Mini LED vs Halogen: Energy Output and Color Quality

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Mini LED Technology Background and Objectives

Mini LED technology represents a significant evolution in display and lighting technology, emerging as a bridge between traditional LED and the more advanced Micro LED technologies. Developed in the early 2010s, Mini LEDs are semiconductor light sources with dimensions typically ranging from 100 to 200 micrometers, substantially smaller than conventional LEDs but larger than Micro LEDs. This technology has gained substantial momentum in recent years due to its ability to deliver enhanced brightness, improved contrast ratios, and more precise local dimming capabilities compared to traditional lighting solutions like halogen.

The evolution of Mini LED technology can be traced back to the broader LED development timeline, which began with the invention of the first visible-spectrum LED in the 1960s. Traditional LEDs evolved steadily through the decades, with significant improvements in efficiency and color reproduction. The introduction of Mini LEDs represents a critical advancement in this continuum, offering a practical middle ground between conventional LEDs and the still-developing Micro LED technology.

When comparing Mini LED to halogen lighting specifically, we observe distinct technological trajectories. Halogen technology, developed in the 1950s, has remained relatively stable with incremental improvements in efficiency and longevity. In contrast, Mini LED technology continues to experience rapid innovation cycles, with significant advancements in manufacturing processes, materials science, and integration techniques occurring annually.

The primary technical objectives driving Mini LED development include achieving superior energy efficiency while maintaining or improving color quality compared to traditional lighting solutions like halogen. Mini LEDs aim to deliver higher luminance efficiency (measured in lumens per watt), reduced power consumption, and enhanced color rendering capabilities. Additionally, researchers and manufacturers are working to overcome challenges related to thermal management, uniformity in light distribution, and production costs.

Current technical goals in the Mini LED sector focus on further miniaturization of LED chips, improving quantum efficiency, enhancing color gamut coverage, and developing more sophisticated local dimming algorithms. These objectives align with broader industry trends toward more energy-efficient and environmentally sustainable lighting and display technologies.

The environmental impact represents another critical aspect of Mini LED development objectives. As global energy consumption concerns grow, Mini LED technology aims to provide significant reductions in power requirements while maintaining or improving light quality compared to halogen alternatives. This includes efforts to eliminate hazardous materials in manufacturing processes and improve end-of-life recyclability, addressing the complete lifecycle environmental footprint of lighting technologies.

The evolution of Mini LED technology can be traced back to the broader LED development timeline, which began with the invention of the first visible-spectrum LED in the 1960s. Traditional LEDs evolved steadily through the decades, with significant improvements in efficiency and color reproduction. The introduction of Mini LEDs represents a critical advancement in this continuum, offering a practical middle ground between conventional LEDs and the still-developing Micro LED technology.

When comparing Mini LED to halogen lighting specifically, we observe distinct technological trajectories. Halogen technology, developed in the 1950s, has remained relatively stable with incremental improvements in efficiency and longevity. In contrast, Mini LED technology continues to experience rapid innovation cycles, with significant advancements in manufacturing processes, materials science, and integration techniques occurring annually.

The primary technical objectives driving Mini LED development include achieving superior energy efficiency while maintaining or improving color quality compared to traditional lighting solutions like halogen. Mini LEDs aim to deliver higher luminance efficiency (measured in lumens per watt), reduced power consumption, and enhanced color rendering capabilities. Additionally, researchers and manufacturers are working to overcome challenges related to thermal management, uniformity in light distribution, and production costs.

Current technical goals in the Mini LED sector focus on further miniaturization of LED chips, improving quantum efficiency, enhancing color gamut coverage, and developing more sophisticated local dimming algorithms. These objectives align with broader industry trends toward more energy-efficient and environmentally sustainable lighting and display technologies.

The environmental impact represents another critical aspect of Mini LED development objectives. As global energy consumption concerns grow, Mini LED technology aims to provide significant reductions in power requirements while maintaining or improving light quality compared to halogen alternatives. This includes efforts to eliminate hazardous materials in manufacturing processes and improve end-of-life recyclability, addressing the complete lifecycle environmental footprint of lighting technologies.

