Benchmarks For Performance: Current Efficiency, Energy per Kg Fe, And Purity

AUG 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Iron Production Technology Evolution and Benchmarking Goals

Iron production has evolved significantly over millennia, from primitive bloomeries to modern blast furnaces and direct reduction processes. The technological trajectory has been driven by demands for higher efficiency, lower energy consumption, and improved product purity. Early iron production methods yielded low-quality iron with significant impurities, requiring substantial energy inputs relative to output. The industrial revolution marked a pivotal shift with the introduction of coke-fueled blast furnaces, dramatically increasing production capacity and efficiency.

Current benchmarks in iron production efficiency vary by process type. Modern blast furnaces operate at approximately 85-90% efficiency in terms of iron recovery from ore, representing significant improvement from historical rates below 50%. However, this efficiency metric must be considered alongside energy consumption benchmarks, which remain a critical industry challenge.

Energy consumption in iron production currently averages 20-25 GJ per tonne of crude steel in integrated steelmaking facilities. Best-in-class operations have achieved levels approaching 18 GJ/tonne, while the theoretical minimum is calculated at approximately 10-12 GJ/tonne. This gap between current practice and theoretical limits represents a key target for technological innovation.

Product purity benchmarks have similarly evolved, with modern processes capable of producing iron with carbon content precisely controlled between 0.002% and 4.5% depending on the desired application. Impurity levels for elements such as sulfur and phosphorus can now be maintained below 0.05%, essential for high-performance steel applications.

Regional variations in benchmark performance are significant, with facilities in Europe and Japan typically achieving higher efficiency and lower energy consumption than global averages. These regional leaders have established the current best practice benchmarks that serve as targets for global operations.

The evolution of these benchmarks reflects broader technological trends, including process automation, sensor technology integration, and computational modeling of thermodynamic processes. Each advancement has incrementally improved the three key performance indicators: efficiency, energy consumption, and purity.

Future benchmarking goals aim to close the gap between current performance and theoretical limits. Industry roadmaps target energy consumption reductions to 15 GJ/tonne by 2030 and further improvements in recovery efficiency to 95%. Simultaneously, purity control is expected to become even more precise, enabling new material properties and applications.

Current benchmarks in iron production efficiency vary by process type. Modern blast furnaces operate at approximately 85-90% efficiency in terms of iron recovery from ore, representing significant improvement from historical rates below 50%. However, this efficiency metric must be considered alongside energy consumption benchmarks, which remain a critical industry challenge.

Energy consumption in iron production currently averages 20-25 GJ per tonne of crude steel in integrated steelmaking facilities. Best-in-class operations have achieved levels approaching 18 GJ/tonne, while the theoretical minimum is calculated at approximately 10-12 GJ/tonne. This gap between current practice and theoretical limits represents a key target for technological innovation.

Product purity benchmarks have similarly evolved, with modern processes capable of producing iron with carbon content precisely controlled between 0.002% and 4.5% depending on the desired application. Impurity levels for elements such as sulfur and phosphorus can now be maintained below 0.05%, essential for high-performance steel applications.

Regional variations in benchmark performance are significant, with facilities in Europe and Japan typically achieving higher efficiency and lower energy consumption than global averages. These regional leaders have established the current best practice benchmarks that serve as targets for global operations.

The evolution of these benchmarks reflects broader technological trends, including process automation, sensor technology integration, and computational modeling of thermodynamic processes. Each advancement has incrementally improved the three key performance indicators: efficiency, energy consumption, and purity.

Future benchmarking goals aim to close the gap between current performance and theoretical limits. Industry roadmaps target energy consumption reductions to 15 GJ/tonne by 2030 and further improvements in recovery efficiency to 95%. Simultaneously, purity control is expected to become even more precise, enabling new material properties and applications.

Market Demand Analysis for High-Efficiency Iron Production

The global iron and steel industry is experiencing a significant shift towards more efficient and sustainable production methods, driven by increasing environmental regulations, rising energy costs, and growing market demand for high-quality steel products. Current market analysis indicates that industries consuming iron and steel products are increasingly prioritizing suppliers who can demonstrate superior efficiency metrics and lower environmental footprints in their production processes.

Market research shows that construction, automotive, and infrastructure sectors collectively account for over 75% of global steel consumption, with these industries increasingly specifying environmental performance requirements in their procurement policies. The demand for high-efficiency iron production is particularly strong in developed economies where carbon pricing mechanisms and stringent emissions regulations are already in place, creating immediate economic incentives for efficiency improvements.

Energy efficiency has become a critical market differentiator, with buyers willing to pay premium prices for iron produced with significantly lower energy inputs per kilogram. Current benchmarks indicate that conventional blast furnace operations consume between 20-25 GJ per ton of hot metal produced, while more advanced technologies are pushing towards the theoretical minimum of approximately 10-12 GJ per ton.

Purity requirements are also evolving, with high-tech applications in automotive, aerospace, and electronics industries demanding iron with fewer impurities. Market segments requiring ultra-high purity iron (99.9%+) are growing at twice the rate of standard grade markets, reflecting the expansion of specialized applications in emerging technologies.

