Assessment Of Cathode Substrate Influence On Deposit Adhesion

AUG 29, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cathode Substrate Technology Background and Objectives

The evolution of cathode substrate technology has been a critical component in the advancement of electrochemical deposition processes since the early 20th century. Initially, simple metallic plates served as cathode substrates with minimal consideration for their surface properties or composition. The field has progressively developed through significant technological breakthroughs in material science, surface engineering, and electrochemistry, leading to today's sophisticated cathode substrate designs optimized for specific deposition applications.

The fundamental relationship between cathode substrate characteristics and deposit adhesion has emerged as a key focus area in recent decades. Research has demonstrated that substrate surface morphology, chemical composition, crystallographic orientation, and pre-treatment methods significantly influence the nucleation, growth, and adhesion mechanisms of electrodeposited materials. This understanding has driven the development of engineered substrate surfaces designed to enhance deposit adhesion through controlled roughness profiles, specific crystal orientations, and tailored surface energies.

Current technological objectives in cathode substrate development center on achieving precise control over deposit adhesion properties for increasingly demanding applications. Industries such as microelectronics, aerospace, and medical device manufacturing require exceptionally reliable adhesion performance while maintaining strict dimensional tolerances and surface quality standards. The push toward miniaturization and advanced functional coatings has further elevated the importance of substrate-deposit interface engineering.

A parallel objective involves developing sustainable cathode substrate technologies that reduce environmental impact while maintaining or improving performance characteristics. This includes research into recyclable substrate materials, reduction of toxic pre-treatment chemicals, and energy-efficient surface modification techniques that enhance adhesion without compromising other functional properties.

The integration of computational modeling with experimental approaches represents another significant technological goal. Advanced simulation techniques now enable prediction of adhesion behavior based on substrate parameters, potentially reducing development cycles and optimizing substrate design for specific deposition conditions. These models increasingly incorporate multi-scale phenomena, from atomic-level interactions to macroscopic mechanical properties.

Looking forward, the field aims to establish standardized methodologies for quantitative assessment of substrate influence on deposit adhesion across diverse material systems and application environments. This standardization would facilitate more effective knowledge transfer between research institutions and industry, accelerating the implementation of optimized cathode substrate technologies in commercial applications and supporting the development of next-generation electrochemical deposition processes.

The fundamental relationship between cathode substrate characteristics and deposit adhesion has emerged as a key focus area in recent decades. Research has demonstrated that substrate surface morphology, chemical composition, crystallographic orientation, and pre-treatment methods significantly influence the nucleation, growth, and adhesion mechanisms of electrodeposited materials. This understanding has driven the development of engineered substrate surfaces designed to enhance deposit adhesion through controlled roughness profiles, specific crystal orientations, and tailored surface energies.

Current technological objectives in cathode substrate development center on achieving precise control over deposit adhesion properties for increasingly demanding applications. Industries such as microelectronics, aerospace, and medical device manufacturing require exceptionally reliable adhesion performance while maintaining strict dimensional tolerances and surface quality standards. The push toward miniaturization and advanced functional coatings has further elevated the importance of substrate-deposit interface engineering.

A parallel objective involves developing sustainable cathode substrate technologies that reduce environmental impact while maintaining or improving performance characteristics. This includes research into recyclable substrate materials, reduction of toxic pre-treatment chemicals, and energy-efficient surface modification techniques that enhance adhesion without compromising other functional properties.

The integration of computational modeling with experimental approaches represents another significant technological goal. Advanced simulation techniques now enable prediction of adhesion behavior based on substrate parameters, potentially reducing development cycles and optimizing substrate design for specific deposition conditions. These models increasingly incorporate multi-scale phenomena, from atomic-level interactions to macroscopic mechanical properties.

Looking forward, the field aims to establish standardized methodologies for quantitative assessment of substrate influence on deposit adhesion across diverse material systems and application environments. This standardization would facilitate more effective knowledge transfer between research institutions and industry, accelerating the implementation of optimized cathode substrate technologies in commercial applications and supporting the development of next-generation electrochemical deposition processes.

Market Analysis for Adhesion-Enhanced Cathode Materials

The global market for adhesion-enhanced cathode materials is experiencing significant growth, driven by the expanding applications in electroplating, battery technology, and electronic component manufacturing. Current market valuations indicate that the electrodeposition industry, where cathode substrate adhesion is critical, represents a substantial segment of the global surface treatment market, with particularly strong demand in automotive, aerospace, and consumer electronics sectors.

