Product Purity Requirements For Downstream Steelmaking In Electrochemical Routes

AUG 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electrochemical Steelmaking Background and Objectives

Electrochemical steelmaking represents a paradigm shift in the steel industry, emerging as a promising alternative to conventional blast furnace-basic oxygen furnace (BF-BOF) and electric arc furnace (EAF) routes. This technology has evolved over the past three decades, with significant acceleration in research and development efforts in the last decade due to increasing environmental pressures and decarbonization goals across global industries.

The fundamental principle of electrochemical steelmaking involves the direct reduction of iron ore to metallic iron through electrochemical processes, bypassing the carbon-intensive reduction methods traditionally employed. Early experimental work in the 1990s demonstrated the feasibility of iron electrowinning, but commercial viability remained elusive due to technical limitations and economic constraints.

Recent technological advancements in electrode materials, cell design, and electrolyte formulations have revitalized interest in this field. The development of more efficient catalysts and membrane technologies has addressed several historical barriers, while the growing availability of renewable electricity has improved the economic outlook for electricity-intensive processes.

The primary objective of electrochemical steelmaking is to achieve substantial reduction in carbon emissions compared to conventional routes. Current steelmaking accounts for approximately 7-9% of global CO2 emissions, making it a critical target for decarbonization efforts. Electrochemical routes potentially offer CO2 reductions of 80-95% when powered by renewable electricity.

Secondary objectives include reducing dependency on coking coal, minimizing other environmental impacts such as particulate emissions and water pollution, and enabling more distributed production models that could transform supply chains. The technology also aims to maintain or improve steel quality while achieving these environmental benefits.

Technical goals for electrochemical steelmaking include increasing current densities to economically viable levels, extending electrode lifespans, improving energy efficiency, and developing scalable reactor designs. Current research focuses on achieving current densities above 300 mA/cm² while maintaining cell voltages below 2V to ensure energy consumption remains competitive with conventional routes.

The trajectory of electrochemical steelmaking technology indicates potential commercial deployment within the next decade, with pilot plants already operational in several countries. The technology evolution is expected to progress from batch processes to continuous operations, and from smaller specialized applications to mainstream steel production.

As the steel industry faces increasing regulatory pressure and carbon pricing mechanisms, electrochemical routes represent not just an environmental improvement but potentially a necessary evolution for the industry's long-term sustainability and competitiveness in a carbon-constrained global economy.

The fundamental principle of electrochemical steelmaking involves the direct reduction of iron ore to metallic iron through electrochemical processes, bypassing the carbon-intensive reduction methods traditionally employed. Early experimental work in the 1990s demonstrated the feasibility of iron electrowinning, but commercial viability remained elusive due to technical limitations and economic constraints.

Recent technological advancements in electrode materials, cell design, and electrolyte formulations have revitalized interest in this field. The development of more efficient catalysts and membrane technologies has addressed several historical barriers, while the growing availability of renewable electricity has improved the economic outlook for electricity-intensive processes.

The primary objective of electrochemical steelmaking is to achieve substantial reduction in carbon emissions compared to conventional routes. Current steelmaking accounts for approximately 7-9% of global CO2 emissions, making it a critical target for decarbonization efforts. Electrochemical routes potentially offer CO2 reductions of 80-95% when powered by renewable electricity.

Secondary objectives include reducing dependency on coking coal, minimizing other environmental impacts such as particulate emissions and water pollution, and enabling more distributed production models that could transform supply chains. The technology also aims to maintain or improve steel quality while achieving these environmental benefits.

Technical goals for electrochemical steelmaking include increasing current densities to economically viable levels, extending electrode lifespans, improving energy efficiency, and developing scalable reactor designs. Current research focuses on achieving current densities above 300 mA/cm² while maintaining cell voltages below 2V to ensure energy consumption remains competitive with conventional routes.

The trajectory of electrochemical steelmaking technology indicates potential commercial deployment within the next decade, with pilot plants already operational in several countries. The technology evolution is expected to progress from batch processes to continuous operations, and from smaller specialized applications to mainstream steel production.