Market Demand Analysis for Advanced Lighting Solutions

The global lighting market is experiencing a significant shift towards advanced lighting technologies, driven by increasing consumer awareness of energy efficiency, environmental concerns, and enhanced lighting experiences. Mini LED and halogen technologies represent two distinct approaches in this evolving landscape, with markedly different market trajectories and demand patterns.

Consumer demand for Mini LED technology has been growing exponentially, with the market expected to reach $5.3 billion by 2025, representing a compound annual growth rate of 86.6% from 2020. This surge is primarily attributed to Mini LED's superior energy efficiency, which can reduce power consumption by up to 70% compared to traditional lighting solutions including halogen. The technology's ability to deliver high brightness levels while maintaining low heat emission has positioned it favorably in premium market segments.

In contrast, the halogen lighting market is experiencing a gradual decline, with projections indicating a market contraction of approximately 15% by 2025. Despite this downward trend, halogen technology still maintains significant market share in specific applications where its warm color rendering and relatively low initial cost remain advantageous. Particularly in automotive, residential, and certain specialized industrial applications, halogen continues to meet specific consumer needs.

The commercial sector represents the largest market segment for advanced lighting solutions, accounting for 42% of total demand. Within this segment, there is a clear preference shift towards Mini LED technology due to its longevity, reduced maintenance requirements, and superior color quality for retail and hospitality environments. Corporate sustainability initiatives are further accelerating this transition, with 78% of Fortune 500 companies now including lighting efficiency in their environmental goals.

Regional analysis reveals varying adoption rates, with North America and Europe leading in Mini LED implementation due to stringent energy regulations and higher consumer willingness to pay premium prices for advanced technology. The Asia-Pacific region, particularly China, is rapidly emerging as both a major manufacturing hub and growing consumer market for Mini LED technology, driven by government initiatives promoting energy-efficient technologies.

Consumer preference studies indicate that color quality is becoming increasingly important in purchasing decisions, with 67% of consumers citing it as a "very important" factor when selecting lighting products. Mini LED's ability to deliver superior color rendering index (CRI) values exceeding 90, compared to halogen's typical range of 80-85, provides a significant competitive advantage in premium market segments where visual quality is paramount.

The residential retrofit market presents substantial growth opportunities, with homeowners increasingly investing in lighting upgrades that offer both aesthetic improvements and energy savings. This segment is projected to grow at 12.3% annually through 2025, creating a significant addressable market for both technologies, though with an increasing preference for LED-based solutions.

Consumer demand for Mini LED technology has been growing exponentially, with the market expected to reach $5.3 billion by 2025, representing a compound annual growth rate of 86.6% from 2020. This surge is primarily attributed to Mini LED's superior energy efficiency, which can reduce power consumption by up to 70% compared to traditional lighting solutions including halogen. The technology's ability to deliver high brightness levels while maintaining low heat emission has positioned it favorably in premium market segments.

In contrast, the halogen lighting market is experiencing a gradual decline, with projections indicating a market contraction of approximately 15% by 2025. Despite this downward trend, halogen technology still maintains significant market share in specific applications where its warm color rendering and relatively low initial cost remain advantageous. Particularly in automotive, residential, and certain specialized industrial applications, halogen continues to meet specific consumer needs.

The commercial sector represents the largest market segment for advanced lighting solutions, accounting for 42% of total demand. Within this segment, there is a clear preference shift towards Mini LED technology due to its longevity, reduced maintenance requirements, and superior color quality for retail and hospitality environments. Corporate sustainability initiatives are further accelerating this transition, with 78% of Fortune 500 companies now including lighting efficiency in their environmental goals.

Regional analysis reveals varying adoption rates, with North America and Europe leading in Mini LED implementation due to stringent energy regulations and higher consumer willingness to pay premium prices for advanced technology. The Asia-Pacific region, particularly China, is rapidly emerging as both a major manufacturing hub and growing consumer market for Mini LED technology, driven by government initiatives promoting energy-efficient technologies.