Market research reveals that industries requiring high-performance electrodeposited coatings are increasingly demanding improved adhesion properties to enhance product durability and reliability. This demand is particularly evident in the electric vehicle battery market, where cathode material adhesion directly impacts battery longevity and performance. The market for advanced cathode materials with superior adhesion properties is projected to grow at an accelerated rate as EV adoption continues worldwide.

Regional analysis shows that Asia-Pacific dominates the market for cathode materials, with China, Japan, and South Korea leading in both production and consumption. North America and Europe follow as significant markets, with growing emphasis on research and development of advanced adhesion technologies. Emerging economies in South America and parts of Africa are showing increased interest in these technologies as their manufacturing sectors expand.

Consumer electronics represents another substantial market segment where adhesion-enhanced cathode materials are gaining traction. The miniaturization trend in electronics has intensified the need for reliable, strongly-adhered metallic coatings on increasingly complex substrate geometries. This has created a specialized market niche for advanced cathode materials that can ensure consistent adhesion on diverse substrate materials.

Market segmentation analysis indicates that premium-grade cathode materials with enhanced adhesion properties command significantly higher prices, reflecting their critical role in high-value applications. The price differential between standard and adhesion-enhanced cathode materials varies by application, with the most stringent applications justifying price premiums of up to several times the base material cost.

Industry surveys indicate that manufacturers are willing to invest in superior cathode materials when the total cost of ownership calculation demonstrates value through reduced rejection rates, extended product lifespans, and decreased warranty claims. This value-based purchasing approach has created opportunities for materials that can demonstrate quantifiable improvements in deposit adhesion performance.

Market forecasts suggest that technological innovations improving the understanding of substrate-deposit interfaces will continue to drive market growth. As industries push toward more demanding applications with harsher operating environments, the market for specialized cathode materials engineered for specific substrate compatibility will likely expand, creating new opportunities for materials science companies and surface treatment specialists.

Market research reveals that industries requiring high-performance electrodeposited coatings are increasingly demanding improved adhesion properties to enhance product durability and reliability. This demand is particularly evident in the electric vehicle battery market, where cathode material adhesion directly impacts battery longevity and performance. The market for advanced cathode materials with superior adhesion properties is projected to grow at an accelerated rate as EV adoption continues worldwide.

Regional analysis shows that Asia-Pacific dominates the market for cathode materials, with China, Japan, and South Korea leading in both production and consumption. North America and Europe follow as significant markets, with growing emphasis on research and development of advanced adhesion technologies. Emerging economies in South America and parts of Africa are showing increased interest in these technologies as their manufacturing sectors expand.

Consumer electronics represents another substantial market segment where adhesion-enhanced cathode materials are gaining traction. The miniaturization trend in electronics has intensified the need for reliable, strongly-adhered metallic coatings on increasingly complex substrate geometries. This has created a specialized market niche for advanced cathode materials that can ensure consistent adhesion on diverse substrate materials.

Market segmentation analysis indicates that premium-grade cathode materials with enhanced adhesion properties command significantly higher prices, reflecting their critical role in high-value applications. The price differential between standard and adhesion-enhanced cathode materials varies by application, with the most stringent applications justifying price premiums of up to several times the base material cost.

Industry surveys indicate that manufacturers are willing to invest in superior cathode materials when the total cost of ownership calculation demonstrates value through reduced rejection rates, extended product lifespans, and decreased warranty claims. This value-based purchasing approach has created opportunities for materials that can demonstrate quantifiable improvements in deposit adhesion performance.

Market forecasts suggest that technological innovations improving the understanding of substrate-deposit interfaces will continue to drive market growth. As industries push toward more demanding applications with harsher operating environments, the market for specialized cathode materials engineered for specific substrate compatibility will likely expand, creating new opportunities for materials science companies and surface treatment specialists.

Current Challenges in Cathode-Deposit Interface Engineering

The interface between cathode substrates and electrodeposited materials represents one of the most critical yet challenging aspects of electrochemical deposition processes. Current engineering challenges in this domain stem from multiple interconnected factors that significantly impact deposit adhesion quality and long-term performance reliability. The fundamental adhesion mechanisms involve complex interactions between substrate surface properties and the nucleation/growth processes of deposited materials, which remain incompletely understood despite decades of research.

