Electrochemical Reduction Of Hematite: Kinetics And Electrode Material Solutions

AUG 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hematite Electrochemical Reduction Background and Objectives

Hematite (α-Fe2O3), as the most abundant iron oxide mineral on Earth, has been a focal point in metallurgical processes for centuries. The electrochemical reduction of hematite represents a critical pathway in modern iron production technologies, offering potentially more environmentally sustainable alternatives to traditional carbon-intensive reduction methods. This technology has evolved significantly over the past decades, transitioning from theoretical concepts to practical applications in various industrial settings.

The historical trajectory of hematite electrochemical reduction began in the early 20th century with rudimentary electrochemical cells, but gained substantial momentum in the 1970s and 1980s with the development of more sophisticated electrode materials and electrolyte systems. Recent advancements in nanotechnology and materials science have further accelerated progress in this field, enabling more efficient reduction processes with lower energy requirements.

Current technological trends indicate a shift toward molten salt electrolysis systems, which offer higher reduction rates and improved energy efficiency compared to aqueous systems. Additionally, there is growing interest in hybrid processes that combine electrochemical reduction with conventional pyrometallurgical methods to optimize overall process efficiency and minimize environmental impact.

The primary technical objectives for hematite electrochemical reduction focus on several key areas. First, enhancing reduction kinetics to achieve commercially viable production rates remains a central challenge. Current systems typically achieve reduction rates that are insufficient for large-scale industrial implementation, necessitating significant improvements in reaction efficiency and electrode design.

Second, developing stable and cost-effective electrode materials capable of withstanding harsh electrochemical conditions presents another critical objective. The ideal electrode materials must balance conductivity, durability, and catalytic activity while remaining economically feasible for industrial-scale deployment.

Third, optimizing electrolyte compositions to facilitate efficient ion transport while minimizing side reactions and electrode degradation represents an important research direction. This includes exploration of novel molten salt mixtures and additives that can enhance reduction performance.

Finally, the technology aims to achieve substantial reductions in energy consumption compared to conventional ironmaking processes. Current benchmarks suggest potential energy savings of 30-40% relative to blast furnace operations, though realizing these benefits requires overcoming significant technical hurdles related to cell design and operational parameters.

The ultimate goal of this technological development is to establish a commercially viable, environmentally sustainable alternative to carbon-based reduction processes for iron production, potentially revolutionizing the metallurgical industry while contributing to global decarbonization efforts.

The historical trajectory of hematite electrochemical reduction began in the early 20th century with rudimentary electrochemical cells, but gained substantial momentum in the 1970s and 1980s with the development of more sophisticated electrode materials and electrolyte systems. Recent advancements in nanotechnology and materials science have further accelerated progress in this field, enabling more efficient reduction processes with lower energy requirements.

Current technological trends indicate a shift toward molten salt electrolysis systems, which offer higher reduction rates and improved energy efficiency compared to aqueous systems. Additionally, there is growing interest in hybrid processes that combine electrochemical reduction with conventional pyrometallurgical methods to optimize overall process efficiency and minimize environmental impact.

The primary technical objectives for hematite electrochemical reduction focus on several key areas. First, enhancing reduction kinetics to achieve commercially viable production rates remains a central challenge. Current systems typically achieve reduction rates that are insufficient for large-scale industrial implementation, necessitating significant improvements in reaction efficiency and electrode design.

Second, developing stable and cost-effective electrode materials capable of withstanding harsh electrochemical conditions presents another critical objective. The ideal electrode materials must balance conductivity, durability, and catalytic activity while remaining economically feasible for industrial-scale deployment.

Third, optimizing electrolyte compositions to facilitate efficient ion transport while minimizing side reactions and electrode degradation represents an important research direction. This includes exploration of novel molten salt mixtures and additives that can enhance reduction performance.

Finally, the technology aims to achieve substantial reductions in energy consumption compared to conventional ironmaking processes. Current benchmarks suggest potential energy savings of 30-40% relative to blast furnace operations, though realizing these benefits requires overcoming significant technical hurdles related to cell design and operational parameters.

The ultimate goal of this technological development is to establish a commercially viable, environmentally sustainable alternative to carbon-based reduction processes for iron production, potentially revolutionizing the metallurgical industry while contributing to global decarbonization efforts.