Consumer preference studies indicate that color quality is becoming increasingly important in purchasing decisions, with 67% of consumers citing it as a "very important" factor when selecting lighting products. Mini LED's ability to deliver superior color rendering index (CRI) values exceeding 90, compared to halogen's typical range of 80-85, provides a significant competitive advantage in premium market segments where visual quality is paramount.

The residential retrofit market presents substantial growth opportunities, with homeowners increasingly investing in lighting upgrades that offer both aesthetic improvements and energy savings. This segment is projected to grow at 12.3% annually through 2025, creating a significant addressable market for both technologies, though with an increasing preference for LED-based solutions.

Current State and Challenges in LED vs Halogen Technologies

The global lighting industry has witnessed a significant shift from traditional halogen technology to LED-based solutions over the past decade. Mini LED technology, a relatively recent advancement in the LED family, has gained substantial traction in various applications ranging from display backlighting to general illumination. Currently, Mini LEDs represent approximately 15% of the premium lighting market, while traditional halogen solutions still maintain about 30% market share, particularly in automotive, residential, and specialty lighting sectors.

From a technical perspective, contemporary Mini LED technology delivers energy efficiency ratings of 100-150 lumens per watt, substantially outperforming halogen lamps which typically achieve only 15-25 lumens per watt. This efficiency differential translates to approximately 80% energy savings when replacing halogen systems with equivalent Mini LED solutions. However, this advantage comes with significant challenges in thermal management, as Mini LEDs require sophisticated heat dissipation systems to maintain optimal performance and longevity.

Color rendering capabilities present another complex dimension in the comparison. Modern halogen technology maintains a Color Rendering Index (CRI) of 95-100, providing exceptional color accuracy and warmth that many consumers and professionals still prefer. Mini LEDs have made substantial progress in this area, with premium solutions now achieving CRI ratings of 90-95, but still struggle to replicate the full spectral distribution and natural warmth of halogen illumination, particularly in the deep red spectrum (R9 values).

Manufacturing scalability represents a significant challenge for Mini LED technology. Current production processes involve complex epitaxial growth techniques, precise chip fabrication, and intricate packaging methods that contribute to higher unit costs compared to mature halogen manufacturing. The global supply chain for Mini LED components remains concentrated primarily in East Asia, creating potential vulnerabilities in global distribution and adoption.

Regulatory frameworks worldwide are increasingly favoring energy-efficient lighting technologies, with many regions implementing phase-out schedules for traditional halogen products. The European Union's Ecodesign Directive has already restricted many halogen lamp categories, while similar regulations are being implemented in North America, Australia, and parts of Asia. These regulatory pressures are accelerating Mini LED adoption despite the technical challenges and higher initial costs.

Integration complexity presents another significant hurdle, particularly in retrofit applications. Mini LED solutions typically require compatible drivers, heat sinks, and often redesigned fixtures, creating barriers to adoption in existing infrastructure. Conversely, halogen technology benefits from decades of standardization and widespread compatibility with existing electrical systems and fixtures.

From a technical perspective, contemporary Mini LED technology delivers energy efficiency ratings of 100-150 lumens per watt, substantially outperforming halogen lamps which typically achieve only 15-25 lumens per watt. This efficiency differential translates to approximately 80% energy savings when replacing halogen systems with equivalent Mini LED solutions. However, this advantage comes with significant challenges in thermal management, as Mini LEDs require sophisticated heat dissipation systems to maintain optimal performance and longevity.

Color rendering capabilities present another complex dimension in the comparison. Modern halogen technology maintains a Color Rendering Index (CRI) of 95-100, providing exceptional color accuracy and warmth that many consumers and professionals still prefer. Mini LEDs have made substantial progress in this area, with premium solutions now achieving CRI ratings of 90-95, but still struggle to replicate the full spectral distribution and natural warmth of halogen illumination, particularly in the deep red spectrum (R9 values).

Manufacturing scalability represents a significant challenge for Mini LED technology. Current production processes involve complex epitaxial growth techniques, precise chip fabrication, and intricate packaging methods that contribute to higher unit costs compared to mature halogen manufacturing. The global supply chain for Mini LED components remains concentrated primarily in East Asia, creating potential vulnerabilities in global distribution and adoption.