As the steel industry faces increasing regulatory pressure and carbon pricing mechanisms, electrochemical routes represent not just an environmental improvement but potentially a necessary evolution for the industry's long-term sustainability and competitiveness in a carbon-constrained global economy.

Market Analysis for High-Purity Steel Products

The high-purity steel market has experienced significant growth over the past decade, driven primarily by increasing demand from advanced manufacturing sectors such as automotive, aerospace, electronics, and medical devices. Current market valuations place the global high-purity steel segment at approximately 45 billion USD, with projected annual growth rates between 6-8% through 2030, outpacing the broader steel industry's 2-3% growth.

This accelerated growth trajectory is largely attributed to the expanding applications of high-purity steel in emerging technologies. The automotive sector, particularly electric vehicle production, requires steel with minimal impurities for battery components and lightweight structural elements. Similarly, the aerospace industry demands ultra-pure steel alloys for critical safety components where material integrity is paramount.

Regional analysis reveals that Asia-Pacific currently dominates the high-purity steel market, accounting for nearly 40% of global consumption, with China, Japan, and South Korea as key players. North America and Europe follow with approximately 25% and 22% market share respectively, while developing markets in South America and Africa represent the fastest-growing segments with annual growth exceeding 10%.

Price premium analysis indicates that high-purity steel products command significant markups compared to conventional steel, with premiums ranging from 30% for moderately pure grades to over 300% for ultra-high-purity specialized alloys. This premium pricing structure has attracted numerous specialty steel producers to expand their high-purity offerings.

Customer segmentation shows distinct requirements across industries. Medical device manufacturers prioritize biocompatibility and corrosion resistance, while semiconductor equipment producers emphasize thermal stability and minimal outgassing properties. The energy sector, particularly renewable energy infrastructure, requires high-purity steel with enhanced fatigue resistance and weatherability characteristics.

Market forecasts suggest that electrochemical steelmaking routes will significantly disrupt traditional supply chains by potentially lowering production costs of high-purity steel by 15-25% while simultaneously reducing carbon emissions. This cost advantage could expand market penetration into previously price-sensitive applications, potentially growing the total addressable market by an additional 20-30% by 2035.

Consumer trends indicate growing preference for sustainably produced materials, with over 65% of industrial buyers now including environmental impact metrics in procurement decisions. This shift favors electrochemical production methods which typically generate fewer emissions than conventional blast furnace operations.

This accelerated growth trajectory is largely attributed to the expanding applications of high-purity steel in emerging technologies. The automotive sector, particularly electric vehicle production, requires steel with minimal impurities for battery components and lightweight structural elements. Similarly, the aerospace industry demands ultra-pure steel alloys for critical safety components where material integrity is paramount.

Regional analysis reveals that Asia-Pacific currently dominates the high-purity steel market, accounting for nearly 40% of global consumption, with China, Japan, and South Korea as key players. North America and Europe follow with approximately 25% and 22% market share respectively, while developing markets in South America and Africa represent the fastest-growing segments with annual growth exceeding 10%.

Price premium analysis indicates that high-purity steel products command significant markups compared to conventional steel, with premiums ranging from 30% for moderately pure grades to over 300% for ultra-high-purity specialized alloys. This premium pricing structure has attracted numerous specialty steel producers to expand their high-purity offerings.

Customer segmentation shows distinct requirements across industries. Medical device manufacturers prioritize biocompatibility and corrosion resistance, while semiconductor equipment producers emphasize thermal stability and minimal outgassing properties. The energy sector, particularly renewable energy infrastructure, requires high-purity steel with enhanced fatigue resistance and weatherability characteristics.

Market forecasts suggest that electrochemical steelmaking routes will significantly disrupt traditional supply chains by potentially lowering production costs of high-purity steel by 15-25% while simultaneously reducing carbon emissions. This cost advantage could expand market penetration into previously price-sensitive applications, potentially growing the total addressable market by an additional 20-30% by 2035.

Consumer trends indicate growing preference for sustainably produced materials, with over 65% of industrial buyers now including environmental impact metrics in procurement decisions. This shift favors electrochemical production methods which typically generate fewer emissions than conventional blast furnace operations.