Material compatibility issues constitute a primary challenge, particularly when depositing advanced functional materials onto conventional substrates. The mismatch in crystal lattice parameters, thermal expansion coefficients, and electronic properties often leads to interfacial stress and subsequent delamination during operation. This becomes especially problematic in high-performance applications such as solid-state batteries and electronic components where interface stability directly impacts device longevity.

Surface preparation techniques present another significant hurdle. Current methods for substrate cleaning, activation, and modification show inconsistent results across different material systems. The presence of native oxide layers, organic contaminants, and surface heterogeneities introduces variability in nucleation site density and distribution, leading to non-uniform adhesion strength across the substrate surface. Industry standards for surface preparation protocols remain fragmented and highly application-specific.

The electrochemical deposition parameters themselves critically influence interface formation. Factors including current density distribution, electrolyte composition, pH gradients near the electrode surface, and pulsing strategies all affect the initial nucleation and growth stages that determine ultimate adhesion quality. Optimizing these parameters requires sophisticated in-situ monitoring capabilities that are not widely available in production environments.

Environmental factors during and after deposition further complicate interface engineering. Exposure to humidity, temperature fluctuations, and atmospheric contaminants can trigger degradation mechanisms at the cathode-deposit interface. Protective strategies such as passivation layers introduce additional interfaces that must be carefully engineered to maintain adhesion integrity throughout the product lifecycle.

Characterization and testing methodologies for interface quality assessment remain limited in their ability to predict long-term performance. Current techniques such as scratch testing, pull tests, and cross-sectional microscopy provide valuable but incomplete information about adhesion mechanisms. Non-destructive evaluation methods with sufficient sensitivity to detect early-stage interface degradation are particularly lacking, hampering preventive maintenance strategies in critical applications.

Addressing these challenges requires interdisciplinary approaches combining surface science, electrochemistry, materials engineering, and advanced characterization techniques to develop more robust and predictable cathode-deposit interfaces for next-generation electrochemical systems.

Material compatibility issues constitute a primary challenge, particularly when depositing advanced functional materials onto conventional substrates. The mismatch in crystal lattice parameters, thermal expansion coefficients, and electronic properties often leads to interfacial stress and subsequent delamination during operation. This becomes especially problematic in high-performance applications such as solid-state batteries and electronic components where interface stability directly impacts device longevity.

Surface preparation techniques present another significant hurdle. Current methods for substrate cleaning, activation, and modification show inconsistent results across different material systems. The presence of native oxide layers, organic contaminants, and surface heterogeneities introduces variability in nucleation site density and distribution, leading to non-uniform adhesion strength across the substrate surface. Industry standards for surface preparation protocols remain fragmented and highly application-specific.

The electrochemical deposition parameters themselves critically influence interface formation. Factors including current density distribution, electrolyte composition, pH gradients near the electrode surface, and pulsing strategies all affect the initial nucleation and growth stages that determine ultimate adhesion quality. Optimizing these parameters requires sophisticated in-situ monitoring capabilities that are not widely available in production environments.

Environmental factors during and after deposition further complicate interface engineering. Exposure to humidity, temperature fluctuations, and atmospheric contaminants can trigger degradation mechanisms at the cathode-deposit interface. Protective strategies such as passivation layers introduce additional interfaces that must be carefully engineered to maintain adhesion integrity throughout the product lifecycle.

Characterization and testing methodologies for interface quality assessment remain limited in their ability to predict long-term performance. Current techniques such as scratch testing, pull tests, and cross-sectional microscopy provide valuable but incomplete information about adhesion mechanisms. Non-destructive evaluation methods with sufficient sensitivity to detect early-stage interface degradation are particularly lacking, hampering preventive maintenance strategies in critical applications.

Addressing these challenges requires interdisciplinary approaches combining surface science, electrochemistry, materials engineering, and advanced characterization techniques to develop more robust and predictable cathode-deposit interfaces for next-generation electrochemical systems.