Regulatory frameworks worldwide are increasingly favoring energy-efficient lighting technologies, with many regions implementing phase-out schedules for traditional halogen products. The European Union's Ecodesign Directive has already restricted many halogen lamp categories, while similar regulations are being implemented in North America, Australia, and parts of Asia. These regulatory pressures are accelerating Mini LED adoption despite the technical challenges and higher initial costs.

Integration complexity presents another significant hurdle, particularly in retrofit applications. Mini LED solutions typically require compatible drivers, heat sinks, and often redesigned fixtures, creating barriers to adoption in existing infrastructure. Conversely, halogen technology benefits from decades of standardization and widespread compatibility with existing electrical systems and fixtures.

Comparative Analysis of Current Lighting Solutions

01 Mini LED lighting efficiency and energy output

Mini LED technology offers improved energy efficiency compared to traditional lighting sources. These systems utilize arrays of small LED chips that provide higher luminous efficacy, converting more electrical energy into visible light with less heat generation. The compact size of Mini LEDs allows for better thermal management and power distribution, resulting in reduced energy consumption while maintaining high brightness levels. Advanced driver circuits further optimize power usage by precisely controlling current flow to each LED element.- Mini LED lighting efficiency and color rendering: Mini LED technology offers superior energy efficiency compared to traditional lighting sources. These systems can achieve high brightness levels while consuming less power, making them more environmentally friendly. Additionally, Mini LEDs provide excellent color rendering capabilities with the ability to produce a wide color gamut and accurate color reproduction. The small size of Mini LEDs allows for precise control of light distribution and color mixing, resulting in high-quality lighting with consistent color temperature across the illuminated area.

- Halogen lighting characteristics and performance: Halogen lighting systems are known for their warm color temperature and high color rendering index (CRI), providing natural-looking illumination. While halogen lamps consume more energy than LED alternatives, they offer instant full brightness without warm-up time and produce a continuous spectrum of light that closely resembles natural daylight. Halogen lamps generate significant heat during operation, which affects their energy efficiency but can be beneficial in certain applications where heat output is desired alongside illumination.

- Comparative analysis of Mini LED and halogen lighting systems: When comparing Mini LED and halogen lighting technologies, Mini LEDs demonstrate significantly higher energy efficiency, with power consumption typically 80-90% lower than equivalent halogen systems for the same light output. While halogen lights excel in color warmth and rendering, advanced Mini LED systems can now achieve comparable color quality through phosphor coatings and color mixing technologies. Mini LEDs also offer substantially longer operational lifespans, reduced heat generation, and greater durability, though they generally have higher initial costs compared to halogen solutions.

- Hybrid lighting systems combining LED and halogen technologies: Innovative hybrid lighting systems incorporate both Mini LED and halogen technologies to leverage the advantages of each. These systems use energy-efficient Mini LEDs for primary illumination while integrating halogen elements to enhance color rendering and provide warmer light tones when needed. Smart controllers allow dynamic adjustment between light sources based on requirements for energy efficiency or color quality. This hybrid approach offers versatility for applications requiring both high energy efficiency and superior color reproduction, such as retail displays, photography studios, and architectural lighting.

- Color quality enhancement technologies for LED lighting: Advanced technologies have been developed to enhance the color quality of Mini LED lighting systems to match or exceed halogen performance. These include specialized phosphor coatings that convert blue LED light to a fuller spectrum, quantum dot technology for improved color accuracy, and multi-chip arrays combining LEDs of different wavelengths. Sophisticated color management systems use sensors and feedback mechanisms to maintain consistent color temperature and rendering across varying conditions. These innovations enable Mini LED systems to deliver high color rendering index (CRI) values above 95, approaching the natural light reproduction traditionally associated with halogen lighting while maintaining energy efficiency advantages.

