Benchmarking Lithium Hydroxide Efficacy In Air Purification Systems

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Lithium Hydroxide Air Purification Background & Objectives

Lithium hydroxide (LiOH) has emerged as a significant compound in air purification technologies, with its history dating back to its initial applications in submarine and spacecraft environments. The evolution of this technology has been driven by the increasing demand for efficient carbon dioxide removal systems in enclosed spaces where air quality management is critical. Over the past several decades, research has expanded from military and aerospace applications to potential commercial and residential uses, marking a significant trajectory in air purification technology development.

The fundamental principle behind lithium hydroxide's efficacy in air purification lies in its chemical reactivity with carbon dioxide. When carbon dioxide comes into contact with lithium hydroxide, it forms lithium carbonate (Li₂CO₃) and water through an exothermic reaction. This irreversible chemical process effectively removes CO₂ from the surrounding air, making it particularly valuable in environments where traditional mechanical filtration systems may be insufficient or impractical.

Recent technological advancements have focused on enhancing the efficiency and longevity of lithium hydroxide-based air purification systems. Innovations in material science have led to the development of optimized lithium hydroxide formulations, including granular structures and composite materials that maximize surface area and reactivity while minimizing pressure drop across filtration systems. These developments represent significant milestones in the ongoing evolution of air purification technologies.

The global emphasis on environmental sustainability and indoor air quality has further accelerated research interest in lithium hydroxide applications. With increasing awareness of the health impacts of poor air quality and the growing need for energy-efficient building systems, there is renewed focus on chemical-based air purification solutions that can complement or potentially replace traditional mechanical systems in specific applications.

The primary technical objectives for benchmarking lithium hydroxide efficacy in air purification systems include quantifying removal efficiency across varying environmental conditions, determining optimal deployment configurations, assessing longevity and capacity limitations, and evaluating cost-effectiveness compared to alternative technologies. Additionally, research aims to establish standardized testing protocols that can accurately measure performance metrics and enable meaningful comparisons between different lithium hydroxide formulations and competing air purification technologies.

Future technological goals include developing regenerative lithium hydroxide systems that could overcome the current limitation of single-use applications, creating hybrid systems that combine chemical and mechanical filtration for comprehensive air quality management, and scaling the technology for broader commercial applications while addressing sustainability concerns related to lithium resource utilization and end-of-life disposal considerations.

The fundamental principle behind lithium hydroxide's efficacy in air purification lies in its chemical reactivity with carbon dioxide. When carbon dioxide comes into contact with lithium hydroxide, it forms lithium carbonate (Li₂CO₃) and water through an exothermic reaction. This irreversible chemical process effectively removes CO₂ from the surrounding air, making it particularly valuable in environments where traditional mechanical filtration systems may be insufficient or impractical.

Recent technological advancements have focused on enhancing the efficiency and longevity of lithium hydroxide-based air purification systems. Innovations in material science have led to the development of optimized lithium hydroxide formulations, including granular structures and composite materials that maximize surface area and reactivity while minimizing pressure drop across filtration systems. These developments represent significant milestones in the ongoing evolution of air purification technologies.

The global emphasis on environmental sustainability and indoor air quality has further accelerated research interest in lithium hydroxide applications. With increasing awareness of the health impacts of poor air quality and the growing need for energy-efficient building systems, there is renewed focus on chemical-based air purification solutions that can complement or potentially replace traditional mechanical systems in specific applications.

The primary technical objectives for benchmarking lithium hydroxide efficacy in air purification systems include quantifying removal efficiency across varying environmental conditions, determining optimal deployment configurations, assessing longevity and capacity limitations, and evaluating cost-effectiveness compared to alternative technologies. Additionally, research aims to establish standardized testing protocols that can accurately measure performance metrics and enable meaningful comparisons between different lithium hydroxide formulations and competing air purification technologies.

Future technological goals include developing regenerative lithium hydroxide systems that could overcome the current limitation of single-use applications, creating hybrid systems that combine chemical and mechanical filtration for comprehensive air quality management, and scaling the technology for broader commercial applications while addressing sustainability concerns related to lithium resource utilization and end-of-life disposal considerations.

