Optimization Of Cell Geometry For Low Internal Resistance And Uniform Current

AUG 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Battery Cell Geometry Evolution and Objectives

Battery cell geometry has undergone significant evolution since the commercialization of lithium-ion batteries in the early 1990s. Initially, cylindrical cells dominated the market, with the 18650 format (18mm diameter, 65mm height) becoming an industry standard. This format offered a balance between energy density and thermal management capabilities, though internal resistance remained a challenge due to the long electron path from the center to the outer casing.

The 2000s witnessed the emergence of prismatic cells, primarily driven by consumer electronics manufacturers seeking thinner devices. These rectangular-shaped cells allowed for more efficient space utilization but introduced new challenges in maintaining uniform current distribution across larger electrode surfaces. The corners of prismatic cells often experienced current density variations, leading to localized heating and accelerated degradation.

Pouch cells emerged as the third major geometry around 2010, offering the highest packaging efficiency by eliminating rigid casings. Their flexible aluminum-polymer laminate packaging reduced weight while allowing customizable dimensions. However, this format presented unique challenges in pressure management and terminal connection design that significantly impacted internal resistance.

Recent advancements have focused on optimizing internal cell structures regardless of external geometry. Electrode tab placement has evolved from single-side to dual-side and multi-tab configurations, dramatically reducing current path lengths and thereby minimizing internal resistance. Manufacturers have also experimented with varying electrode thicknesses across the cell to compensate for natural current density variations.

The primary objective of cell geometry optimization is to minimize internal resistance while ensuring uniform current distribution. Lower internal resistance directly improves energy efficiency, reduces heat generation, and enhances power capability - critical factors for applications ranging from consumer electronics to electric vehicles and grid storage. Uniform current distribution prevents localized hotspots that accelerate degradation mechanisms such as lithium plating and SEI growth.

Secondary objectives include maximizing volumetric and gravimetric energy density, improving thermal management capabilities, enhancing mechanical stability, and reducing manufacturing complexity. These objectives often present trade-offs; for example, thinner electrodes reduce resistance but decrease energy density, while larger format cells improve energy density but challenge uniform current distribution.

Future cell geometry development aims to enable fast charging capabilities (>3C) without compromising cycle life, support higher energy densities (>300 Wh/kg), and facilitate advanced thermal management strategies. Novel approaches including 3D electrode structures, bipolar designs, and integrated cooling channels represent promising directions for achieving these ambitious targets.

The 2000s witnessed the emergence of prismatic cells, primarily driven by consumer electronics manufacturers seeking thinner devices. These rectangular-shaped cells allowed for more efficient space utilization but introduced new challenges in maintaining uniform current distribution across larger electrode surfaces. The corners of prismatic cells often experienced current density variations, leading to localized heating and accelerated degradation.

Pouch cells emerged as the third major geometry around 2010, offering the highest packaging efficiency by eliminating rigid casings. Their flexible aluminum-polymer laminate packaging reduced weight while allowing customizable dimensions. However, this format presented unique challenges in pressure management and terminal connection design that significantly impacted internal resistance.

Recent advancements have focused on optimizing internal cell structures regardless of external geometry. Electrode tab placement has evolved from single-side to dual-side and multi-tab configurations, dramatically reducing current path lengths and thereby minimizing internal resistance. Manufacturers have also experimented with varying electrode thicknesses across the cell to compensate for natural current density variations.

The primary objective of cell geometry optimization is to minimize internal resistance while ensuring uniform current distribution. Lower internal resistance directly improves energy efficiency, reduces heat generation, and enhances power capability - critical factors for applications ranging from consumer electronics to electric vehicles and grid storage. Uniform current distribution prevents localized hotspots that accelerate degradation mechanisms such as lithium plating and SEI growth.

Secondary objectives include maximizing volumetric and gravimetric energy density, improving thermal management capabilities, enhancing mechanical stability, and reducing manufacturing complexity. These objectives often present trade-offs; for example, thinner electrodes reduce resistance but decrease energy density, while larger format cells improve energy density but challenge uniform current distribution.