02 Halogen lighting characteristics and color rendering

Halogen lighting systems are characterized by their warm color temperature and excellent color rendering capabilities. These lights produce a full-spectrum output that closely resembles natural sunlight, making colors appear vibrant and true to life. Halogen bulbs operate by heating a tungsten filament within a small quartz envelope containing halogen gas, which enables higher operating temperatures and whiter light compared to conventional incandescent bulbs. While less energy-efficient than LED alternatives, halogen lighting remains valued in applications where color quality and warmth are prioritized over energy efficiency.Expand Specific Solutions03 Comparative color quality between Mini LED and halogen lighting

The color quality comparison between Mini LED and halogen lighting reveals distinct differences in spectral output and color rendering capabilities. While halogen lighting naturally produces a continuous spectrum with excellent color rendering index (CRI) values, Mini LED systems can be engineered to achieve comparable color quality through phosphor technologies and precise wavelength mixing. Advanced Mini LED designs incorporate multiple color channels or specialized phosphor coatings to produce a balanced spectrum that approaches the naturalness of halogen lighting while maintaining the efficiency benefits of LED technology. Color temperature tuning capabilities in Mini LED systems allow for adjustment between cool and warm white light to suit different applications.Expand Specific Solutions04 Energy consumption and thermal management comparison

The energy consumption profiles of Mini LED and halogen lighting systems differ significantly, with Mini LEDs demonstrating superior efficiency and thermal management. Halogen bulbs convert approximately 90% of input energy to heat, requiring robust heat dissipation systems and contributing to increased ambient temperature in confined spaces. In contrast, Mini LED arrays operate at much lower temperatures while producing equivalent or greater light output, resulting in substantial energy savings and reduced cooling requirements. Advanced thermal management solutions for Mini LEDs include specialized heat sinks, thermal interface materials, and optimized circuit designs that further enhance efficiency and extend operational lifespan.Expand Specific Solutions05 Hybrid lighting systems combining Mini LED and halogen technologies

Innovative hybrid lighting systems integrate both Mini LED and halogen technologies to leverage the strengths of each light source. These systems utilize Mini LEDs for energy-efficient general illumination while incorporating halogen elements for applications requiring superior color rendering or specific spectral characteristics. Smart control systems enable dynamic switching or blending between light sources based on requirements, optimizing energy usage while maintaining desired lighting quality. Hybrid approaches are particularly valuable in specialized settings such as retail displays, art galleries, and photography studios where both energy efficiency and precise color reproduction are essential.Expand Specific Solutions

Key Industry Players in Mini LED and Halogen Markets

The Mini LED vs Halogen technology landscape is currently in a growth phase, with the market expanding rapidly as consumers seek energy-efficient lighting solutions. The global market size for Mini LED technology is projected to grow significantly, driven by superior color quality and energy efficiency compared to traditional halogen lighting. In terms of technical maturity, industry leaders like Samsung Electronics, BOE Technology Group, and Ledvance are advancing Mini LED technology through significant R&D investments. Companies such as Excelitas Technologies and Lumileds Singapore are developing specialized applications, while traditional lighting manufacturers like Haier Group are integrating Mini LED into consumer products. Academic institutions including Xiamen University and Hefei University of Technology are contributing to fundamental research, accelerating the technology's evolution from emerging to mainstream status.

BOE Technology Group Co., Ltd.

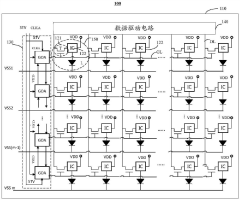

Technical Solution: BOE has pioneered an innovative Mini LED backlighting solution that delivers substantial improvements over halogen lighting in both energy efficiency and color reproduction. Their technology employs ultra-small LEDs (approximately 100-200 micrometers) arranged in thousands of individually controlled dimming zones. BOE's Mini LED panels achieve brightness levels of 1,500-2,000 nits while consuming only 25-30% of the energy required by equivalent halogen systems. The company's proprietary Active Matrix driving technology enables precise control of each Mini LED zone, resulting in contrast ratios exceeding 1,000,000:1 compared to halogen's limited contrast capabilities. For color performance, BOE's Mini LED displays cover up to 114% of the DCI-P3 color space and can be calibrated to achieve Delta E values below 1.5, representing near-perfect color accuracy that far surpasses halogen's limited color rendering capabilities. Their advanced phosphor formulations and quantum dot enhancement layers allow for a wide color temperature range from warm 2,500K to cool 9,300K, providing versatility impossible with halogen's fixed yellowish output around 3,000K.