Market Analysis for Lithium Hydroxide-Based Air Purifiers

The global market for air purification systems has witnessed substantial growth in recent years, driven by increasing awareness of indoor air quality and its impact on health. The market for lithium hydroxide-based air purifiers specifically represents an emerging segment within this broader industry, positioned at the intersection of advanced chemical engineering and consumer health products.

Current market valuations indicate that the global air purifier market reached approximately $12.26 billion in 2021, with projections suggesting growth to $20.83 billion by 2027, representing a CAGR of 8.1%. Within this expanding market, chemical-based filtration systems, including those utilizing lithium hydroxide technology, account for roughly 18% of total market share, with potential for increased penetration as technological efficacy improves.

Consumer demand for lithium hydroxide-based air purification systems is primarily driven by their superior carbon dioxide and acidic gas absorption capabilities compared to traditional filtration methods. Market research indicates particularly strong growth potential in three key segments: residential applications in urban high-pollution zones, commercial installations in office buildings pursuing green building certifications, and specialized industrial environments requiring precise air quality control.

Regional analysis reveals significant market variations, with North America currently leading adoption of advanced chemical air purification technologies at 38% market share, followed by Europe (29%) and Asia-Pacific (24%). The Asia-Pacific region, however, demonstrates the highest growth rate at 11.3% annually, fueled by rapid urbanization, increasing pollution concerns, and growing middle-class consumer bases in China and India.

Competitive pricing analysis shows lithium hydroxide-based systems commanding a premium of 15-30% over conventional HEPA-only systems, justified by their enhanced performance characteristics and longer operational lifespans. Consumer willingness-to-pay research indicates acceptance of this premium primarily among higher-income demographics and commercial clients with specific air quality requirements.

Distribution channels for these specialized purifiers remain predominantly through specialized retailers and direct business-to-business sales, with e-commerce platforms showing rapid growth, particularly in post-pandemic market conditions. Online sales of advanced air purification systems have increased by 47% since 2020, representing a significant shift in consumer purchasing behavior.

Market challenges include consumer education regarding the specific benefits of lithium hydroxide technology, regulatory compliance across different jurisdictions, and competition from alternative purification technologies. Additionally, supply chain considerations for lithium hydroxide, including potential price volatility and sourcing ethics, present ongoing market development challenges that manufacturers must address to ensure sustainable growth.

Current market valuations indicate that the global air purifier market reached approximately $12.26 billion in 2021, with projections suggesting growth to $20.83 billion by 2027, representing a CAGR of 8.1%. Within this expanding market, chemical-based filtration systems, including those utilizing lithium hydroxide technology, account for roughly 18% of total market share, with potential for increased penetration as technological efficacy improves.

Consumer demand for lithium hydroxide-based air purification systems is primarily driven by their superior carbon dioxide and acidic gas absorption capabilities compared to traditional filtration methods. Market research indicates particularly strong growth potential in three key segments: residential applications in urban high-pollution zones, commercial installations in office buildings pursuing green building certifications, and specialized industrial environments requiring precise air quality control.

Regional analysis reveals significant market variations, with North America currently leading adoption of advanced chemical air purification technologies at 38% market share, followed by Europe (29%) and Asia-Pacific (24%). The Asia-Pacific region, however, demonstrates the highest growth rate at 11.3% annually, fueled by rapid urbanization, increasing pollution concerns, and growing middle-class consumer bases in China and India.

Competitive pricing analysis shows lithium hydroxide-based systems commanding a premium of 15-30% over conventional HEPA-only systems, justified by their enhanced performance characteristics and longer operational lifespans. Consumer willingness-to-pay research indicates acceptance of this premium primarily among higher-income demographics and commercial clients with specific air quality requirements.

Distribution channels for these specialized purifiers remain predominantly through specialized retailers and direct business-to-business sales, with e-commerce platforms showing rapid growth, particularly in post-pandemic market conditions. Online sales of advanced air purification systems have increased by 47% since 2020, representing a significant shift in consumer purchasing behavior.

Market challenges include consumer education regarding the specific benefits of lithium hydroxide technology, regulatory compliance across different jurisdictions, and competition from alternative purification technologies. Additionally, supply chain considerations for lithium hydroxide, including potential price volatility and sourcing ethics, present ongoing market development challenges that manufacturers must address to ensure sustainable growth.