Contemporary Adhesion Enhancement Methodologies

01 Surface treatment methods for improved cathode adhesion

Various surface treatment methods can be applied to cathode substrates to enhance deposit adhesion. These treatments include chemical etching, mechanical roughening, and plasma treatment to create a more favorable surface topography. By modifying the surface characteristics of the substrate, these methods increase the effective surface area and create mechanical interlocking points for the deposited material, resulting in stronger adhesion between the cathode substrate and the deposited layer.- Surface treatment methods for improved adhesion: Various surface treatment methods can be applied to cathode substrates to enhance deposit adhesion. These include mechanical treatments like roughening, chemical etching, and plasma treatments that modify the surface topography and chemistry. Such treatments increase the surface area and create anchor points for the deposited material, resulting in stronger mechanical interlocking and improved adhesion between the cathode substrate and the deposited layer.

- Interlayer application techniques: Applying intermediate layers between the cathode substrate and the main deposit can significantly improve adhesion. These interlayers often consist of materials that have good affinity to both the substrate and the deposit, acting as an adhesion promoter. Various deposition techniques can be used for these interlayers, including electroplating, physical vapor deposition, and chemical vapor deposition, with the thickness and composition of the interlayer carefully controlled to optimize adhesion properties.

- Substrate material selection and preparation: The choice of substrate material and its preparation significantly impact deposit adhesion. Materials with compatible crystal structures and thermal expansion coefficients to the deposit material show better adhesion properties. Proper cleaning and degreasing of the substrate prior to deposition is essential to remove contaminants that could interfere with adhesion. Heat treatment of substrates before deposition can also improve adhesion by relieving internal stresses and optimizing surface properties.

- Electrodeposition process parameters optimization: Optimizing electrodeposition process parameters is crucial for achieving strong adhesion between the deposit and cathode substrate. Key parameters include current density, temperature, pH, electrolyte composition, and agitation. Pulse plating techniques can produce deposits with improved adhesion compared to conventional DC plating. The addition of specific additives to the electrolyte can also enhance deposit adhesion by modifying the nucleation and growth mechanisms of the deposited layer.

- Post-deposition treatments for adhesion enhancement: Various post-deposition treatments can be applied to improve the adhesion of deposits on cathode substrates. Heat treatment after deposition can promote diffusion at the interface, creating a stronger bond between the deposit and substrate. Mechanical treatments such as burnishing or rolling can reduce internal stresses in the deposit that might lead to delamination. Chemical treatments can also be applied to modify the interface properties and enhance long-term adhesion stability.

02 Interlayer materials to promote adhesion

Introducing interlayer materials between the cathode substrate and the deposited layer can significantly improve adhesion. These intermediate layers often consist of materials that have good affinity to both the substrate and the deposit. They can act as adhesion promoters by creating strong chemical bonds with both surfaces or by providing a gradual transition between materials with different properties, thereby reducing interfacial stress and preventing delamination.Expand Specific Solutions03 Substrate material selection and preparation

The choice of substrate material and its preparation significantly impact deposit adhesion in cathode applications. Selecting materials with compatible thermal expansion coefficients and appropriate crystallographic structures can minimize stress at the interface. Proper cleaning procedures to remove contaminants, oxides, and organic residues from the substrate surface prior to deposition are essential for achieving strong adhesion, as these impurities can create weak boundary layers that compromise the bond strength.Expand Specific Solutions04 Deposition process parameters optimization

Optimizing deposition process parameters is crucial for enhancing adhesion between cathode substrates and deposits. Parameters such as temperature, pressure, deposition rate, and current density significantly influence the microstructure and adhesion properties of the deposited layer. Controlled heating and cooling rates can minimize thermal stress, while appropriate current density ensures uniform deposition and reduces internal stresses that might lead to delamination.Expand Specific Solutions05 Post-deposition treatments for adhesion enhancement

Various post-deposition treatments can be applied to improve the adhesion of deposits on cathode substrates. These include thermal annealing, which promotes diffusion at the interface and relieves residual stresses; mechanical treatments that can densify the deposit and improve contact; and chemical treatments that can strengthen the interfacial bonds. These post-processing steps help to consolidate the deposit-substrate interface and enhance long-term adhesion stability under operational conditions.Expand Specific Solutions

Leading Organizations in Cathode Substrate Development

The cathode substrate adhesion technology landscape is currently in a growth phase, with an estimated market size of $2-3 billion and expanding at 7-9% annually. The field demonstrates moderate technological maturity, with significant advancements being driven by key players across multiple sectors. Applied Materials and Oerlikon Surface Solutions lead in industrial applications, while research institutions like Nanjing University and Jilin University contribute fundamental innovations. The automotive sector shows increasing interest, with Peugeot SA and Henkel AG developing specialized adhesion solutions. Research organizations including CNRS and CEA are advancing theoretical frameworks, while materials companies like DuPont, BASF, and 3M focus on novel substrate formulations. The technology is approaching commercial maturity but still requires optimization for specialized applications.