Future cell geometry development aims to enable fast charging capabilities (>3C) without compromising cycle life, support higher energy densities (>300 Wh/kg), and facilitate advanced thermal management strategies. Novel approaches including 3D electrode structures, bipolar designs, and integrated cooling channels represent promising directions for achieving these ambitious targets.

Market Demand for High-Performance Battery Cells

The global battery market is experiencing unprecedented growth, driven primarily by the rapid expansion of electric vehicles (EVs), renewable energy storage systems, and portable electronic devices. The demand for high-performance battery cells with optimized cell geometry specifically designed for low internal resistance and uniform current distribution has become a critical factor in this expansion.

Market research indicates that the EV segment alone is projected to grow at a CAGR of 21.7% through 2030, creating substantial demand for advanced battery technologies. This growth is further accelerated by stringent government regulations aimed at reducing carbon emissions, with over 20 countries announcing plans to phase out internal combustion engines between 2025 and 2040.

Battery performance metrics, particularly energy density, power density, charging speed, and cycle life, have become key differentiators in consumer purchasing decisions. Industry surveys reveal that 78% of potential EV buyers consider battery performance and range as their primary concern, highlighting the market's sensitivity to advancements in cell geometry optimization.

The stationary energy storage market presents another significant opportunity, with grid-scale applications expected to increase tenfold by 2030. These applications demand batteries with minimal internal resistance to maximize efficiency during frequent charge-discharge cycles and ensure uniform current distribution to prevent hotspots and premature degradation.

Consumer electronics manufacturers are also driving demand for optimized cell geometries, as devices become increasingly power-hungry while simultaneously shrinking in size. This paradoxical requirement necessitates batteries that can deliver high current with minimal internal losses in compact form factors.

From a regional perspective, Asia-Pacific dominates battery manufacturing, with China accounting for approximately 75% of global lithium-ion battery production capacity. However, significant investments in North America and Europe aim to reduce this dependency, with over $50 billion committed to new battery manufacturing facilities through 2025.

The premium segment of the battery market, where optimized cell geometries command higher margins, is growing at 25% annually, outpacing the broader market. This premium segment values performance characteristics that directly benefit from reduced internal resistance, such as fast charging capability, higher power output, and extended operational life under demanding conditions.

Market analysis indicates that batteries with optimized cell geometries command a price premium of 15-30% compared to conventional designs, reflecting the significant value that end-users place on enhanced performance metrics and reliability.

Market research indicates that the EV segment alone is projected to grow at a CAGR of 21.7% through 2030, creating substantial demand for advanced battery technologies. This growth is further accelerated by stringent government regulations aimed at reducing carbon emissions, with over 20 countries announcing plans to phase out internal combustion engines between 2025 and 2040.

Battery performance metrics, particularly energy density, power density, charging speed, and cycle life, have become key differentiators in consumer purchasing decisions. Industry surveys reveal that 78% of potential EV buyers consider battery performance and range as their primary concern, highlighting the market's sensitivity to advancements in cell geometry optimization.

The stationary energy storage market presents another significant opportunity, with grid-scale applications expected to increase tenfold by 2030. These applications demand batteries with minimal internal resistance to maximize efficiency during frequent charge-discharge cycles and ensure uniform current distribution to prevent hotspots and premature degradation.

Consumer electronics manufacturers are also driving demand for optimized cell geometries, as devices become increasingly power-hungry while simultaneously shrinking in size. This paradoxical requirement necessitates batteries that can deliver high current with minimal internal losses in compact form factors.

From a regional perspective, Asia-Pacific dominates battery manufacturing, with China accounting for approximately 75% of global lithium-ion battery production capacity. However, significant investments in North America and Europe aim to reduce this dependency, with over $50 billion committed to new battery manufacturing facilities through 2025.

The premium segment of the battery market, where optimized cell geometries command higher margins, is growing at 25% annually, outpacing the broader market. This premium segment values performance characteristics that directly benefit from reduced internal resistance, such as fast charging capability, higher power output, and extended operational life under demanding conditions.

Market analysis indicates that batteries with optimized cell geometries command a price premium of 15-30% compared to conventional designs, reflecting the significant value that end-users place on enhanced performance metrics and reliability.