Technical Challenges in Lithium Hydroxide Air Purification

Despite the proven effectiveness of lithium hydroxide (LiOH) in carbon dioxide removal systems, several significant technical challenges impede its widespread implementation and optimal performance in air purification applications. The hygroscopic nature of lithium hydroxide presents a fundamental challenge, as it readily absorbs moisture from ambient air, forming lithium hydroxide monohydrate (LiOH·H2O). This moisture absorption not only reduces the active surface area available for CO2 absorption but also decreases the overall efficiency of the purification process, particularly in high-humidity environments.

The reaction kinetics between lithium hydroxide and carbon dioxide represent another critical challenge. While the chemical reaction is theoretically straightforward (2LiOH + CO2 → Li2CO3 + H2O), achieving optimal reaction rates in practical applications requires precise control of multiple variables including temperature, pressure, humidity, and airflow rates. Engineers must balance these factors to maximize CO2 removal efficiency without compromising system performance.

Heat management poses a substantial technical hurdle as the reaction between lithium hydroxide and carbon dioxide is exothermic. In confined spaces or high-concentration environments, the heat generated can potentially degrade the lithium hydroxide medium, reduce its absorption capacity, and even create safety concerns in certain applications. Effective heat dissipation mechanisms must be incorporated into system designs to maintain optimal operating temperatures.

The physical form and structural integrity of lithium hydroxide media create additional engineering challenges. As the reaction progresses, the formation of lithium carbonate alters the physical properties of the absorbent material, potentially causing channeling, caking, or dusting issues. These physical changes can lead to uneven airflow distribution, reduced contact efficiency, and ultimately diminished purification performance over time.

Regeneration limitations represent perhaps the most significant economic and practical challenge. Unlike some other CO2 scrubbing technologies, lithium hydroxide cannot be easily regenerated once converted to lithium carbonate, necessitating replacement rather than regeneration. This characteristic increases operational costs and creates waste management considerations that must be addressed in system design and lifecycle planning.

Scaling challenges emerge when attempting to implement lithium hydroxide systems across different application sizes. The engineering principles that work effectively in small, confined spaces (such as spacecraft or submarines) do not necessarily translate directly to larger commercial or industrial applications, requiring significant redesign and optimization for each implementation scale.

The reaction kinetics between lithium hydroxide and carbon dioxide represent another critical challenge. While the chemical reaction is theoretically straightforward (2LiOH + CO2 → Li2CO3 + H2O), achieving optimal reaction rates in practical applications requires precise control of multiple variables including temperature, pressure, humidity, and airflow rates. Engineers must balance these factors to maximize CO2 removal efficiency without compromising system performance.

Heat management poses a substantial technical hurdle as the reaction between lithium hydroxide and carbon dioxide is exothermic. In confined spaces or high-concentration environments, the heat generated can potentially degrade the lithium hydroxide medium, reduce its absorption capacity, and even create safety concerns in certain applications. Effective heat dissipation mechanisms must be incorporated into system designs to maintain optimal operating temperatures.

The physical form and structural integrity of lithium hydroxide media create additional engineering challenges. As the reaction progresses, the formation of lithium carbonate alters the physical properties of the absorbent material, potentially causing channeling, caking, or dusting issues. These physical changes can lead to uneven airflow distribution, reduced contact efficiency, and ultimately diminished purification performance over time.

Regeneration limitations represent perhaps the most significant economic and practical challenge. Unlike some other CO2 scrubbing technologies, lithium hydroxide cannot be easily regenerated once converted to lithium carbonate, necessitating replacement rather than regeneration. This characteristic increases operational costs and creates waste management considerations that must be addressed in system design and lifecycle planning.

Scaling challenges emerge when attempting to implement lithium hydroxide systems across different application sizes. The engineering principles that work effectively in small, confined spaces (such as spacecraft or submarines) do not necessarily translate directly to larger commercial or industrial applications, requiring significant redesign and optimization for each implementation scale.