Market Applications and Demand Analysis for Reduced Iron Products

The global market for reduced iron products derived from hematite electrochemical reduction processes has shown significant growth potential across multiple industrial sectors. Steel manufacturing remains the primary application, where high-purity reduced iron serves as a premium feedstock for electric arc furnaces and specialized steel production. This market segment is projected to grow steadily due to increasing demand for high-grade steel in automotive, construction, and infrastructure development.

The clean energy transition has created emerging applications for reduced iron products in energy storage systems, particularly in flow batteries and certain types of fuel cells where iron-based materials offer cost advantages over precious metals. Additionally, the electronics industry utilizes high-purity reduced iron in specialized components and magnetic materials, representing a smaller but higher-value market segment.

Environmental regulations worldwide are driving demand for cleaner iron production methods. Traditional blast furnace processes generate substantial CO2 emissions, while electrochemical reduction of hematite offers a potentially lower-carbon alternative when powered by renewable energy. This alignment with decarbonization goals has attracted interest from steel producers facing carbon pricing mechanisms and environmental compliance requirements.

Regional market analysis reveals varying demand patterns. Developed economies in North America and Europe focus on high-value applications and environmentally sustainable production methods, while rapidly industrializing nations in Asia prioritize cost-effective scaling of production capacity. China remains the largest consumer of reduced iron products, followed by India and other emerging economies with expanding manufacturing sectors.

Market research indicates that price sensitivity varies significantly by application. Commodity steel production remains highly cost-conscious, while specialized applications in electronics and energy storage demonstrate greater willingness to pay premium prices for higher purity and performance characteristics. This market segmentation suggests opportunities for differentiated product offerings based on purity levels and specific performance attributes.

Supply chain considerations also influence market dynamics. The availability and cost of high-grade hematite feedstock, access to reliable and affordable electricity, and proximity to end-users all affect the commercial viability of electrochemical reduction processes. Regions with abundant iron ore resources and low-cost renewable energy hold competitive advantages in this emerging market.

Future market growth will likely be driven by technological improvements in electrochemical reduction efficiency, electrode durability, and process scalability. As these advancements reduce production costs and improve product quality, new applications and market segments may emerge, further expanding the commercial potential of electrochemically reduced iron products.

The clean energy transition has created emerging applications for reduced iron products in energy storage systems, particularly in flow batteries and certain types of fuel cells where iron-based materials offer cost advantages over precious metals. Additionally, the electronics industry utilizes high-purity reduced iron in specialized components and magnetic materials, representing a smaller but higher-value market segment.

Environmental regulations worldwide are driving demand for cleaner iron production methods. Traditional blast furnace processes generate substantial CO2 emissions, while electrochemical reduction of hematite offers a potentially lower-carbon alternative when powered by renewable energy. This alignment with decarbonization goals has attracted interest from steel producers facing carbon pricing mechanisms and environmental compliance requirements.

Regional market analysis reveals varying demand patterns. Developed economies in North America and Europe focus on high-value applications and environmentally sustainable production methods, while rapidly industrializing nations in Asia prioritize cost-effective scaling of production capacity. China remains the largest consumer of reduced iron products, followed by India and other emerging economies with expanding manufacturing sectors.

Market research indicates that price sensitivity varies significantly by application. Commodity steel production remains highly cost-conscious, while specialized applications in electronics and energy storage demonstrate greater willingness to pay premium prices for higher purity and performance characteristics. This market segmentation suggests opportunities for differentiated product offerings based on purity levels and specific performance attributes.

Supply chain considerations also influence market dynamics. The availability and cost of high-grade hematite feedstock, access to reliable and affordable electricity, and proximity to end-users all affect the commercial viability of electrochemical reduction processes. Regions with abundant iron ore resources and low-cost renewable energy hold competitive advantages in this emerging market.

Future market growth will likely be driven by technological improvements in electrochemical reduction efficiency, electrode durability, and process scalability. As these advancements reduce production costs and improve product quality, new applications and market segments may emerge, further expanding the commercial potential of electrochemically reduced iron products.