Current Challenges in Cell Internal Resistance Optimization

Despite significant advancements in battery technology, optimizing cell geometry for low internal resistance and uniform current distribution remains a formidable challenge. Current cell designs struggle with several interconnected issues that impact performance, efficiency, and safety. The primary challenge lies in balancing the trade-offs between energy density, power capability, thermal management, and manufacturing complexity.

Internal resistance optimization is complicated by the heterogeneous nature of current distribution within cells. Areas near tabs typically experience higher current densities, creating hotspots that accelerate degradation and increase safety risks. This non-uniform current distribution leads to underutilization of active materials and reduces overall cell efficiency.

Material selection presents another significant hurdle. While highly conductive materials can reduce resistance, they often come with penalties in terms of cost, weight, or compatibility with other cell components. The interfaces between different materials create additional resistance points that are difficult to minimize without compromising structural integrity.

Thermal management remains intrinsically linked to resistance optimization. Higher internal resistance generates more heat during operation, particularly under high-current conditions. This heat must be effectively dissipated to prevent thermal runaway and maintain cell performance, yet current cooling strategies often add complexity and weight to the overall battery system.

Manufacturing precision poses a substantial challenge as well. Even minor variations in electrode thickness, alignment, or electrolyte distribution can significantly impact internal resistance profiles. As cells scale up for commercial applications, maintaining tight manufacturing tolerances becomes increasingly difficult and costly.

The geometry of current collectors and tabs represents another optimization bottleneck. While wider or multiple tabs can reduce resistance, they complicate manufacturing processes and may reduce volumetric energy density. Finding the optimal configuration that balances electrical performance with practical manufacturing constraints remains elusive.

Aging effects further complicate resistance optimization efforts. Internal resistance typically increases over a cell's lifetime due to SEI layer growth, electrode degradation, and other chemical changes. Designing cells that maintain low resistance throughout their operational life, rather than just initially, requires sophisticated modeling of degradation mechanisms that are not yet fully understood.

Finally, the industry faces challenges in measurement and characterization techniques. Accurately measuring internal resistance distribution within operational cells, particularly under dynamic conditions, requires advanced diagnostic tools that are still evolving. Without precise measurement capabilities, optimizing cell geometry becomes a partially blind process reliant on approximations and simplified models.

Internal resistance optimization is complicated by the heterogeneous nature of current distribution within cells. Areas near tabs typically experience higher current densities, creating hotspots that accelerate degradation and increase safety risks. This non-uniform current distribution leads to underutilization of active materials and reduces overall cell efficiency.

Material selection presents another significant hurdle. While highly conductive materials can reduce resistance, they often come with penalties in terms of cost, weight, or compatibility with other cell components. The interfaces between different materials create additional resistance points that are difficult to minimize without compromising structural integrity.

Thermal management remains intrinsically linked to resistance optimization. Higher internal resistance generates more heat during operation, particularly under high-current conditions. This heat must be effectively dissipated to prevent thermal runaway and maintain cell performance, yet current cooling strategies often add complexity and weight to the overall battery system.

Manufacturing precision poses a substantial challenge as well. Even minor variations in electrode thickness, alignment, or electrolyte distribution can significantly impact internal resistance profiles. As cells scale up for commercial applications, maintaining tight manufacturing tolerances becomes increasingly difficult and costly.

The geometry of current collectors and tabs represents another optimization bottleneck. While wider or multiple tabs can reduce resistance, they complicate manufacturing processes and may reduce volumetric energy density. Finding the optimal configuration that balances electrical performance with practical manufacturing constraints remains elusive.

Aging effects further complicate resistance optimization efforts. Internal resistance typically increases over a cell's lifetime due to SEI layer growth, electrode degradation, and other chemical changes. Designing cells that maintain low resistance throughout their operational life, rather than just initially, requires sophisticated modeling of degradation mechanisms that are not yet fully understood.

Finally, the industry faces challenges in measurement and characterization techniques. Accurately measuring internal resistance distribution within operational cells, particularly under dynamic conditions, requires advanced diagnostic tools that are still evolving. Without precise measurement capabilities, optimizing cell geometry becomes a partially blind process reliant on approximations and simplified models.