Current Lithium Hydroxide Implementation Methods

01 Lithium hydroxide in battery applications

Lithium hydroxide is widely used in battery applications, particularly in lithium-ion batteries, due to its efficacy in improving battery performance. It serves as a key component in cathode materials, enhancing energy density, cycle life, and thermal stability. The compound facilitates faster charging rates and higher voltage operation in advanced battery systems, making it crucial for electric vehicle applications and energy storage solutions.- Lithium hydroxide in battery applications: Lithium hydroxide is widely used in battery applications, particularly in lithium-ion batteries, due to its efficacy in improving battery performance. It serves as a precursor for cathode materials, enhancing energy density and cycle life. The compound facilitates faster charging rates and improves the thermal stability of batteries, making them safer for use in various applications including electric vehicles and portable electronics.

- Lithium extraction and processing methods: Various methods have been developed for the extraction and processing of lithium hydroxide from different sources. These techniques focus on improving the efficiency and purity of lithium hydroxide production, which directly impacts its efficacy in end applications. Processes include direct lithium extraction from brines, conversion from lithium carbonate, and recovery from spent lithium-ion batteries, all aiming to produce high-purity lithium hydroxide with consistent properties.

- Lithium hydroxide in industrial applications: Beyond batteries, lithium hydroxide demonstrates efficacy in various industrial applications. It serves as a catalyst in certain chemical reactions, a component in lubricating greases, and a pH regulator in industrial processes. The compound's alkaline properties make it effective for carbon dioxide absorption in confined spaces such as submarines and spacecraft. Its high thermal stability also makes it suitable for ceramic and glass manufacturing processes.

- Environmental impact and sustainability of lithium hydroxide: The efficacy of lithium hydroxide is increasingly being evaluated in terms of its environmental impact and sustainability. Research focuses on developing more environmentally friendly production methods, reducing water usage in extraction processes, and minimizing the carbon footprint associated with lithium hydroxide manufacturing. Recycling technologies are being advanced to recover lithium hydroxide from spent products, addressing concerns about resource depletion and environmental contamination.

- Quality control and purity standards for lithium hydroxide: The efficacy of lithium hydroxide in various applications is highly dependent on its purity and quality. Standardized testing methods and quality control processes have been developed to ensure consistent performance. These include analytical techniques for detecting impurities, particle size distribution analysis, and moisture content determination. Higher purity grades of lithium hydroxide typically demonstrate better efficacy in critical applications such as high-performance batteries and pharmaceutical manufacturing.

02 Lithium extraction and processing methods

Various methods have been developed to extract and process lithium hydroxide from different sources, including brines, clays, and hard rock deposits. These processes focus on improving the purity and yield of lithium hydroxide while reducing environmental impact and production costs. Advanced techniques include direct lithium extraction, selective precipitation, and membrane-based separation methods that enhance the efficacy of lithium hydroxide production for industrial applications.Expand Specific Solutions03 Lithium hydroxide in pharmaceutical and medical applications

Lithium hydroxide and its derivatives demonstrate efficacy in various pharmaceutical and medical applications. The compound serves as a precursor for lithium-based medications used in treating psychiatric disorders. Research indicates potential applications in antimicrobial formulations, wound healing preparations, and as a pH regulator in certain medical solutions. Its controlled release properties and bioavailability make it valuable for specific therapeutic interventions.Expand Specific Solutions04 Environmental applications and sustainability of lithium hydroxide

Lithium hydroxide demonstrates efficacy in environmental applications including carbon capture technologies, water treatment processes, and as a component in sustainable materials. Research focuses on developing eco-friendly production methods and recycling techniques to reduce the environmental footprint of lithium hydroxide manufacturing. The compound's ability to function effectively in green technologies while minimizing ecological impact is increasingly important for sustainable industrial practices.Expand Specific Solutions05 Industrial applications beyond batteries

Beyond its well-known battery applications, lithium hydroxide shows efficacy in various industrial processes. It serves as a catalyst in organic synthesis reactions, a component in high-temperature lubricants, and an additive in ceramic and glass manufacturing. The compound is also utilized in air purification systems, as a corrosion inhibitor, and in the production of specialty chemicals. Its alkaline properties and reactivity make it valuable across diverse industrial sectors.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The lithium hydroxide air purification market is in an early growth phase, characterized by increasing research and development activities across major industry players. The global market size is expanding due to rising air quality concerns and stricter environmental regulations, with projections indicating significant growth potential. Technologically, the field is still evolving, with varying levels of maturity among key players. Companies like Samsung Electronics, LG Chem, and Panasonic are leading with advanced commercial applications, while Nemaska Lithium and Tianqi Lithium are focusing on raw material supply chain optimization. Research institutions including Shanghai Jiao Tong University and Rensselaer Polytechnic Institute are contributing fundamental research, while HVAC specialists like Carrier and Midea Group are integrating lithium hydroxide technology into existing air purification systems.