Regional market analysis reveals that Asian markets, particularly China and India, represent the largest volume demand for improved iron production efficiency, driven by massive infrastructure development and manufacturing sectors. However, European markets lead in demanding higher environmental performance standards, with regulatory frameworks increasingly tying market access to demonstrable efficiency improvements.

The market for technologies that can improve iron production benchmarks is projected to grow substantially, with consulting firm estimates suggesting that investments in efficiency-improving technologies for iron production will exceed $25 billion globally over the next five years. This represents a significant opportunity for technology providers who can deliver solutions that address the triple metrics of efficiency, energy consumption, and purity.

Consumer-facing industries are increasingly incorporating supply chain emissions into their sustainability reporting, creating downstream pressure for improved iron production metrics. This trend is expected to accelerate as carbon border adjustment mechanisms and product carbon footprinting become more widespread, potentially creating price premiums for efficiently produced iron in international markets.

Market research shows that construction, automotive, and infrastructure sectors collectively account for over 75% of global steel consumption, with these industries increasingly specifying environmental performance requirements in their procurement policies. The demand for high-efficiency iron production is particularly strong in developed economies where carbon pricing mechanisms and stringent emissions regulations are already in place, creating immediate economic incentives for efficiency improvements.

Energy efficiency has become a critical market differentiator, with buyers willing to pay premium prices for iron produced with significantly lower energy inputs per kilogram. Current benchmarks indicate that conventional blast furnace operations consume between 20-25 GJ per ton of hot metal produced, while more advanced technologies are pushing towards the theoretical minimum of approximately 10-12 GJ per ton.

Purity requirements are also evolving, with high-tech applications in automotive, aerospace, and electronics industries demanding iron with fewer impurities. Market segments requiring ultra-high purity iron (99.9%+) are growing at twice the rate of standard grade markets, reflecting the expansion of specialized applications in emerging technologies.

Regional market analysis reveals that Asian markets, particularly China and India, represent the largest volume demand for improved iron production efficiency, driven by massive infrastructure development and manufacturing sectors. However, European markets lead in demanding higher environmental performance standards, with regulatory frameworks increasingly tying market access to demonstrable efficiency improvements.

The market for technologies that can improve iron production benchmarks is projected to grow substantially, with consulting firm estimates suggesting that investments in efficiency-improving technologies for iron production will exceed $25 billion globally over the next five years. This represents a significant opportunity for technology providers who can deliver solutions that address the triple metrics of efficiency, energy consumption, and purity.

Consumer-facing industries are increasingly incorporating supply chain emissions into their sustainability reporting, creating downstream pressure for improved iron production metrics. This trend is expected to accelerate as carbon border adjustment mechanisms and product carbon footprinting become more widespread, potentially creating price premiums for efficiently produced iron in international markets.

Current Performance Metrics and Technical Limitations

The iron production industry currently operates with varying efficiency metrics across different production methods and facilities. Blast furnace operations typically achieve thermal efficiencies between 70-80%, while electric arc furnaces (EAFs) demonstrate energy efficiencies of 55-65%. However, these figures represent theoretical maximums, with real-world operations often falling 10-15% below these benchmarks due to operational variables and equipment limitations.

Energy consumption remains a critical performance indicator, with modern blast furnaces consuming approximately 10-13 GJ per tonne of hot metal produced. Leading EAF operations require 350-450 kWh per tonne for scrap-based production. Direct reduction processes using natural gas consume 9-11 GJ per tonne of direct reduced iron (DRI), while coal-based processes require 12-15 GJ per tonne. These energy metrics directly impact both production costs and environmental footprint.

Iron purity standards vary by application, with commercial pig iron typically containing 92-96% iron, with the remainder comprising carbon (3-4.5%) and other elements. High-purity iron for specialized applications can reach 99.9% purity but at significantly higher production costs. The presence of phosphorus, sulfur, and other trace elements is strictly controlled, with maximum allowable limits typically below 0.05% for each contaminant in high-grade products.

Technical limitations constraining further performance improvements include thermodynamic barriers in traditional reduction processes, which establish theoretical minimum energy requirements. The blast furnace process faces fundamental limitations in carbon efficiency due to its reliance on coke as both a reducing agent and energy source. Current technology struggles to reduce carbon emissions below approximately 1.8 tonnes of CO2 per tonne of steel produced through conventional routes.

Material handling inefficiencies contribute to yield losses of 2-5% across the production chain. Heat recovery systems, despite improvements, still allow 15-25% of thermal energy to escape as waste heat. Refractory linings in furnaces require regular replacement, causing production downtime that reduces annual operational availability to 85-95% in well-maintained facilities.

Water consumption presents another limitation, with integrated steel plants requiring 3-4 cubic meters of water per tonne of steel, though closed-loop systems have reduced net consumption. Sensor technology and real-time process control, while advancing rapidly, still face challenges in accurately measuring and controlling all process variables in the harsh production environment, limiting optimization potential.