Technical Challenges in Electrochemical Reduction of Hematite

The electrochemical reduction of hematite (Fe2O3) to metallic iron presents several significant technical challenges that have hindered its widespread industrial implementation. One of the primary obstacles is the slow reaction kinetics, particularly at the solid-liquid interface. The multi-step electron transfer process requires overcoming substantial activation energy barriers, resulting in high overpotentials and reduced energy efficiency. This kinetic limitation becomes more pronounced as the reaction progresses, with the formation of intermediate iron oxides (such as magnetite, Fe3O4) creating additional diffusion barriers.

Electrode material selection poses another critical challenge. Traditional carbon-based electrodes suffer from rapid degradation in the highly corrosive electrolyte environments typically used for hematite reduction. The electrode materials must simultaneously provide excellent electrical conductivity, electrochemical stability, and catalytic activity toward iron oxide reduction. Finding materials that balance these properties while remaining economically viable for large-scale applications has proven difficult.

The complex phase transformations during the reduction process further complicate the reaction engineering. The transition from hematite to magnetite and subsequently to wüstite (FeO) before final reduction to metallic iron involves significant structural reorganization. These phase changes can lead to mechanical stress, particle disintegration, and loss of electrical contact within the electrode matrix, severely impacting process efficiency and stability over extended operation periods.

Electrolyte composition and stability represent another significant challenge. The electrolyte must facilitate efficient ion transport while maintaining compatibility with both the electrode materials and the evolving iron species. Many electrolytes that demonstrate good performance suffer from degradation through side reactions or become contaminated with dissolved iron species, necessitating frequent replacement and increasing operational costs.

Scale-up issues present formidable barriers to industrial implementation. Laboratory-scale successes often fail to translate to industrial settings due to heat management problems, uneven current distribution across larger electrodes, and mass transport limitations. The design of electrochemical cells that can maintain uniform reaction conditions throughout larger volumes remains an engineering challenge.

Energy efficiency concerns are paramount, as the theoretical energy requirements for electrochemical reduction already position this process at a competitive disadvantage compared to conventional pyrometallurgical routes. Parasitic reactions, particularly hydrogen evolution in aqueous systems, further reduce faradaic efficiency and increase energy consumption per unit of iron produced.

Electrode material selection poses another critical challenge. Traditional carbon-based electrodes suffer from rapid degradation in the highly corrosive electrolyte environments typically used for hematite reduction. The electrode materials must simultaneously provide excellent electrical conductivity, electrochemical stability, and catalytic activity toward iron oxide reduction. Finding materials that balance these properties while remaining economically viable for large-scale applications has proven difficult.

The complex phase transformations during the reduction process further complicate the reaction engineering. The transition from hematite to magnetite and subsequently to wüstite (FeO) before final reduction to metallic iron involves significant structural reorganization. These phase changes can lead to mechanical stress, particle disintegration, and loss of electrical contact within the electrode matrix, severely impacting process efficiency and stability over extended operation periods.

Electrolyte composition and stability represent another significant challenge. The electrolyte must facilitate efficient ion transport while maintaining compatibility with both the electrode materials and the evolving iron species. Many electrolytes that demonstrate good performance suffer from degradation through side reactions or become contaminated with dissolved iron species, necessitating frequent replacement and increasing operational costs.

Scale-up issues present formidable barriers to industrial implementation. Laboratory-scale successes often fail to translate to industrial settings due to heat management problems, uneven current distribution across larger electrodes, and mass transport limitations. The design of electrochemical cells that can maintain uniform reaction conditions throughout larger volumes remains an engineering challenge.

Energy efficiency concerns are paramount, as the theoretical energy requirements for electrochemical reduction already position this process at a competitive disadvantage compared to conventional pyrometallurgical routes. Parasitic reactions, particularly hydrogen evolution in aqueous systems, further reduce faradaic efficiency and increase energy consumption per unit of iron produced.

