacturing scales and AMOLED production efficiencies improve.

Market research indicates that consumers increasingly recognize and value color depth as a purchase criterion, with 72% of premium smartphone buyers and 68% of high-end television purchasers citing color accuracy as "very important" or "extremely important" in recent surveys. This represents a significant shift from five years ago when only 45% of consumers prioritized this feature.

Industry forecasts suggest that by 2025, displays capable of reproducing over 1 billion colors will become standard in mid-range devices, while premium segments will push toward 10-bit and 12-bit color depth capabilities. This trend is accelerating the competition between Mini LED and AMOLED technologies, with manufacturers investing heavily in R&D to maximize color performance while optimizing production costs.

The enterprise and commercial sectors are emerging as significant growth drivers, with digital signage, automotive displays, and medical imaging applications increasingly requiring higher color accuracy. These B2B segments are projected to grow at 18.3% annually through 2027, outpacing the consumer market and potentially reshaping technology investment priorities for display manufacturers.

Mini LED and AMOLED Technical Challenges

Both Mini LED and AMOLED technologies face distinct technical challenges in achieving optimal color depth performance. Mini LED backlighting systems struggle with precise local dimming control due to the physical limitations of LED zone density. Even with thousands of dimming zones, Mini LED displays cannot match the pixel-level light control of OLED technologies, resulting in blooming effects where bright objects on dark backgrounds create visible halos.

The manufacturing process for Mini LED presents significant yield challenges, particularly in achieving consistent LED chip quality and precise placement during assembly. The miniaturization of LED chips to sizes below 100 micrometers introduces complexities in handling, positioning, and electrical connection that impact production costs and reliability.

AMOLED displays face their own set of technical hurdles in color depth implementation. The organic materials used in AMOLED pixels experience uneven aging, with blue subpixels typically degrading faster than red and green counterparts. This differential degradation leads to color shifts over time, affecting long-term color accuracy and consistency across the display.

Power consumption management represents another critical challenge for AMOLED technology. Displaying bright content, particularly white backgrounds, requires significantly more power than darker content, creating efficiency concerns for applications requiring high brightness levels. This characteristic necessitates sophisticated power management algorithms to balance visual quality with battery life.

Color calibration and management systems differ substantially between these technologies. Mini LED displays must coordinate backlight dimming zones with LCD color filters to achieve accurate color reproduction, requiring complex algorithms to prevent color shifting during dynamic content playback. AMOLED displays require individual pixel-level calibration to compensate for manufacturing variations in organic material deposition.

Thermal management presents challenges for both technologies but manifests differently. Mini LED backlighting systems generate considerable heat that must be efficiently dissipated to maintain performance and longevity. AMOLED displays experience performance degradation at high temperatures, with potential acceleration of organic material breakdown affecting color accuracy and display lifespan.

Cost-performance optimization remains an ongoing challenge, with Mini LED technology requiring significant investment in backlighting systems while still utilizing traditional LCD panels. AMOLED manufacturing processes demand extremely precise deposition of organic materials and thin-film transistors, contributing to higher production costs and potential yield issues at larger screen sizes.

The manufacturing process for Mini LED presents significant yield challenges, particularly in achieving consistent LED chip quality and precise placement during assembly. The miniaturization of LED chips to sizes below 100 micrometers introduces complexities in handling, positioning, and electrical connection that impact production costs and reliability.

AMOLED displays face their own set of technical hurdles in color depth implementation. The organic materials used in AMOLED pixels experience uneven aging, with blue subpixels typically degrading faster than red and green counterparts. This differential degradation leads to color shifts over time, affecting long-term color accuracy and consistency across the display.

Power consumption management represents another critical challenge for AMOLED technology. Displaying bright content, particularly white backgrounds, requires significantly more power than darker content, creating efficiency concerns for applications requiring high brightness levels. This characteristic necessitates sophisticated power management algorithms to balance visual quality with battery life.