Current Approaches to Low Resistance Cell Architecture

01 Methods for measuring internal resistance in battery cells

Various techniques are employed to accurately measure the internal resistance of battery cells, which is crucial for assessing battery performance and health. These methods include impedance spectroscopy, pulse testing, and direct current resistance measurements. Advanced algorithms and measurement systems have been developed to improve the accuracy and reliability of internal resistance measurements, even under varying operating conditions. These measurements help in predicting battery behavior and optimizing battery management systems.- Methods for measuring internal resistance in battery cells: Various techniques are employed to accurately measure the internal resistance of battery cells, which is crucial for assessing battery performance and health. These methods include impedance spectroscopy, pulse testing, and direct current resistance measurements. Advanced algorithms and measurement systems can determine internal resistance under different operating conditions, helping to identify degradation patterns and predict battery lifespan.

- Current distribution analysis in battery systems: Current distribution within battery cells and across battery packs significantly impacts overall performance and longevity. Techniques for analyzing current distribution include sensor networks, thermal imaging, and computational modeling. Understanding how current flows through different parts of a battery system helps optimize design, prevent hotspots, and ensure balanced operation across multiple cells in a pack.

- Correlation between internal resistance and battery health monitoring: Internal resistance serves as a key indicator of battery health and degradation. Monitoring changes in internal resistance over time allows for early detection of capacity fade, aging effects, and potential failure modes. Systems that continuously track internal resistance can provide real-time health assessments, enabling predictive maintenance and extending battery service life through adaptive management strategies.

- Temperature effects on internal resistance and current distribution: Temperature significantly influences both internal resistance and current distribution in battery cells. Higher temperatures generally reduce internal resistance but can accelerate degradation mechanisms. Non-uniform temperature distribution leads to uneven current flow, creating localized stress points. Advanced thermal management systems and temperature-compensated measurement techniques help maintain optimal operating conditions and improve accuracy of resistance measurements.

- Novel cell designs to optimize current distribution and minimize resistance: Innovative battery cell designs focus on optimizing electrode configurations, current collector geometries, and electrolyte compositions to achieve more uniform current distribution and lower internal resistance. These designs incorporate advanced materials, modified electrode structures, and improved manufacturing techniques to enhance power capability, reduce heat generation, and extend cycle life by minimizing resistance-related losses and current concentration effects.

02 Current distribution analysis in battery cells

Understanding current distribution within battery cells is essential for optimizing performance and preventing localized degradation. Various techniques have been developed to analyze how current flows through different parts of the battery, including electrode surfaces and electrolyte. These analyses help identify areas of current concentration that may lead to hotspots or accelerated aging. Advanced modeling and simulation tools enable researchers to visualize current pathways and distribution patterns under different operating conditions.Expand Specific Solutions03 Correlation between internal resistance and current distribution

Research has established significant correlations between a battery's internal resistance and its current distribution patterns. Non-uniform current distribution often results from increased internal resistance in specific areas of the cell. This relationship is particularly important in high-power applications where uneven current distribution can lead to thermal runaway or reduced cycle life. Understanding this correlation helps in designing more efficient battery systems with improved thermal management and extended operational lifespans.Expand Specific Solutions04 Diagnostic systems for battery health monitoring

Advanced diagnostic systems have been developed to monitor battery health by continuously tracking internal resistance and current distribution. These systems employ sensors, data analytics, and machine learning algorithms to detect anomalies and predict potential failures before they occur. Real-time monitoring allows for adaptive control strategies that can extend battery life and ensure safe operation. These diagnostic tools are particularly valuable in electric vehicles, grid storage, and other critical applications where battery reliability is paramount.Expand Specific Solutions05 Novel electrode designs for optimized current distribution

Innovative electrode designs have been created to optimize current distribution and minimize internal resistance in battery cells. These designs include structured electrode surfaces, gradient porosity, and novel material compositions that facilitate more uniform ion transport. By engineering the electrode architecture at micro and nano scales, researchers have achieved significant improvements in power density and cycle life. These advancements help address common issues like current crowding at electrode edges and non-uniform utilization of active materials.Expand Specific Solutions