Current Challenges in Electrochemical Steel Purification

Electrochemical steel production routes face significant purification challenges that must be addressed to meet downstream steelmaking requirements. Traditional steelmaking processes have established purification methods, but electrochemical routes introduce new complexities in achieving the necessary product purity. The primary challenge lies in removing impurities such as sulfur, phosphorus, nitrogen, and various trace elements that can severely compromise steel quality and performance characteristics.

The presence of carbon impurities presents a particular challenge in electrochemical processes. Unlike conventional methods where carbon content can be controlled through established practices, electrochemical routes often struggle with precise carbon management. This is critical as carbon levels directly impact mechanical properties, including hardness, ductility, and tensile strength of the final steel product.

Oxygen control represents another significant hurdle. Electrochemical processes can introduce excess oxygen, leading to inclusion formation and reduced steel quality. Current technologies lack efficient methods to monitor and regulate oxygen levels in real-time during electrochemical processing, resulting in inconsistent product quality and increased rejection rates.

Trace element management poses additional difficulties. Elements such as copper, tin, antimony, and arsenic, even in minute concentrations, can significantly degrade steel properties. Conventional removal techniques are often incompatible with electrochemical routes, necessitating novel approaches to selective impurity extraction without disrupting the core electrochemical processes.

The interface between electrochemical purification and subsequent processing steps creates compatibility issues. Current electrochemical methods may produce intermediate products with impurity profiles that are challenging to address in downstream processes, creating bottlenecks in the production chain and limiting overall efficiency.

Energy efficiency concerns further complicate purification efforts. While electrochemical routes offer potential sustainability benefits, the additional energy required for achieving high-purity products can offset these advantages. The industry faces the challenge of developing purification techniques that maintain energy efficiency while meeting stringent purity requirements.

Scaling issues represent a significant barrier to commercial implementation. Laboratory-scale electrochemical purification methods often demonstrate promising results, but translating these to industrial-scale operations introduces new challenges related to process control, equipment design, and economic viability. The gap between theoretical purification capabilities and practical industrial application remains substantial.

Regulatory and market demands for increasingly pure steel products add pressure to overcome these technical challenges. As industries such as automotive, aerospace, and medical device manufacturing require higher-performance materials, electrochemical steel production must evolve to meet these specifications while maintaining economic competitiveness with traditional routes.

The presence of carbon impurities presents a particular challenge in electrochemical processes. Unlike conventional methods where carbon content can be controlled through established practices, electrochemical routes often struggle with precise carbon management. This is critical as carbon levels directly impact mechanical properties, including hardness, ductility, and tensile strength of the final steel product.

Oxygen control represents another significant hurdle. Electrochemical processes can introduce excess oxygen, leading to inclusion formation and reduced steel quality. Current technologies lack efficient methods to monitor and regulate oxygen levels in real-time during electrochemical processing, resulting in inconsistent product quality and increased rejection rates.

Trace element management poses additional difficulties. Elements such as copper, tin, antimony, and arsenic, even in minute concentrations, can significantly degrade steel properties. Conventional removal techniques are often incompatible with electrochemical routes, necessitating novel approaches to selective impurity extraction without disrupting the core electrochemical processes.

The interface between electrochemical purification and subsequent processing steps creates compatibility issues. Current electrochemical methods may produce intermediate products with impurity profiles that are challenging to address in downstream processes, creating bottlenecks in the production chain and limiting overall efficiency.

Energy efficiency concerns further complicate purification efforts. While electrochemical routes offer potential sustainability benefits, the additional energy required for achieving high-purity products can offset these advantages. The industry faces the challenge of developing purification techniques that maintain energy efficiency while meeting stringent purity requirements.

Scaling issues represent a significant barrier to commercial implementation. Laboratory-scale electrochemical purification methods often demonstrate promising results, but translating these to industrial-scale operations introduces new challenges related to process control, equipment design, and economic viability. The gap between theoretical purification capabilities and practical industrial application remains substantial.