Color calibration and management systems differ substantially between these technologies. Mini LED displays must coordinate backlight dimming zones with LCD color filters to achieve accurate color reproduction, requiring complex algorithms to prevent color shifting during dynamic content playback. AMOLED displays require individual pixel-level calibration to compensate for manufacturing variations in organic material deposition.

Thermal management presents challenges for both technologies but manifests differently. Mini LED backlighting systems generate considerable heat that must be efficiently dissipated to maintain performance and longevity. AMOLED displays experience performance degradation at high temperatures, with potential acceleration of organic material breakdown affecting color accuracy and display lifespan.

Cost-performance optimization remains an ongoing challenge, with Mini LED technology requiring significant investment in backlighting systems while still utilizing traditional LCD panels. AMOLED manufacturing processes demand extremely precise deposition of organic materials and thin-film transistors, contributing to higher production costs and potential yield issues at larger screen sizes.

Current Color Depth Solutions Comparison

01 Color depth enhancement in Mini LED displays

Mini LED technology utilizes thousands of tiny LED chips as a backlight source for LCD panels, enabling precise local dimming zones that significantly improve contrast ratios and color depth. By controlling these zones independently, Mini LED displays can achieve deeper blacks and more vibrant colors, approaching OLED-like performance while maintaining higher brightness levels. Advanced driver ICs and backlight control algorithms further optimize color reproduction and bit depth capabilities.- Color depth enhancement in Mini LED displays: Mini LED technology utilizes thousands of tiny LED chips as a backlight source for LCD panels, enabling precise local dimming to enhance contrast ratios and color depth. By controlling individual LED zones, Mini LED displays can achieve deeper blacks and more vibrant colors compared to traditional LED backlighting. Advanced driver ICs and algorithms optimize the color reproduction capabilities, allowing for higher bit depth processing and expanded color gamuts that approach OLED quality while maintaining higher brightness levels.

- AMOLED color depth technologies: AMOLED displays utilize active matrix technology with organic light-emitting diodes to achieve superior color depth through pixel-level light emission. Each pixel in an AMOLED display can be individually controlled to emit light at various intensity levels, enabling true blacks and infinite contrast ratios. Advanced AMOLED panels support 10-bit or higher color depth, allowing for over a billion colors and smoother gradients. The organic materials used in AMOLED displays naturally produce vibrant colors with wide color gamuts that exceed standard RGB color spaces.

- Driving methods for high color depth displays: Specialized driving methods are employed to achieve enhanced color depth in both Mini LED and AMOLED displays. These include pulse width modulation (PWM) techniques, frame rate control (FRC), and dithering algorithms that can simulate higher bit depths even on panels with physical limitations. Advanced compensation algorithms correct for non-uniformities and color shifts across the display area. Multi-frame rendering techniques combine data from consecutive frames to increase the effective color depth, while adaptive refresh rate technologies optimize power consumption while maintaining color accuracy.

- Color management systems for display technologies: Sophisticated color management systems are implemented in both Mini LED and AMOLED displays to ensure accurate color reproduction and consistent color depth across different content types. These systems include hardware calibration tools, color space conversion algorithms, and gamma correction techniques. Adaptive color processing adjusts display parameters based on ambient lighting conditions and content characteristics. HDR processing enhances the dynamic range of displayed content, allowing for more detailed highlights and shadows while preserving color accuracy across the entire luminance range.

- Hybrid display technologies combining Mini LED and AMOLED benefits: Emerging hybrid display technologies aim to combine the advantages of both Mini LED and AMOLED to achieve superior color depth. These include dual-layer displays that use Mini LED backlighting with AMOLED color filters, or tandem structures that integrate both technologies in different ways. Some approaches use Mini LED for high brightness elements while using AMOLED for deep blacks and color accuracy. Advanced quantum dot color conversion layers enhance the color gamut in both technologies, while specialized optical films improve viewing angles and reduce reflections to maintain color fidelity under various conditions.