Current Electrode Materials and Reduction Process Solutions

01 Electrochemical reduction methods for hematite

Various electrochemical methods can be employed for the reduction of hematite (Fe2O3) to extract iron or produce other valuable compounds. These methods typically involve applying electrical potential to facilitate the reduction process, which can be more environmentally friendly than traditional pyrometallurgical approaches. The electrochemical reduction can be conducted in different electrolyte solutions and under various conditions to optimize the reduction efficiency and control the reaction kinetics.- Electrochemical reduction methods for hematite: Various electrochemical methods can be employed for the reduction of hematite (Fe2O3) to other iron compounds or metallic iron. These methods involve applying electrical potential to facilitate the reduction process under controlled conditions. The electrochemical reduction approach offers advantages such as precise control over reaction parameters, environmentally friendly processing, and potentially lower energy requirements compared to traditional thermal reduction methods.

- Kinetic parameters affecting hematite reduction: Several kinetic parameters significantly influence the electrochemical reduction of hematite, including temperature, pH, electrode potential, current density, and electrolyte composition. Understanding these parameters is crucial for optimizing the reduction process and controlling the reaction rate. Research has shown that the reduction kinetics can be enhanced by adjusting these parameters to create favorable conditions for electron transfer at the electrode-electrolyte interface.

- Catalyst systems for improved reduction efficiency: Various catalyst systems have been developed to enhance the kinetics of hematite electrochemical reduction. These catalysts can lower the activation energy required for the reduction process, thereby improving reaction rates and efficiency. Catalysts may include noble metals, transition metal compounds, and composite materials that facilitate electron transfer and accelerate the reduction of hematite to desired iron products.

- Electrode materials and configurations: The choice of electrode materials and their configurations plays a critical role in the electrochemical reduction of hematite. Various electrode materials, including carbon-based electrodes, metal electrodes, and composite electrodes, have been investigated for their impact on reduction kinetics. Electrode surface area, morphology, and conductivity significantly affect the electron transfer rate and overall reduction efficiency. Innovative electrode designs can enhance mass transfer and reaction kinetics during the electrochemical reduction process.

- Reaction mechanisms and intermediate phases: The electrochemical reduction of hematite involves complex reaction mechanisms with multiple intermediate phases. Understanding these mechanisms is essential for controlling the reduction process and product quality. Research has identified various reaction pathways, including the formation of magnetite (Fe3O4) and wüstite (FeO) as intermediate phases before complete reduction to metallic iron. The kinetics of each step in the reduction sequence can be influenced by different factors, and the rate-determining step may vary depending on the reaction conditions.

02 Kinetic parameters affecting hematite reduction

Several kinetic parameters significantly influence the electrochemical reduction of hematite, including temperature, current density, electrode potential, and electrolyte composition. These parameters affect the reaction rate, efficiency, and selectivity of the reduction process. Understanding and controlling these kinetic factors is crucial for optimizing the electrochemical reduction of hematite for industrial applications and improving the overall process economics.Expand Specific Solutions03 Catalyst systems for enhanced reduction kinetics

Various catalyst systems can be employed to enhance the kinetics of hematite electrochemical reduction. These catalysts can lower the activation energy required for the reduction reaction, thereby increasing the reaction rate and efficiency. Common catalysts include noble metals, transition metal compounds, and certain metal oxides that can facilitate electron transfer during the reduction process. The selection of appropriate catalysts depends on factors such as cost, stability, and compatibility with the electrolyte system.Expand Specific Solutions04 Electrode materials and configurations for hematite reduction

The choice of electrode materials and configurations plays a critical role in the electrochemical reduction of hematite. Various materials such as carbon-based electrodes, platinum, titanium, and other metals have been investigated for their effectiveness in hematite reduction. The electrode configuration, including surface area, porosity, and geometry, significantly affects the reaction kinetics by influencing mass transfer, electron transfer rates, and current distribution. Optimizing these factors can lead to improved reduction efficiency and selectivity.Expand Specific Solutions05 Process monitoring and control techniques

Advanced monitoring and control techniques are essential for understanding and optimizing the kinetics of hematite electrochemical reduction. These techniques include electrochemical impedance spectroscopy, cyclic voltammetry, chronoamperometry, and in-situ spectroscopic methods. Real-time monitoring allows for the determination of reaction mechanisms, identification of rate-limiting steps, and optimization of process parameters. Implementing effective control strategies based on these monitoring techniques can significantly improve the efficiency and selectivity of the hematite reduction process.Expand Specific Solutions