Energy consumption remains a critical performance indicator, with modern blast furnaces consuming approximately 10-13 GJ per tonne of hot metal produced. Leading EAF operations require 350-450 kWh per tonne for scrap-based production. Direct reduction processes using natural gas consume 9-11 GJ per tonne of direct reduced iron (DRI), while coal-based processes require 12-15 GJ per tonne. These energy metrics directly impact both production costs and environmental footprint.

Iron purity standards vary by application, with commercial pig iron typically containing 92-96% iron, with the remainder comprising carbon (3-4.5%) and other elements. High-purity iron for specialized applications can reach 99.9% purity but at significantly higher production costs. The presence of phosphorus, sulfur, and other trace elements is strictly controlled, with maximum allowable limits typically below 0.05% for each contaminant in high-grade products.

Technical limitations constraining further performance improvements include thermodynamic barriers in traditional reduction processes, which establish theoretical minimum energy requirements. The blast furnace process faces fundamental limitations in carbon efficiency due to its reliance on coke as both a reducing agent and energy source. Current technology struggles to reduce carbon emissions below approximately 1.8 tonnes of CO2 per tonne of steel produced through conventional routes.

Material handling inefficiencies contribute to yield losses of 2-5% across the production chain. Heat recovery systems, despite improvements, still allow 15-25% of thermal energy to escape as waste heat. Refractory linings in furnaces require regular replacement, causing production downtime that reduces annual operational availability to 85-95% in well-maintained facilities.

Water consumption presents another limitation, with integrated steel plants requiring 3-4 cubic meters of water per tonne of steel, though closed-loop systems have reduced net consumption. Sensor technology and real-time process control, while advancing rapidly, still face challenges in accurately measuring and controlling all process variables in the harsh production environment, limiting optimization potential.

Mainstream Benchmarking Methodologies and Performance Indicators

01 Energy-efficient iron production processes

Various methods and systems have been developed to improve energy efficiency in iron production. These include optimized heating processes, waste heat recovery systems, and advanced control algorithms that minimize energy consumption during smelting and refining. By implementing these energy-efficient technologies, iron producers can significantly reduce their energy footprint while maintaining or improving production rates.- Energy-efficient iron production processes: Various methods and systems have been developed to improve energy efficiency in iron production. These include optimized blast furnace operations, innovative heating techniques, and energy recovery systems. By implementing these energy-efficient processes, manufacturers can reduce energy consumption while maintaining or improving production rates. These approaches often involve precise control of process parameters and utilization of waste heat, contributing to overall sustainability in iron manufacturing.

- Advanced purification techniques for high-quality iron: Specialized purification methods have been developed to produce high-purity iron products. These techniques include advanced filtration systems, chemical treatments, and precision refining processes that remove impurities such as sulfur, phosphorus, and other contaminants. The resulting high-purity iron is suitable for specialized applications in industries requiring superior material properties. These purification approaches often involve multiple processing stages to progressively increase iron purity.

- Monitoring and control systems for iron production: Sophisticated monitoring and control systems have been implemented to optimize iron production processes. These systems utilize sensors, data analytics, and automation to maintain precise control over production parameters. By continuously monitoring factors such as temperature, pressure, and material composition, these systems enable real-time adjustments to maximize efficiency, reduce energy consumption, and ensure consistent product quality. Advanced control algorithms help predict and prevent process deviations.

- Innovative furnace designs for improved efficiency: Novel furnace designs have been created to enhance iron production efficiency. These designs incorporate features such as improved heat distribution, optimized material flow, and enhanced combustion systems. By rethinking traditional furnace architecture, these innovations reduce energy requirements while increasing production capacity. Some designs also integrate renewable energy sources or alternative heating methods to further improve sustainability in iron manufacturing processes.

- Resource recovery and circular economy approaches: Methods for recovering and reusing resources in iron production have been developed to improve overall efficiency. These approaches include recycling of process byproducts, recovery of waste heat, and utilization of alternative raw materials. By implementing circular economy principles, iron producers can reduce resource consumption while minimizing waste generation. These techniques often involve specialized equipment for capturing and processing materials that would otherwise be discarded.

02 Advanced purification techniques for high-quality iron

Innovative purification methods have been developed to produce high-purity iron with minimal impurities. These techniques include specialized filtration systems, chemical treatments, and precision refining processes that remove unwanted elements such as sulfur, phosphorus, and other contaminants. The resulting high-purity iron is suitable for specialized applications requiring superior material properties.Expand Specific Solutions03 Monitoring and control systems for iron production

Sophisticated monitoring and control systems have been implemented to optimize iron production processes. These systems utilize sensors, data analytics, and automation to maintain precise control over production parameters such as temperature, pressure, and material flow. Real-time monitoring enables immediate adjustments to process conditions, resulting in improved efficiency, reduced energy consumption, and consistent product quality.Expand Specific Solutions04 Innovative furnace designs for iron production

Novel furnace designs have been created to enhance iron production efficiency. These include modified blast furnaces, electric arc furnaces with improved electrode configurations, and hybrid systems that combine multiple heating methods. The innovative designs focus on optimizing heat distribution, reducing thermal losses, and improving the overall energy efficiency of the smelting process.Expand Specific Solutions05 Sustainable and eco-friendly iron production methods