02 AMOLED color reproduction technologies

AMOLED displays utilize active matrix organic light-emitting diodes that emit their own light, eliminating the need for backlighting. This self-emissive nature allows for perfect blacks, infinite contrast ratios, and superior color reproduction. AMOLED panels can display wider color gamuts (such as DCI-P3 and Rec.2020) and support higher bit depths through advanced pixel structures and driving methods. Compensation circuits are implemented to maintain color accuracy and prevent degradation over time.Expand Specific Solutions03 Hybrid display technologies combining Mini LED and AMOLED

Innovative hybrid display solutions combine the advantages of both Mini LED and AMOLED technologies to achieve superior color depth and image quality. These hybrid approaches may use Mini LED backlighting with AMOLED color filters, or segment displays into zones using different technologies. The combination allows for enhanced HDR performance, improved power efficiency, and expanded color gamut coverage while mitigating the limitations of each individual technology.Expand Specific Solutions04 Color management systems for high bit depth displays

Advanced color management systems are essential for maximizing the color depth capabilities of both Mini LED and AMOLED displays. These systems include sophisticated algorithms for color mapping, gamma correction, and dithering techniques that can effectively increase the perceived bit depth. Hardware-based solutions incorporate specialized processing units that handle color transformations in real-time, enabling 10-bit, 12-bit, or even higher color depth representation while maintaining frame rates and power efficiency.Expand Specific Solutions05 Pixel structure innovations for enhanced color depth

Novel pixel architectures and subpixel arrangements significantly impact the color depth capabilities of both Mini LED and AMOLED displays. These innovations include RGBW pixel layouts, pentile arrangements, and micro-lens arrays that improve light efficiency and color reproduction. Advanced thin-film transistor (TFT) backplanes with higher electron mobility support faster refresh rates and more precise voltage control, enabling finer gradations of color and improved bit depth representation without visible banding artifacts.Expand Specific Solutions

Key Display Manufacturers and Ecosystem

The Mini LED vs AMOLED color depth competition is evolving in a rapidly growing display market, currently transitioning from early adoption to mainstream implementation. Major players like BOE Technology, Samsung Electronics, and TCL China Star Optoelectronics are driving innovation in both technologies. Mini LED technology, championed by companies such as BOE Mled Technology and Lumileds Singapore, is approaching maturity with significant advancements in backlighting solutions. Meanwhile, AMOLED technology, led by Samsung Electronics and BOE, offers superior color depth and contrast but faces manufacturing complexity challenges. The market is experiencing convergence as manufacturers like TCL and BOE develop hybrid solutions that leverage strengths of both technologies to optimize color performance.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has developed advanced Mini LED backlight technology that achieves significantly improved color depth compared to traditional LCD displays. Their Mini LED solutions utilize thousands of miniaturized LED chips arranged in multiple dimming zones (typically 1000+ zones in premium models), allowing for precise local dimming control. This enables contrast ratios exceeding 1,000,000:1 and color depth support of up to 1.07 billion colors (10-bit). BOE's proprietary quantum dot enhancement film (QDEF) layer works in conjunction with Mini LED backlighting to expand the color gamut to over 90% of the DCI-P3 standard. Their latest panels feature advanced driver ICs capable of processing 12-bit color signals internally while outputting 10-bit color, resulting in smoother gradients and reduced banding effects compared to standard 8-bit panels.

Strengths: Superior brightness (up to 1500 nits peak), excellent HDR performance with minimal blooming compared to conventional LCDs, better power efficiency than full-array local dimming, and longer lifespan than AMOLED. Weaknesses: Cannot achieve the perfect blacks of AMOLED due to some light leakage in dimming zones, thicker panel construction than AMOLED, and higher manufacturing complexity leading to increased costs.

TCL China Star Optoelectronics Technology Co., Ltd.

Technical Solution: TCL CSOT has developed their proprietary "Vidrian Mini LED" technology that integrates the Mini LED backlight directly onto a glass substrate using semiconductor processing techniques. This approach allows for significantly higher density of Mini LED chips (up to 25,000 LEDs in premium models) and more precise dimming zones (2000+) compared to conventional assembly methods. Their advanced local dimming algorithms analyze content in real-time to optimize contrast and minimize blooming effects. TCL CSOT's Mini LED displays support 12-bit internal color processing with 10-bit output, delivering over 1.07 billion colors with quantum dot enhancement layer expanding the color gamut to 95% of the DCI-P3 standard. Their latest generation incorporates advanced optical films that reduce internal reflections and improve light uniformity across the panel, addressing common Mini LED challenges.