Applied Materials, Inc.

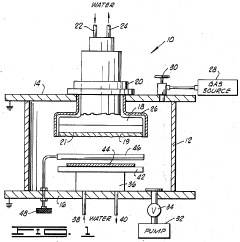

Technical Solution: Applied Materials has developed advanced Physical Vapor Deposition (PVD) technology specifically designed to enhance cathode substrate adhesion in battery manufacturing. Their Endura® platform utilizes a multi-step surface preparation process that includes plasma cleaning and ion bombardment to remove surface contaminants and create optimal surface energy for subsequent deposition[1]. The company's proprietary "adhesion layer" technology employs transition metal interlayers between the cathode active material and current collector, forming strong chemical bonds at the interface. Their process controls substrate temperature within ±2°C during deposition, as thermal expansion mismatch has been identified as a critical factor affecting long-term adhesion stability[3]. Applied Materials has also pioneered the use of gradient composition layers that gradually transition from substrate-compatible to cathode-compatible materials, reducing interfacial stress and improving adhesion under thermal cycling conditions typical in battery operation.

Strengths: Industry-leading precision in deposition parameters control, enabling customized adhesion solutions for different cathode chemistries. Their equipment offers exceptional uniformity across large substrates, critical for commercial-scale production. Weaknesses: Their high-end equipment solutions require significant capital investment compared to conventional coating technologies, and the complex multi-step processes may reduce throughput in high-volume manufacturing environments.

Oerlikon Surface Solutions AG

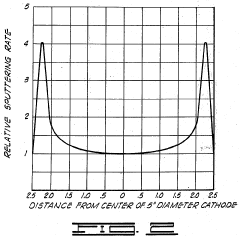

Technical Solution: Oerlikon Surface Solutions has developed specialized plasma-enhanced coating technologies for improving cathode substrate adhesion in energy storage applications. Their BALIQ® coating system employs a modified arc evaporation process that creates exceptionally dense and smooth interface layers between cathode materials and current collectors[2]. The company's approach focuses on tailoring the surface energy and topography of substrates through controlled plasma etching prior to deposition, creating mechanical interlocking features at the micro and nano scales. Oerlikon's proprietary S3p® (Scalable Pulsed Power Plasma) technology enables precise control of ion energy during deposition, allowing for optimization of adhesion without thermal damage to temperature-sensitive substrates[4]. Their research has demonstrated that controlling the crystallographic orientation of initial deposition layers can significantly enhance adhesion strength by promoting epitaxial growth at the interface. Additionally, Oerlikon has developed specialized post-deposition treatments using pulsed laser annealing to relieve interfacial stress while maintaining the integrity of the cathode material structure.

Strengths: Exceptional control over plasma parameters allowing for customized interface engineering even with challenging material combinations. Their technology excels at creating adhesion-promoting nanostructures without compromising electrical conductivity. Weaknesses: The specialized equipment and expertise required for their advanced plasma processes may limit widespread adoption, and the technology may be less cost-effective for high-volume, lower-cost battery applications.

Critical Patents in Cathode-Deposit Bonding Mechanisms

Process for depositing on substrates by spraying an autolubricating coating of metal chalcogenides,coating optained by such process and sprayable composition for application of the process

PatentWO1980000712A1

Innovation

- The process involves subjecting the cathodic target area to a magnetic field and varying the distance between the target and substrate, using a composition with excess chalcogenides or metalloids to enhance deposition efficiency and adherence, allowing for deposition on substrates with varying surface roughness, and achieving a turbostratic structure for improved wear resistance and humidity resistance.