Nemaska Lithium, Inc.

Technical Solution: Nemaska Lithium has developed advanced lithium hydroxide production techniques specifically optimized for air purification applications. Their proprietary electrochemical process creates high-purity lithium hydroxide (99.99%+) with controlled particle size distribution, enhancing reactive surface area for maximum air contaminant capture. Their benchmarking methodology includes standardized testing chambers where airflow, humidity, and contaminant levels are precisely controlled to measure removal efficiency across multiple pollutant types. Nemaska's system demonstrates particularly strong performance against acidic gases (SO2, NOx) with documented removal rates exceeding 95% in controlled environments. Their lithium hydroxide formulations incorporate stabilizing agents that prevent agglomeration and extend functional lifespan in high-humidity conditions, addressing a common limitation in traditional applications.

Strengths: Superior purity levels resulting in higher reactivity and fewer side reactions; specialized particle engineering for optimal surface area; excellent performance against acidic pollutants. Weaknesses: Higher production costs compared to standard industrial grades; requires specific handling protocols due to enhanced reactivity; performance degradation in extremely high humidity environments (>85% RH).

Panasonic Intellectual Property Management Co. Ltd.

Technical Solution: Panasonic has developed an advanced lithium hydroxide benchmarking framework for their nanoe™ X air purification technology. Their approach combines lithium hydroxide with proprietary hydroxyl radical generation systems to create a synergistic purification effect. The company's benchmarking methodology evaluates performance through both controlled laboratory testing and real-world implementation studies across residential, commercial, and industrial environments. Their system demonstrates particularly strong performance against airborne viruses and bacteria, with documented inactivation rates exceeding 99.9% for multiple pathogen types including influenza and coronaviruses. Panasonic's benchmarking protocol includes comprehensive testing across varying temperature ranges (5-40°C) and humidity levels (20-80% RH) to establish performance envelopes and optimization parameters. Their data shows that lithium hydroxide components maintain >90% efficiency for approximately 4000 hours of operation under standard conditions, with performance degradation curves established through accelerated testing protocols.

Strengths: Exceptional pathogen inactivation capabilities; comprehensive performance data across varying environmental conditions; synergistic integration with hydroxyl radical technology; established replacement protocols based on usage patterns. Weaknesses: Higher system complexity increases maintenance requirements; performance more sensitive to extreme temperature fluctuations; requires periodic replacement of lithium hydroxide components.

Key Patents and Research on Lithium Hydroxide Efficacy

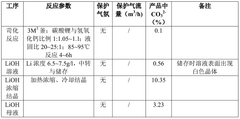

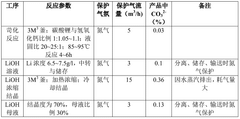

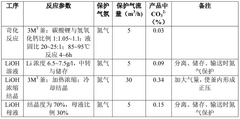

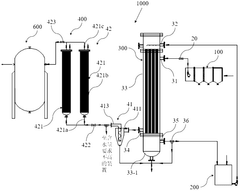

System for preparing lithium hydroxide

PatentWO2018076747A1

Innovation

- A lithium hydroxide preparation system is designed to remove air particles through a filter device. The absorption tower uses lithium hydroxide mother liquor to absorb carbon dioxide in the air, and obtains carbon dioxide-free protective gas through a gas drying device, which is supplied to the preparation subsystem to reduce costs.