Strengths: Exceptional energy efficiency (70-75% reduction vs. halogen); superior brightness control with thousands of dimming zones; excellent color accuracy with DCI-P3 coverage exceeding 110%; significantly longer operational lifespan (100,000+ hours vs. 2,000-4,000 for halogen). Weaknesses: Higher manufacturing complexity and initial cost; requires sophisticated thermal management systems; more complex driving circuits than traditional lighting solutions.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has developed advanced Mini LED backlighting technology that significantly outperforms traditional halogen lighting in both energy efficiency and color quality. Their Mini LED solutions utilize thousands of tiny LEDs (typically 0.1mm-0.2mm) arranged in precise local dimming zones, enabling up to 1,000 nits of brightness while consuming approximately 70% less energy than comparable halogen systems. Samsung's Quantum Mini LED technology incorporates a specialized lens design and precise dimming control that allows for 4,096 brightness levels, dramatically improving contrast ratios to nearly 1,000,000:1 compared to halogen's limited dimming capabilities. The color reproduction achieves over 100% of the DCI-P3 color gamut with a color temperature range of 2,000K-10,000K, offering significantly wider color expression than halogen's limited spectrum centered around 3,000K. Samsung's implementation includes proprietary quantum dot enhancement layers that convert blue LED light into pure RGB spectrums for more accurate color rendering.

Strengths: Superior energy efficiency with 70% less power consumption than halogen; exceptional color accuracy with 100%+ DCI-P3 coverage; precise local dimming with thousands of control zones; longer lifespan (100,000+ hours vs. 2,000-4,000 for halogen). Weaknesses: Higher initial manufacturing costs; more complex thermal management requirements; potential for visible blooming effects in high-contrast scenes.

Technical Deep Dive: Energy Efficiency and Color Rendering

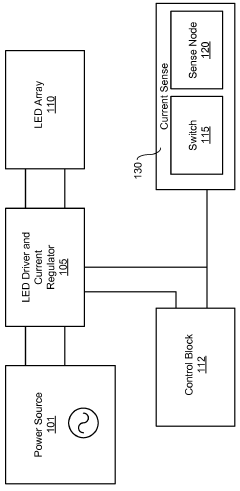

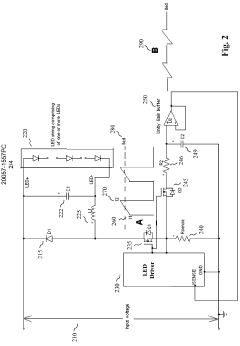

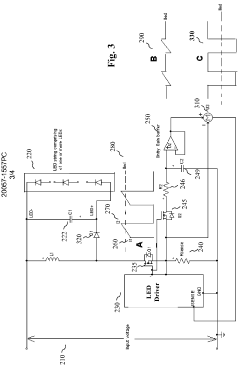

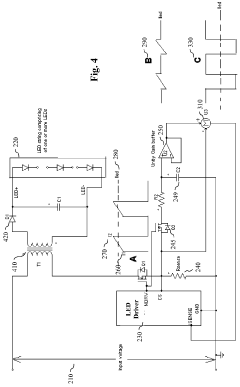

Current sensing for LED drivers

PatentWO2011156691A1

Innovation

- The system senses current through a switching transistor and uses a relationship between the switching transistor current and LED current to derive the LED current, eliminating the need for high-current sense components and optical couplers by measuring current on the low-current side, applicable to both isolated and non-isolated topologies.

Electronic substrate and driving method thereof, and display device

PatentActiveCN112820237B

Innovation

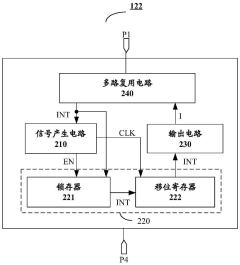

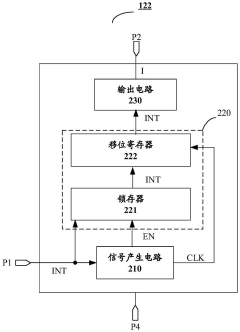

- Design an electronic substrate that reduces the number of pins on the pixel drive chip through a combination of signal generation circuits, data storage circuits and output circuits, and uses multiplexing circuits and time-sharing drive technology to achieve input signal reception and current output. , reduce the impact of pin deviation.