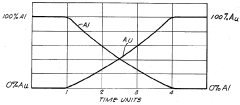

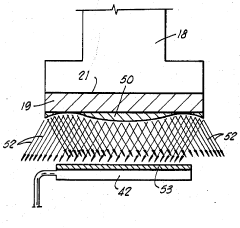

Method for obtaining adhesion of multilayer thin films

PatentInactiveUS3986944A

Innovation

- A graded interface is created between thin layers of materials with compatible bulk properties by using an adhesion layer with bulk properties similar to aluminum, where the adhesion layer is sputtered nonuniformly onto the deposit material, forming a strong crystalline bond with the substrate, even if the surface properties are not compatible, such as between oxidized aluminum and metals like copper or gold.

Environmental Impact of Cathode Substrate Materials

The environmental impact of cathode substrate materials in electrodeposition processes represents a critical consideration for sustainable industrial practices. Traditional substrate materials such as copper, nickel, and stainless steel have long been utilized for their excellent conductivity and mechanical properties, but their environmental footprint throughout their lifecycle demands thorough examination.

Mining and extraction processes for these metals often involve significant energy consumption, habitat disruption, and potential release of toxic substances into ecosystems. Copper mining, for instance, generates substantial waste rock and tailings that can lead to acid mine drainage, affecting water quality in surrounding areas. Similarly, nickel extraction processes are energy-intensive and can result in soil contamination and biodiversity loss.

Manufacturing and processing of cathode substrates contribute to environmental concerns through energy consumption, greenhouse gas emissions, and the use of potentially harmful chemicals for surface preparation. Surface treatments like acid etching or chemical activation, while essential for deposit adhesion, often utilize solutions containing heavy metals or strong acids that require careful handling and disposal.

Recycling challenges present another environmental dimension. While metals like copper have established recycling infrastructures, composite substrates or those with complex coatings may be difficult to process at end-of-life. The adhesion between deposits and substrates can sometimes complicate separation processes necessary for effective recycling, potentially leading to downcycling or disposal rather than complete material recovery.

Recent innovations have focused on developing more environmentally benign substrate materials and surface preparation techniques. Bio-based substrates, recycled metal alloys, and water-based surface activation methods represent promising alternatives that could reduce environmental impact while maintaining adhesion performance. Additionally, advances in green chemistry have led to less toxic electrolyte formulations that can achieve strong deposit adhesion on various substrates.

Regulatory frameworks increasingly influence material selection for cathode substrates. Legislation such as RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) in Europe has prompted industries to seek alternatives to environmentally problematic materials, driving innovation in substrate development and surface preparation technologies that enhance deposit adhesion while minimizing ecological harm.

Life cycle assessment (LCA) studies comparing different cathode substrate materials have revealed that environmental impacts often extend beyond the immediate manufacturing process to include raw material sourcing, energy requirements, and end-of-life considerations. These comprehensive analyses are becoming essential tools for industries seeking to optimize both technical performance and environmental sustainability in electrodeposition processes.

Mining and extraction processes for these metals often involve significant energy consumption, habitat disruption, and potential release of toxic substances into ecosystems. Copper mining, for instance, generates substantial waste rock and tailings that can lead to acid mine drainage, affecting water quality in surrounding areas. Similarly, nickel extraction processes are energy-intensive and can result in soil contamination and biodiversity loss.

Manufacturing and processing of cathode substrates contribute to environmental concerns through energy consumption, greenhouse gas emissions, and the use of potentially harmful chemicals for surface preparation. Surface treatments like acid etching or chemical activation, while essential for deposit adhesion, often utilize solutions containing heavy metals or strong acids that require careful handling and disposal.

Recycling challenges present another environmental dimension. While metals like copper have established recycling infrastructures, composite substrates or those with complex coatings may be difficult to process at end-of-life. The adhesion between deposits and substrates can sometimes complicate separation processes necessary for effective recycling, potentially leading to downcycling or disposal rather than complete material recovery.

Recent innovations have focused on developing more environmentally benign substrate materials and surface preparation techniques. Bio-based substrates, recycled metal alloys, and water-based surface activation methods represent promising alternatives that could reduce environmental impact while maintaining adhesion performance. Additionally, advances in green chemistry have led to less toxic electrolyte formulations that can achieve strong deposit adhesion on various substrates.

Regulatory frameworks increasingly influence material selection for cathode substrates. Legislation such as RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) in Europe has prompted industries to seek alternatives to environmentally problematic materials, driving innovation in substrate development and surface preparation technologies that enhance deposit adhesion while minimizing ecological harm.