Strengths: Exceptional brightness capability (up to 2000 nits peak), superior HDR performance with minimal blooming, better power efficiency than conventional LCDs, and significantly longer lifespan than OLED technology. Weaknesses: Higher manufacturing complexity and cost than conventional LCDs, cannot achieve the perfect black levels of OLED, and thicker overall panel construction than AMOLED solutions.

Color Reproduction Patents and Innovations

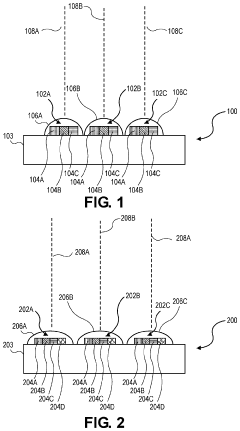

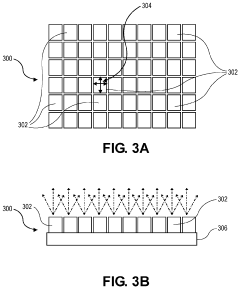

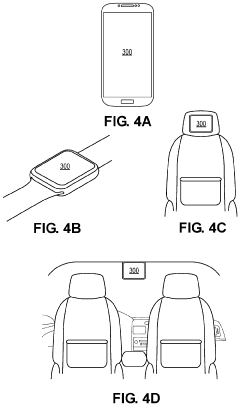

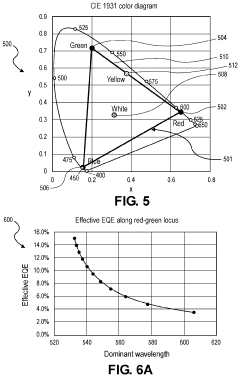

Microled display

PatentActiveUS20230196965A1

Innovation

- Incorporating a fourth microLED that emits light along the red-green locus, such as yellow or amber, to improve overall display efficiency by reducing the dominance of red microLED performance, thereby enhancing the EQE and lumens per watt (lm/W) gain.

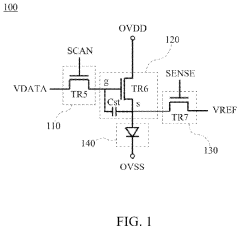

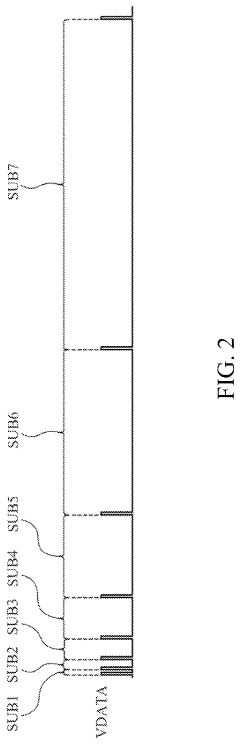

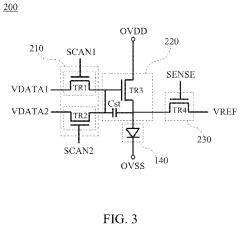

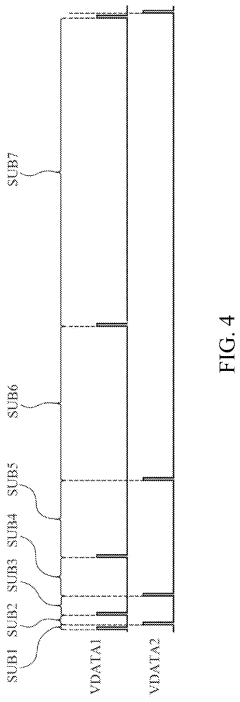

Pixel-driving circuit and display device

PatentActiveUS20240029628A1

Innovation

- A pixel-driving circuit is designed with a switching circuit and a driving circuit that alternately provides pulse signals with odd and even sub-cycles, reducing the driving frequency by increasing the duty cycle of the smallest sub-cycle, thereby reducing the overall driving frequency and allowing for higher resolution and more sub-cycles.