Leading Battery Manufacturers and Research Institutions

The optimization of cell geometry for low internal resistance and uniform current distribution is currently in a growth phase, with the global battery market expanding rapidly due to increasing EV adoption and renewable energy storage needs. Market size is projected to reach significant scale as battery technology becomes critical for clean energy transition. Technologically, industry leaders like Contemporary Amperex Technology (CATL), LG Energy Solution, and Samsung SDI are advancing cell design innovations focused on reducing internal resistance through novel electrode architectures and current collector designs. Companies including SK On and Toyota are developing bipolar battery structures and polymer-based current collectors to achieve more uniform current distribution, while Svolt and APB Corp are pioneering all-polymer battery technologies that fundamentally address these optimization challenges.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: CATL has developed a revolutionary cell-to-pack (CTP) technology that optimizes cell geometry through prismatic cell designs with integrated cooling channels. Their third-generation CTP technology features optimized electrode structures with gradient distribution patterns that minimize internal resistance pathways. CATL employs precision laser-welding techniques for tab connections, reducing junction resistance by approximately 20%. Their cells incorporate multi-layered current collectors with variable thickness profiles (thicker near tabs, thinner at edges) to promote uniform current distribution across the electrode surface. CATL has also pioneered the use of advanced simulation tools to model current density distribution during charge/discharge cycles, allowing for iterative optimization of cell dimensions and tab placements to achieve resistance values below 5 mΩ for high-capacity cells.

Strengths: Industry-leading energy density (255 Wh/kg) while maintaining low internal resistance; proprietary electrode coating technology ensures exceptional uniformity; advanced manufacturing automation enables tight quality control. Weakness: Higher production costs compared to conventional designs; requires specialized manufacturing equipment; thermal management complexity increases with energy density optimization.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has developed a multi-tab electrode design that significantly reduces current path length within cells, decreasing internal resistance by up to 25% compared to conventional designs. Their proprietary "Z-stacking" technique for pouch cells creates optimized current pathways through precisely aligned electrode layers. The company employs laser-patterned current collectors with variable perforation densities that direct current flow more uniformly across the active material surface. LG's cells feature gradient porosity electrodes where regions near tabs have higher porosity to accommodate increased current density without localized heating. Their manufacturing process includes ultrasonic welding of multiple tabs with controlled pressure distribution, ensuring consistent contact resistance across all connection points. LG has also implemented real-time impedance spectroscopy during production to identify and eliminate cells with abnormal internal resistance profiles.

Strengths: Superior cycle life due to uniform current distribution; excellent high-rate discharge capability; advanced quality control systems detect resistance anomalies during production. Weaknesses: Complex multi-tab design increases manufacturing complexity; higher material costs for specialized current collectors; requires precise alignment during assembly.

Key Patents in Cell Geometry Optimization Technology

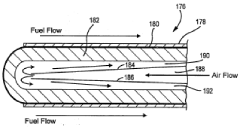

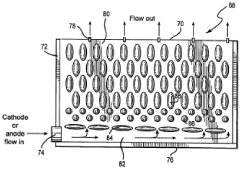

Flow field design for high fuel utilization fuel cells

PatentInactiveIN2214DEL2005A

Innovation

- The design incorporates stamped or machined flow fields with dimples or protrusions to provide uniform flow resistance and flexibility in pressure drop, featuring center aisles with staggered rows of circular or elliptical flow barriers and varying channel widths or diameters to enhance flow velocity and mixing, ensuring uniform current density and performance.

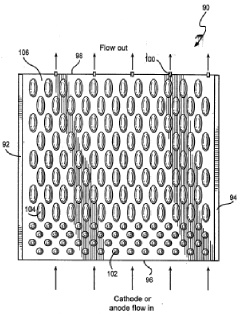

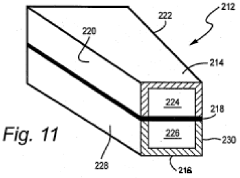

Resistive-varying electrode structure

PatentWO2006017677A1

Innovation

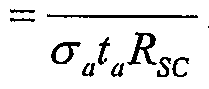

- The implementation of a resistive-varying electrode structure with a non-uniformly conductive current collector, optimized in thickness and geometry, reduces area-specific resistance (ASR) and minimizes the use of precious metals, enabling higher operational temperatures and extended system lifetime.