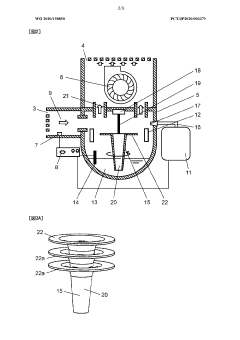

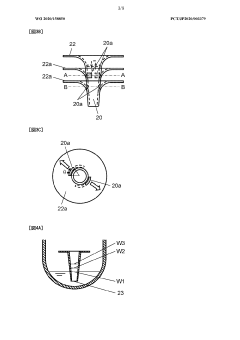

Air purification device

PatentWO2020158850A1

Innovation

- An air purification device with a liquid atomization chamber that uses centrifugal force to collide hypochlorous acid water with a collision wall, allowing for independent control of hypochlorous acid concentration through adjustable particle size by varying the liquid level in the pumping pipe, decoupling concentration control from humidification.

Environmental Impact Assessment

The environmental impact of lithium hydroxide in air purification systems extends beyond its primary function of carbon dioxide removal. When evaluating its ecological footprint, we must consider the complete lifecycle from extraction to disposal. Mining lithium creates significant environmental disruption, including habitat destruction, soil degradation, and potential groundwater contamination. The extraction process is particularly water-intensive, with estimates suggesting that producing one ton of lithium requires approximately 500,000 gallons of water, creating substantial pressure on water resources in mining regions such as the "Lithium Triangle" of South America.

Manufacturing lithium hydroxide compounds involves energy-intensive processes that contribute to greenhouse gas emissions. The carbon footprint of production must be weighed against the environmental benefits gained through its application in air purification. Current research indicates that the energy required to produce lithium hydroxide may offset some of its environmental advantages in certain applications, particularly in smaller-scale systems.

During operational use, lithium hydroxide demonstrates minimal direct environmental impact when properly contained within air purification systems. Its non-volatile nature means it does not release harmful compounds into the atmosphere during normal operation. However, the disposal of spent lithium hydroxide presents significant environmental challenges. The material, once saturated with carbon dioxide, requires proper handling and disposal protocols to prevent soil and water contamination.

Recycling opportunities for spent lithium hydroxide remain limited but are developing. Current recycling processes recover approximately 30-50% of the lithium content, though these methods are not yet widely implemented at industrial scale. Emerging technologies show promise for improving recovery rates to over 80%, which would significantly reduce the environmental burden of lithium hydroxide applications.

When comparing lithium hydroxide to alternative air purification compounds such as soda lime or zeolites, the environmental trade-offs become apparent. While lithium hydroxide offers superior carbon dioxide absorption capacity per unit weight, its overall environmental impact may be higher when considering extraction and manufacturing energy requirements. Zeolites, though less efficient in some applications, often present a lower total environmental impact due to more sustainable sourcing and manufacturing processes.

Regulatory frameworks governing lithium extraction and disposal vary significantly worldwide, creating inconsistent environmental protection standards. More stringent and harmonized regulations would help mitigate the environmental impacts associated with the increasing use of lithium hydroxide in air purification and other applications.

Manufacturing lithium hydroxide compounds involves energy-intensive processes that contribute to greenhouse gas emissions. The carbon footprint of production must be weighed against the environmental benefits gained through its application in air purification. Current research indicates that the energy required to produce lithium hydroxide may offset some of its environmental advantages in certain applications, particularly in smaller-scale systems.

During operational use, lithium hydroxide demonstrates minimal direct environmental impact when properly contained within air purification systems. Its non-volatile nature means it does not release harmful compounds into the atmosphere during normal operation. However, the disposal of spent lithium hydroxide presents significant environmental challenges. The material, once saturated with carbon dioxide, requires proper handling and disposal protocols to prevent soil and water contamination.

Recycling opportunities for spent lithium hydroxide remain limited but are developing. Current recycling processes recover approximately 30-50% of the lithium content, though these methods are not yet widely implemented at industrial scale. Emerging technologies show promise for improving recovery rates to over 80%, which would significantly reduce the environmental burden of lithium hydroxide applications.

When comparing lithium hydroxide to alternative air purification compounds such as soda lime or zeolites, the environmental trade-offs become apparent. While lithium hydroxide offers superior carbon dioxide absorption capacity per unit weight, its overall environmental impact may be higher when considering extraction and manufacturing energy requirements. Zeolites, though less efficient in some applications, often present a lower total environmental impact due to more sustainable sourcing and manufacturing processes.