Power Efficiency vs Color Performance

When comparing Mini LED and AMOLED display technologies, power efficiency and color performance represent critical factors that influence both consumer experience and device design considerations. Mini LED displays typically demonstrate superior power efficiency in scenarios displaying bright content. This advantage stems from their backlight architecture, which can selectively dim or brighten specific zones, reducing power consumption when displaying predominantly dark content with bright highlights.

AMOLED displays, conversely, excel in power efficiency when displaying darker content, as individual pixels can be completely turned off, consuming virtually no power in black areas. This characteristic makes AMOLED particularly advantageous for applications with dark-mode interfaces or content with significant black regions, such as many video streaming platforms and mobile applications.

The relationship between power consumption and brightness levels differs significantly between these technologies. Mini LED displays maintain relatively consistent power consumption across brightness levels, with modest increases at higher brightness settings. AMOLED power consumption scales more directly with the brightness and quantity of illuminated pixels, resulting in potentially dramatic power savings for dark content but higher consumption for bright, full-screen applications.

Color performance introduces additional complexity to this comparison. AMOLED displays generally offer superior color volume and saturation, particularly in reproducing deep blacks and vibrant colors simultaneously. This advantage derives from their self-emissive nature, allowing for infinite contrast ratios that Mini LED, despite its advanced local dimming capabilities, cannot fully match.

However, Mini LED displays often demonstrate better color consistency across different brightness levels and viewing angles. AMOLED displays may experience color shifting at extreme viewing angles and can suffer from brightness-dependent color accuracy variations. Additionally, Mini LED typically maintains more consistent color reproduction over the display's lifespan, whereas AMOLED may experience color degradation, particularly with blue subpixels, leading to potential color imbalance over time.

The power-to-performance ratio ultimately depends on specific use cases. Content-creation professionals may prioritize the color accuracy and consistency of Mini LED despite potentially higher power requirements. Mobile device manufacturers might favor AMOLED for its power efficiency with dark interfaces, despite potential long-term color degradation concerns. Gaming applications present a particularly complex scenario, as they combine high brightness requirements with rapid scene changes, creating variable power demands that affect both technologies differently.

AMOLED displays, conversely, excel in power efficiency when displaying darker content, as individual pixels can be completely turned off, consuming virtually no power in black areas. This characteristic makes AMOLED particularly advantageous for applications with dark-mode interfaces or content with significant black regions, such as many video streaming platforms and mobile applications.

The relationship between power consumption and brightness levels differs significantly between these technologies. Mini LED displays maintain relatively consistent power consumption across brightness levels, with modest increases at higher brightness settings. AMOLED power consumption scales more directly with the brightness and quantity of illuminated pixels, resulting in potentially dramatic power savings for dark content but higher consumption for bright, full-screen applications.

Color performance introduces additional complexity to this comparison. AMOLED displays generally offer superior color volume and saturation, particularly in reproducing deep blacks and vibrant colors simultaneously. This advantage derives from their self-emissive nature, allowing for infinite contrast ratios that Mini LED, despite its advanced local dimming capabilities, cannot fully match.

However, Mini LED displays often demonstrate better color consistency across different brightness levels and viewing angles. AMOLED displays may experience color shifting at extreme viewing angles and can suffer from brightness-dependent color accuracy variations. Additionally, Mini LED typically maintains more consistent color reproduction over the display's lifespan, whereas AMOLED may experience color degradation, particularly with blue subpixels, leading to potential color imbalance over time.

The power-to-performance ratio ultimately depends on specific use cases. Content-creation professionals may prioritize the color accuracy and consistency of Mini LED despite potentially higher power requirements. Mobile device manufacturers might favor AMOLED for its power efficiency with dark interfaces, despite potential long-term color degradation concerns. Gaming applications present a particularly complex scenario, as they combine high brightness requirements with rapid scene changes, creating variable power demands that affect both technologies differently.