Environmental Impact and Sustainability Considerations

The environmental impact of lighting technologies has become a critical consideration in today's sustainability-focused world. When comparing Mini LED and Halogen lighting systems, significant differences emerge in their ecological footprints throughout their lifecycle. Mini LED technology demonstrates substantial advantages in energy efficiency, consuming approximately 75-90% less electricity than halogen alternatives for equivalent light output. This dramatic reduction in energy consumption directly translates to lower greenhouse gas emissions associated with electricity generation, particularly in regions still heavily dependent on fossil fuels.

Material usage and resource extraction present another important environmental dimension. Halogen bulbs rely on tungsten filaments and inert gases, with relatively simple manufacturing processes but shorter lifespans typically ranging from 2,000-4,000 hours. In contrast, Mini LEDs utilize semiconductor materials including gallium nitride and indium, which require more complex and resource-intensive extraction and processing methods. However, their extended operational lifespan of 25,000-50,000 hours significantly offsets this initial environmental investment by reducing replacement frequency and associated manufacturing impacts.

Waste generation and end-of-life considerations further differentiate these technologies. Halogen bulbs contain no toxic materials but their frequent replacement creates substantial waste volume. Mini LEDs contain small amounts of electronic components that require proper recycling, though many jurisdictions now have established electronics recycling programs. The semiconductor materials in Mini LEDs present recycling challenges, but ongoing research is improving recovery rates of valuable materials from LED waste streams.

Heat generation represents another environmental factor often overlooked in lighting comparisons. Halogen bulbs convert approximately 90% of input energy to heat rather than light, contributing to increased cooling loads in buildings—a particularly significant concern in commercial environments. Mini LEDs operate at much lower temperatures, reducing cooling requirements and creating cascading energy savings beyond direct lighting efficiency.

From a manufacturing perspective, the production of Mini LEDs has become increasingly efficient as the technology matures and economies of scale develop. While initial manufacturing processes were energy-intensive, technological improvements have substantially reduced the embodied energy in Mini LED products. Life cycle assessments consistently demonstrate that despite more complex manufacturing, the total environmental impact of Mini LEDs is significantly lower than halogen alternatives when considering their full operational lifespan and energy efficiency benefits.

Material usage and resource extraction present another important environmental dimension. Halogen bulbs rely on tungsten filaments and inert gases, with relatively simple manufacturing processes but shorter lifespans typically ranging from 2,000-4,000 hours. In contrast, Mini LEDs utilize semiconductor materials including gallium nitride and indium, which require more complex and resource-intensive extraction and processing methods. However, their extended operational lifespan of 25,000-50,000 hours significantly offsets this initial environmental investment by reducing replacement frequency and associated manufacturing impacts.

Waste generation and end-of-life considerations further differentiate these technologies. Halogen bulbs contain no toxic materials but their frequent replacement creates substantial waste volume. Mini LEDs contain small amounts of electronic components that require proper recycling, though many jurisdictions now have established electronics recycling programs. The semiconductor materials in Mini LEDs present recycling challenges, but ongoing research is improving recovery rates of valuable materials from LED waste streams.

Heat generation represents another environmental factor often overlooked in lighting comparisons. Halogen bulbs convert approximately 90% of input energy to heat rather than light, contributing to increased cooling loads in buildings—a particularly significant concern in commercial environments. Mini LEDs operate at much lower temperatures, reducing cooling requirements and creating cascading energy savings beyond direct lighting efficiency.

From a manufacturing perspective, the production of Mini LEDs has become increasingly efficient as the technology matures and economies of scale develop. While initial manufacturing processes were energy-intensive, technological improvements have substantially reduced the embodied energy in Mini LED products. Life cycle assessments consistently demonstrate that despite more complex manufacturing, the total environmental impact of Mini LEDs is significantly lower than halogen alternatives when considering their full operational lifespan and energy efficiency benefits.