Leading Research Institutions and Industrial Implementers

The electrochemical reduction of hematite market is currently in an early growth phase, characterized by increasing research activity and emerging commercial applications. The global market size remains relatively modest but is expanding as industries seek more sustainable iron production methods. Technologically, this field is in a transitional stage between laboratory research and industrial implementation. Leading players include academic institutions like University of Science & Technology Beijing and Central South University, which are advancing fundamental research, while industrial entities such as Industrie De Nora SpA and Siemens AG are developing practical applications. Chinese organizations dominate research output, with companies like China ENFI Engineering Corp. focusing on scaling technologies. Western companies including 24M Technologies and Toshiba Corp. are exploring niche applications in energy storage and advanced materials processing.

Institute of Process Engineering, Chinese Academy of Sciences

Technical Solution: The Institute of Process Engineering (IPE) at the Chinese Academy of Sciences has developed advanced electrochemical reduction systems for hematite conversion using modified electrode materials. Their approach incorporates nanostructured iron-based catalysts with controlled morphology to enhance electron transfer kinetics during the reduction process. IPE researchers have demonstrated that by using carbon-supported iron oxide nanoparticles with specific surface treatments, the reduction potential can be significantly lowered while maintaining high conversion efficiency. Their technology employs pulse electrodeposition techniques to create highly active electrode surfaces with optimized porosity, which facilitates mass transport during the reduction reaction. Recent studies have shown their electrodes achieve over 90% conversion efficiency at lower applied potentials compared to conventional materials, with enhanced stability over multiple reduction cycles.

Strengths: Superior catalyst design with nanoscale engineering provides excellent electron transfer kinetics and reduced overpotential requirements. Their electrode materials demonstrate exceptional stability during long-term operation. Weaknesses: The complex preparation methods for their specialized electrode materials may present scaling challenges for industrial implementation, and the high-purity precursors required increase production costs.

Industrie De Nora SpA

Technical Solution: Industrie De Nora has pioneered dimensionally stable electrodes (DSA®) technology that has been adapted for hematite reduction applications. Their proprietary electrode materials feature mixed metal oxide coatings on titanium substrates, specifically engineered to withstand the harsh conditions of iron oxide reduction processes. De Nora's approach focuses on optimizing the microstructure and composition of the electrode surface to enhance electrocatalytic activity while minimizing side reactions. Their latest generation electrodes incorporate specialized dopants that significantly improve the selectivity toward Fe2O3 reduction pathways. The company has developed a comprehensive electrode manufacturing process that ensures uniform coating distribution and strong adhesion to the substrate, resulting in extended electrode lifetimes even under high current density operations. Their electrochemical cells are designed with optimized geometry to ensure uniform current distribution and efficient mass transfer, critical factors in hematite reduction kinetics.

Strengths: Exceptional electrode durability and stability in industrial settings, with proven technology that can be scaled to commercial production levels. Their electrodes maintain consistent performance over thousands of operating hours. Weaknesses: Higher initial capital investment compared to conventional materials, and their systems may require specialized maintenance protocols to preserve optimal performance characteristics.

Key Patents and Scientific Breakthroughs in Hematite Reduction

Electrochemical Reduction of Metal Oxides

PatentInactiveUS20070181438A1

Innovation

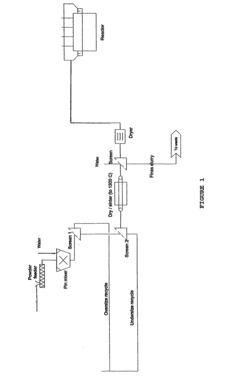

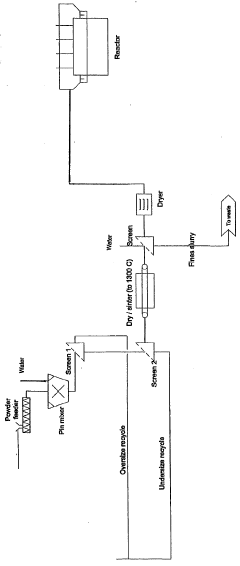

- A metal oxide feed material in the form of powders or pellets with specific porosity (35-60% open connected pore structure) and mechanical strength, designed to allow penetration of molten electrolyte and withstand thermal shock, is prepared through agglomeration and sintering processes to facilitate continuous or semi-continuous electrochemical reduction in an electrolytic cell.