Manufacturing Cost Analysis and Scalability

The manufacturing cost structure of Mini LED and AMOLED technologies reveals significant differences that impact their market adoption and scalability. Mini LED displays currently command a 30-40% cost premium over traditional LCD panels, primarily due to the complex backlighting system requiring thousands of tiny LED chips. This cost differential is gradually narrowing as manufacturing processes mature and economies of scale take effect, with industry analysts projecting a reduction to 15-20% premium by 2025.

AMOLED manufacturing, dominated by Samsung Display and LG Display, involves highly specialized vacuum deposition processes that require substantial capital investment. The initial facility setup costs for AMOLED production lines typically range from $5-8 billion, creating significant barriers to entry. Yield rates remain a critical challenge, with industry averages hovering around 70-80% for premium AMOLED panels, compared to over 90% for mature LCD and Mini LED technologies.

Material costs present another dimension of comparison. AMOLED displays utilize organic compounds that are relatively expensive and subject to degradation over time, particularly for blue subpixels. Mini LED backlighting systems rely on inorganic semiconductor materials that offer longer lifespans but require precise placement technologies. The semiconductor substrate costs for Mini LED have decreased approximately 15% year-over-year as production volumes increase.

From a scalability perspective, Mini LED technology demonstrates advantages in leveraging existing LCD manufacturing infrastructure. Manufacturers can retrofit current LCD production lines to accommodate Mini LED backlighting with incremental investments of $200-300 million per line, representing a more accessible upgrade path. This adaptability has enabled companies like TCL, BOE, and AUO to rapidly scale Mini LED production without building entirely new facilities.

Labor requirements also differ significantly between technologies. AMOLED production remains more labor-intensive despite automation advances, requiring approximately 30% more specialized technicians per square meter of display produced compared to Mini LED manufacturing. This differential contributes to higher operational costs in regions with rising labor expenses.

Energy consumption during manufacturing presents another cost factor, with AMOLED fabrication requiring approximately 25-35% more energy per unit area due to the vacuum deposition processes and high-temperature operations. This energy intensity impacts both production costs and environmental sustainability metrics, becoming increasingly relevant as manufacturers face carbon reduction pressures.

AMOLED manufacturing, dominated by Samsung Display and LG Display, involves highly specialized vacuum deposition processes that require substantial capital investment. The initial facility setup costs for AMOLED production lines typically range from $5-8 billion, creating significant barriers to entry. Yield rates remain a critical challenge, with industry averages hovering around 70-80% for premium AMOLED panels, compared to over 90% for mature LCD and Mini LED technologies.

Material costs present another dimension of comparison. AMOLED displays utilize organic compounds that are relatively expensive and subject to degradation over time, particularly for blue subpixels. Mini LED backlighting systems rely on inorganic semiconductor materials that offer longer lifespans but require precise placement technologies. The semiconductor substrate costs for Mini LED have decreased approximately 15% year-over-year as production volumes increase.

From a scalability perspective, Mini LED technology demonstrates advantages in leveraging existing LCD manufacturing infrastructure. Manufacturers can retrofit current LCD production lines to accommodate Mini LED backlighting with incremental investments of $200-300 million per line, representing a more accessible upgrade path. This adaptability has enabled companies like TCL, BOE, and AUO to rapidly scale Mini LED production without building entirely new facilities.

Labor requirements also differ significantly between technologies. AMOLED production remains more labor-intensive despite automation advances, requiring approximately 30% more specialized technicians per square meter of display produced compared to Mini LED manufacturing. This differential contributes to higher operational costs in regions with rising labor expenses.

Energy consumption during manufacturing presents another cost factor, with AMOLED fabrication requiring approximately 25-35% more energy per unit area due to the vacuum deposition processes and high-temperature operations. This energy intensity impacts both production costs and environmental sustainability metrics, becoming increasingly relevant as manufacturers face carbon reduction pressures.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!