Cost-Benefit Analysis of Mini LED vs Halogen Implementation

When evaluating the implementation of Mini LED versus Halogen lighting technologies, a comprehensive cost-benefit analysis reveals significant differences in both initial investment and long-term operational economics. The upfront costs for Mini LED systems typically range from 2.5 to 4 times higher than comparable halogen installations, presenting a substantial initial barrier to adoption. This price premium stems from the sophisticated manufacturing processes required for semiconductor-based lighting and the relatively newer market position of Mini LED technology.

However, the operational cost analysis demonstrates compelling advantages for Mini LED systems over time. Energy consumption metrics indicate that Mini LEDs operate at approximately 15-20% of the power requirements of equivalent halogen systems, translating to proportional reductions in electricity costs. In commercial applications with extended daily operation hours, this can result in energy cost recovery periods of 1.5 to 3 years, depending on local electricity rates and usage patterns.

Maintenance economics further favor Mini LED implementation. The average operational lifespan of quality Mini LED components ranges from 50,000 to 100,000 hours, compared to 2,000 to 5,000 hours for typical halogen bulbs. This disparity translates to significantly reduced replacement frequency and associated labor costs, with some installations reporting up to 95% reduction in maintenance expenditures over a five-year period.

Environmental cost considerations also factor into the analysis. Mini LED systems generate substantially less heat during operation, reducing cooling requirements in climate-controlled environments by an estimated 5-10% compared to halogen installations. This secondary energy saving effect compounds the direct electrical consumption advantage, particularly in densely illuminated commercial spaces.

Productivity and performance benefits, while more difficult to quantify precisely, represent additional economic value. The superior color rendering capabilities of Mini LED technology (typically achieving CRI ratings of 90+ compared to halogen's 80-90 range) can enhance visual comfort and reduce eye strain in workplace environments. Studies in retail environments have demonstrated that improved lighting quality can positively impact sales metrics by 3-7%, representing a potential return on investment beyond direct operational savings.

Regulatory considerations may also influence the cost-benefit equation, as energy efficiency standards continue to evolve globally. Several jurisdictions have implemented or proposed phase-out timelines for less efficient lighting technologies, potentially rendering halogen systems obsolete and requiring replacement regardless of their functional status. This regulatory risk factor should be incorporated into long-term implementation planning and return-on-investment calculations.

However, the operational cost analysis demonstrates compelling advantages for Mini LED systems over time. Energy consumption metrics indicate that Mini LEDs operate at approximately 15-20% of the power requirements of equivalent halogen systems, translating to proportional reductions in electricity costs. In commercial applications with extended daily operation hours, this can result in energy cost recovery periods of 1.5 to 3 years, depending on local electricity rates and usage patterns.

Maintenance economics further favor Mini LED implementation. The average operational lifespan of quality Mini LED components ranges from 50,000 to 100,000 hours, compared to 2,000 to 5,000 hours for typical halogen bulbs. This disparity translates to significantly reduced replacement frequency and associated labor costs, with some installations reporting up to 95% reduction in maintenance expenditures over a five-year period.

Environmental cost considerations also factor into the analysis. Mini LED systems generate substantially less heat during operation, reducing cooling requirements in climate-controlled environments by an estimated 5-10% compared to halogen installations. This secondary energy saving effect compounds the direct electrical consumption advantage, particularly in densely illuminated commercial spaces.

Productivity and performance benefits, while more difficult to quantify precisely, represent additional economic value. The superior color rendering capabilities of Mini LED technology (typically achieving CRI ratings of 90+ compared to halogen's 80-90 range) can enhance visual comfort and reduce eye strain in workplace environments. Studies in retail environments have demonstrated that improved lighting quality can positively impact sales metrics by 3-7%, representing a potential return on investment beyond direct operational savings.

Regulatory considerations may also influence the cost-benefit equation, as energy efficiency standards continue to evolve globally. Several jurisdictions have implemented or proposed phase-out timelines for less efficient lighting technologies, potentially rendering halogen systems obsolete and requiring replacement regardless of their functional status. This regulatory risk factor should be incorporated into long-term implementation planning and return-on-investment calculations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!