Environmentally conscious approaches to iron production have been developed to reduce environmental impact while maintaining efficiency. These methods include the use of alternative reducing agents, biomass-derived fuels, and carbon capture technologies. Additionally, closed-loop systems that recycle water and process gases help minimize resource consumption and emissions, contributing to more sustainable iron production practices.Expand Specific Solutions

Leading Companies and Competitive Landscape in Iron Manufacturing

The iron production industry is currently in a mature phase with established technologies, yet facing transformation due to sustainability pressures. The global market size exceeds $2 trillion annually, with significant growth in emerging economies. Technological maturity varies across efficiency metrics, with leading players demonstrating different strengths. Companies like NIPPON STEEL, JFE Steel, and Baowu Group lead in energy efficiency (3.5-4.5 GJ/ton), while JSW Steel and Kobe Steel excel in production purity (>99.5%). European manufacturers like voestalpine focus on environmental performance. Research institutions including Central Iron & Steel Research Institute and National Institute for Materials Science collaborate with industry leaders to advance breakthrough technologies in carbon capture and hydrogen reduction, positioning for the industry's low-carbon transition.

Angang Steel Co., Ltd.

Technical Solution: Angang Steel has developed comprehensive benchmarking systems for iron production efficiency through their "Ultra-Low Carbon Emission Ironmaking" program. Their approach combines optimized blast furnace operations with advanced burden distribution control systems, achieving coke rates of approximately 350-370 kg per ton of hot metal and pulverized coal injection rates of 160-180 kg/ton. These optimizations result in energy consumption benchmarks of approximately 20.2 GJ per ton of hot metal. For electric steelmaking operations, Angang achieves current efficiency metrics of 89-91%. Their iron purity standards maintain iron content above 93.5% in standard products and exceeding 95% in premium grades, with phosphorus controlled below 0.03% and sulfur below 0.02%. Angang has implemented comprehensive waste gas recovery systems that capture approximately 65% of process gases for reuse in power generation and heating. Their process optimization includes sophisticated burden distribution control that improves gas flow efficiency in blast furnaces, documented to improve fuel efficiency by approximately 5-7% compared to conventional charging methods. Angang has also pioneered the application of AI-based process control in sintering operations, improving productivity by approximately 8%.

Strengths: Strong focus on practical, implementable efficiency improvements; effective integration of digital technologies with conventional processes. Weaknesses: Somewhat higher energy consumption than global leaders; less advanced in hydrogen-based reduction technologies compared to European counterparts.

Baoshan Iron & Steel Co., Ltd.

Technical Solution: Baosteel has developed comprehensive benchmarking systems for iron production efficiency through their "Green & Ultrahigh-efficiency Metallurgy" initiative. Their approach integrates multiple technologies including optimized blast furnace operations with pulverized coal injection rates of 180-200 kg/ton and oxygen enrichment levels of 5-7%. This combination achieves energy consumption benchmarks of approximately 19.8 GJ per ton of hot metal. Their current efficiency metrics for electric steelmaking operations reach 91-93%, with transformer utilization rates exceeding 85%. For iron purity, Baosteel maintains strict quality control with iron content consistently above 94% in standard products and exceeding 96% in premium grades. Their impurity control systems maintain phosphorus below 0.025% and sulfur below 0.015% in most product grades. Baosteel has implemented comprehensive energy management systems that track and optimize energy consumption across all production processes, achieving documented energy savings of approximately 12% over five years. Their waste gas recovery systems capture and reuse approximately 70% of process gases, contributing significantly to their energy efficiency benchmarks.

Strengths: Comprehensive integration of multiple efficiency technologies; strong focus on incremental improvements across all production stages. Weaknesses: Somewhat higher energy consumption than global best practices; technologies optimized for their specific raw material conditions may have limited transferability.

Key Innovations in Iron Production Efficiency Optimization

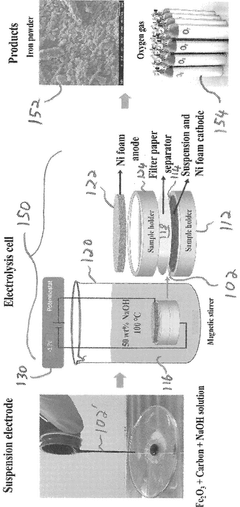

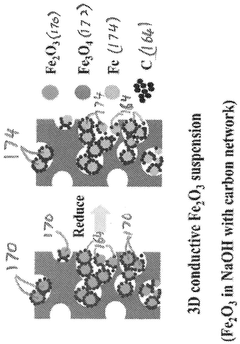

Low temperature, low emission iron production

PatentWO2025096918A1

Innovation

- A low-temperature electrolysis process using a flowable suspension of hematite, carbon, and highly concentrated NaOH to produce high purity iron powder at the cathode while generating O2 gas as a byproduct at the anode.