Life cycle assessment (LCA) studies comparing different cathode substrate materials have revealed that environmental impacts often extend beyond the immediate manufacturing process to include raw material sourcing, energy requirements, and end-of-life considerations. These comprehensive analyses are becoming essential tools for industries seeking to optimize both technical performance and environmental sustainability in electrodeposition processes.

Standardization and Testing Protocols for Adhesion Assessment

The standardization of adhesion testing protocols is critical for ensuring reliable and reproducible assessments of cathode substrate influence on deposit adhesion. Current industry practices reveal significant variations in testing methodologies, leading to inconsistent results across different research groups and manufacturing facilities. Establishing unified protocols would enable meaningful comparisons between different substrate materials and surface treatments.

A comprehensive standardization framework should address sample preparation, testing conditions, and data analysis methods. For sample preparation, parameters such as substrate cleaning procedures, surface roughness measurements, and pre-treatment documentation must be precisely defined. Testing environments should specify temperature ranges, humidity levels, and atmospheric composition to minimize environmental variables that could affect adhesion performance.

The selection of appropriate testing methods represents another crucial aspect of standardization. Pull-off tests, scratch tests, peel tests, and thermal cycling tests each provide different insights into adhesion mechanisms. A tiered approach incorporating multiple complementary methods would yield more comprehensive assessments of adhesion quality. For instance, initial screening might employ simple tape tests, followed by quantitative measurements using more sophisticated instrumentation for promising candidates.

Quantification metrics require particular attention in standardization efforts. Force measurements should be normalized by contact area, and reporting should include statistical analysis with confidence intervals. Failure mode analysis should distinguish between cohesive failure within deposits, adhesive failure at interfaces, and substrate failure, as these provide critical insights into weakness points.

Accelerated aging protocols represent an essential component of comprehensive testing regimes. These protocols should simulate the environmental stresses encountered during product lifecycles, including thermal cycling, humidity exposure, and mechanical vibration. Correlation studies between accelerated testing and real-world performance are necessary to validate the predictive value of standardized tests.

Inter-laboratory validation studies would significantly strengthen the reliability of proposed standards. Round-robin testing involving multiple facilities can identify protocol weaknesses and establish reproducibility limits. Such collaborative efforts would accelerate the adoption of standardized methods across the industry and research communities.

Digital imaging and automated analysis techniques offer opportunities to reduce subjective interpretations in adhesion assessment. Machine learning algorithms trained on extensive datasets could potentially identify subtle patterns in adhesion behavior that might escape human observation, further enhancing the objectivity and sensitivity of standardized protocols.

A comprehensive standardization framework should address sample preparation, testing conditions, and data analysis methods. For sample preparation, parameters such as substrate cleaning procedures, surface roughness measurements, and pre-treatment documentation must be precisely defined. Testing environments should specify temperature ranges, humidity levels, and atmospheric composition to minimize environmental variables that could affect adhesion performance.

The selection of appropriate testing methods represents another crucial aspect of standardization. Pull-off tests, scratch tests, peel tests, and thermal cycling tests each provide different insights into adhesion mechanisms. A tiered approach incorporating multiple complementary methods would yield more comprehensive assessments of adhesion quality. For instance, initial screening might employ simple tape tests, followed by quantitative measurements using more sophisticated instrumentation for promising candidates.

Quantification metrics require particular attention in standardization efforts. Force measurements should be normalized by contact area, and reporting should include statistical analysis with confidence intervals. Failure mode analysis should distinguish between cohesive failure within deposits, adhesive failure at interfaces, and substrate failure, as these provide critical insights into weakness points.

Accelerated aging protocols represent an essential component of comprehensive testing regimes. These protocols should simulate the environmental stresses encountered during product lifecycles, including thermal cycling, humidity exposure, and mechanical vibration. Correlation studies between accelerated testing and real-world performance are necessary to validate the predictive value of standardized tests.

Inter-laboratory validation studies would significantly strengthen the reliability of proposed standards. Round-robin testing involving multiple facilities can identify protocol weaknesses and establish reproducibility limits. Such collaborative efforts would accelerate the adoption of standardized methods across the industry and research communities.

Digital imaging and automated analysis techniques offer opportunities to reduce subjective interpretations in adhesion assessment. Machine learning algorithms trained on extensive datasets could potentially identify subtle patterns in adhesion behavior that might escape human observation, further enhancing the objectivity and sensitivity of standardized protocols.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!