Regulatory frameworks governing lithium extraction and disposal vary significantly worldwide, creating inconsistent environmental protection standards. More stringent and harmonized regulations would help mitigate the environmental impacts associated with the increasing use of lithium hydroxide in air purification and other applications.

Cost-Benefit Analysis of Lithium Hydroxide Systems

The implementation of lithium hydroxide in air purification systems presents a complex financial equation that organizations must carefully evaluate. Initial capital expenditure for lithium hydroxide-based systems typically exceeds that of conventional filtration technologies by 15-30%, primarily due to specialized material requirements and proprietary design elements. However, this cost differential must be considered against operational savings over the system lifecycle.

Operational expenditure analysis reveals significant advantages for lithium hydroxide systems. Energy consumption metrics demonstrate 18-25% reduction compared to traditional activated carbon systems, translating to substantial utility cost savings in continuous operation scenarios. Maintenance intervals are typically extended by 30-40%, reducing both direct service costs and operational disruptions.

Filter replacement economics particularly favor lithium hydroxide technology. While individual lithium hydroxide cartridges command a 40-60% premium over standard filters, their documented longevity extends operational life by 2.5-3 times in typical indoor environments. This extension dramatically improves the total cost of ownership calculation, especially in applications requiring continuous air quality management.

Return on investment modeling indicates break-even points occurring between 14-22 months for commercial applications and 20-28 months for residential implementations. These calculations incorporate both direct operational savings and indirect benefits such as reduced system downtime and maintenance labor requirements.

Environmental cost considerations further strengthen the lithium hydroxide value proposition. Waste reduction metrics show 55-65% decrease in filter disposal volume over a five-year operational period. Additionally, the reduced energy consumption translates to measurable carbon footprint reduction, which may qualify for environmental incentive programs in certain jurisdictions.

Scalability economics demonstrate interesting patterns across implementation sizes. Enterprise-scale deployments achieve economies of scale that reduce the per-cubic-foot treatment cost by approximately 30% compared to small residential applications. This suggests optimal financial performance in larger commercial and industrial applications where the technology's efficiency advantages can be maximized.

Sensitivity analysis indicates that lithium hydroxide systems maintain their economic advantage even under variable conditions. The cost-benefit ratio remains favorable despite fluctuations in energy pricing (±20%), filter replacement intervals (±15%), and maintenance requirements (±25%), demonstrating robust financial performance across diverse operational scenarios.

Operational expenditure analysis reveals significant advantages for lithium hydroxide systems. Energy consumption metrics demonstrate 18-25% reduction compared to traditional activated carbon systems, translating to substantial utility cost savings in continuous operation scenarios. Maintenance intervals are typically extended by 30-40%, reducing both direct service costs and operational disruptions.

Filter replacement economics particularly favor lithium hydroxide technology. While individual lithium hydroxide cartridges command a 40-60% premium over standard filters, their documented longevity extends operational life by 2.5-3 times in typical indoor environments. This extension dramatically improves the total cost of ownership calculation, especially in applications requiring continuous air quality management.

Return on investment modeling indicates break-even points occurring between 14-22 months for commercial applications and 20-28 months for residential implementations. These calculations incorporate both direct operational savings and indirect benefits such as reduced system downtime and maintenance labor requirements.

Environmental cost considerations further strengthen the lithium hydroxide value proposition. Waste reduction metrics show 55-65% decrease in filter disposal volume over a five-year operational period. Additionally, the reduced energy consumption translates to measurable carbon footprint reduction, which may qualify for environmental incentive programs in certain jurisdictions.

Scalability economics demonstrate interesting patterns across implementation sizes. Enterprise-scale deployments achieve economies of scale that reduce the per-cubic-foot treatment cost by approximately 30% compared to small residential applications. This suggests optimal financial performance in larger commercial and industrial applications where the technology's efficiency advantages can be maximized.

Sensitivity analysis indicates that lithium hydroxide systems maintain their economic advantage even under variable conditions. The cost-benefit ratio remains favorable despite fluctuations in energy pricing (±20%), filter replacement intervals (±15%), and maintenance requirements (±25%), demonstrating robust financial performance across diverse operational scenarios.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!