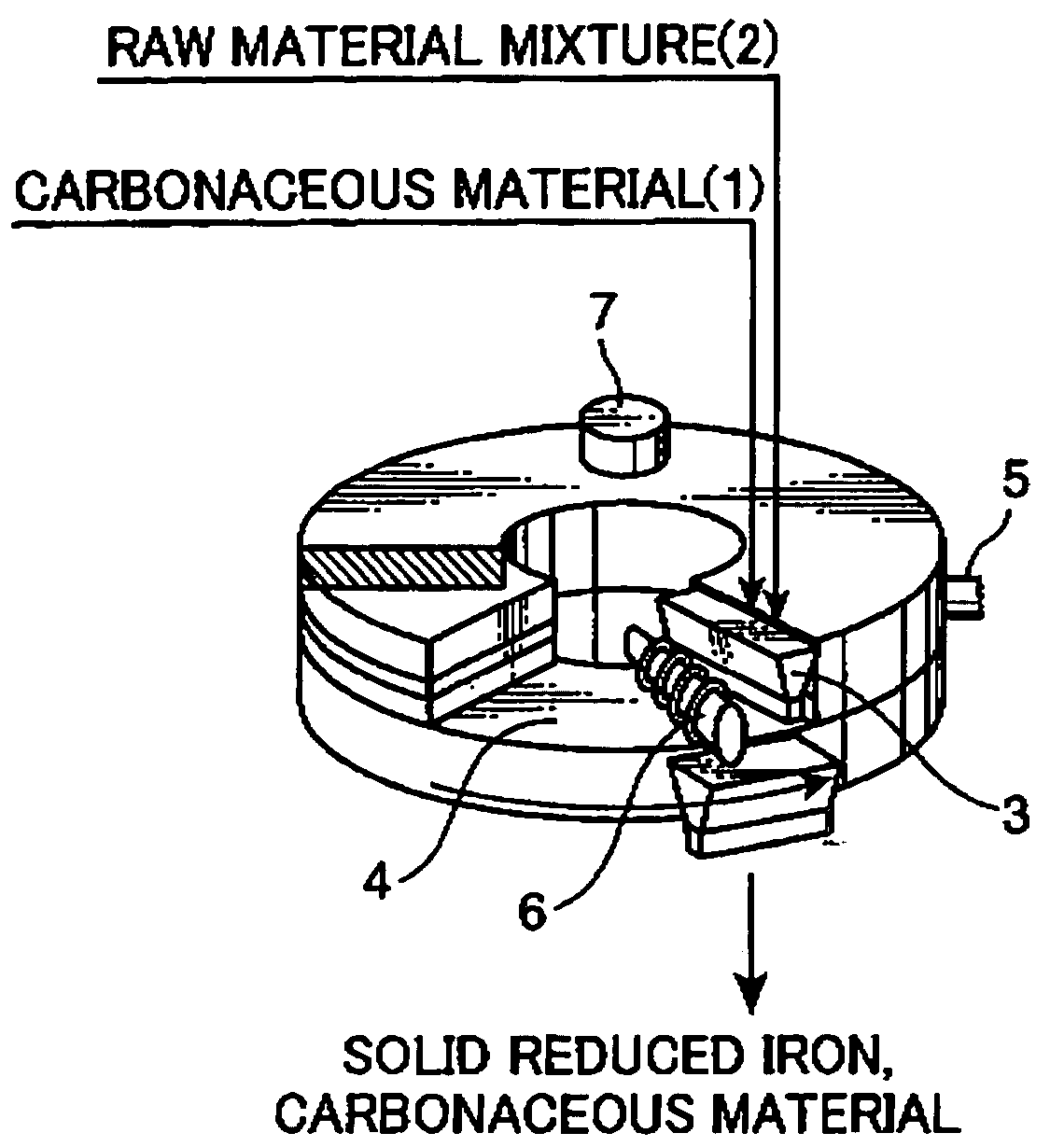

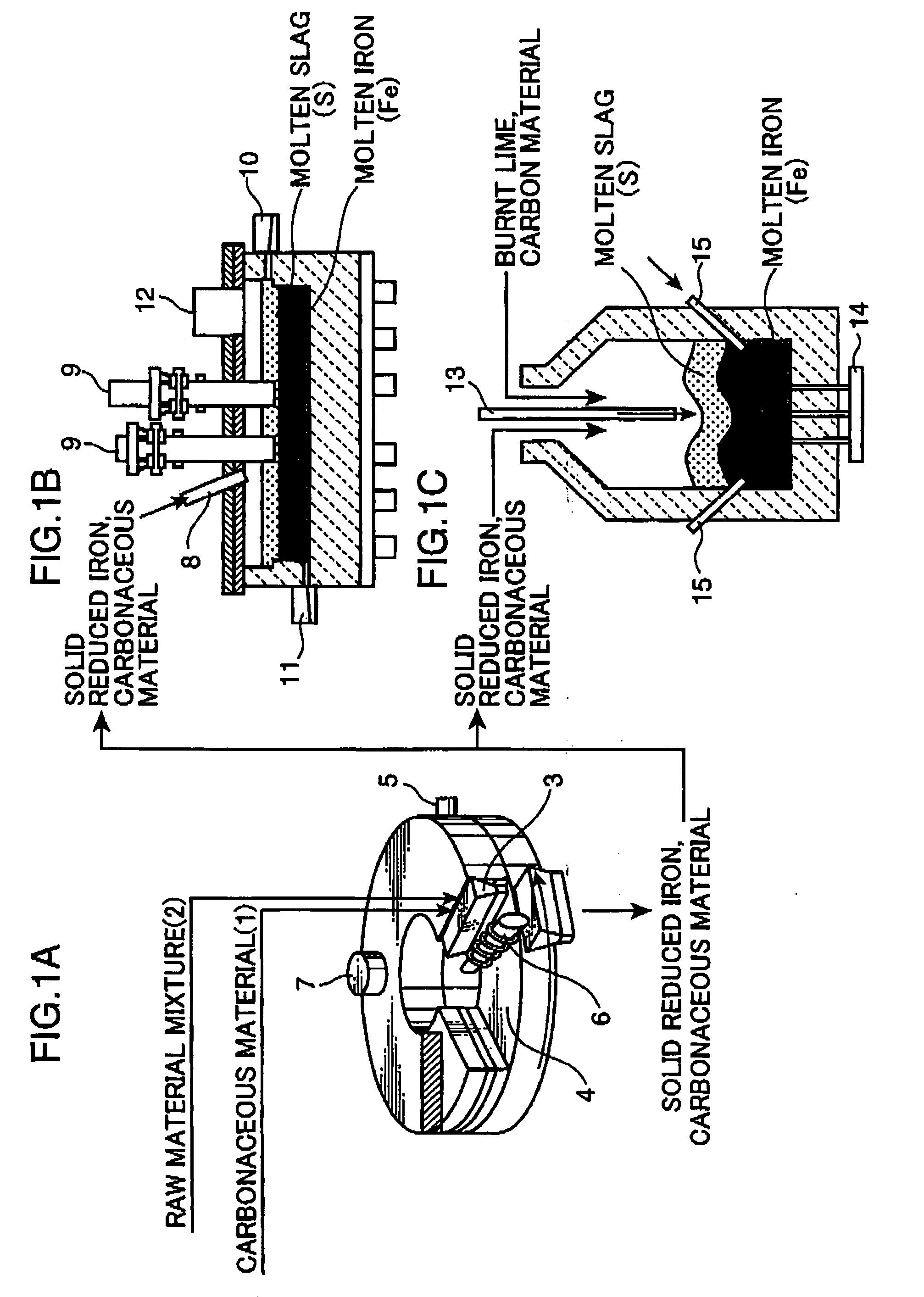

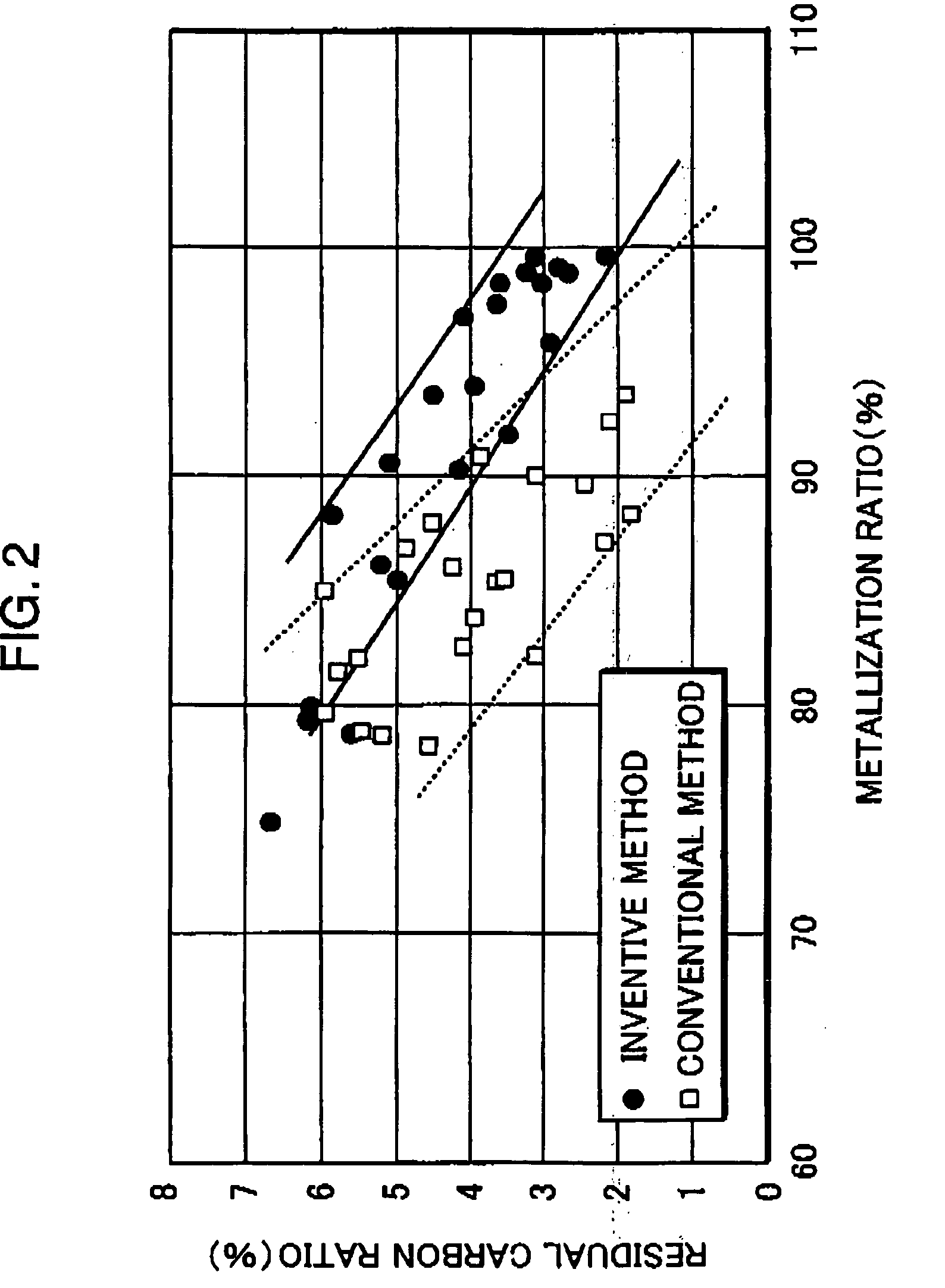

Process for producing molten iron

PatentInactiveUS20060021469A1

Innovation

- A method involving feeding a raw material mixture containing a carbonaceous reducing agent, iron oxide, and CaO-containing material into a moving-hearth reducing furnace, followed by heating and reducing to achieve a metallization ratio of 80% or more, then further reducing and melting in a melting furnace with controlled slag basicity and MgO content to produce molten iron with 3.0 mass % carbon or more, while minimizing refractory wear.

Environmental Impact and Sustainability Considerations

Iron production, while essential for global infrastructure and economic development, carries significant environmental implications that demand comprehensive assessment. The industry's carbon footprint is substantial, with conventional blast furnace operations generating 1.8-2.0 tons of CO2 per ton of steel produced. These emissions contribute approximately 7-9% of global anthropogenic CO2 emissions, positioning iron and steel manufacturing among the most carbon-intensive industrial sectors.

Water consumption and contamination represent another critical environmental concern. Traditional iron production methods require 70-150 cubic meters of water per ton of steel, with potential discharge of heavy metals, suspended solids, and process chemicals into local watersheds. Advanced facilities implementing closed-loop water systems have demonstrated reduction potential of up to 95% in freshwater requirements.