Regulatory and market demands for increasingly pure steel products add pressure to overcome these technical challenges. As industries such as automotive, aerospace, and medical device manufacturing require higher-performance materials, electrochemical steel production must evolve to meet these specifications while maintaining economic competitiveness with traditional routes.

Current Purification Methods for Electrochemical Steel

01 Electrochemical refining processes for high-purity steel

Electrochemical refining processes can be employed to produce high-purity steel by removing impurities through controlled electrochemical reactions. These processes involve the use of electrolytic cells where impurities are separated from the steel matrix by applying electrical current. The technique allows for selective removal of elements that affect steel quality, resulting in products with superior mechanical properties and corrosion resistance.- Electrochemical refining processes for high-purity steel: Electrochemical refining processes can be employed to produce high-purity steel by removing impurities through controlled electrolysis. These processes involve the dissolution of raw steel at the anode and selective deposition of purified steel at the cathode, effectively separating impurities that remain in the electrolyte solution. This method allows for precise control of the steel composition and can achieve significantly higher purity levels compared to conventional steelmaking methods.

- Impurity removal techniques in electrochemical steelmaking: Various techniques can be implemented to remove specific impurities during electrochemical steelmaking processes. These include the use of specialized electrolytes, controlled potential electrolysis, and multi-stage purification processes. By targeting specific impurities such as sulfur, phosphorus, nitrogen, and trace metals, these techniques can significantly enhance the purity of the final steel product, resulting in improved mechanical properties and performance characteristics.

- Advanced electrode materials and configurations: The development of advanced electrode materials and configurations plays a crucial role in enhancing the efficiency and effectiveness of electrochemical steelmaking processes. Innovative electrode designs, including composite electrodes, coated electrodes, and three-dimensional electrode structures, can improve current distribution, reduce energy consumption, and enhance the selective removal of impurities. These advancements contribute significantly to achieving higher purity steel products with consistent quality.

- Process monitoring and control systems: Sophisticated monitoring and control systems are essential for maintaining optimal conditions during electrochemical steelmaking processes. These systems utilize real-time sensors, data analytics, and automated feedback mechanisms to continuously adjust process parameters such as current density, temperature, and electrolyte composition. By ensuring precise control over the electrochemical reactions, these systems help achieve consistent high-purity steel production while minimizing energy consumption and operational costs.

- Novel electrolyte formulations: The development of novel electrolyte formulations has significantly advanced the field of electrochemical steelmaking. These specialized electrolytes contain carefully selected additives and compounds that enhance conductivity, improve current efficiency, and facilitate the selective removal of impurities. Some formulations also incorporate complexing agents that bind with specific impurities, preventing their deposition at the cathode and thereby increasing the purity of the final steel product. These innovative electrolyte systems represent a key factor in achieving ultra-high purity steel through electrochemical processes.

02 Impurity removal techniques in electrochemical steelmaking

Various techniques can be implemented to remove impurities during electrochemical steelmaking. These include optimized electrode configurations, controlled electrolyte compositions, and specific current density parameters. By manipulating these factors, manufacturers can effectively reduce contaminants such as sulfur, phosphorus, and non-metallic inclusions, thereby enhancing the overall purity of the steel product.Expand Specific Solutions03 Advanced monitoring and control systems for purity enhancement

Modern electrochemical steelmaking employs sophisticated monitoring and control systems to maintain and improve product purity. These systems utilize real-time analysis of process parameters, automated feedback mechanisms, and predictive modeling to optimize the refining process. By continuously adjusting operating conditions based on data inputs, these systems ensure consistent purity levels and reduce variability in the final steel product.Expand Specific Solutions04 Novel electrode materials and configurations

Innovative electrode materials and configurations have been developed to enhance the efficiency of electrochemical steelmaking and improve product purity. These advancements include specialized alloy electrodes, composite materials with improved conductivity, and geometrically optimized electrode designs. Such innovations facilitate more precise control over the electrochemical reactions, leading to better removal of impurities and higher purity steel products.Expand Specific Solutions05 Integration of secondary refining processes