Electrochemical reduction of metal oxides

PatentInactiveAU2005254589A1

Innovation

- A process and apparatus for electrochemically reducing metal oxides in the form of powders or pellets with controlled porosity (35-60%), density (2.5-3.5 g/cc), and size (1-4 mm) to enable effective penetration of molten electrolyte and minimize breakdown, using a CaCl2-based electrolyte in an electrolytic cell with a graphite anode, and subsequent washing to produce metal with low oxygen content.

Environmental Impact and Sustainability Considerations

The electrochemical reduction of hematite represents a significant advancement in sustainable metallurgical processing, offering potential environmental benefits compared to conventional pyrometallurgical methods. This process operates at lower temperatures, resulting in substantially reduced energy consumption and greenhouse gas emissions. Traditional iron production through blast furnaces generates approximately 1.8 tons of CO2 per ton of steel produced, whereas electrochemical reduction pathways can potentially reduce these emissions by 30-50% when powered by renewable energy sources.

Water consumption presents another critical environmental consideration. Electrochemical processes typically require less water than conventional methods, with potential reductions of 15-25% in overall water footprint. However, the electrolyte solutions used in these processes may contain potentially harmful substances that require careful management and recycling protocols to prevent environmental contamination.

The sustainability profile of electrode materials warrants particular attention. Current high-performance electrodes often incorporate rare earth elements or precious metals that present sustainability challenges related to resource scarcity and extraction impacts. Research into abundant, non-toxic alternatives such as carbon-based materials, modified iron alloys, and certain metal oxides shows promising results for reducing the environmental footprint of electrode manufacturing while maintaining acceptable performance metrics.

Life cycle assessment (LCA) studies indicate that the environmental advantages of electrochemical hematite reduction are highly dependent on the electricity source. When powered by renewable energy, the process demonstrates clear environmental benefits; however, if powered by coal-based electricity, these advantages may be negated. This underscores the importance of integrating renewable energy systems with electrochemical reduction technologies to maximize sustainability benefits.

Waste management represents another significant consideration. The process generates spent electrolytes and electrode materials that require proper handling and recycling. Emerging circular economy approaches include electrolyte regeneration systems that can recover and reuse up to 85% of solution components, significantly reducing waste streams and associated environmental impacts.

Regulatory frameworks worldwide are increasingly recognizing electrochemical processes as Best Available Techniques (BAT) for certain metallurgical applications. The European Union's Industrial Emissions Directive and similar regulations in North America and Asia are beginning to incorporate specific provisions for electrochemical metal production, potentially accelerating industry adoption through regulatory incentives and compliance requirements.

Water consumption presents another critical environmental consideration. Electrochemical processes typically require less water than conventional methods, with potential reductions of 15-25% in overall water footprint. However, the electrolyte solutions used in these processes may contain potentially harmful substances that require careful management and recycling protocols to prevent environmental contamination.

The sustainability profile of electrode materials warrants particular attention. Current high-performance electrodes often incorporate rare earth elements or precious metals that present sustainability challenges related to resource scarcity and extraction impacts. Research into abundant, non-toxic alternatives such as carbon-based materials, modified iron alloys, and certain metal oxides shows promising results for reducing the environmental footprint of electrode manufacturing while maintaining acceptable performance metrics.

Life cycle assessment (LCA) studies indicate that the environmental advantages of electrochemical hematite reduction are highly dependent on the electricity source. When powered by renewable energy, the process demonstrates clear environmental benefits; however, if powered by coal-based electricity, these advantages may be negated. This underscores the importance of integrating renewable energy systems with electrochemical reduction technologies to maximize sustainability benefits.

Waste management represents another significant consideration. The process generates spent electrolytes and electrode materials that require proper handling and recycling. Emerging circular economy approaches include electrolyte regeneration systems that can recover and reuse up to 85% of solution components, significantly reducing waste streams and associated environmental impacts.