Land degradation from mining operations extends the environmental footprint beyond production facilities. Iron ore extraction typically disturbs 4-8 hectares per million tons of ore, with rehabilitation success varying significantly across regions and regulatory frameworks. Progressive rehabilitation techniques have shown promise in restoring ecosystem functionality when implemented with scientific rigor.

Energy efficiency benchmarks reveal substantial variation across production methods. While conventional blast furnaces consume 18-20 GJ per ton of hot metal, direct reduction technologies utilizing natural gas require approximately 10-12 GJ per ton. Emerging hydrogen-based reduction processes aim to further reduce this to 8-10 GJ per ton while eliminating direct carbon emissions.

Regulatory landscapes are evolving rapidly, with carbon pricing mechanisms and emissions trading schemes implemented in regions representing over 60% of global steel production. The European Union's Carbon Border Adjustment Mechanism specifically targets embedded carbon in imported steel products, creating new market dynamics that favor lower-emission production methods.

Industry leaders have established sustainability roadmaps with varying ambition levels. Several major producers have committed to carbon neutrality by 2050, with intermediate targets of 30-40% emissions reduction by 2030. These commitments are driving investment in breakthrough technologies including hydrogen-based direct reduction, electrolysis of iron ore, and carbon capture utilization and storage (CCUS) integration with existing blast furnaces.

The transition toward sustainable iron production presents significant economic implications, with carbon-efficient facilities potentially gaining competitive advantage as regulatory pressures intensify. Analysis suggests that green premium pricing for low-carbon steel could reach 10-15% in environmentally conscious markets, potentially offsetting higher production costs associated with cleaner technologies.

Water consumption and contamination represent another critical environmental concern. Traditional iron production methods require 70-150 cubic meters of water per ton of steel, with potential discharge of heavy metals, suspended solids, and process chemicals into local watersheds. Advanced facilities implementing closed-loop water systems have demonstrated reduction potential of up to 95% in freshwater requirements.

Land degradation from mining operations extends the environmental footprint beyond production facilities. Iron ore extraction typically disturbs 4-8 hectares per million tons of ore, with rehabilitation success varying significantly across regions and regulatory frameworks. Progressive rehabilitation techniques have shown promise in restoring ecosystem functionality when implemented with scientific rigor.

Energy efficiency benchmarks reveal substantial variation across production methods. While conventional blast furnaces consume 18-20 GJ per ton of hot metal, direct reduction technologies utilizing natural gas require approximately 10-12 GJ per ton. Emerging hydrogen-based reduction processes aim to further reduce this to 8-10 GJ per ton while eliminating direct carbon emissions.