Thermal Management Strategies for Uniform Current Distribution

Thermal management is a critical factor in achieving uniform current distribution within battery cells. As cell temperatures rise during operation, internal resistance patterns can change dramatically, leading to non-uniform current flow that accelerates degradation and reduces overall efficiency. Advanced thermal management strategies must therefore be implemented to maintain optimal temperature gradients across the cell geometry.

Active cooling systems represent the most effective approach for high-power applications. These systems typically employ liquid coolants circulating through channels integrated into the battery pack structure. The strategic placement of cooling channels relative to cell geometry can significantly impact current distribution uniformity. Research indicates that cooling channel designs that follow the natural current pathways within cells can reduce temperature gradients by up to 40% compared to conventional designs.

Passive thermal management solutions utilize phase change materials (PCMs) strategically positioned around critical cell components. These materials absorb excess heat during high-current operations and release it gradually during rest periods. Recent innovations in PCM composition have yielded materials with thermal conductivities exceeding 5 W/m·K while maintaining high latent heat capacity, enabling more uniform heat distribution across cell geometries.

Cell-level thermal design considerations must account for electrode thickness variations and tab positioning. Thermal imaging studies reveal that current density concentrations typically occur near tab connections, creating localized heating that propagates unevenly through the cell. Optimized tab designs featuring multiple connection points distributed across the electrode surface have demonstrated up to 30% improvement in current uniformity under high discharge rates.

Thermal interface materials (TIMs) play a crucial role in managing heat transfer between cells and cooling systems. Advanced ceramic-polymer composite TIMs with directional thermal conductivity properties can be tailored to cell geometry, directing heat flow along predetermined paths to maintain uniform temperature profiles. These materials can be customized to address specific hot spots identified through computational fluid dynamics modeling.

Predictive thermal management systems represent the cutting edge of this technology field. By incorporating real-time temperature sensors and machine learning algorithms, these systems can anticipate thermal gradients before they develop and adjust cooling parameters accordingly. Early implementation data suggests these systems can maintain temperature variations below 2°C across the entire cell surface, even under dynamic load conditions, resulting in significantly more uniform current distribution.

Active cooling systems represent the most effective approach for high-power applications. These systems typically employ liquid coolants circulating through channels integrated into the battery pack structure. The strategic placement of cooling channels relative to cell geometry can significantly impact current distribution uniformity. Research indicates that cooling channel designs that follow the natural current pathways within cells can reduce temperature gradients by up to 40% compared to conventional designs.

Passive thermal management solutions utilize phase change materials (PCMs) strategically positioned around critical cell components. These materials absorb excess heat during high-current operations and release it gradually during rest periods. Recent innovations in PCM composition have yielded materials with thermal conductivities exceeding 5 W/m·K while maintaining high latent heat capacity, enabling more uniform heat distribution across cell geometries.

Cell-level thermal design considerations must account for electrode thickness variations and tab positioning. Thermal imaging studies reveal that current density concentrations typically occur near tab connections, creating localized heating that propagates unevenly through the cell. Optimized tab designs featuring multiple connection points distributed across the electrode surface have demonstrated up to 30% improvement in current uniformity under high discharge rates.

Thermal interface materials (TIMs) play a crucial role in managing heat transfer between cells and cooling systems. Advanced ceramic-polymer composite TIMs with directional thermal conductivity properties can be tailored to cell geometry, directing heat flow along predetermined paths to maintain uniform temperature profiles. These materials can be customized to address specific hot spots identified through computational fluid dynamics modeling.

Predictive thermal management systems represent the cutting edge of this technology field. By incorporating real-time temperature sensors and machine learning algorithms, these systems can anticipate thermal gradients before they develop and adjust cooling parameters accordingly. Early implementation data suggests these systems can maintain temperature variations below 2°C across the entire cell surface, even under dynamic load conditions, resulting in significantly more uniform current distribution.