Regulatory frameworks worldwide are increasingly recognizing electrochemical processes as Best Available Techniques (BAT) for certain metallurgical applications. The European Union's Industrial Emissions Directive and similar regulations in North America and Asia are beginning to incorporate specific provisions for electrochemical metal production, potentially accelerating industry adoption through regulatory incentives and compliance requirements.

Economic Feasibility and Scalability Assessment

The economic feasibility of electrochemical reduction of hematite is significantly influenced by several key factors including capital expenditure, operational costs, and market dynamics. Initial investment requirements for establishing industrial-scale electrochemical reduction facilities are substantial, with specialized equipment such as advanced electrodes, power supply systems, and monitoring infrastructure representing major cost components. Current estimates indicate that capital costs range from $5,000 to $15,000 per ton of annual production capacity, depending on process configuration and scale.

Operational economics present both challenges and opportunities. Energy consumption remains a critical cost driver, with typical processes requiring 2.5-4.0 kWh per kilogram of reduced iron. This energy intensity necessitates access to affordable and reliable power sources to maintain economic viability. Regions with low electricity costs or renewable energy infrastructure offer significant competitive advantages for commercial implementation.

Raw material costs exhibit favorable economics, as hematite is abundant globally with established supply chains. However, electrode material selection significantly impacts both capital and operational expenses. Noble metal electrodes deliver superior performance but at prohibitive costs for large-scale applications. Recent advancements in carbon-based and mixed metal oxide electrodes show promise for balancing performance and cost considerations.

Scalability assessment reveals promising pathways for industrial implementation. Laboratory-scale processes have successfully demonstrated conversion efficiencies exceeding 85%, with pilot plants achieving throughputs of 50-200 kg per day. The modular nature of electrochemical systems presents advantages for incremental capacity expansion, allowing for phased investment approaches that reduce initial capital requirements and financial risk.

Technical scalability challenges include maintaining uniform current distribution across larger electrode surfaces, managing heat dissipation in scaled systems, and ensuring consistent product quality at higher production volumes. Engineering solutions such as optimized cell design, advanced flow distribution systems, and precise process control mechanisms have demonstrated effectiveness in addressing these challenges.

Market economics support continued development, with reduced iron products commanding premium pricing in specialized applications such as high-purity metal production and advanced materials manufacturing. The process also offers potential value from environmental credits in jurisdictions with carbon pricing mechanisms, as electrochemical reduction typically generates 30-50% lower carbon emissions compared to conventional pyrometallurgical processes when powered by low-carbon electricity sources.

Operational economics present both challenges and opportunities. Energy consumption remains a critical cost driver, with typical processes requiring 2.5-4.0 kWh per kilogram of reduced iron. This energy intensity necessitates access to affordable and reliable power sources to maintain economic viability. Regions with low electricity costs or renewable energy infrastructure offer significant competitive advantages for commercial implementation.

Raw material costs exhibit favorable economics, as hematite is abundant globally with established supply chains. However, electrode material selection significantly impacts both capital and operational expenses. Noble metal electrodes deliver superior performance but at prohibitive costs for large-scale applications. Recent advancements in carbon-based and mixed metal oxide electrodes show promise for balancing performance and cost considerations.

Scalability assessment reveals promising pathways for industrial implementation. Laboratory-scale processes have successfully demonstrated conversion efficiencies exceeding 85%, with pilot plants achieving throughputs of 50-200 kg per day. The modular nature of electrochemical systems presents advantages for incremental capacity expansion, allowing for phased investment approaches that reduce initial capital requirements and financial risk.

Technical scalability challenges include maintaining uniform current distribution across larger electrode surfaces, managing heat dissipation in scaled systems, and ensuring consistent product quality at higher production volumes. Engineering solutions such as optimized cell design, advanced flow distribution systems, and precise process control mechanisms have demonstrated effectiveness in addressing these challenges.

Market economics support continued development, with reduced iron products commanding premium pricing in specialized applications such as high-purity metal production and advanced materials manufacturing. The process also offers potential value from environmental credits in jurisdictions with carbon pricing mechanisms, as electrochemical reduction typically generates 30-50% lower carbon emissions compared to conventional pyrometallurgical processes when powered by low-carbon electricity sources.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!