Electrochemical steelmaking can be integrated with secondary refining processes to achieve superior product purity. These complementary techniques include vacuum degassing, ladle metallurgy, and specialized slag treatments that work in conjunction with electrochemical methods. The combined approach addresses different types of impurities through multiple mechanisms, resulting in steel products with exceptionally high purity levels suitable for demanding applications.Expand Specific Solutions

Leading Companies in Electrochemical Steel Production

The electrochemical steelmaking sector is currently in an early growth phase, with market size expanding as industries seek more sustainable production methods. The competitive landscape features established steel giants like ArcelorMittal, JFE Steel, and Nucor alongside Chinese powerhouses such as Jiangsu Shagang Group and Baotou Iron & Steel. Technical maturity remains moderate, with companies focusing on improving product purity to meet downstream requirements. Leading players like Kobe Steel and voestalpine are investing in R&D to overcome impurity challenges, while research institutions like Central Iron & Steel Research Institute collaborate with manufacturers to develop advanced purification technologies. The industry faces a critical transition period as it balances traditional steelmaking expertise with emerging electrochemical innovations.

JFE Steel Corp.

Technical Solution: JFE Steel has pioneered an electrochemical refining technology called "E-Refine" specifically targeting trace element control in downstream steelmaking. Their system employs specialized electrode configurations with proprietary coatings that enhance selectivity for removing copper, tin, and other tramp elements that conventional methods struggle to eliminate. The process operates at lower temperatures (1200-1400°C) than traditional refining, utilizing pulsed DC current to create controlled oxidation-reduction reactions at the electrode-melt interface. JFE's approach incorporates a multi-stage filtration system that progressively removes impurities based on their electrochemical properties, achieving final product purities exceeding 99.98% for critical applications. The technology includes an AI-driven control system that optimizes current density and pulse parameters based on real-time compositional analysis.

Strengths: Exceptional removal of difficult tramp elements; reduced energy consumption through lower operating temperatures; precise control over final composition. Weaknesses: Process throughput limitations; electrode degradation requiring regular replacement; higher operational complexity requiring specialized training.

Kobe Steel, Ltd.

Technical Solution: Kobe Steel has developed the "ECOARC" electrochemical purification system specifically designed for downstream steel processing. This technology utilizes a combination of electrochemical principles and slag chemistry optimization to achieve ultra-high purity levels. The system features a three-phase electrode configuration that creates localized high-energy zones for targeted impurity removal. Kobe's innovation includes specialized flux formulations that work synergistically with the electrochemical process to capture and isolate contaminants. Their process achieves remarkable reductions in oxygen content (below 10ppm), nitrogen (below 30ppm), and hydrogen (below 1.5ppm), making it particularly suitable for high-performance steel applications. The ECOARC system incorporates continuous circulation of the molten metal through electrochemical cells with precisely controlled current densities and residence times to optimize purification efficiency.

Strengths: Exceptional control of gaseous elements (O, N, H) critical for mechanical properties; integrated approach combining electrochemistry and metallurgy; modular design allowing retrofitting to existing facilities. Weaknesses: Higher energy costs per ton compared to conventional refining; complex maintenance requirements; limited effectiveness for certain metallic impurities.

Key Innovations in Steel Purity Enhancement

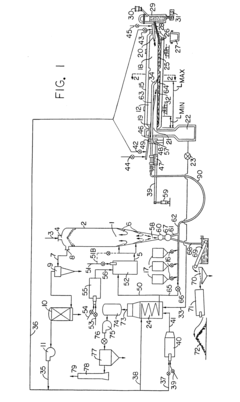

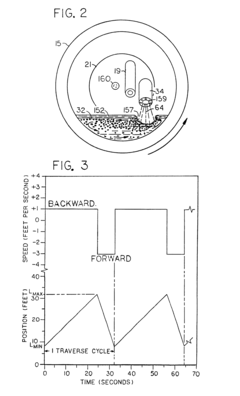

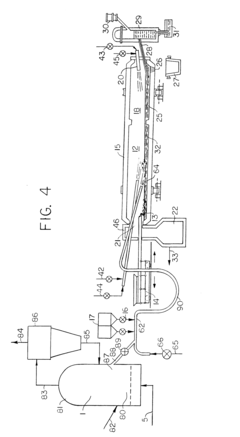

Direct iron and steelmaking

PatentInactiveUS6652802B2

Innovation

- A continuous process combining solid-state iron oxide reduction with continuous metal melting, using pressurized hot reducing gases and minimizing oxygen injection, achieves efficient in-furnace heat transfer and post-combustion, reducing environmental impact and energy consumption by utilizing recirculated gases and lower-purity oxygen, and dispersing hot reduced iron to enhance melting efficiency.