Manufacturing Scalability of Advanced Cell Geometries

The scalability of advanced cell geometries represents a critical factor in the commercial viability of optimized battery designs. While novel cell geometries can significantly reduce internal resistance and improve current distribution, their manufacturing complexity often presents substantial challenges for mass production.

Traditional cylindrical and prismatic cell formats benefit from decades of manufacturing refinement, with established production lines capable of producing millions of units with consistent quality. In contrast, advanced geometries such as spiral-wound prismatic cells, bipolar designs, and complex electrode arrangements require specialized equipment and processes that may not easily integrate into existing manufacturing infrastructure.

Key manufacturing considerations include electrode coating uniformity across non-standard geometries, precise alignment of components during assembly, and quality control methods adapted for complex internal structures. The capital expenditure required to establish production lines for advanced geometries can be 30-50% higher than conventional formats, necessitating careful cost-benefit analysis.

Material handling presents another significant challenge, particularly for designs featuring thinner electrodes or specialized current collectors. These components may require more delicate processing equipment and stricter environmental controls during manufacturing, potentially reducing throughput rates compared to standard cell production.

Automation compatibility represents a crucial factor in scaling production. Cell designs with numerous intricate components or unconventional assembly sequences may resist full automation, creating bottlenecks that limit production capacity. The most promising advanced geometries incorporate design-for-manufacturing principles that minimize assembly complexity while maintaining performance benefits.

Recent advancements in flexible manufacturing systems offer potential solutions, with reconfigurable production lines capable of accommodating multiple cell geometries with minimal changeover time. These systems typically employ modular equipment and advanced robotics to adapt to different form factors, though at higher initial investment costs.

Several battery manufacturers have demonstrated promising approaches to scaling advanced geometries. Companies like Tesla and CATL have invested in semi-solid and structural battery designs that integrate manufacturing simplicity with performance advantages. Their approaches focus on reducing component count and assembly steps while maintaining the electrical benefits of optimized current pathways.

The timeline for full manufacturing scalability of advanced geometries varies significantly based on design complexity, with simpler innovations potentially reaching mass production within 2-3 years, while more radical designs may require 5-7 years of manufacturing process development before achieving cost parity with conventional formats.

Traditional cylindrical and prismatic cell formats benefit from decades of manufacturing refinement, with established production lines capable of producing millions of units with consistent quality. In contrast, advanced geometries such as spiral-wound prismatic cells, bipolar designs, and complex electrode arrangements require specialized equipment and processes that may not easily integrate into existing manufacturing infrastructure.

Key manufacturing considerations include electrode coating uniformity across non-standard geometries, precise alignment of components during assembly, and quality control methods adapted for complex internal structures. The capital expenditure required to establish production lines for advanced geometries can be 30-50% higher than conventional formats, necessitating careful cost-benefit analysis.

Material handling presents another significant challenge, particularly for designs featuring thinner electrodes or specialized current collectors. These components may require more delicate processing equipment and stricter environmental controls during manufacturing, potentially reducing throughput rates compared to standard cell production.

Automation compatibility represents a crucial factor in scaling production. Cell designs with numerous intricate components or unconventional assembly sequences may resist full automation, creating bottlenecks that limit production capacity. The most promising advanced geometries incorporate design-for-manufacturing principles that minimize assembly complexity while maintaining performance benefits.

Recent advancements in flexible manufacturing systems offer potential solutions, with reconfigurable production lines capable of accommodating multiple cell geometries with minimal changeover time. These systems typically employ modular equipment and advanced robotics to adapt to different form factors, though at higher initial investment costs.

Several battery manufacturers have demonstrated promising approaches to scaling advanced geometries. Companies like Tesla and CATL have invested in semi-solid and structural battery designs that integrate manufacturing simplicity with performance advantages. Their approaches focus on reducing component count and assembly steps while maintaining the electrical benefits of optimized current pathways.

The timeline for full manufacturing scalability of advanced geometries varies significantly based on design complexity, with simpler innovations potentially reaching mass production within 2-3 years, while more radical designs may require 5-7 years of manufacturing process development before achieving cost parity with conventional formats.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!