Regulatory landscapes are evolving rapidly, with carbon pricing mechanisms and emissions trading schemes implemented in regions representing over 60% of global steel production. The European Union's Carbon Border Adjustment Mechanism specifically targets embedded carbon in imported steel products, creating new market dynamics that favor lower-emission production methods.

Industry leaders have established sustainability roadmaps with varying ambition levels. Several major producers have committed to carbon neutrality by 2050, with intermediate targets of 30-40% emissions reduction by 2030. These commitments are driving investment in breakthrough technologies including hydrogen-based direct reduction, electrolysis of iron ore, and carbon capture utilization and storage (CCUS) integration with existing blast furnaces.

The transition toward sustainable iron production presents significant economic implications, with carbon-efficient facilities potentially gaining competitive advantage as regulatory pressures intensify. Analysis suggests that green premium pricing for low-carbon steel could reach 10-15% in environmentally conscious markets, potentially offsetting higher production costs associated with cleaner technologies.

Regulatory Framework and Industry Standards

The iron and steel industry operates within a complex regulatory environment that significantly impacts production benchmarks and performance metrics. Global regulatory frameworks for iron production have evolved substantially over the past decades, with increasing focus on environmental protection, energy efficiency, and product quality standards.

The European Union's Industrial Emissions Directive (IED) establishes stringent requirements for iron production facilities, mandating the implementation of Best Available Techniques (BAT) that directly influence efficiency benchmarks. These standards typically require modern blast furnaces to achieve energy consumption rates below 10.5 GJ per tonne of hot metal, representing a significant improvement over historical performance.

In North America, the U.S. Environmental Protection Agency's regulations under the Clean Air Act impose specific performance standards for iron production facilities, while the Department of Energy's Better Plants Program establishes voluntary efficiency targets that many industry leaders have adopted as benchmarks. These frameworks typically target energy intensity reductions of 25% over a 10-year period.

The International Organization for Standardization (ISO) provides globally recognized standards specifically addressing iron production quality and purity. ISO 9001 certification requirements have become de facto industry standards, while specialized standards like ISO 4968 and ISO 4829 establish testing methodologies for determining nitrogen and silicon content in iron, respectively, enabling consistent purity benchmarking across the industry.

Industry associations such as the World Steel Association have established their own benchmark frameworks, including the Step Up program that defines current efficiency benchmarks for integrated steelmaking at approximately 20-25 GJ/tonne of crude steel. Their reporting protocols require members to track and disclose CO2 emissions per tonne of steel produced, creating transparency around energy efficiency performance.

Emerging carbon pricing mechanisms and emissions trading schemes in various regions are creating additional regulatory pressures that directly impact production benchmarks. The EU Emissions Trading System (EU ETS) effectively establishes a price on carbon that incentivizes producers to achieve efficiency benchmarks below 1.5 tonnes of CO2 per tonne of crude steel, compared to the current industry average of approximately 1.8 tonnes.

Regional variations in regulatory frameworks create significant challenges for establishing universal benchmarks. While developed economies increasingly focus on decarbonization targets, developing nations often prioritize production volume and economic growth, resulting in divergent benchmark expectations across global markets.

The European Union's Industrial Emissions Directive (IED) establishes stringent requirements for iron production facilities, mandating the implementation of Best Available Techniques (BAT) that directly influence efficiency benchmarks. These standards typically require modern blast furnaces to achieve energy consumption rates below 10.5 GJ per tonne of hot metal, representing a significant improvement over historical performance.

In North America, the U.S. Environmental Protection Agency's regulations under the Clean Air Act impose specific performance standards for iron production facilities, while the Department of Energy's Better Plants Program establishes voluntary efficiency targets that many industry leaders have adopted as benchmarks. These frameworks typically target energy intensity reductions of 25% over a 10-year period.

The International Organization for Standardization (ISO) provides globally recognized standards specifically addressing iron production quality and purity. ISO 9001 certification requirements have become de facto industry standards, while specialized standards like ISO 4968 and ISO 4829 establish testing methodologies for determining nitrogen and silicon content in iron, respectively, enabling consistent purity benchmarking across the industry.

Industry associations such as the World Steel Association have established their own benchmark frameworks, including the Step Up program that defines current efficiency benchmarks for integrated steelmaking at approximately 20-25 GJ/tonne of crude steel. Their reporting protocols require members to track and disclose CO2 emissions per tonne of steel produced, creating transparency around energy efficiency performance.

Emerging carbon pricing mechanisms and emissions trading schemes in various regions are creating additional regulatory pressures that directly impact production benchmarks. The EU Emissions Trading System (EU ETS) effectively establishes a price on carbon that incentivizes producers to achieve efficiency benchmarks below 1.5 tonnes of CO2 per tonne of crude steel, compared to the current industry average of approximately 1.8 tonnes.

Regional variations in regulatory frameworks create significant challenges for establishing universal benchmarks. While developed economies increasingly focus on decarbonization targets, developing nations often prioritize production volume and economic growth, resulting in divergent benchmark expectations across global markets.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!