Environmental Impact Assessment of Electrochemical Routes

The environmental impact assessment of electrochemical routes for steelmaking reveals significant advantages over conventional blast furnace-basic oxygen furnace (BF-BOF) processes. Electrochemical steelmaking demonstrates potential for substantial reduction in carbon emissions, with estimates suggesting up to 85-95% lower CO2 emissions when powered by renewable electricity sources compared to traditional methods.

Water usage patterns in electrochemical processes differ markedly from conventional steelmaking. While traditional methods require substantial water volumes for cooling and gas cleaning, electrochemical routes typically consume 30-40% less water. However, the electrolyte management in these systems introduces new challenges related to water quality and potential contamination with process chemicals.

Air quality improvements represent another significant environmental benefit. The elimination of coking operations and reduction in high-temperature combustion processes substantially reduces emissions of particulate matter, sulfur oxides, nitrogen oxides, and volatile organic compounds. Studies indicate potential reductions of these pollutants by 60-80% compared to integrated steel plants.

Land use requirements for electrochemical facilities are generally smaller than traditional integrated steel mills, potentially reducing habitat disruption and allowing for more flexible facility siting. This advantage becomes particularly relevant when considering brownfield redevelopment opportunities in former industrial areas.

Waste generation profiles shift dramatically with electrochemical processes. While slag volumes may decrease by 40-60%, new waste streams emerge, including spent electrolytes, electrode materials, and specialized filtration residues. The composition of these wastes differs fundamentally from traditional steelmaking byproducts, necessitating development of new recycling and disposal protocols.

Energy efficiency considerations reveal complex tradeoffs. While electrochemical routes eliminate the need for coal as a reducing agent, they require significant electrical input. The environmental benefit hinges critically on electricity source - with renewable energy, these processes offer dramatic improvements, but with fossil fuel-generated electricity, the advantages diminish substantially.

Life cycle assessment studies indicate that product purity requirements for downstream applications significantly influence overall environmental impact. Higher purity demands may necessitate additional processing steps or more intensive electrochemical conditions, potentially offsetting some environmental gains through increased energy consumption or chemical usage.

Regulatory frameworks worldwide are evolving to accommodate these emerging technologies, with carbon pricing mechanisms and emissions trading systems increasingly favoring low-carbon production methods. This regulatory landscape will likely accelerate adoption of electrochemical routes despite current technical and economic challenges.

Water usage patterns in electrochemical processes differ markedly from conventional steelmaking. While traditional methods require substantial water volumes for cooling and gas cleaning, electrochemical routes typically consume 30-40% less water. However, the electrolyte management in these systems introduces new challenges related to water quality and potential contamination with process chemicals.

Air quality improvements represent another significant environmental benefit. The elimination of coking operations and reduction in high-temperature combustion processes substantially reduces emissions of particulate matter, sulfur oxides, nitrogen oxides, and volatile organic compounds. Studies indicate potential reductions of these pollutants by 60-80% compared to integrated steel plants.

Land use requirements for electrochemical facilities are generally smaller than traditional integrated steel mills, potentially reducing habitat disruption and allowing for more flexible facility siting. This advantage becomes particularly relevant when considering brownfield redevelopment opportunities in former industrial areas.

Waste generation profiles shift dramatically with electrochemical processes. While slag volumes may decrease by 40-60%, new waste streams emerge, including spent electrolytes, electrode materials, and specialized filtration residues. The composition of these wastes differs fundamentally from traditional steelmaking byproducts, necessitating development of new recycling and disposal protocols.

Energy efficiency considerations reveal complex tradeoffs. While electrochemical routes eliminate the need for coal as a reducing agent, they require significant electrical input. The environmental benefit hinges critically on electricity source - with renewable energy, these processes offer dramatic improvements, but with fossil fuel-generated electricity, the advantages diminish substantially.

Life cycle assessment studies indicate that product purity requirements for downstream applications significantly influence overall environmental impact. Higher purity demands may necessitate additional processing steps or more intensive electrochemical conditions, potentially offsetting some environmental gains through increased energy consumption or chemical usage.

Regulatory frameworks worldwide are evolving to accommodate these emerging technologies, with carbon pricing mechanisms and emissions trading systems increasingly favoring low-carbon production methods. This regulatory landscape will likely accelerate adoption of electrochemical routes despite current technical and economic challenges.

Quality Control Standards for Electrochemical Steel Products

Quality control standards for electrochemical steel production have evolved significantly to address the unique challenges presented by these innovative processes. The standards primarily focus on ensuring consistent product quality through rigorous monitoring and control of impurity levels throughout the production cycle. Current international standards specify maximum allowable concentrations for critical impurities such as sulfur (<0.010%), phosphorus (<0.015%), nitrogen (<0.006%), and oxygen (<0.003%) for high-grade electrochemical steel products.

These standards are increasingly incorporating real-time monitoring requirements, with specifications for continuous measurement of carbon content, which must typically remain below 0.08% for most commercial applications. Advanced electrochemical routes have necessitated the development of new testing protocols specifically designed to detect trace elements that can significantly impact downstream processing, including hydrogen (maximum 2 ppm) and non-metallic inclusions.

Industry benchmarks have established classification systems for electrochemical steel products based on purity levels, with premium grades requiring total residual element concentrations below 0.05% by weight. These classifications directly correlate with mechanical properties and formability characteristics essential for high-value applications in automotive and aerospace sectors.

Certification procedures for electrochemical steel products now commonly include spectroscopic analysis requirements at multiple production stages, with sampling frequencies determined by production volume and intended application. The standards specify statistical process control methodologies, requiring capability indices (Cpk) greater than 1.33 for critical quality parameters to ensure consistent product performance.

Traceability requirements have become increasingly stringent, with standards mandating comprehensive documentation of raw material sources, process parameters, and quality test results throughout the production chain. This enables full product history verification and supports root cause analysis when quality deviations occur.

Emerging standards are beginning to address sustainability metrics alongside traditional quality parameters, incorporating carbon footprint considerations and recycled content requirements that complement the inherent environmental advantages of electrochemical steelmaking routes. These integrated standards reflect the industry's movement toward holistic quality assessment frameworks that balance technical performance with environmental impact.

These standards are increasingly incorporating real-time monitoring requirements, with specifications for continuous measurement of carbon content, which must typically remain below 0.08% for most commercial applications. Advanced electrochemical routes have necessitated the development of new testing protocols specifically designed to detect trace elements that can significantly impact downstream processing, including hydrogen (maximum 2 ppm) and non-metallic inclusions.

Industry benchmarks have established classification systems for electrochemical steel products based on purity levels, with premium grades requiring total residual element concentrations below 0.05% by weight. These classifications directly correlate with mechanical properties and formability characteristics essential for high-value applications in automotive and aerospace sectors.

Certification procedures for electrochemical steel products now commonly include spectroscopic analysis requirements at multiple production stages, with sampling frequencies determined by production volume and intended application. The standards specify statistical process control methodologies, requiring capability indices (Cpk) greater than 1.33 for critical quality parameters to ensure consistent product performance.

Traceability requirements have become increasingly stringent, with standards mandating comprehensive documentation of raw material sources, process parameters, and quality test results throughout the production chain. This enables full product history verification and supports root cause analysis when quality deviations occur.

Emerging standards are beginning to address sustainability metrics alongside traditional quality parameters, incorporating carbon footprint considerations and recycled content requirements that complement the inherent environmental advantages of electrochemical steelmaking routes. These integrated standards reflect the industry's movement toward holistic quality assessment frameworks that balance technical performance with environmental impact.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!